Materials, tools and software

3D Printers dimension (Tools)

3D scanner (Tools)

PLA (Materials)

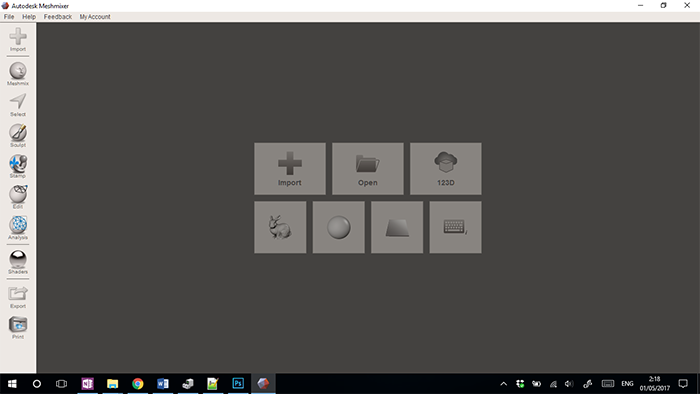

Meshmixer (Materials)

Solidworks (Software)

3D Printers dimension (Tools)

3D scanner (Tools)

PLA (Materials)

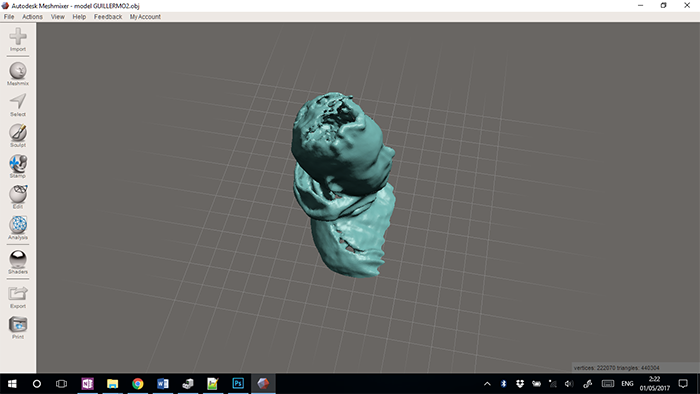

Meshmixer (Materials)

Solidworks (Software)

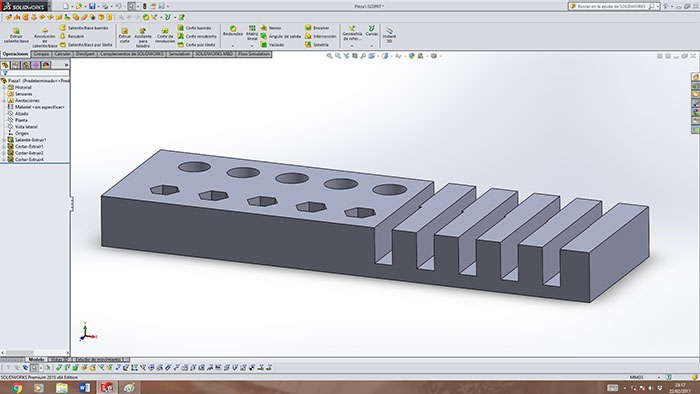

In this program we can modeling yours designs in 2D and 3D if you can export to many formats.

It's a test design of the printing where you can take different measures for the settings of the printing.

