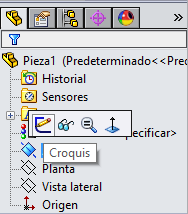

Solidworks

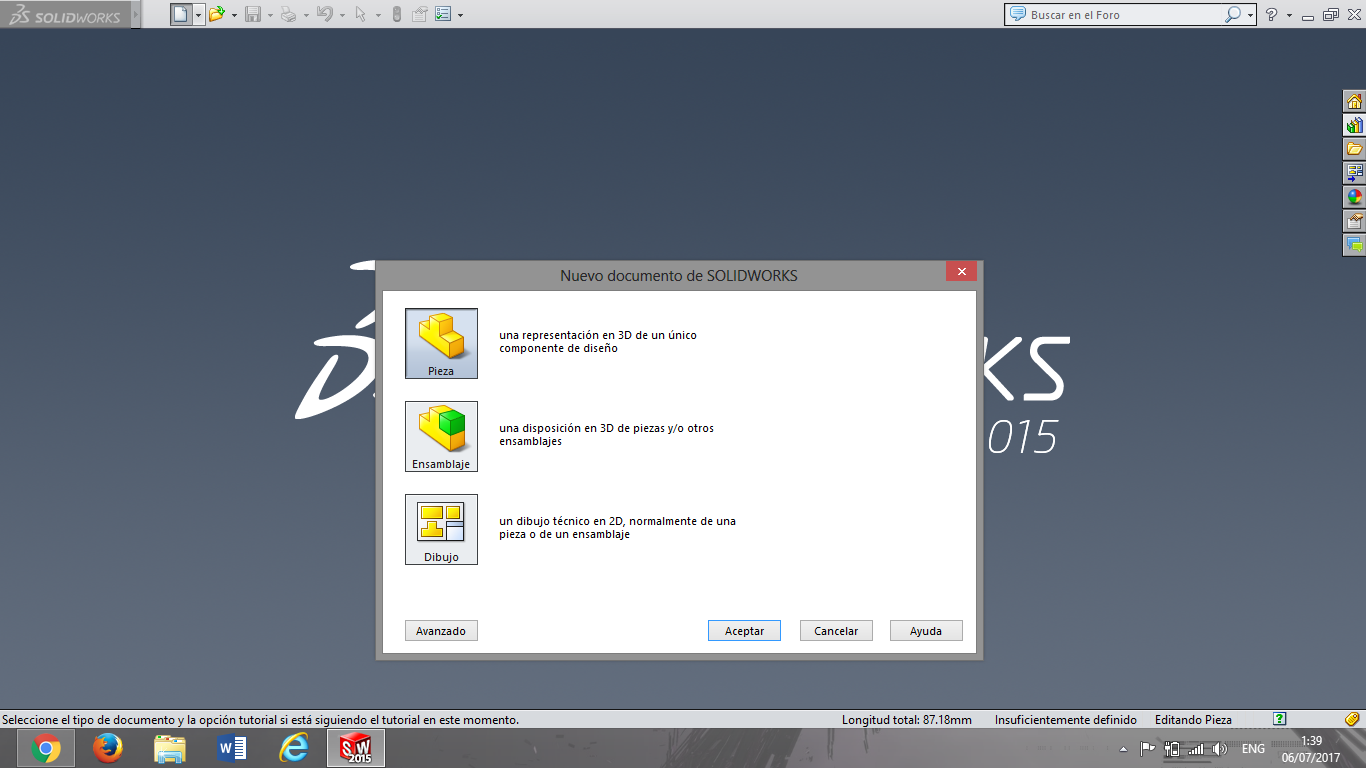

In this assignment I used this software for make the the figure, for this design first create a comb to have the right measure, then make the design

in Solidworks is easy interface, you must take into account the measures in which you are making the drawings.

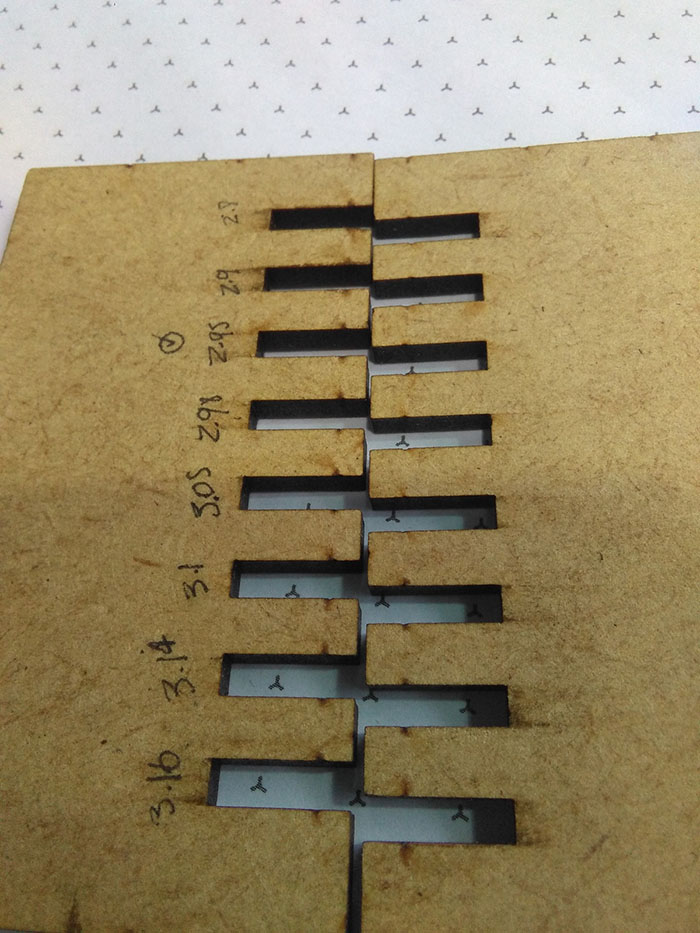

With this first laser cut find the correct measures for a good presfit, this taste is for the other design for know how much the laser wears on this type of wood also to what

kind of power is working with the laser.

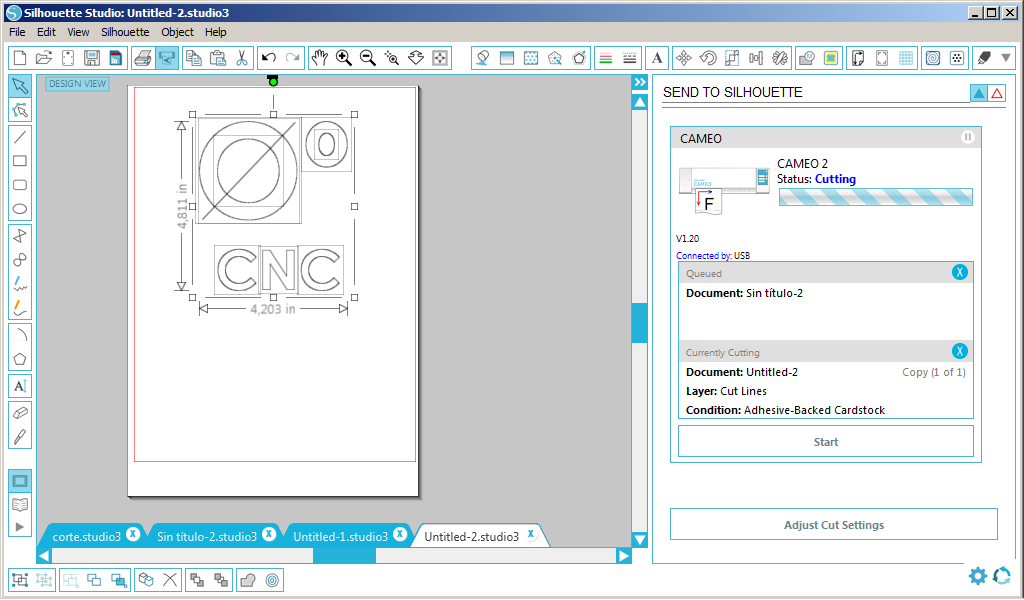

- Cut something on the vinylcutter

For Vinyl cutter, I use a Cameo machine, it's a small plotter, the software for edit the files for machine is Silhouette Studio, in this software you can modify the area of

work and parameters of the design need.

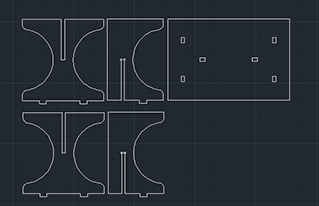

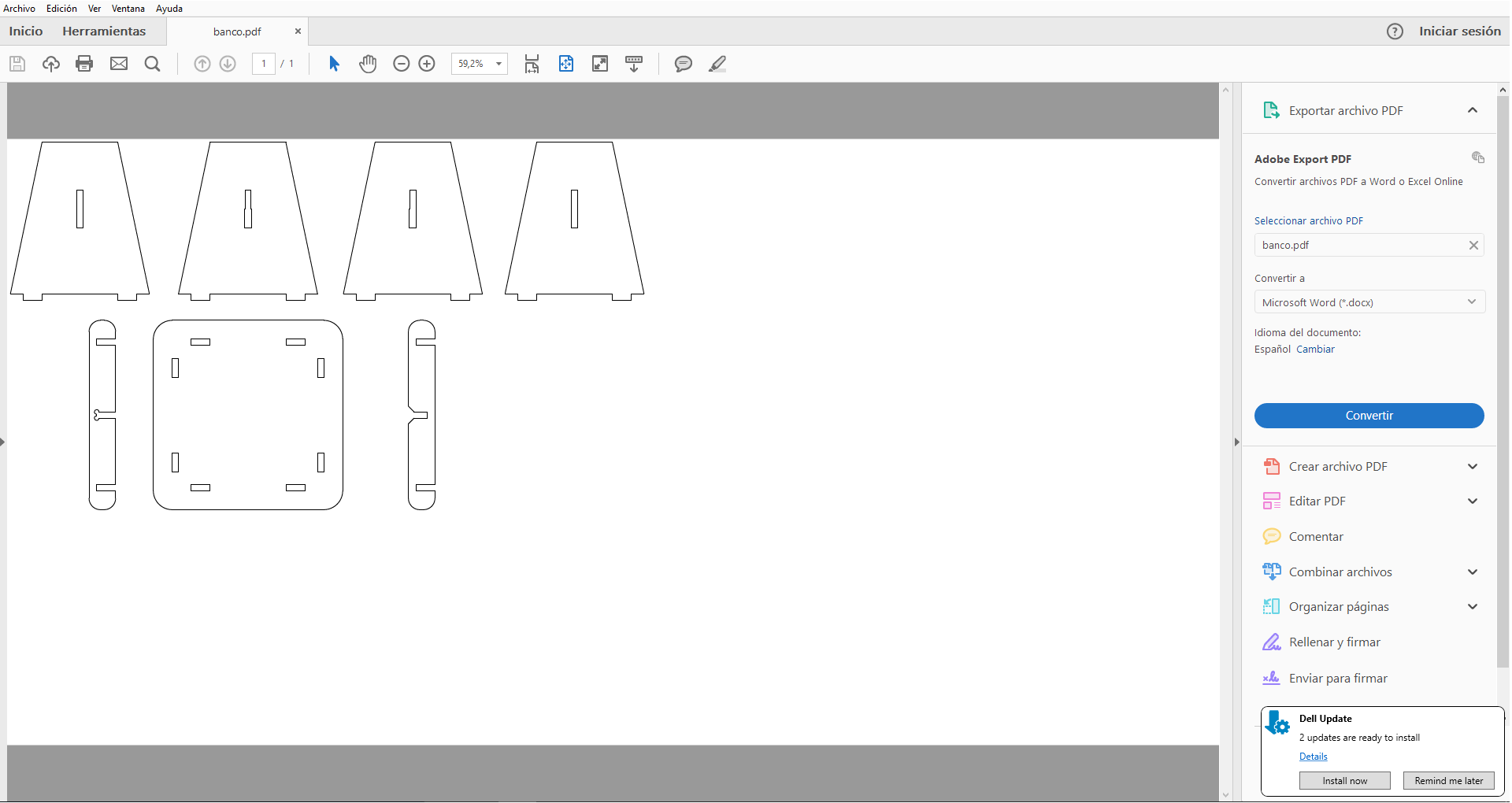

- design, make, and document a parametric press-fit construction kit, accounting for the lasercutter kerf, which can be assembled in multiple ways

