In this assignment we face a challenge both group and individual, understand the structural, support and assembly logic are fundamental parts when designing a prototype of any Project, there are many variables in when to the part of modeldo in 3D due to the Number of programs that exist in the Market. In both assignments we use Rhino due to its excellent accuracy when modeling the prototype in 3 dimensions, we also use illustrator and corel draw, to later laser cut the proposals. Several errors that occurred were:

-Error reading the laser cut file, not selecting the appropriate format.

-Set different power and speed values to those set for cutting according to the type of material.

-In the cardboard box we used security joints which did not work because the carton was easily deformed.

Many times when we face new machines and configuration of programs, it is necessary to do many tests to know in depth the functionality of the machine to use.

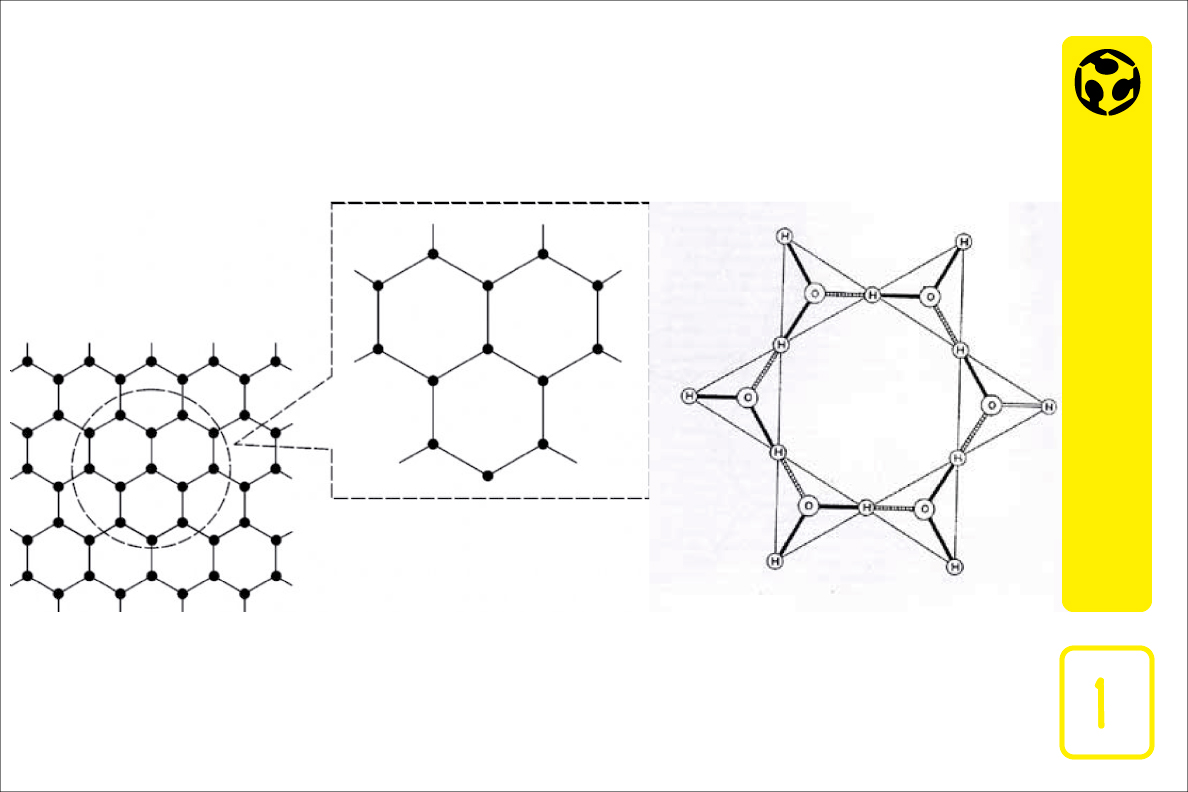

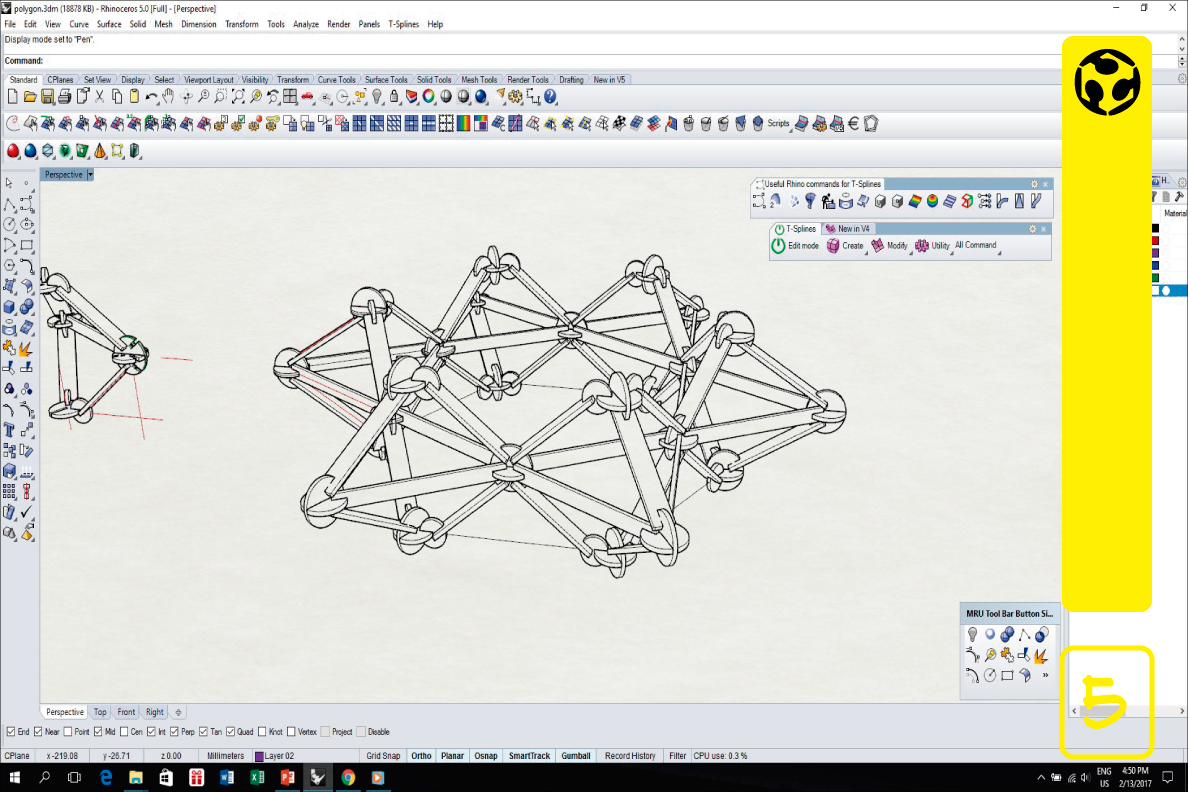

1. For individual assignment research on geometric forms and how to generate structures with growth, first analyze the shapes in 2 dimensions and then explore how to generate a three-dimensionality without losing its original composition.