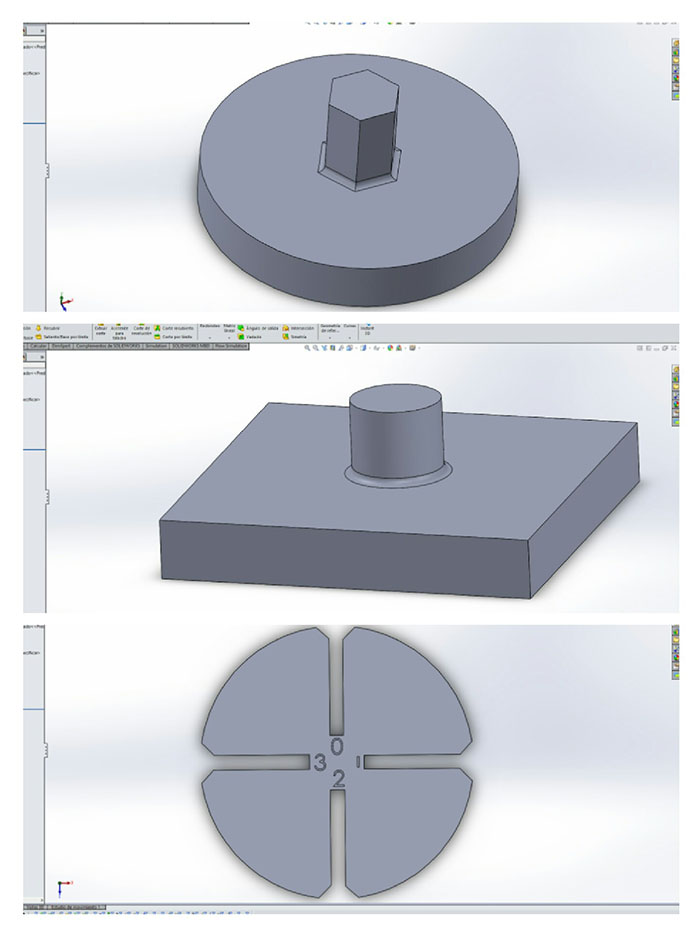

A piece in which an essay is generated to know the behavior of the same to be able to generate presffit and constructive details or sets.

To perform a print test we use SolidWorks in which we can model your designs in 2D or 3D and you can export in several formats.

In order to realize the piece for test of impression took into account several factors to analyze among them the behavior of assemblies with

several dimensions, thicknesses and geometries.

It is a design that tests the printing where different measures can be taken for the configuration of the printing.

A piece in which an essay is generated to know the behavior of the same to be able to generate details and constructive sets or press fit.

In addition, my brother designed a piece in which we analyze and understand the behavior of 3D printing below a link to visualize their information

With all these data, we were very useful to be able to design our pieces.

To print, check the calibration of the machine and the correct collocation of material.

We put in the plate permanent stick for a greater addition.

I had only one problem, which you can see the process of the print test where the filament did not stick on the plate. To solve this I put

some glue sticks.