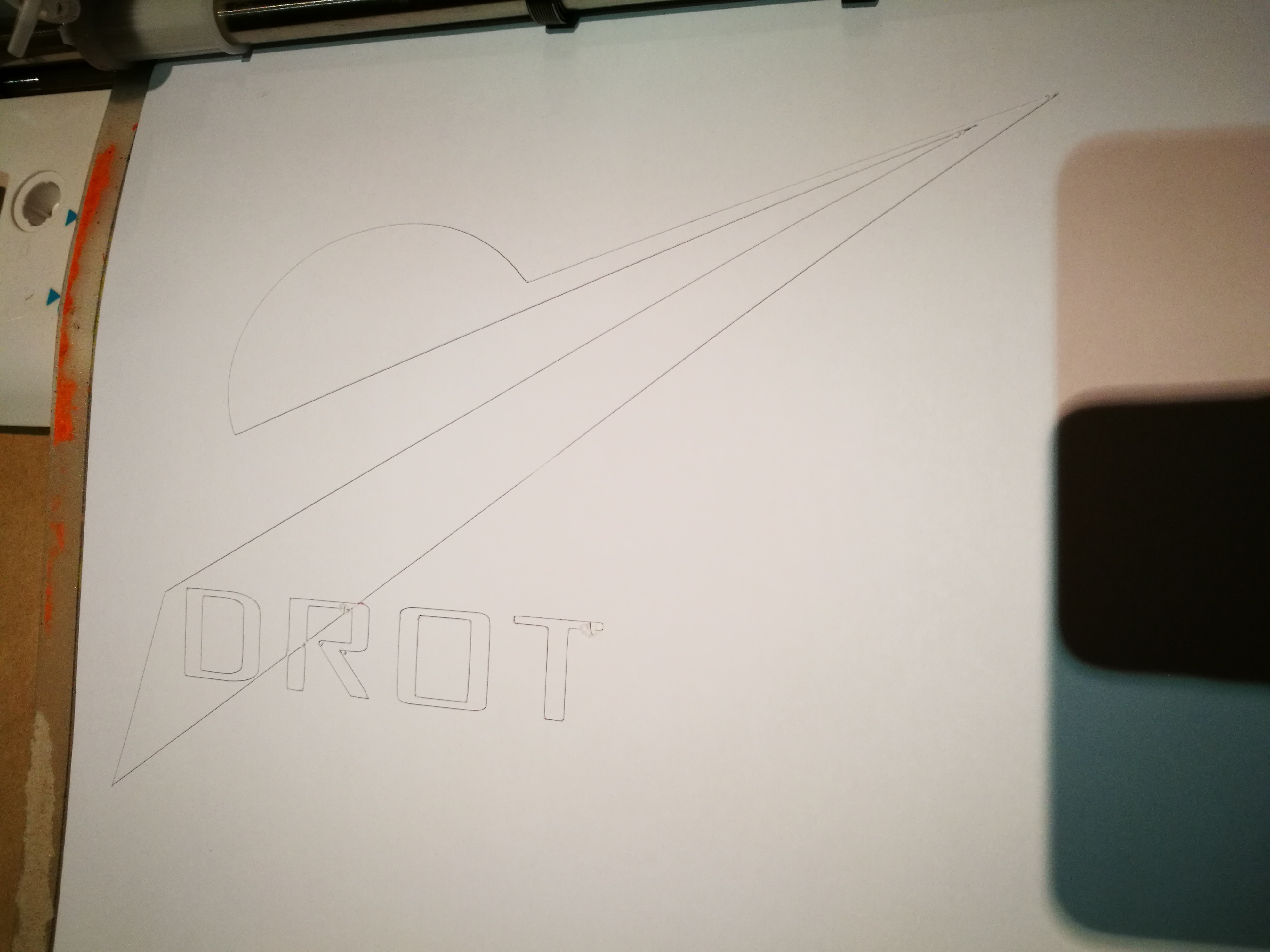

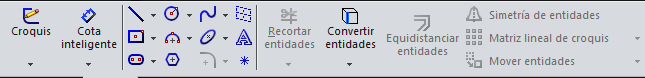

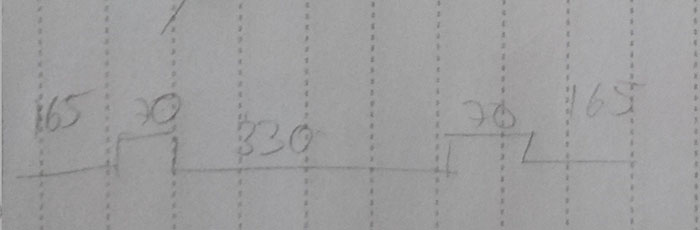

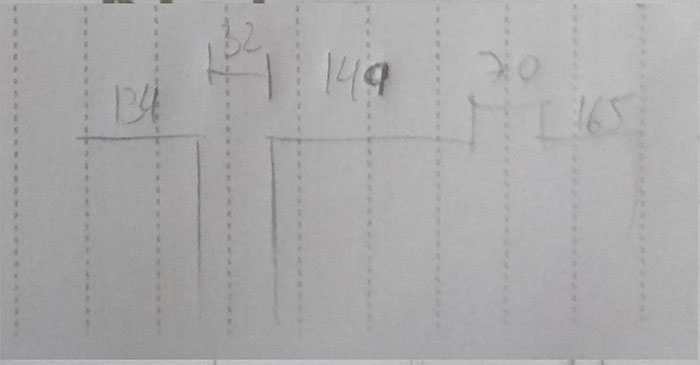

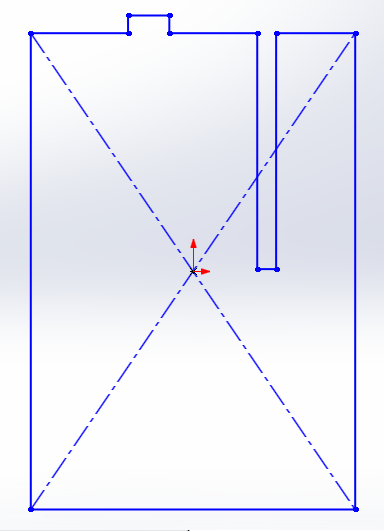

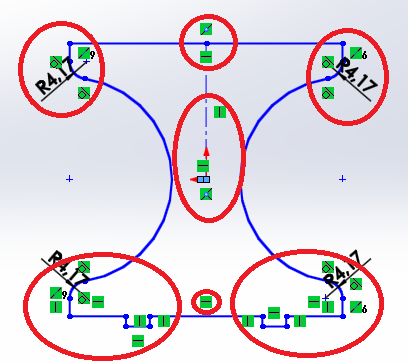

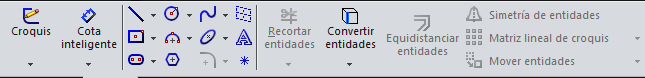

To star first make a sketch of the design with measures and details, and when start the program solidworks work first in 2D, make sure to measures is right consider thickness of

the material, for a correct press fit. then continue with the software seeing if the units are correct before you begin to draw so that you coincide with the size of the sketch.

