Materials, tools and software

Shopbot Full-Size(Tools)

MDF (Materials)

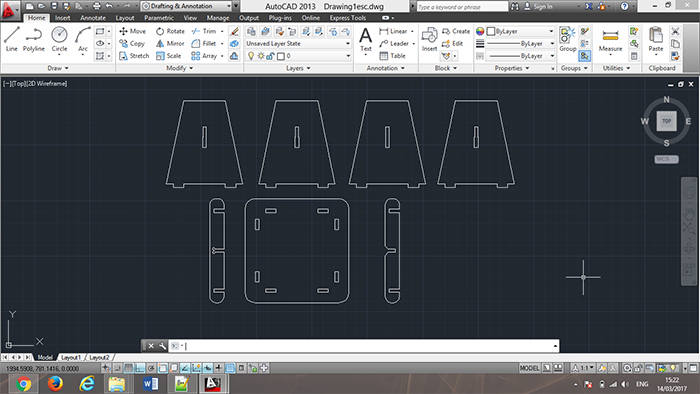

Autocad (Software)

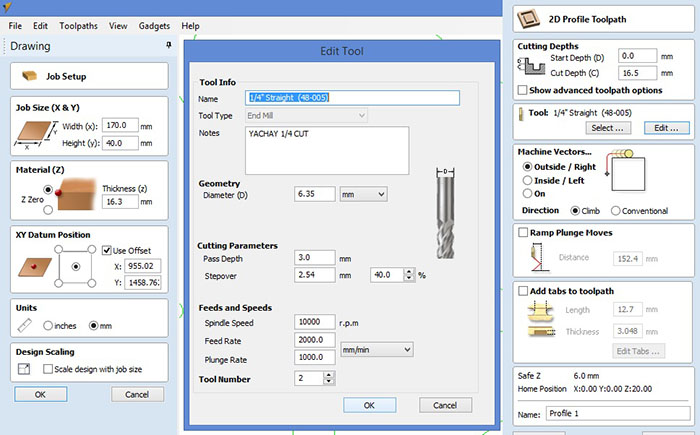

VCarve Pro Shopbot(Software)

Shopbot Full-Size(Tools)

MDF (Materials)

Autocad (Software)

VCarve Pro Shopbot(Software)

Check switch OFF and the variator frequency ON

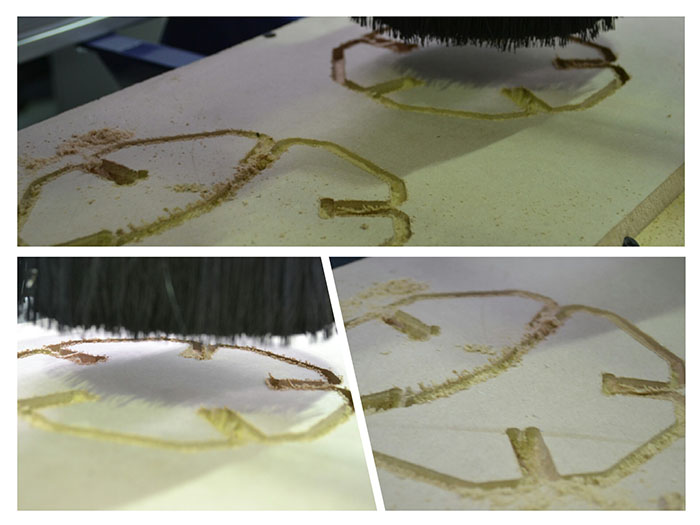

put the material (wood) on the table of the machin with screw.

select the mill of the chosen material

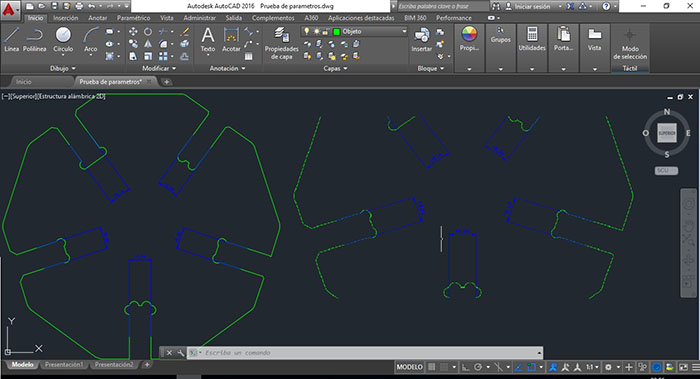

with design the new project I take ergonomic measures and make a bidimensional object with pressfit,make a sacale model in the cotting laser. I used this software for the design. In which two-dimensional files were designed which, when joined together by a system of pressure assemblies, form a fully functional three-dimensional object which was installed in our department together with the design of my brother's table, generating the complete set.

In this part make functional test. We introduce a piece in which we can make calculations to prove the current

operation of assemblies for different applications.

The file is designed with basic 2D design tools and constraints based on the thickness of materials that can be

contaminated in the laboratory for the power of furniture design.

Open the VCarve Pro Shopbot Software with the piece and change parameters for "X - Y" axis then put on 0 the "Z" axisfor this put

on the matirial the sensor and check the clamp is making a ground connection (the mill must touch the sensor). Select the unit

to work

In the next part select the toolpath options for this work I select smooth out of the piece. then take the correct mill and the correct

direction.

The next example we dont select the correct mill, this caused errors of the units in the piece.

In the development of the tests of the machine, we generated an error in the file as it can observed in the next image so that it took to make a review of the machine where an fail was determined in an update by which to solve it it was proceeded to uninstall this update and proceed with the normal operation of the machine.

Then proceed to hold the material on the bed using a drill and screws. We proceed to mechanize the file that was previously loaded.

The table was made by Juan Guerra for his assigment, in the next link can see his work

This two items can see in the top of documentation

We had a problem with the software of the software of the machine but we update the software.