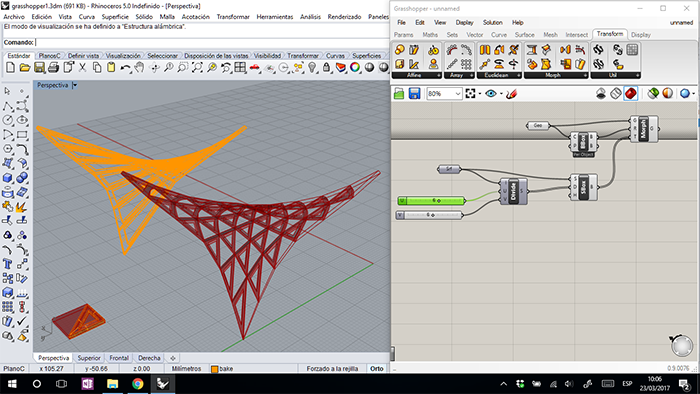

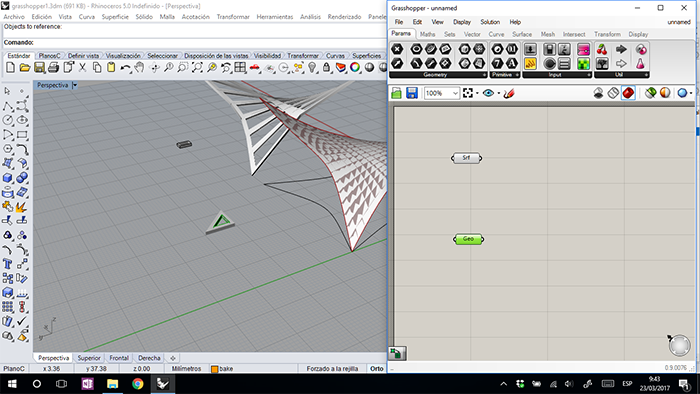

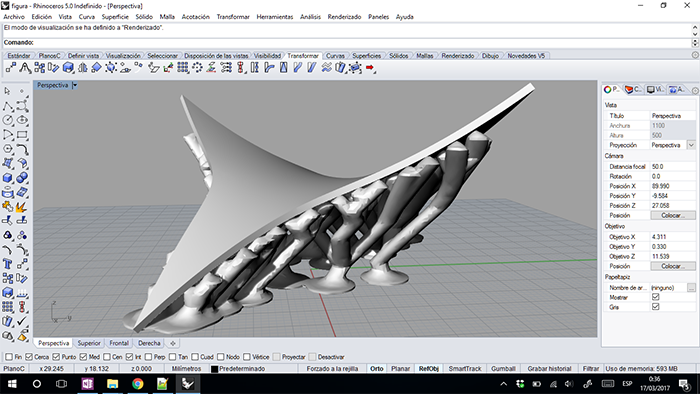

For this process, I use Rhino + Grasshopper to make a parametric design and make an artistic piece.

This piece is very difficult to perform in another process based on the complexity of its details in

which it is a syncretism between a geometric and organic morphology symbolizing a rupture between the

fractal geometry of nature.

Within the design was generated a curved surface with four points of level for which the different genre

heights, the development of the supports was done with Meshmixer.

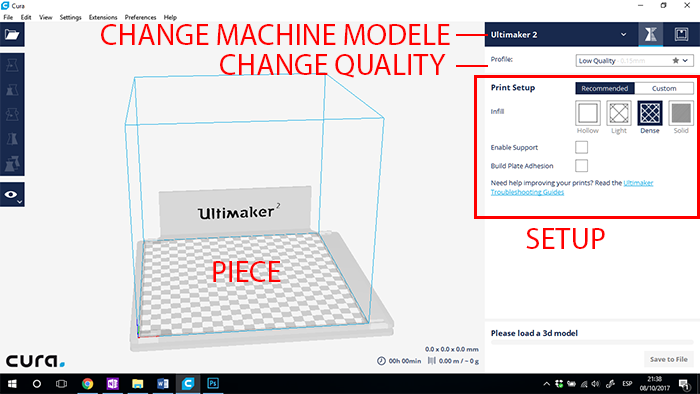

All this modeling saved in STL format and Cura software used to generate the print files.

The limitation of this process found in the time of printing and the size of the bed.

On the other hand we could observe the flexibility of elaboration of complex pieces and customized designs.

To print on this machine, the CURA software used in which we calibrate the print parameters as shown in the first image and in the following; the print process can be seen.

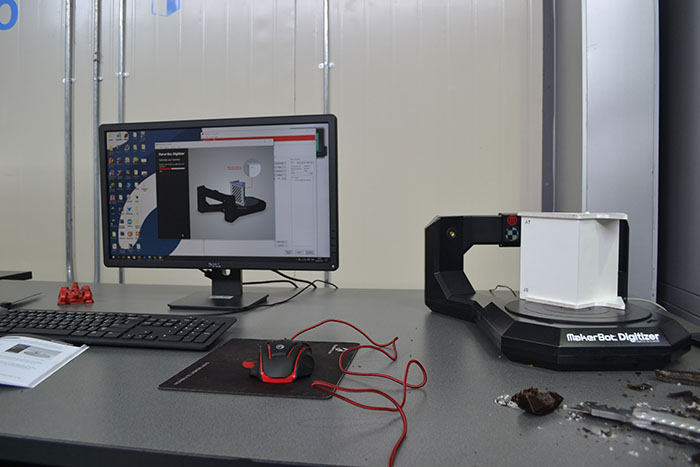

To start to use the scanner, take the following cautions:

- Install the software in your PC

- Make sure the lens cap is closed

- Calibrate the scanner

- Place the scanner with in a low light

- It is advisable not to scan bright objects in bright areas

With this tool, can scanning something big objects.