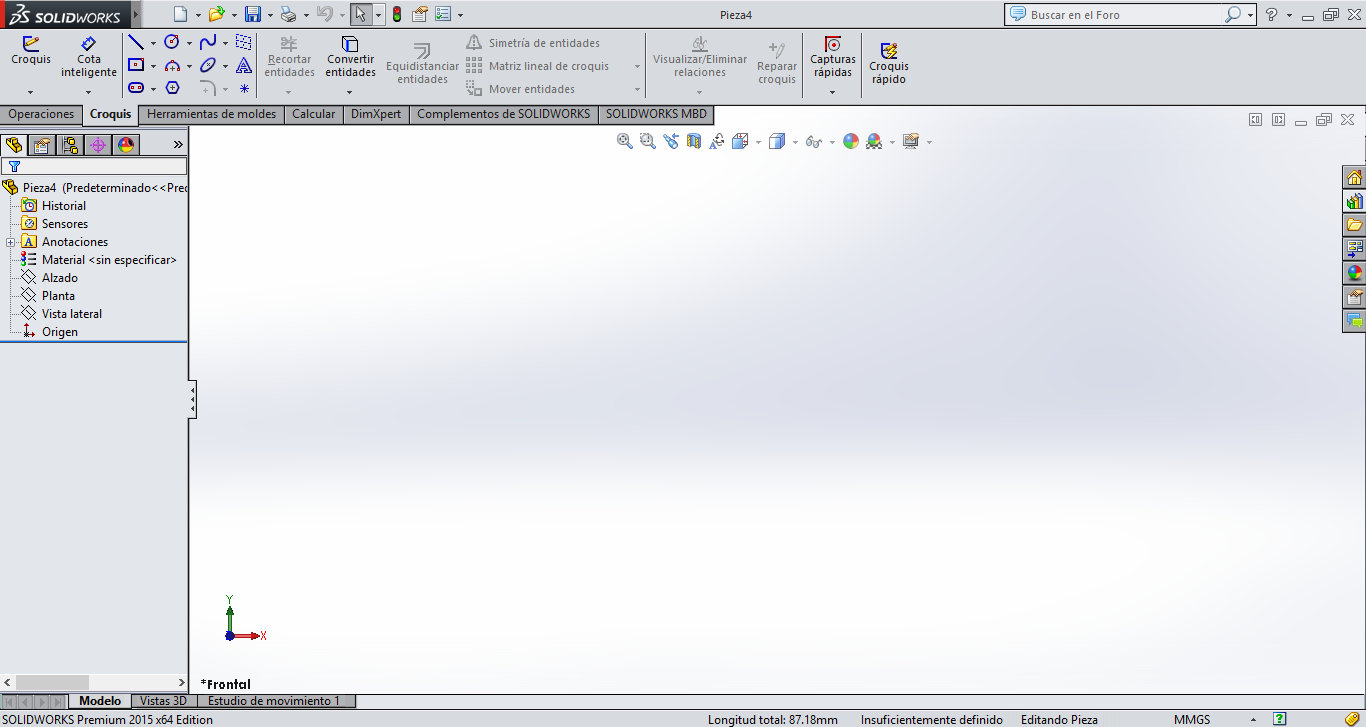

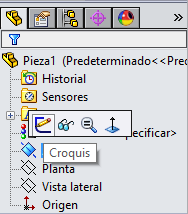

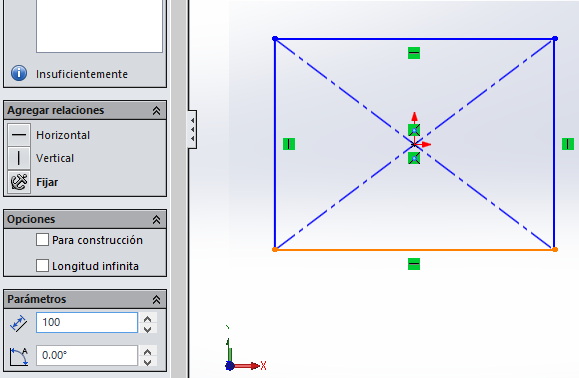

Before you start drawing we must know some essential commands to draw in Solidworks. Select the correct area of you need work, in 2D you select sketch in the area you decided to

work, this sketch you must click in the area and select the icon with a pencil.

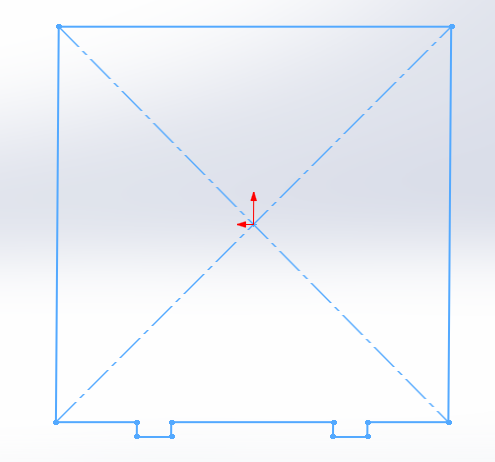

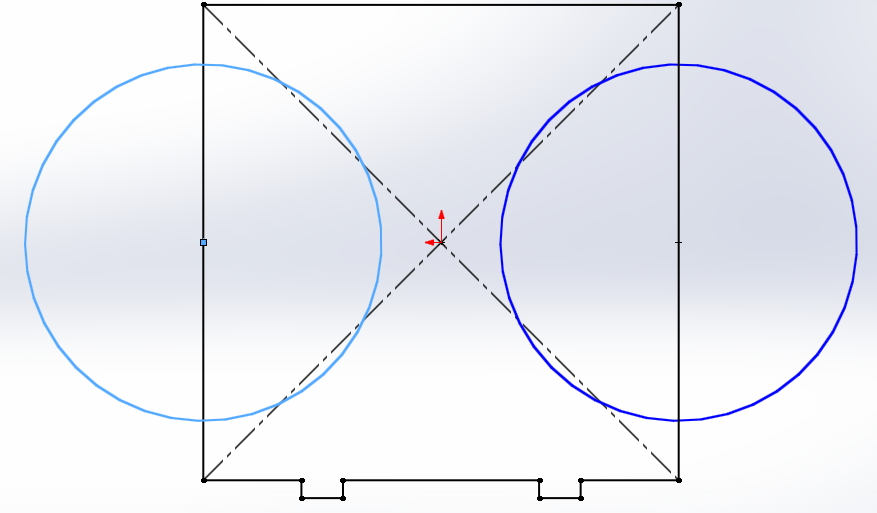

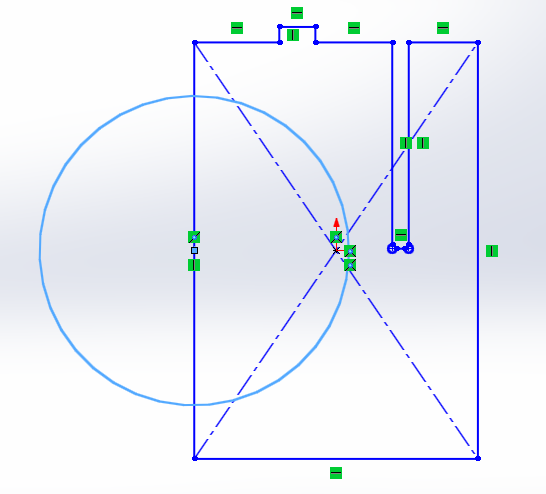

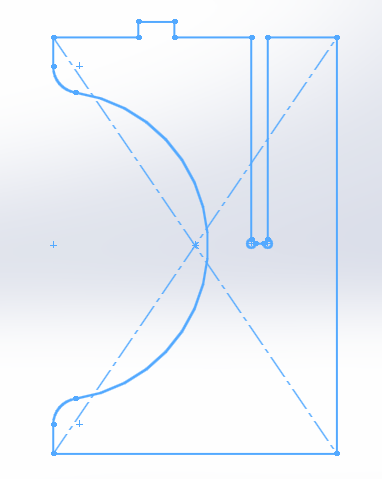

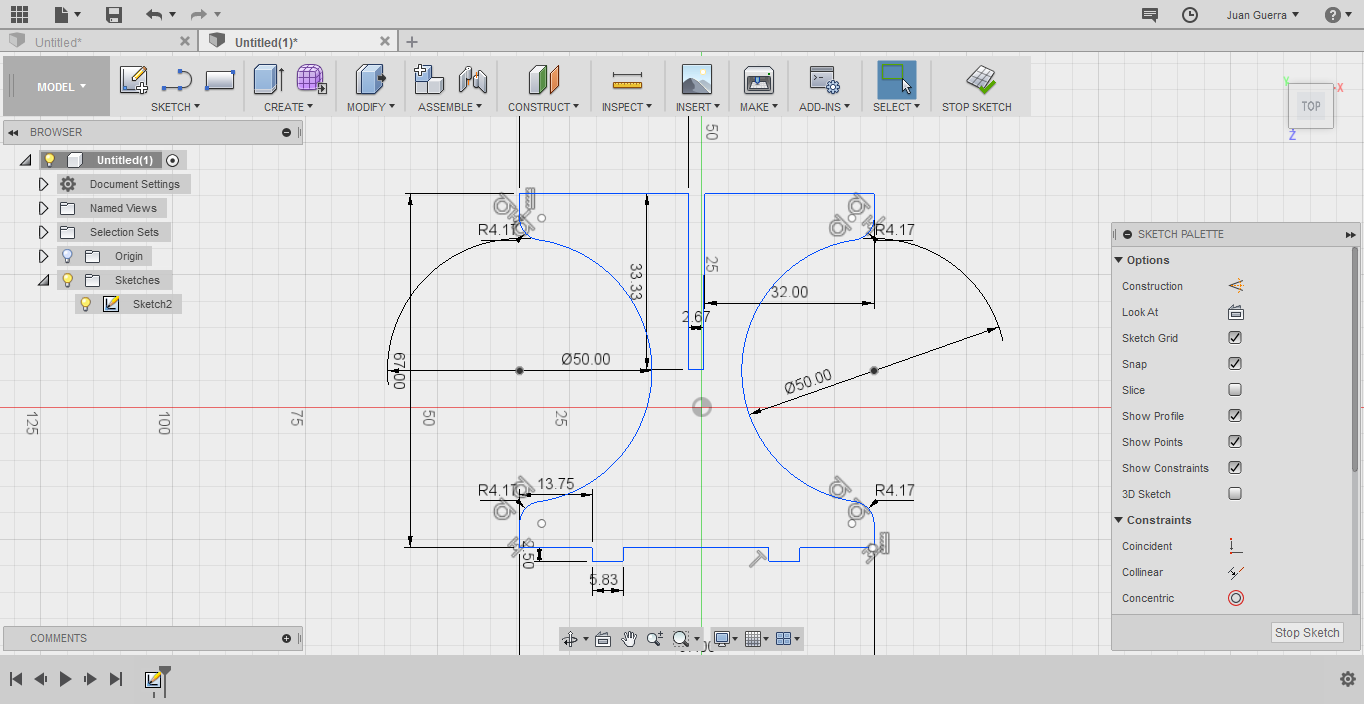

based in sketches, drawing with the commands seen using the tool center rectangle to make a square fast with the measures annotated, make a circles of radius 300 mm in the middle

of the line, using the tools sketch rounding and trim entities, remove the excess line and sketch rounding rounded the corners, finally make a coupling to fit the pieces of 32 mm.