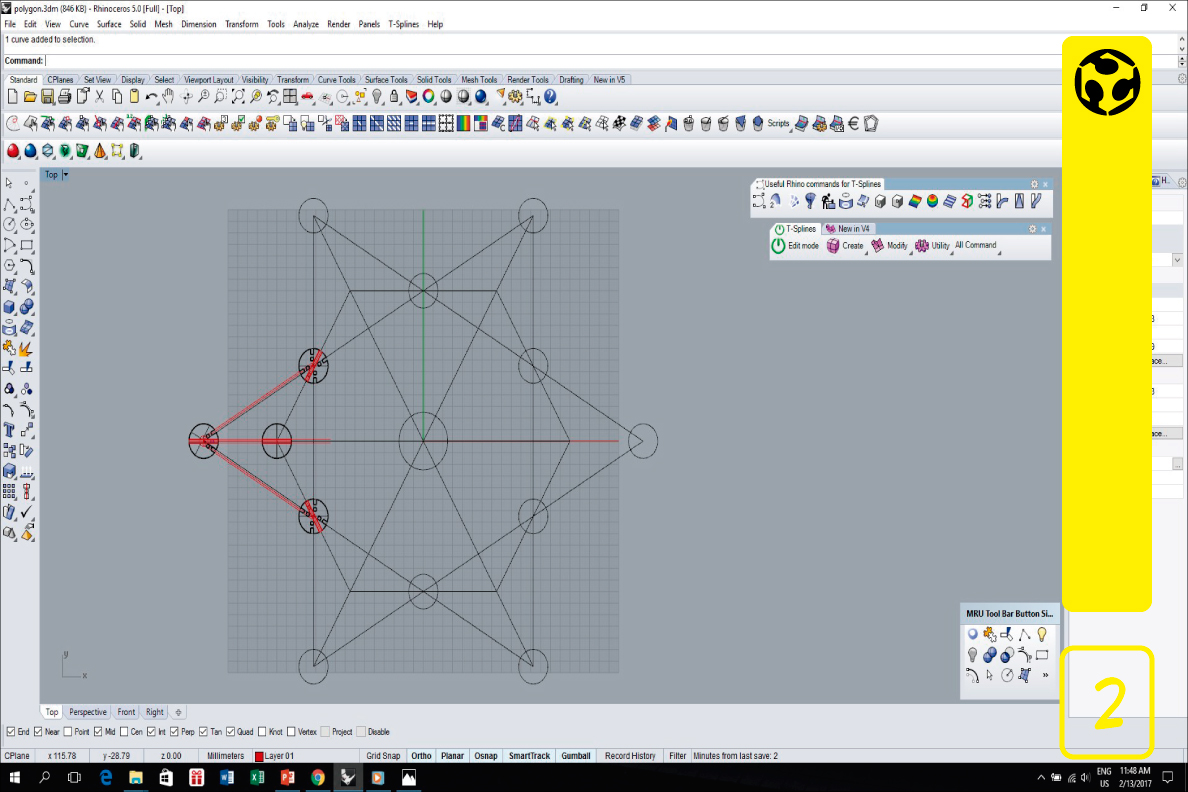

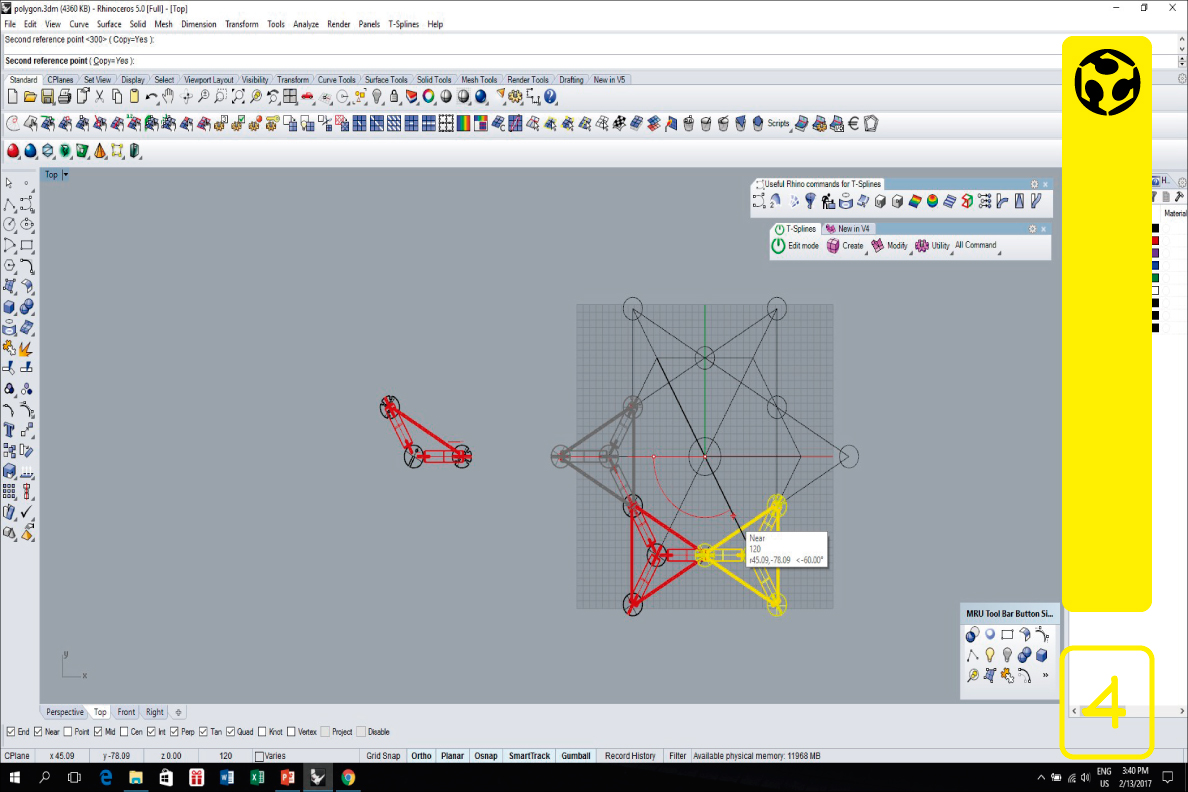

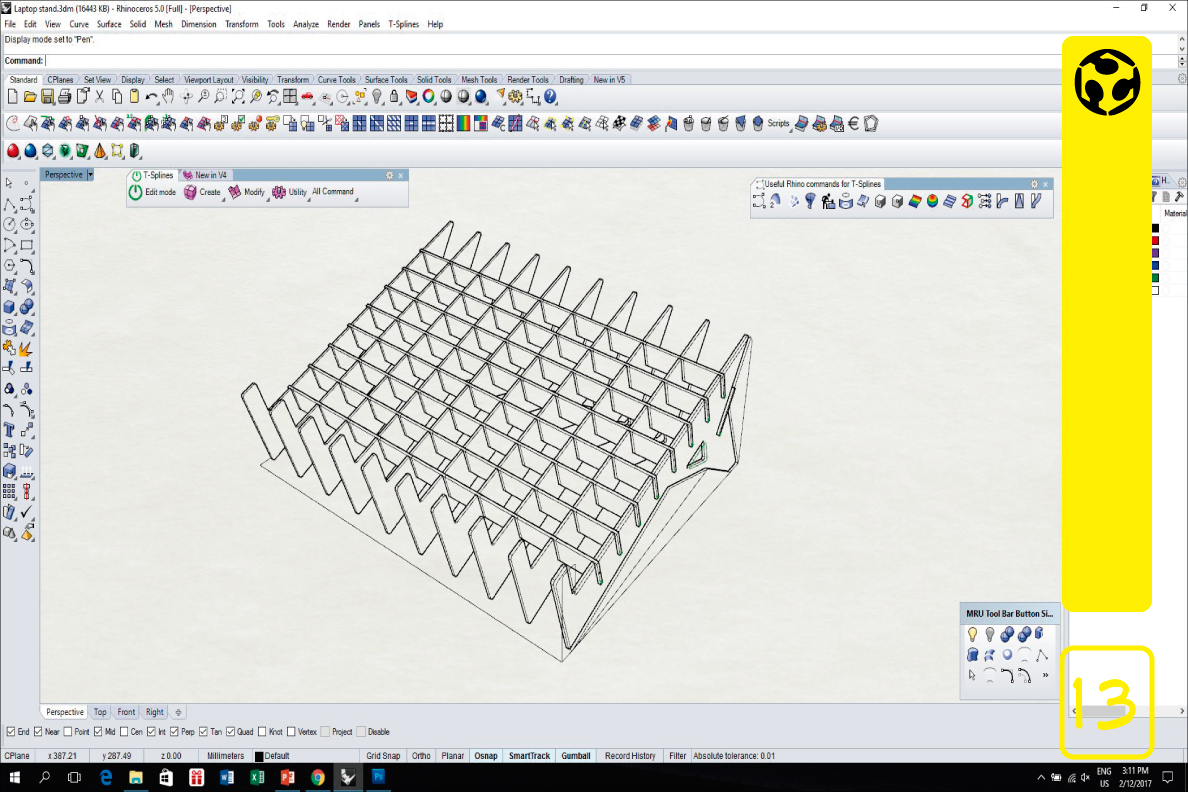

2. In Rhino draw the composition of the structure of 2 dimensions, to be able to generate elevation points to realize its three-dimensionality. I design articulating parts that allow me to generate the growth of the structure both horizontally and vertically.

