Propose a final project that integrates the range of units covered, answering:

1) What will it do?

I was learning about CNC machines and I decide to apply the CNC principles to make a wheel with the same precision.

This wheel or system is going to work using a g-code, we could generate a g-code and this system is going to make it like a CNC.

The system is going to work with a g-code uploaded on a SD Card.

2) Who's done what beforehand?

I think to my project is based on the CNC beginning, all the principles about movement like CNC machine is applied.

I am using a g-code, this g code is based on x, y and z vectors.

I don't know a system like this applied on a wheel.

Goliath CNC - An Autonomous Robotic Machine Tool for Makers

In this last lapse, I find a project called Goliath CNC. it is a little similar of my idea, but I made my final project and this project was launched after .

A portable robot that mills, cuts, and engraves to turn BIG ideas into tangible items with any materials and various CAD file formats.

Propose a final project that integrates the range of units covered, answering:

3) What materials and components will be required?

Electronic design:

Atmega 328P

Botton (1)

Led blue (1)

Led Yellow (1)

R 499 Ohm (2)

R 10K Ohm (1)

Xtal 18Mhz (1)

C 22 pF (2)

C 100 nF (2)

C 10 uF (1)

C 1uF (1)

Stepper Motors NEMA 17

A4988 stepper mootor driver.

Electronic Boards

Mechanical design:

Filament for 3D printing

Wood

Wires

Mecanized

Cilicone Rubber for Wheel

Screws and nuts

4) Where will they come from?

The majority of the components we can find in the Fab Lab.

But I need to buy the stepper driver motor and the SD card module in a Local Electronic Store..

5) How much will it cost?

Electronic design:

($5.0)

Atmega 328P

Botton (1)

Led blue (1)

Led Yellow (1)

R 499 Ohm (2)

R 10K Ohm (1)

Xtal 18Mhz (1)

C 22 pF (2)

C 100 nF (2)

C 10 uF (1)

C 1uF (1)

($26.0)

Stepper Motors NEMA 17

($20.0)

A4988 stepper mootor driver.

($2.0)

Electronic Boards

($5.0)

SD card module

Mechanical design:

($20.0)

Filament for 3D printing

($15.0)

Wood

($2.0)

Wires

($12.0)

Cilicone Rubber for Wheel

($4.0)

Screws and nuts

6) What parts and systems will be made?

Support structure

Wheel

Electronic boards to control the system

The code and communications to convert the g-code to movement

7) What processes will be used?

ELECTRONIC PRODUCTION to create the boards.

3D PRINT for the support structur.

EMBEDDED PROGRAMING to generate the code

MOLDING ANDCASTING to get the wheel

NETWORKING AND COMMUNICATIONS for the data transmision.

COMPOSITES for the wheel

3D DESIGN for the support structure and wheel.

8) What tasks need to be completed?

Make the wheel and structur suport.

Generate a code to read a g-code and convert it on steps to generate movement with motors.

Create a board to read data with a SD Card and connect the stepper motor driver.

9) What questions need to be answered?

How strong is the wheel?

What will look interesting?

How wheel with CNC propierties are made?

How can transform the data to proses on my wheel?

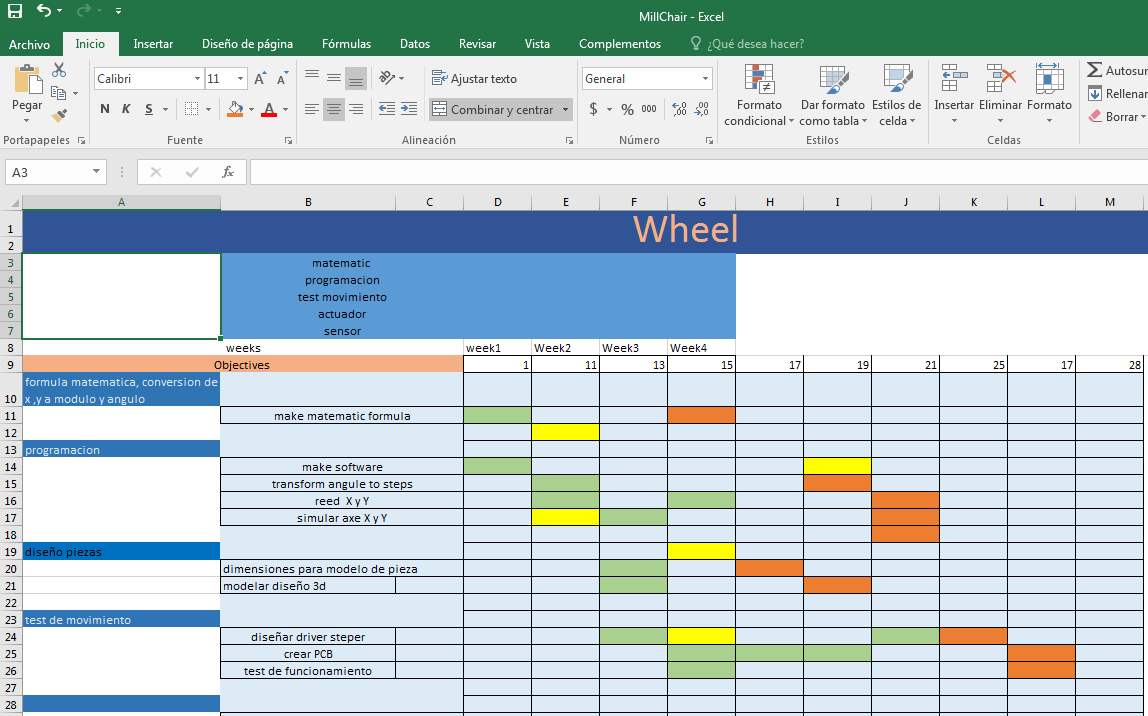

10) What is the schedule?

11) How will it be evaluated?

The principal propose of this project is create a wheel with CNC machine characteristics, the way to work with a g-code and process the g-code to get movement but with a wheel. I think it is the most important characteristic of my system to be evaluated.