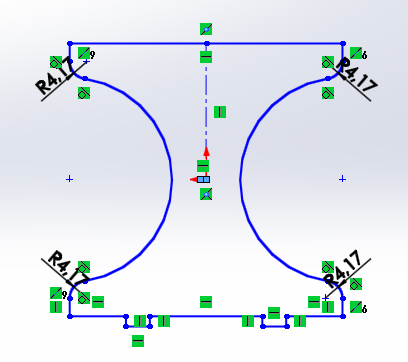

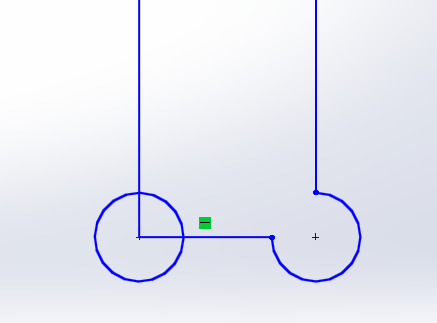

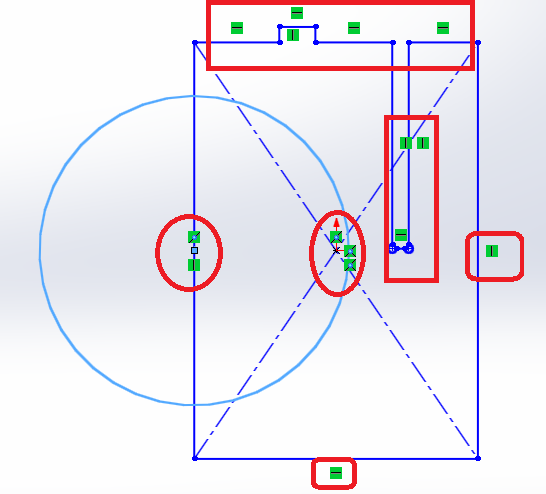

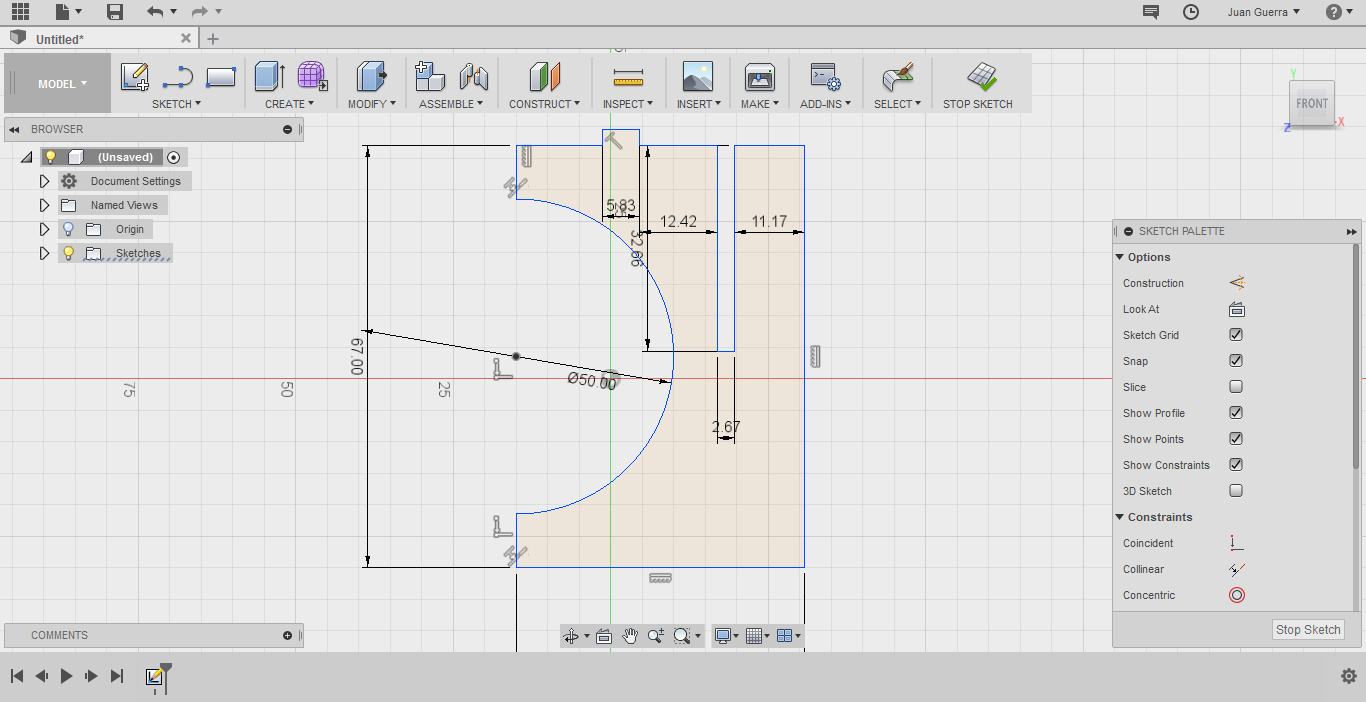

In the second design also based in sketches, first make measures of the top line of the sketches with the tool center rectangle make a square and the couplings in the space of 31

this measure is different of sketches because corrected at dimension of material, dog bone in the couplings for So that the feet can be adjusted completely, and we repeat the previous

process make a circle of 300 mm of radius and complement with tools sketch rounding and trim entities to finish the design.

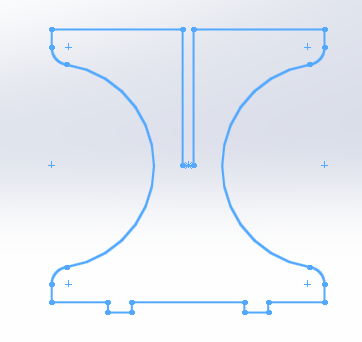

In the last piece make a rectangle for the table, to situate rectangle since the middle of the lateral line measure of 134 in horizontal and 165 in vertical to point to make

rectangle, to second rectangle, take de same measure in horizontal 134 and add 171 for make the rectangle starting from the middle and use the tool symmetry of entities to complete

in all de design.

All this symbol notifies work with restrictions, with respect to another line, if you removes this restriction you don’t work in a parametric design, these restrictions are linked to each other because if you modify one the others change the measure respect to the modified line.

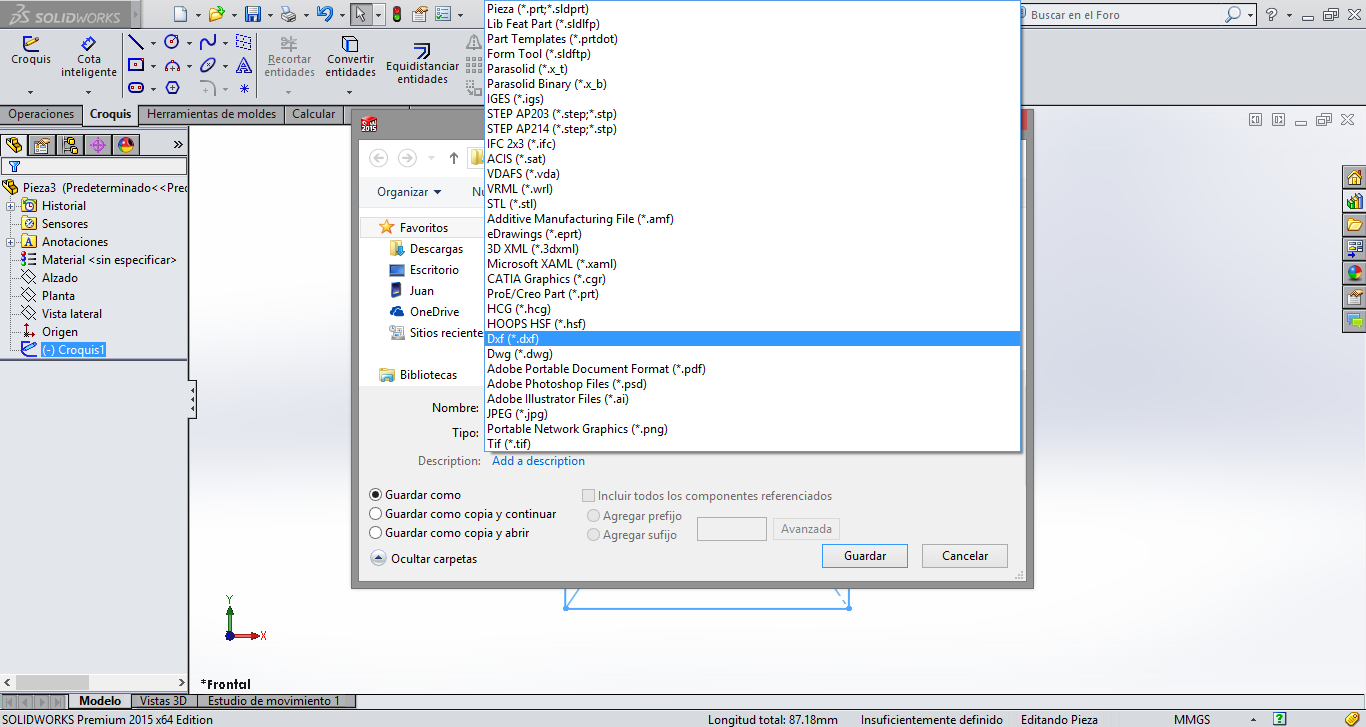

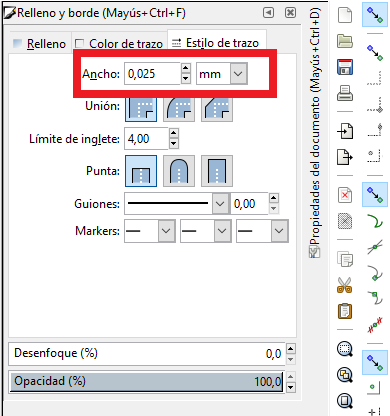

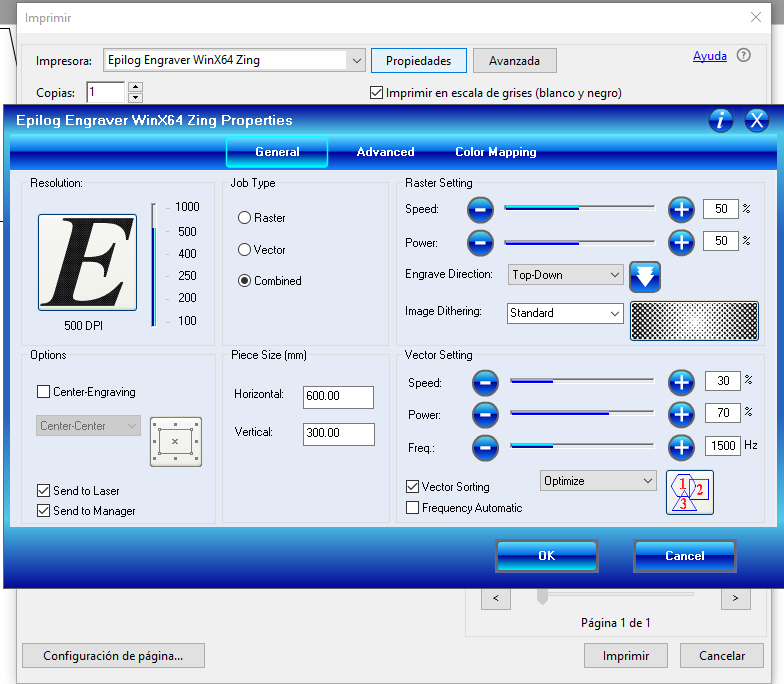

Already finished design export to the fotmat dxf, So that the software recognizes it and can edit and adjust it, first change the size of the dimension

the size of the iron to be used, situate the design anywhere and change the cut line at 0.025 and adjust the recorded if necesary, finally export a format

PDF to cut.

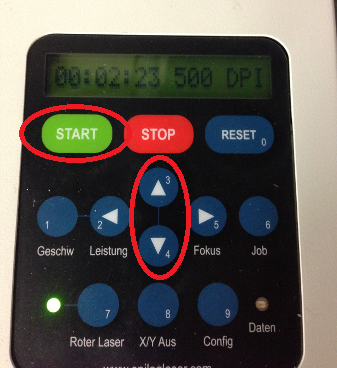

Open the file in pdf and click in print and select the machine to use, in this window change the parameter, change the speed, power and freq of vector setting in 30, 70 and 1500

respectively, don’t forget change piece size at size of your material, then for setting the machine you need use only two buttons for adjust the bed of work and once make this

press start to cut the design.

