Assignment

Software

Rhinoceros 5.0

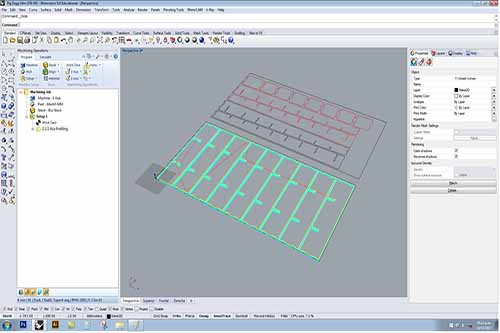

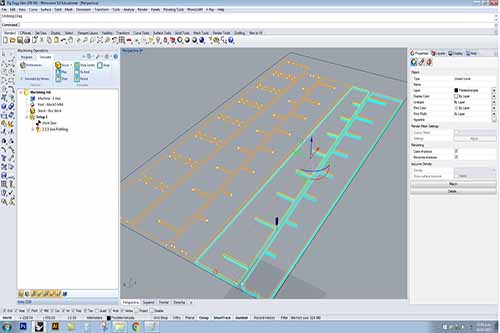

Rhino CAM

Mach 3

Materials

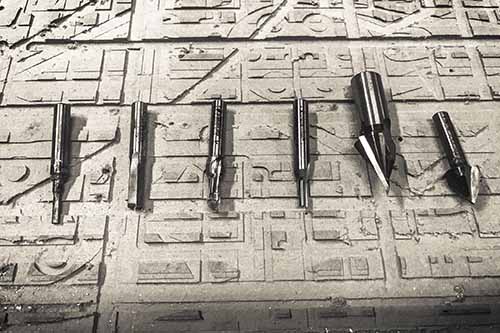

CNC Router Bits

MDF 1/2" and 1"

Sealant, varnish, paint

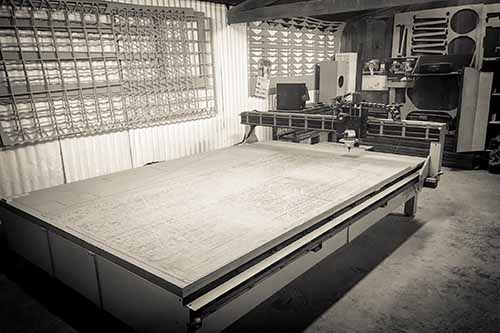

Guatemalan Fab Lab + a CNC Router

La Granja Fab Lab was founded at 2013 in the city of Quetzaltenango. Its roots lie in the scarcity of knowledge about technology in the region, the high cost of the machine service available for the digital manufacture, besides wanting to contribute to improving local products To reduce the excessive consumption of imported products. (Reduce Ecological Footprint) See More at fablabs.io

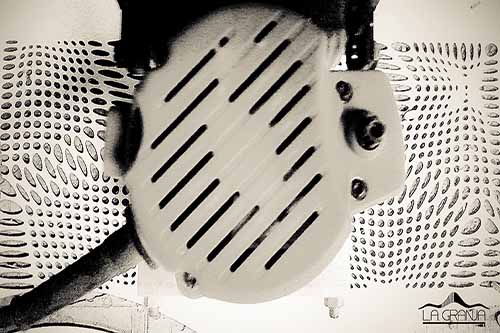

The CNC assigment is something we expected because it is our favorite machine at the fab lab. In fact, our lab is organized with CNC as the main actor. We have 3 years of experience, learning from materials, router bits, finishes, delivery, experimentation and make the cnc sometimes work, like a laser cutter, or a carpentry saw. In our countries, the lack of machinery and experience makes us face many economic and technical difficulties.

La Granja Fab Lab is a CNC Lab based in Quetzaltenango!

To learn CNC our experience can be summarized in:

1. Learning and mastering CAD 2. experience a lot with CAM 3. Know local materials and learn with local craftsmen 4. Have a good router bits kit 5. Learn the post-cut processes: Assembles, inserts (encastres), fits, finishes, paint, varnishes, Screws, nails, moldings, etc.

CAD/CAM

Computer-Aided Design (CAD): diseño asistido por computadora (DAC)

According to wikipedia Computer-aided design (CAD) Computer-aided design (CAD) is the use of computer systems (or workstations) to aid in the creation, modification, analysis, or optimization of a design. CAD software is used to increase the productivity of the designer, improve the quality of design, improve communications through documentation, and to create a database for manufacturing. CAD output is often in the form of electronic files for print, machining, or other manufacturing operations. The term CADD (for Computer Aided Design and Drafting) is also used.