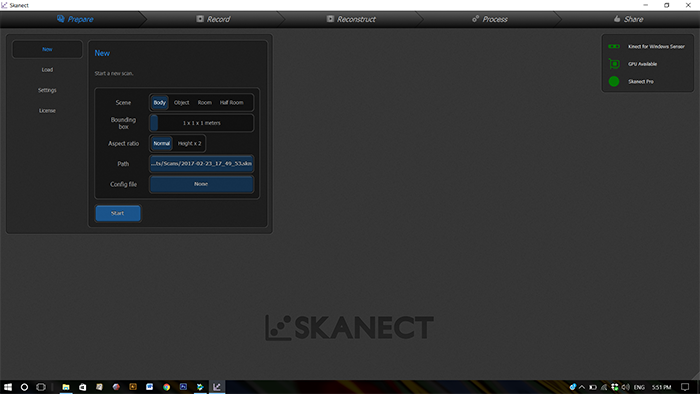

Frist install the SKANECT software and the drivers of Microsoft Kinect

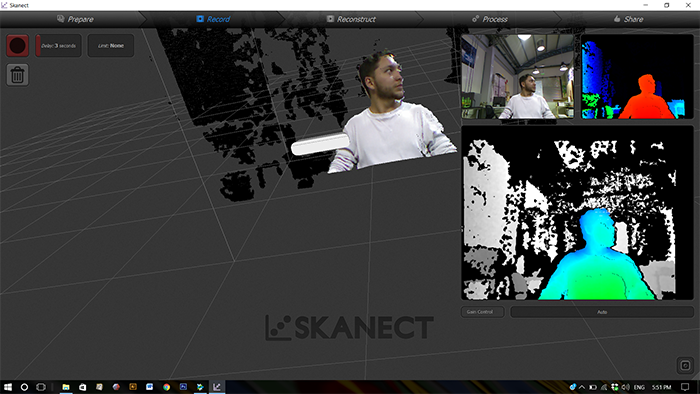

Second, in the skanect take the correct distance with the object to scan put its green color and we can proceed to scan.

For correct scanning, check that the kinect is evenly distributed.

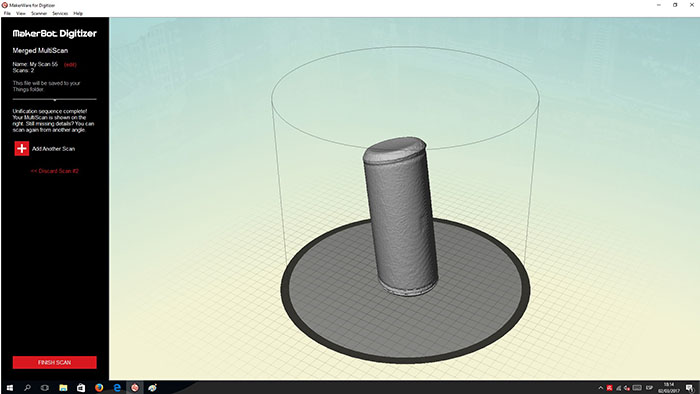

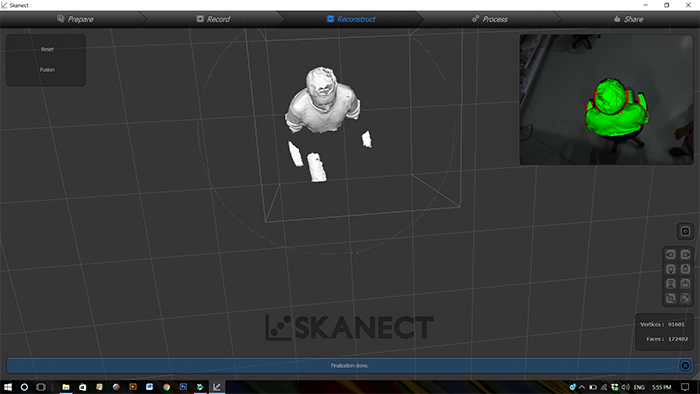

When do you get the files to proceed to edit and repair the fails in this software.

This file can harm the printing.

Yes, In this assignment, I can see the operation of 3D printing and the differences with the other processes

In the documentation can see all process to make this assignment

The versatility and ease of development with which almost anything can be create in this process

Can see this two items in my documentation

I had only one problem, which you can see the process of the print test where the filament did not stick on the plate. To solve this I put some glue sticks