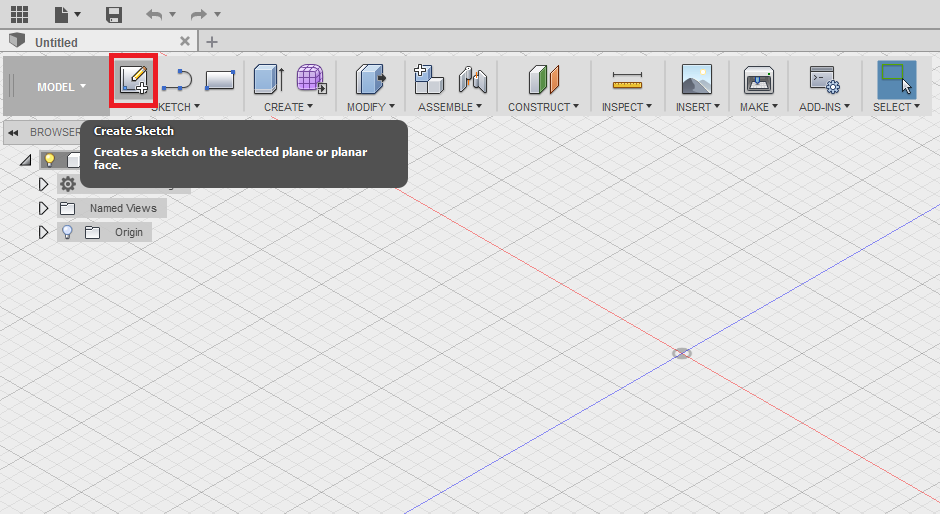

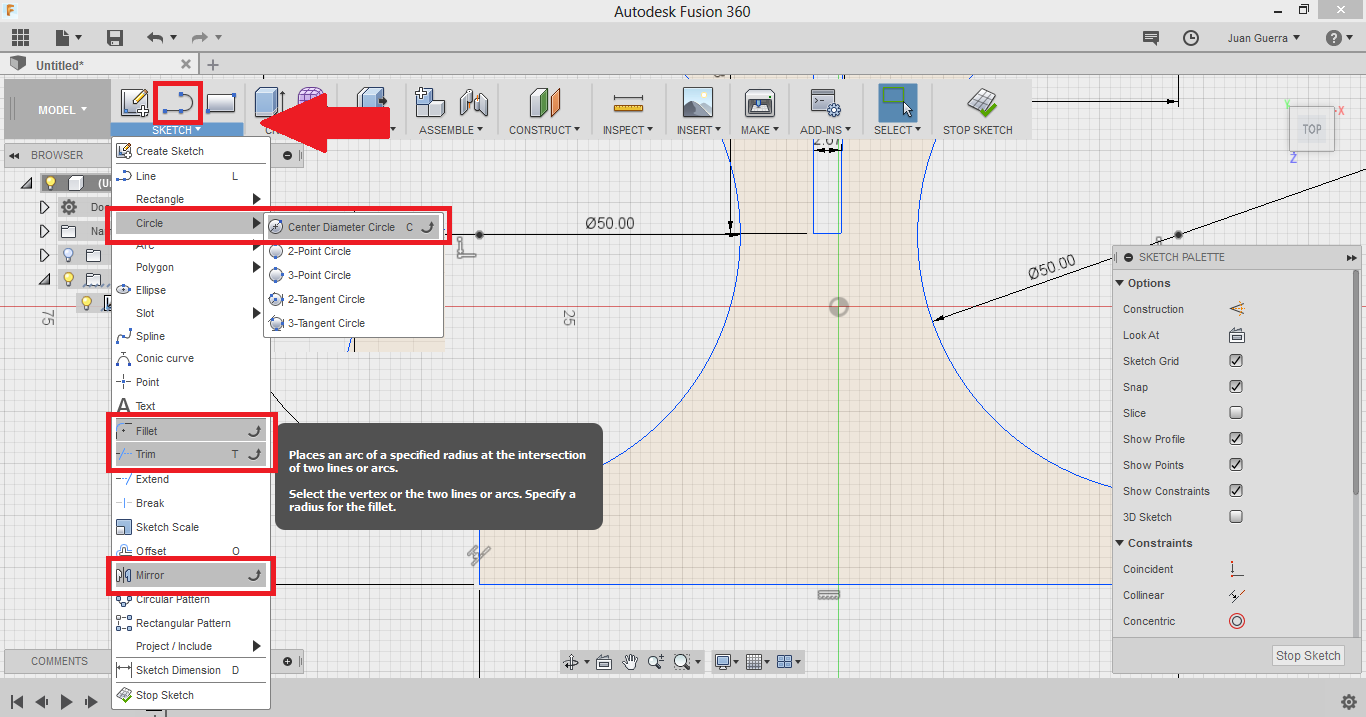

fusion 360

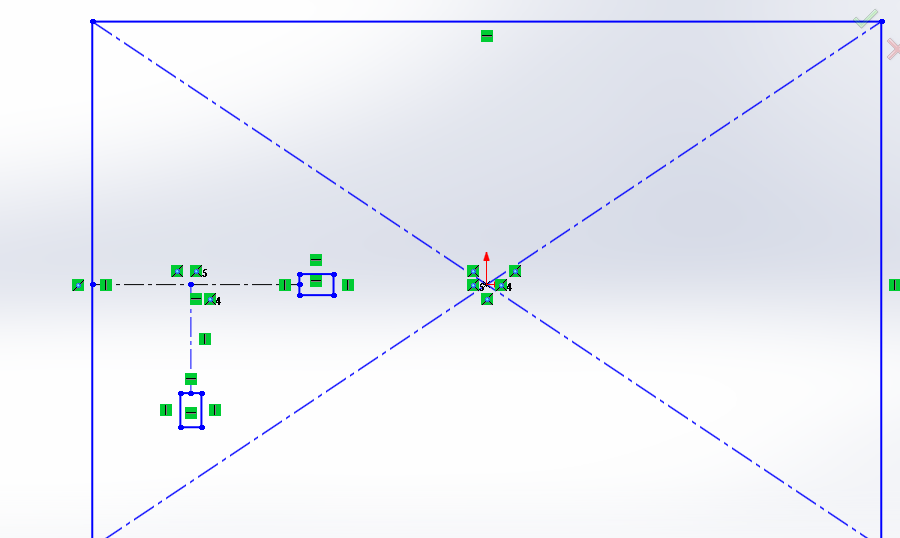

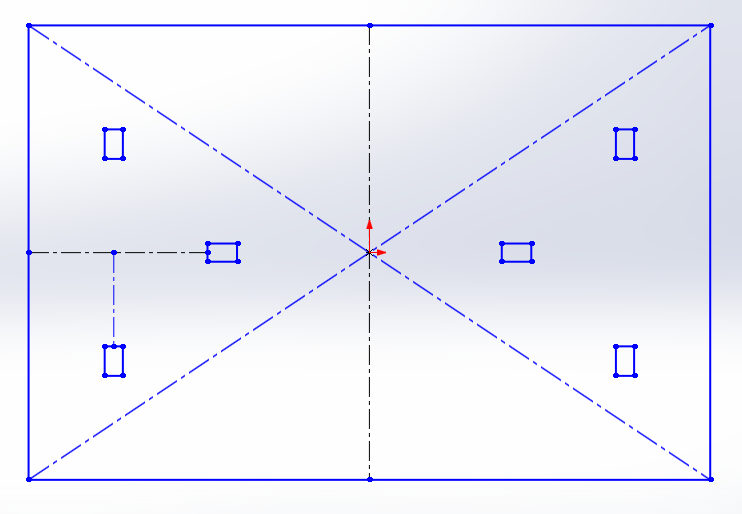

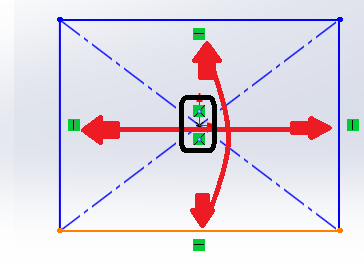

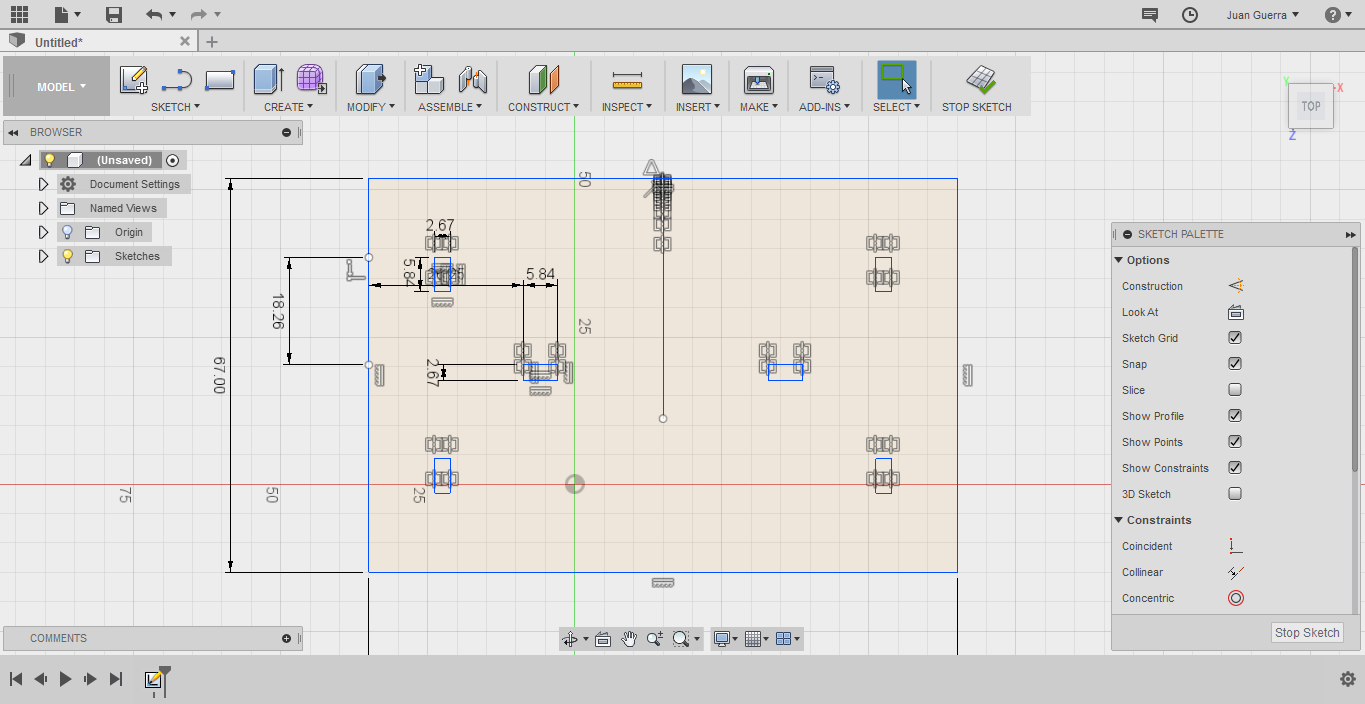

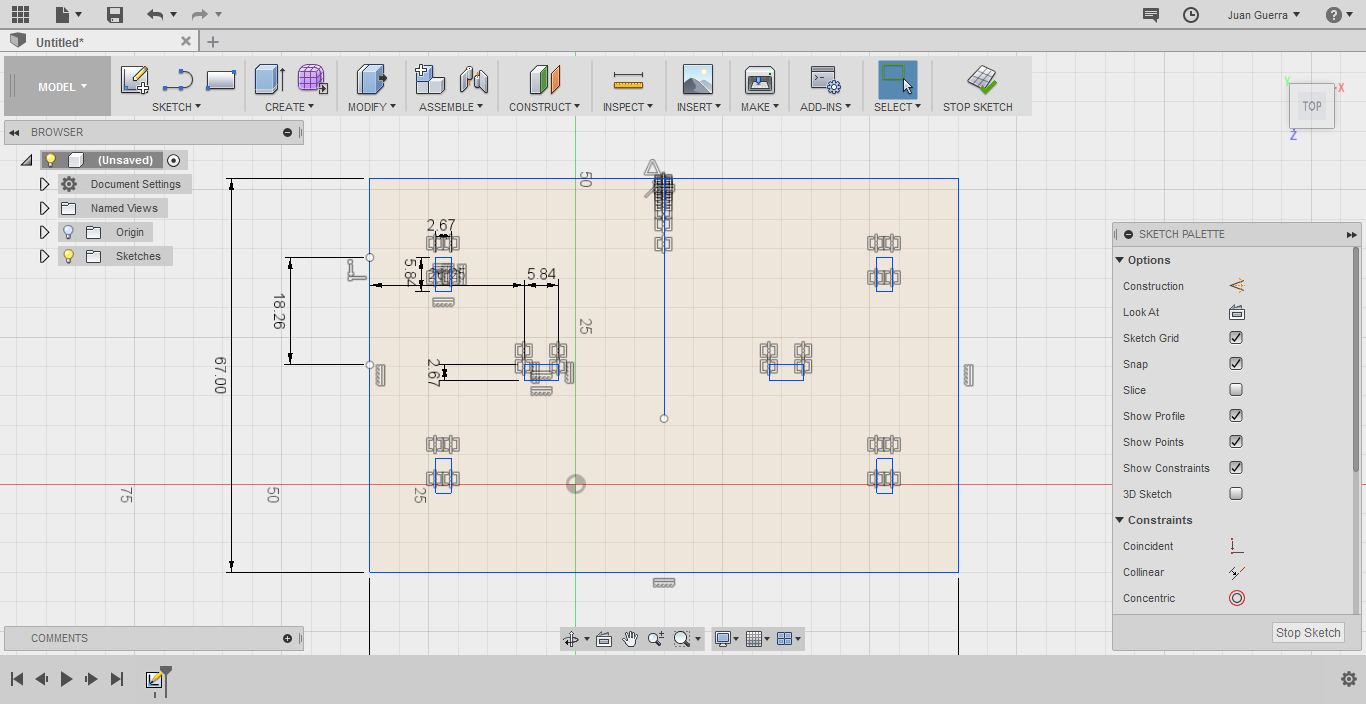

For test the other software I use Fusion 360, this software is similar at solidworks, I make the same design to compare with another program and see the difference, this

software is free and you can download in the page of Autodesk, Fusion is like AutoCAD because have the same commands but with more specifications and complete because this

