Assignment

Group assignment:

make lasercutter test part(s), varying cutting settings and slot dimensions

Individual assignment:

cut something on the vinylcutter

design, make, and document a parametric press-fit construction kit,

accounting for the lasercutter kerf, which can be assembled in multiple ways

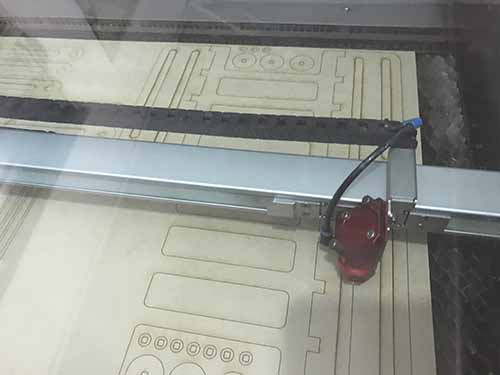

Laser Cutter

Laser cutting is a technology that uses a laser to cut materials, and is typically used for industrial manufacturing applications, but is also starting to be used by schools, small businesses, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics.

One of the most popular of the new desktop tools is the laser cutter, which is mostly a 2D device. It uses a poweful laser to cut a precise pattern of any complexity into sheets of whatever material yoy feed it, from plastics and woods to thin metal.

Many CAD programs can break a 3-D object into 2-D parts so they can be fabricated with a laser cutter, and the neatly slotted toghether like one of those plywood toys kits.

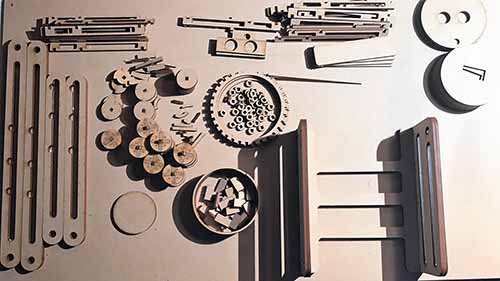

For this assignment i decided to experiment with different materials and strategies of laser cutting and assembly. I chose 3 models: a catapult, a lens case and a lamp. The downloadable files are in the following links:

Catapult by Obuq from Thingiverse

Portable Glasses Case from Thingiverse

Orbit Lamp from Instructables

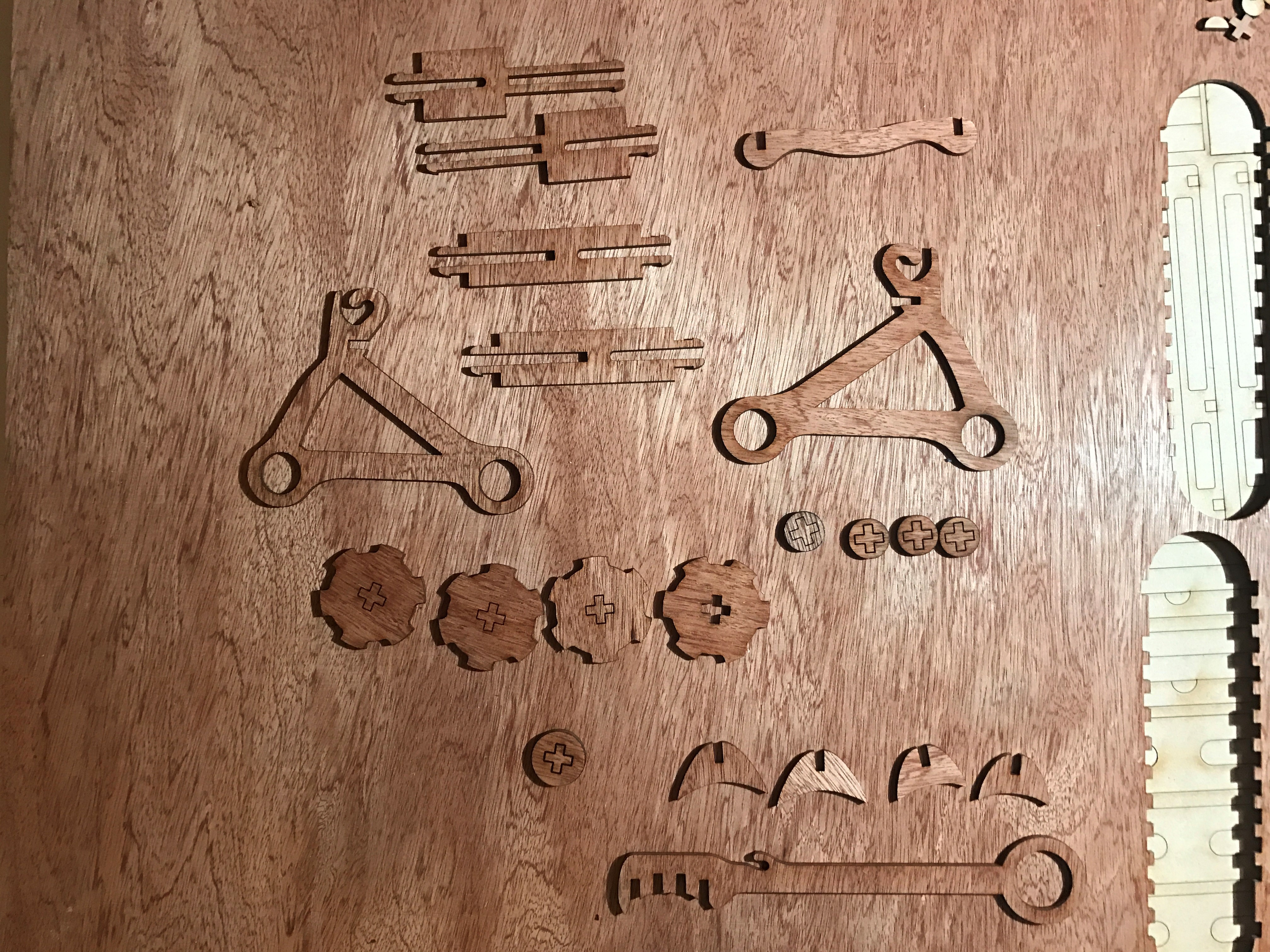

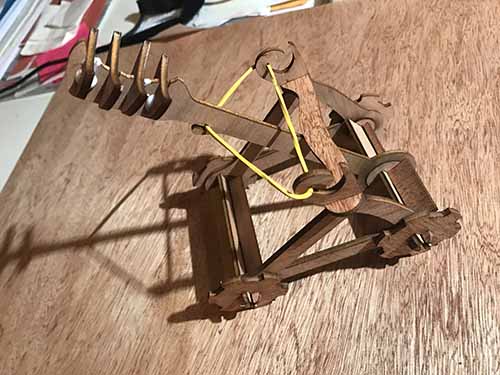

Catapult

A simple catapult for the laser-cutter.

Just needs one elastic band in addition to the laser-cut pieces.

See "catapult instructions.pdf" on how to assembly.

Designed for 3mm (1/8 inches) MDF or Plywood

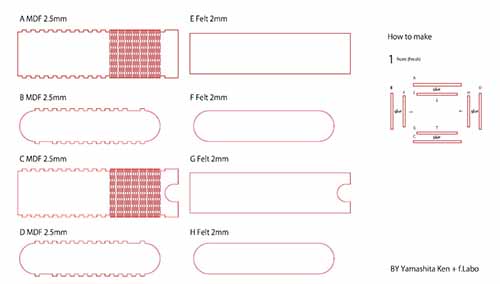

Portable Glasses Case

A simple case for the laser-cutter.

Designed for 3mm (1/8 inches) MDF or Plywood

Orbit Lamp

Inspired by the Kerf lamp The Orbit Table Lamp is a interactive, open design to be downloaded, customized and assembled using 4mm Poplar Ply and a simple Arduino circuit to control the LED’s.

Using movements of the hand, the lamp is able to turn on, off and change its brightness using an ultra sonic sensor.

The project was part of a Massey University, Industrial Design paper at the Wellington Fab Lab in New Zealand. Designed by Elliot Gonzales, Jan Louise Ballesfin, Ron Christiansen and Devon Mahoney.