Computer-Aided Manufacturing (CAM): fabricación asistida por computadora (FAC)

And about Computer-Aided Manufacturing (CAM) wikipedia says is the use of software to control machine tools and related ones in the manufacturing of workpieces. CAM may also refer to the use of a computer to assist in all operations of a manufacturing plant, including planning, management, transportation and storage.Its primary purpose is to create a faster production process and components and tooling with more precise dimensions and material consistency, which in some cases, uses only the required amount of raw material (thus minimizing waste), while simultaneously reducing energy consumption. CAM is now a system used in schools and lower educational purposes. CAM is a subsequent computer-aided process after computer-aided design (CAD) and sometimes computer-aided engineering (CAE), as the model generated in CAD and verified in CAE can be input into CAM software, which then controls the machine tool. CAM is used in many schools alongside computer-aided design (CAD) to create objects.

It is very important to learn the relationship between CAD and CAM, we can not manufacture if we do not have a good drawing and a good 3D model. For this reason it is very important to exercise a CAD software, so that you do not have problems in the machining.

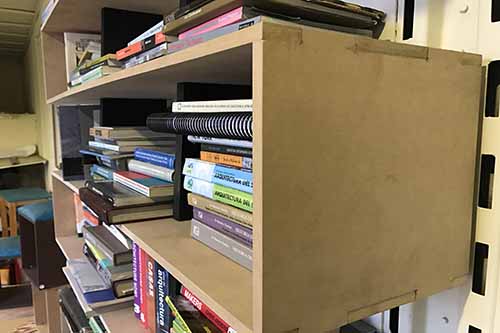

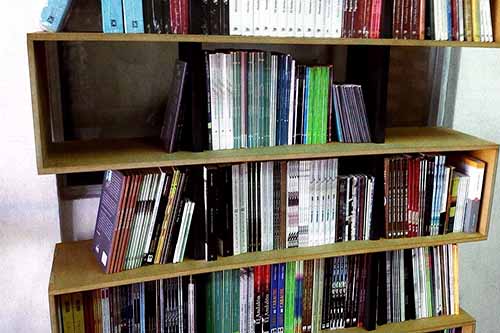

Furniture CNC

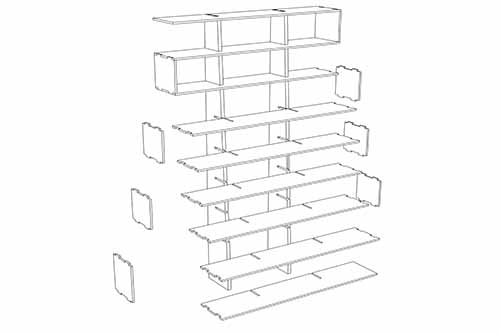

1. Select what type of furniture we want to make. It is important to imagine that we are going to assemble something in 3D but before we have to cut everything in 2D

2. Work some sketches trying to define the assemblies, the elements to tension and compression of the furniture, the order in which the pieces will be assembled. Will we have vertical, horizontal, oblique pieces? How are we going to order the cut in cnc?

3. Draw all components using CAD software. For this assignment I will use Rhinoceros 5.0

4. Dimension all assemblies and connections (encastres)

5. In 3D do a simulation of furniture assembly, this helps a lot to visualize errors before cutting

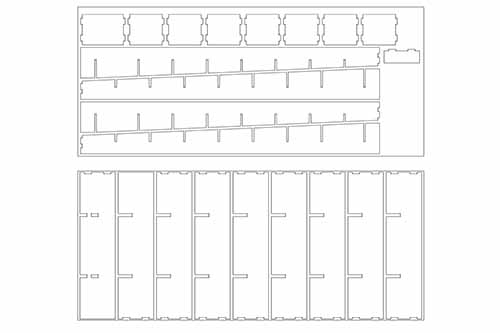

6. Make necessary adjustments to drawing: scaling, line color, line weight, etc. In this step it is very important to consider the thickness of the material.

7. To do the cutting of the furniture, it is necessary the nest and place all the pieces that make up the furniture in a 2D orthogonal view

8. Clean all parts and make necessary adjustments with sandpaper

9. Assemble all parts and review structure

10. Apply finishes to pieces of furniture: sealant, paint, varnish, adhesives. This part only requires imagination to customize the furniture

What is the best material?

It is important to select materials for any CNC project. There are soft, rigid, dense, light materials. And for each cutting strategy you have to learn how to do the machining, with the router bit suitable for each material, know how deep to cut and the speed with which you have to configure in the CAM software.

Then I think there is no better material, you have to select the most suitable for each project and have a lot of experience with machining.