software is for work more in 3D.

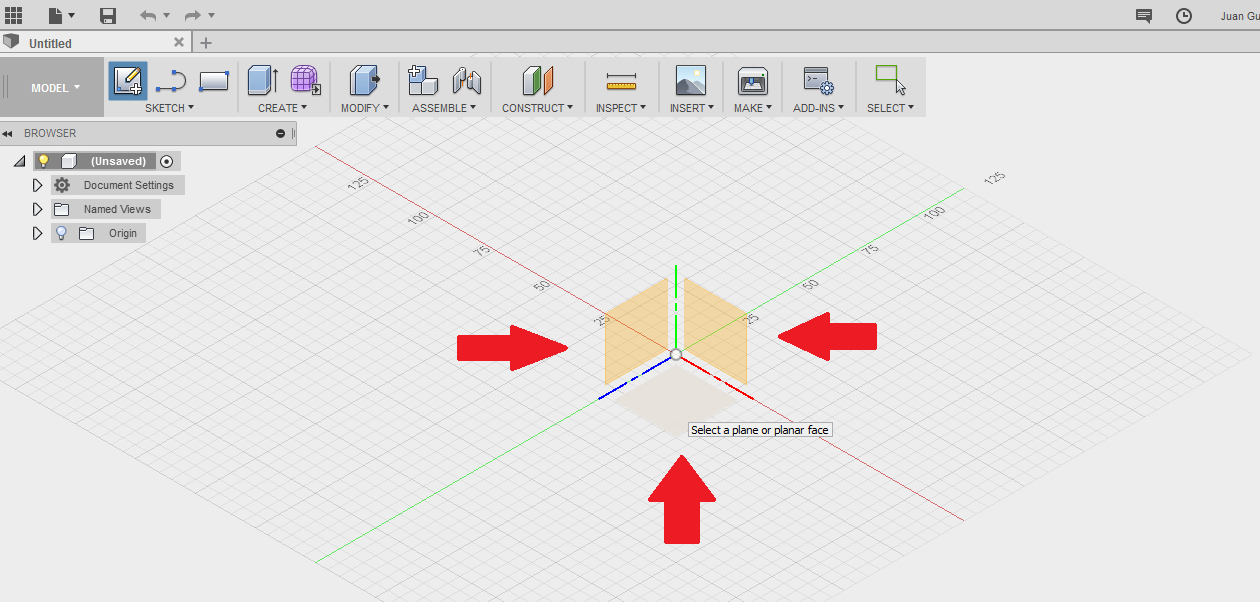

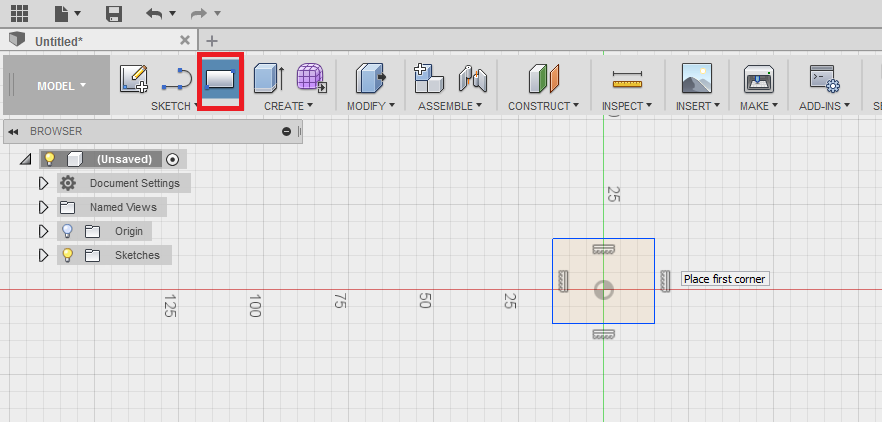

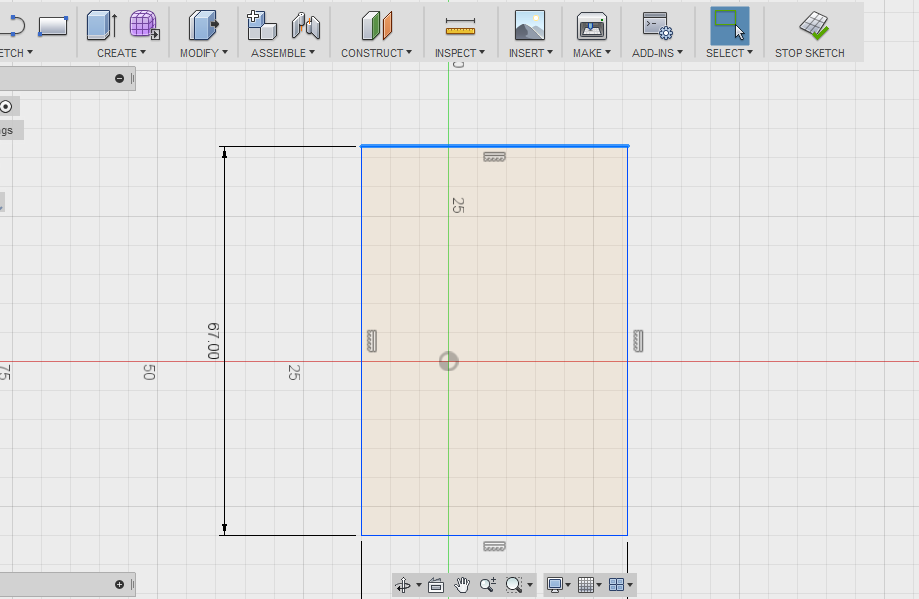

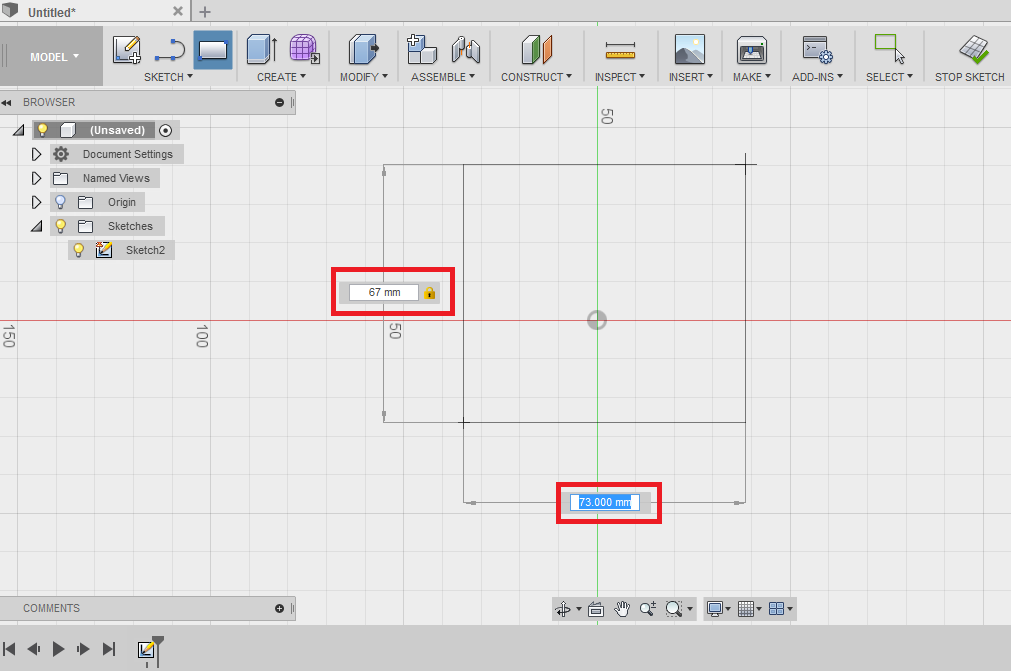

To start with the design, first press sketch and next select the plane to work, then with the command rectangle make a square of the measures, you can give it a specific

measurement only write de number of measure and next with the key “TAB” for give the second measure. The tree design has the same beginning with the command rectangle.