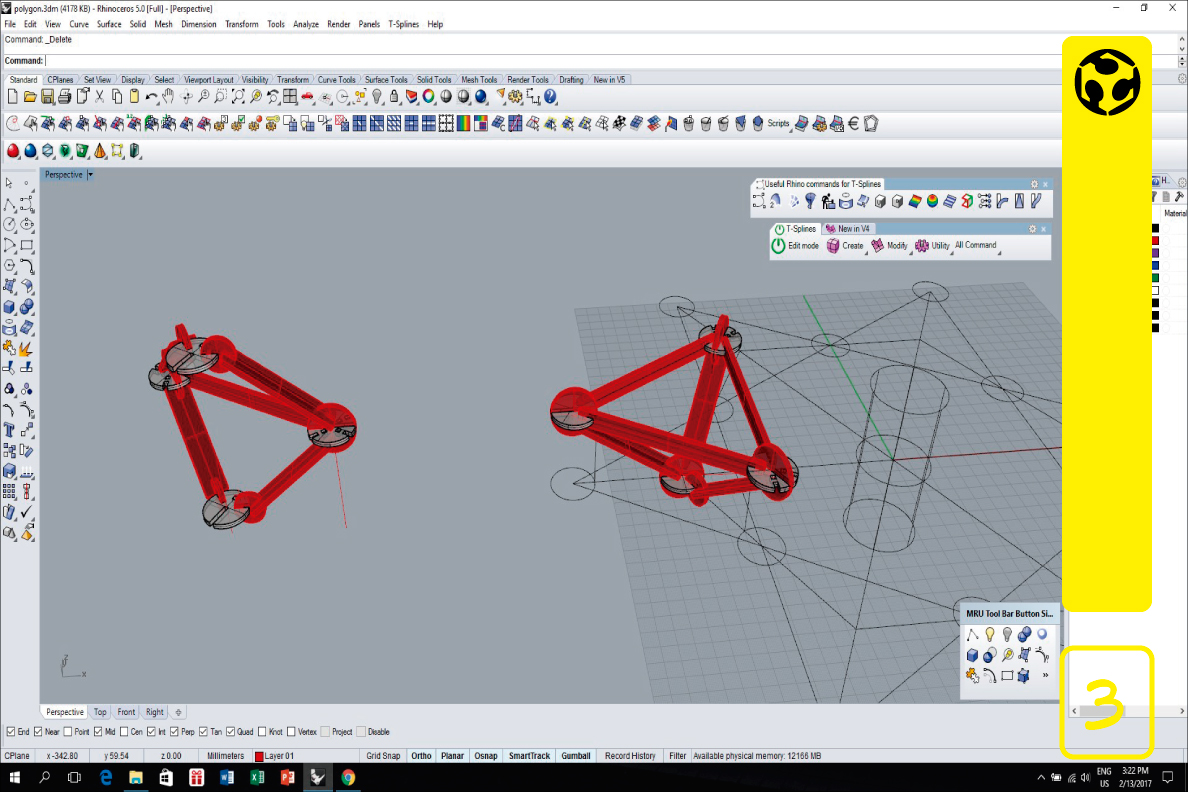

3. After exploring with the articulating parts, make a structural module and then proceed with their total assembly, using the rhino platform.

