Assignment

Group project: test the design rules for your printer

Design and 3D print an object (small, few cm) that could not be made subtractively

3D Scan an object

Materials

3D scan: white spray

3D print: PLA (Polylactic Acid)

3D Design Rules and Tips

By doing this assignment I found interesting to follow the guide of Ponoko.com

3D Design Tips and

Here are some common problems you need to look out for when you’re creating your 3D designs:

Inverted normals

Minimum wall thickness

Minimum detail size

Minimum object size

Product orientation

Entrapped support material

Un-makeable product geometries

About Ponoko.com rules

When you upload a design to your Personal Factory, it will automatically check your file to make sure it fits with the 3D design rules. The rules are simply about giving clear instructions to your Personal Factory so you get exactly what you want. We suggest you check over your designs as thoroughly as possible before uploading them. This should help avoid the need for troubleshooting afterwards.

But, if you do miss something, don't worry. The good news is, your Personal Factory can usually detect the specific cause of the problem, automatically fix it for you or show you an error message that will point you in the right direction. Here are the things you should check before uploading a design:

3D file type

3D file size

Inverted normals

Maximum product size

Minimum product size

Non-mesh VRML 97 designs

One part per file

Non-manifold mesh

Design and 3D Printing

At La Granja Fab Lab we do not yet have a 3D printer, but at the Fab Academy we have learned the performance they have and in the near future we hope to obtain resources to work on projects. The strategy to comply with this assignment was to network with my colleagues in Costa Rica and El Salvador.

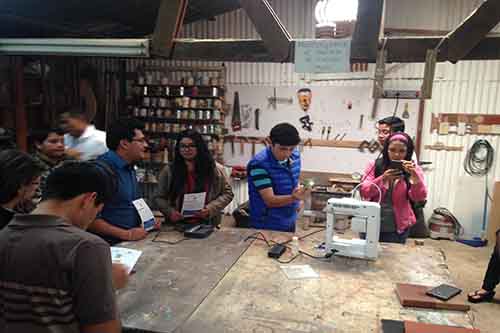

We also invited 3D Systems to come to give a 3D Printing workshop, was very good because we see the interest that 3D Print in cities like Quetzaltenango. We learned the basic configurations for the printer, also that the files are extremely important to make the process more assertive.

3D Scanning

The 3D scanner is another tool based on the fab lab, complementary with 3D printing to have a more effective reach with each project. We also did not have a scanner in our fab lab, but I searched with apps and programs for pc to have a scanner exercise.

In my research, I found a lot of alternatives to make a scanner, do not have high precision and also not for something very sophisticated. But they do allow a rapprochement and an experience.

The exercise will develop it with:

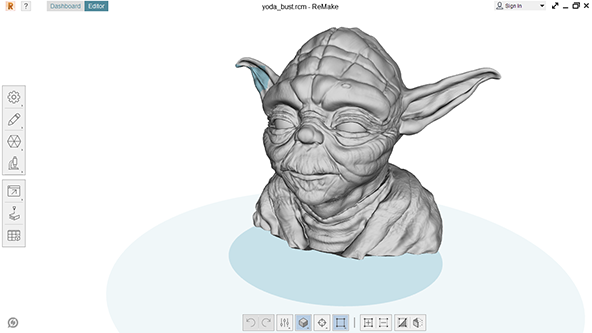

REMAKE developed by Autodesk

And Trimensional an app for iOS