Then with the measures make the others parts of the design, for the others parts I use commands line, trim, circle, filet and mirror, all these commands are in the toolbar

in sketch.

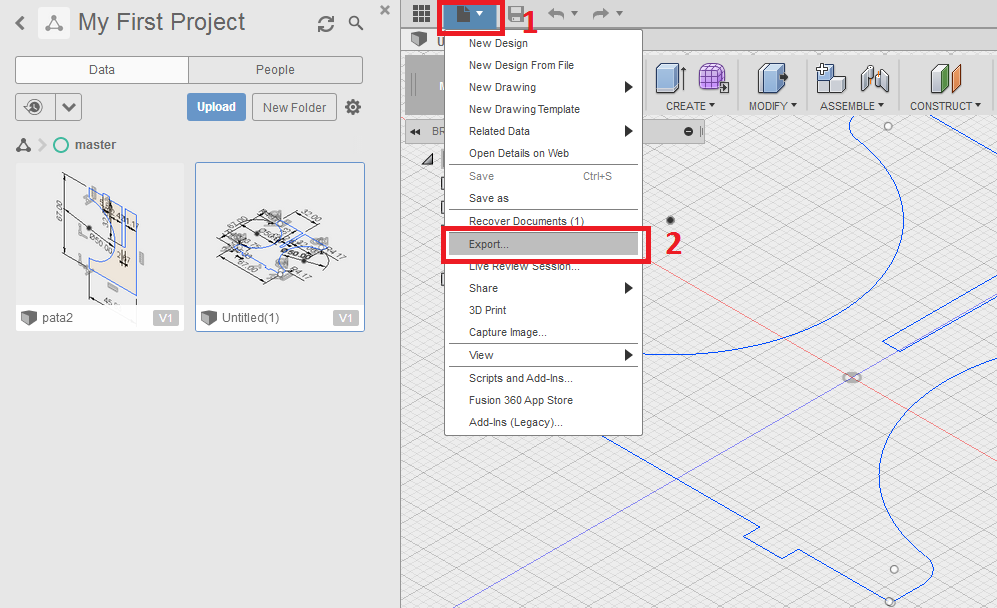

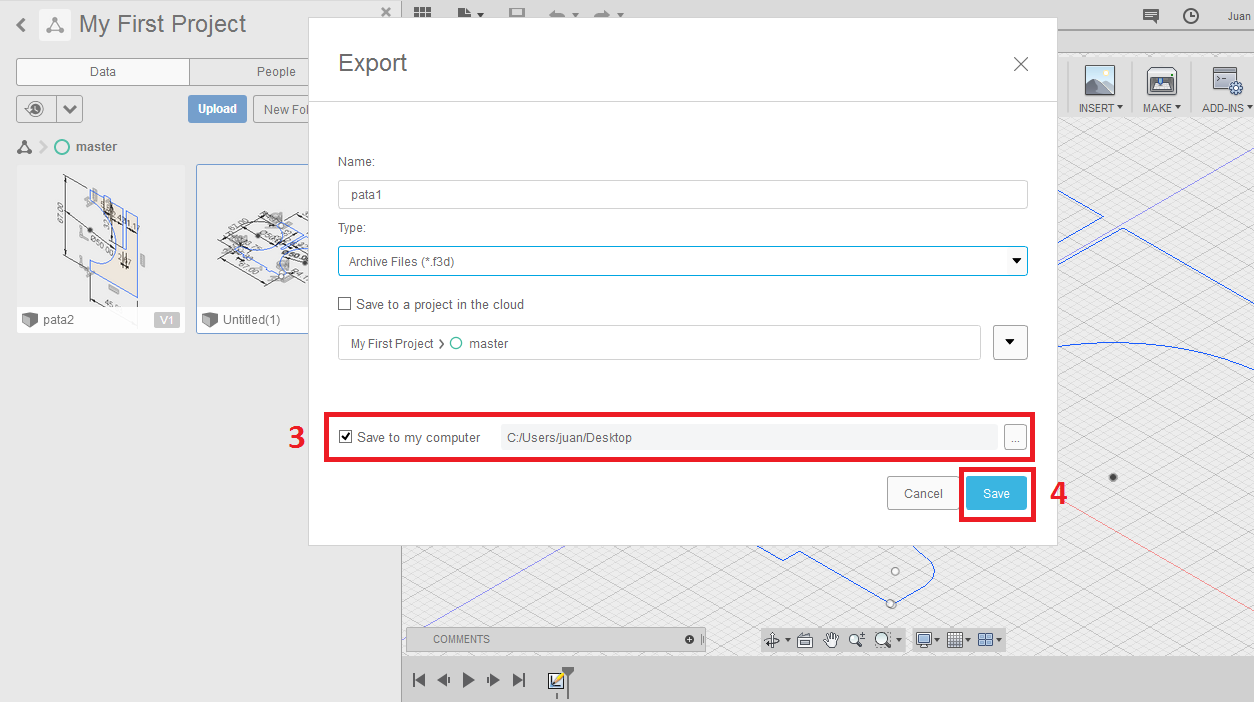

In the software fusion 360, the files save in a cloud but if you need download the file first go at file and click in export, next you select the ubication and download the

file.

Learning outcomes

- Demonstrate and describe parametric 2D modelling processes

This demonstration is in the third objective of the page, I use solidworks this software uses parametric design and for this assignment I occupy and describe the design in this

program.

- Identify and explain processes involved in using the laser cutter.

The process is not complicated for complement and edit the design if you need you can use Inkscape, remember for use the machine probably you need an extractor for the smoke and

all that produce the laser cut machine.

Develop, evaluate and construct the final prototype

For the test with the first laser cut, the presfit is very good and the pieces fit well, a recommendation first make sure of the measures before of cut this is for no problem

with a presfit or tatting in others measures, remember make a sketch with all the measures for no complicate at moment of make the CAD.

Have I:

- Explained how you parametrically designed your files

For the parametric design use solidworks and you can see the process, up in the page.

- Shown how you made your press-fit kit

For your presfit teste I recommended measure the width of the material and give higher and lower values for test and get a correct presfit of the material that you use, recommended

if you work with millimeters increase by one millimeter the biggest and smallest measures.

Vinyl Cutting

stickers

For the vinyl cutting use a stickers in a cameo machine, you can see the vinyl cut in the second objective.

- Identify and explain processes involved in using this machine.