5. Complete structural module.

5. Complete structural module.

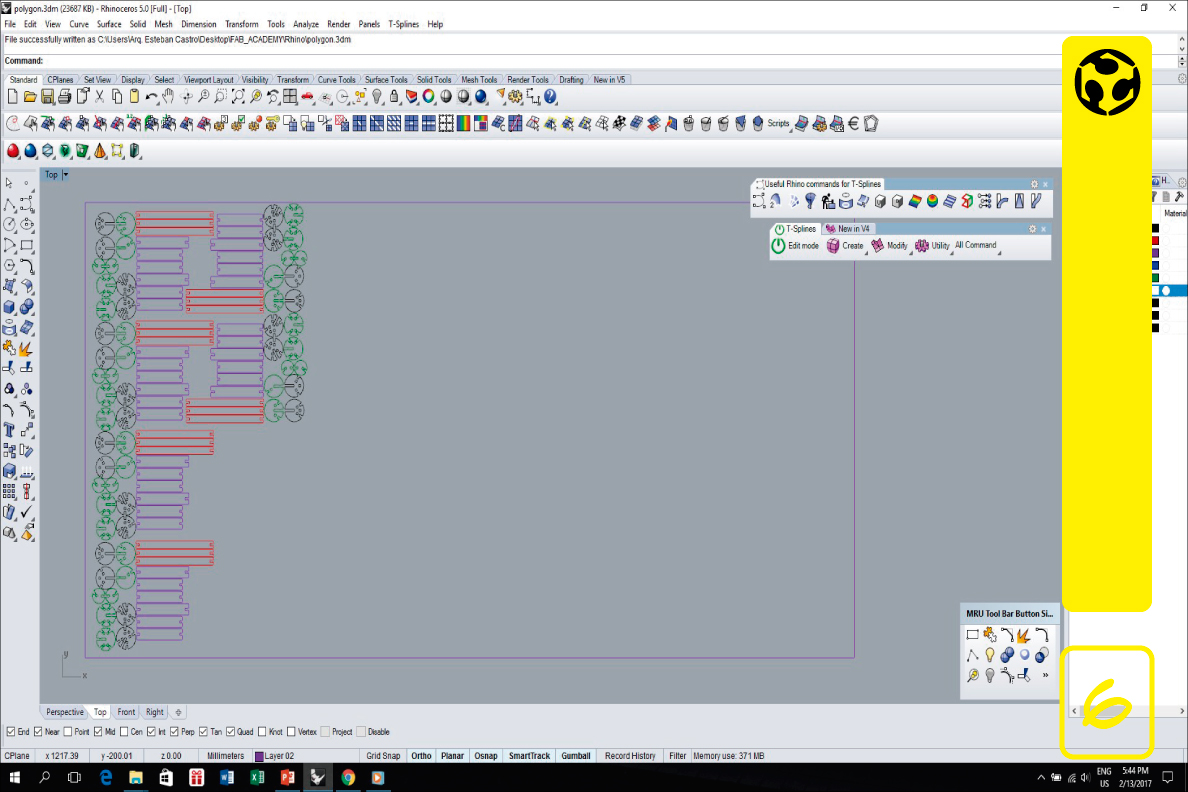

6. After generating the entire structural module is proceeded to the cutting in 2 dimensions for its respective laser cutting process in MDF and for its assembly.