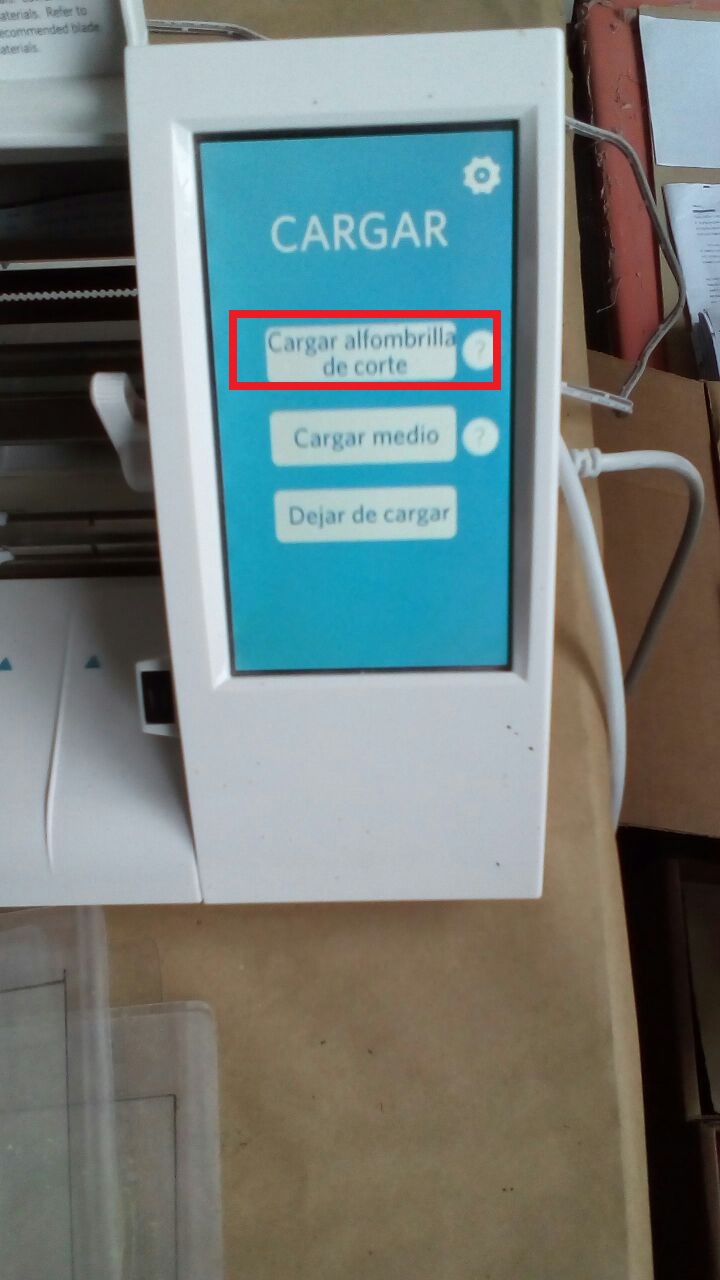

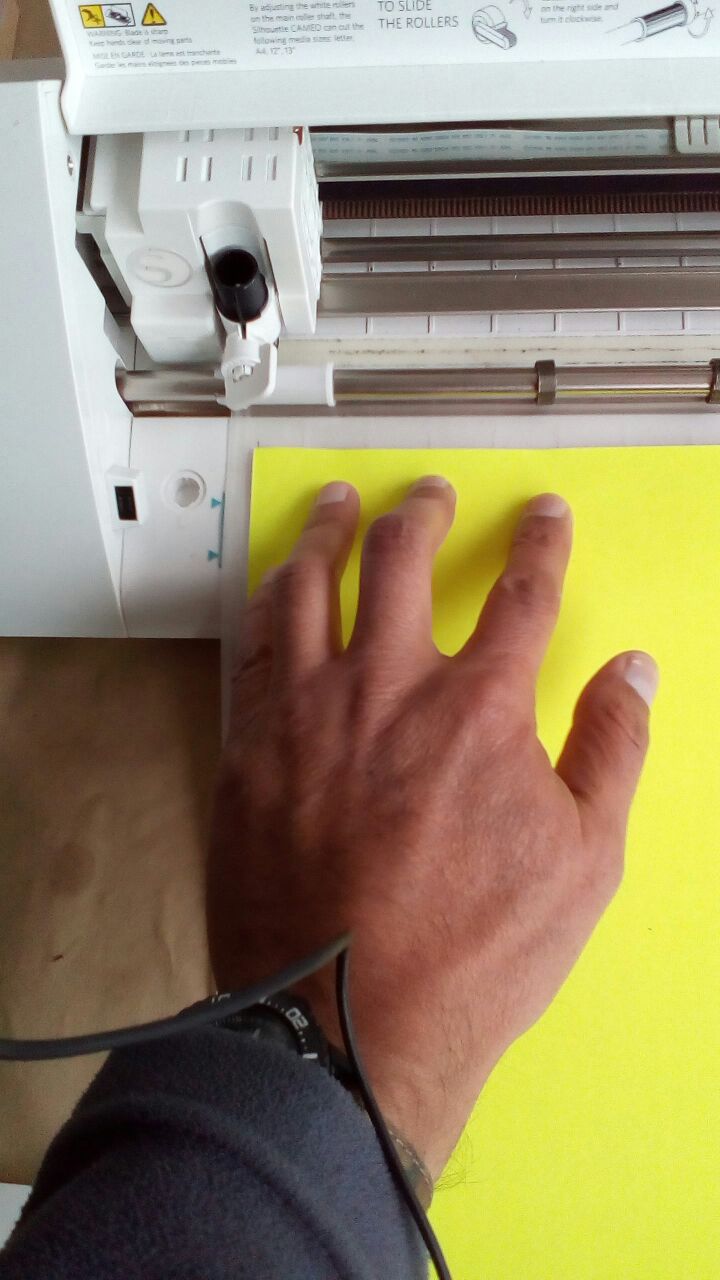

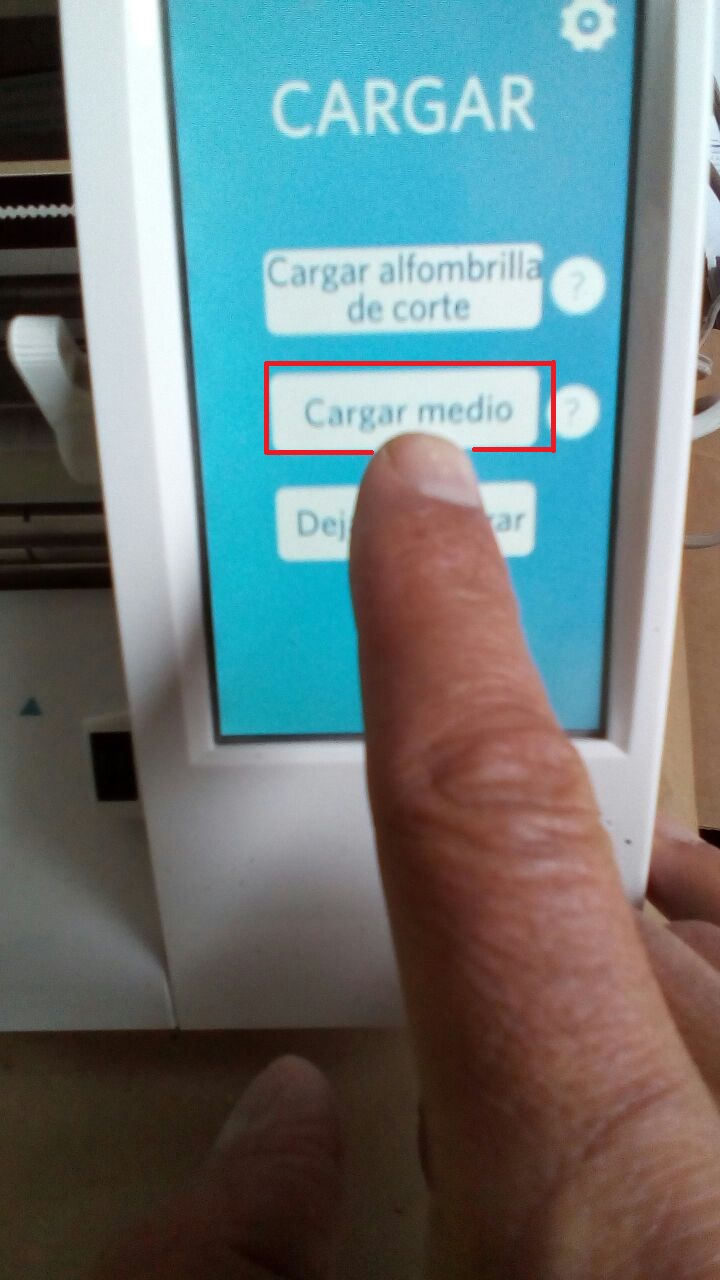

The first step to occupy the machine, first need calibrate the height of the blade, this depend of the archive or for you need occupy, the point red indicates blade level,

this calibrate is for the depth of the blade relative to the paper, next step press in load cutting mat and collocate the paper or adhesive in the mark and in the end of the

preparation of the machine press “load medium” and the paper enter in the cutter, and finally in the software press cut and the machine begin the cut.

- Design and create the final object.

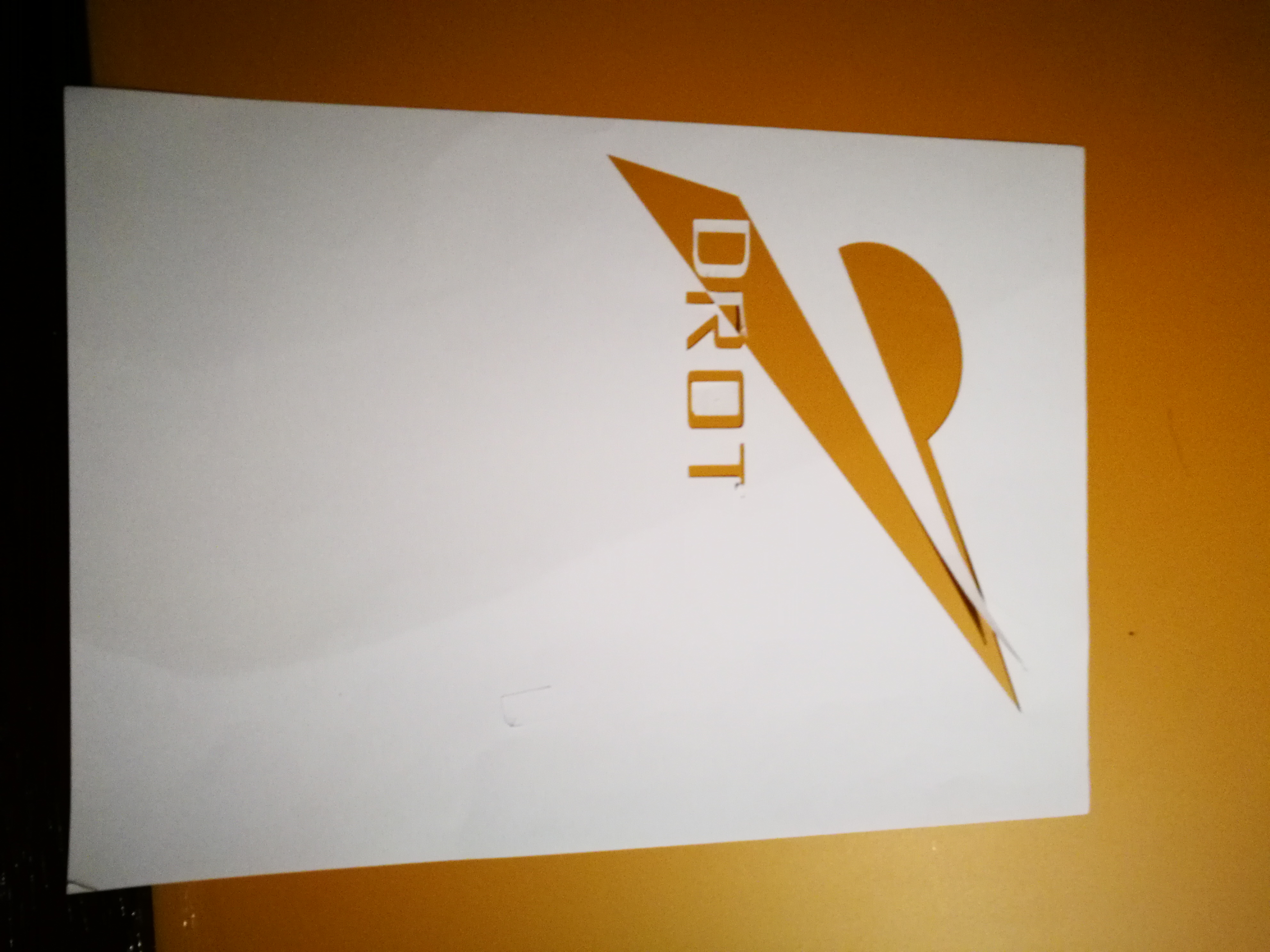

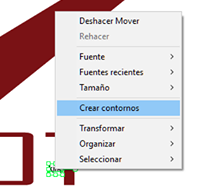

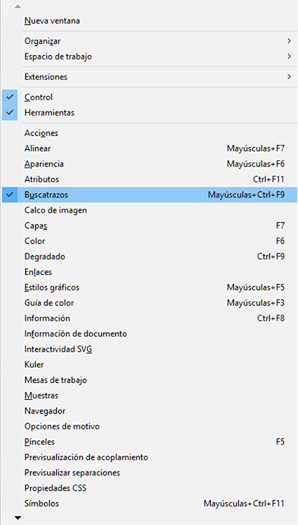

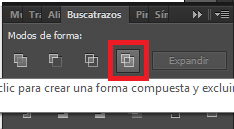

For the design is very simple, the design is made in the software illustrator, the first step to make the design is use the tool feather or pen, with this tool make two

triangles and one half circle and one triangle of another color, then add text, when the text and design is in the correct position select all and right click and press in

create contours, done this step go at window and click in searchers and in the box that appears select the four option for create the effect in the letters and in the design.

have I

- Explained how you drew your files.

For drew the file use the software illustrator and cut a simple but great design and the simple process you can see in overhead of this point.

- Shown how you made your vinyl project.

This process you can found in the second objective of laser cut and in vinyl cutting.

- Included your design files and photos of your finished project

Dwonload files

Files in Repo