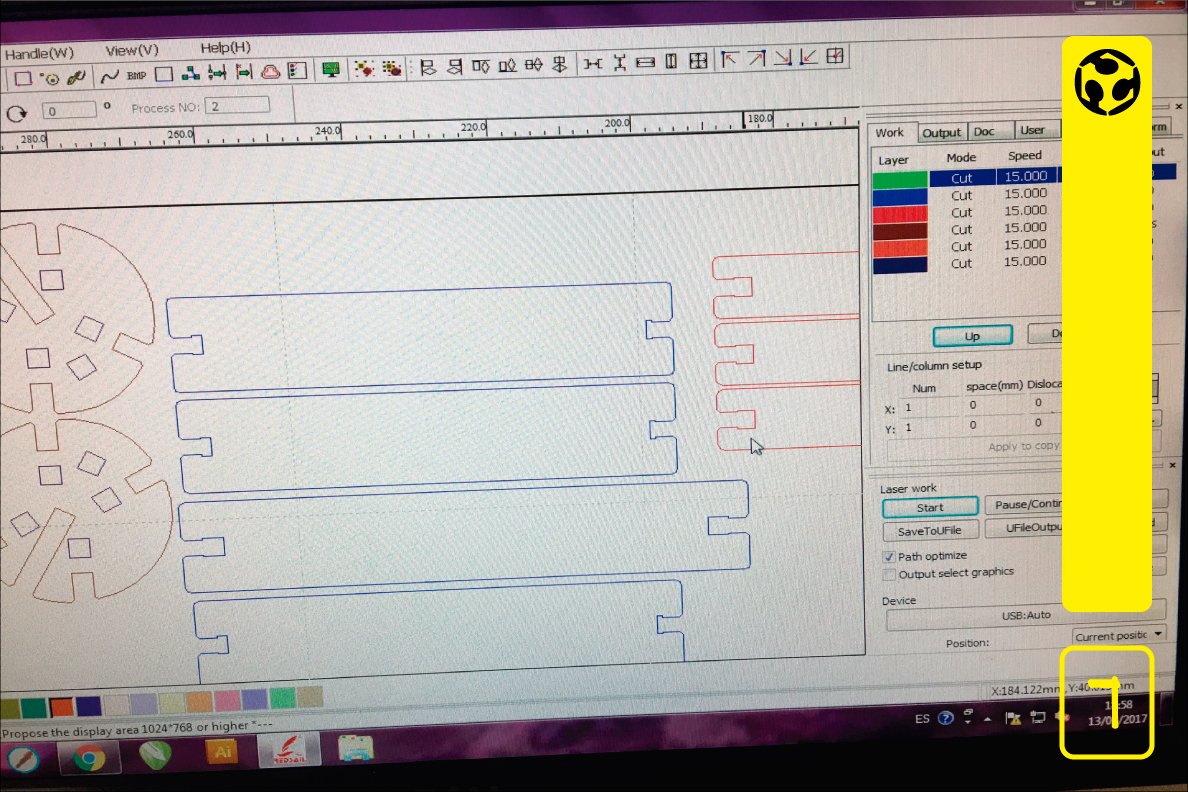

7. We work with different programs like Rhino, illustrator and corel draw to generate the files for the manufacture and laser cutting. The values used to perform the cut in the laser machine were: Max power 70, min power 65 and velocity 15.

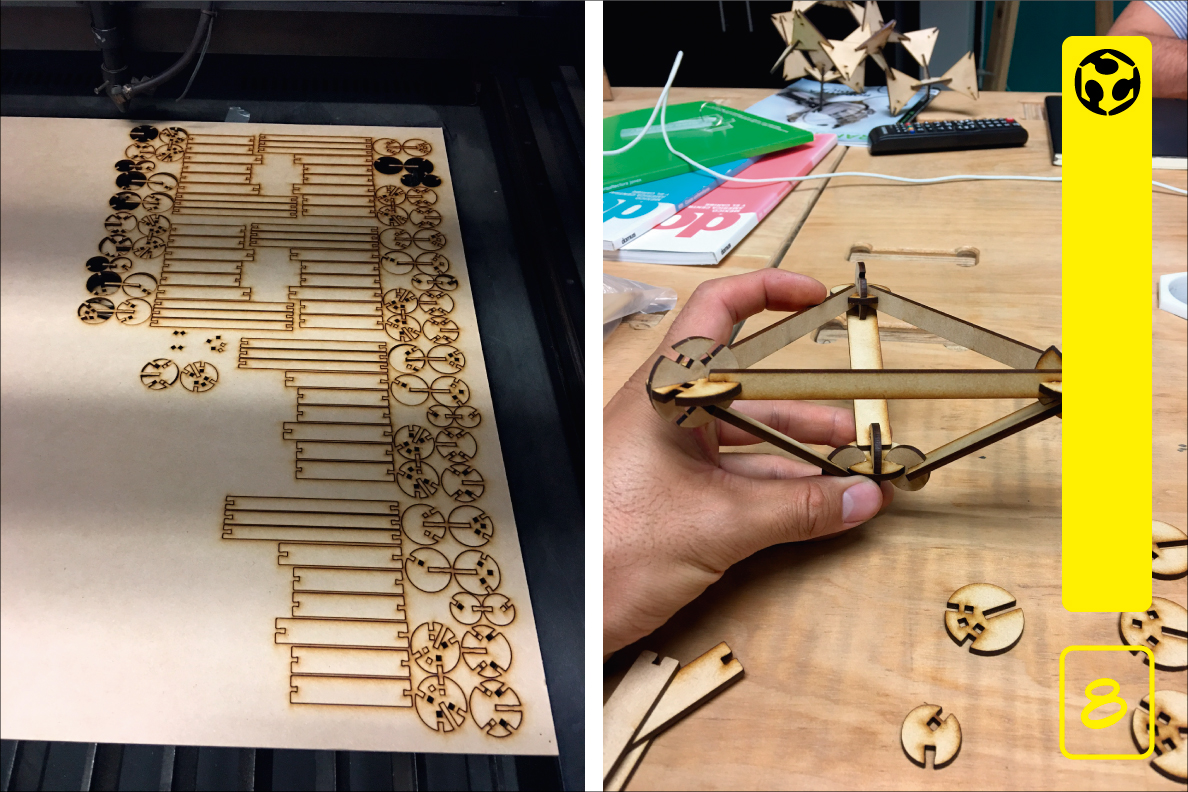

8. Laser cutting process and assembly of a structural module.

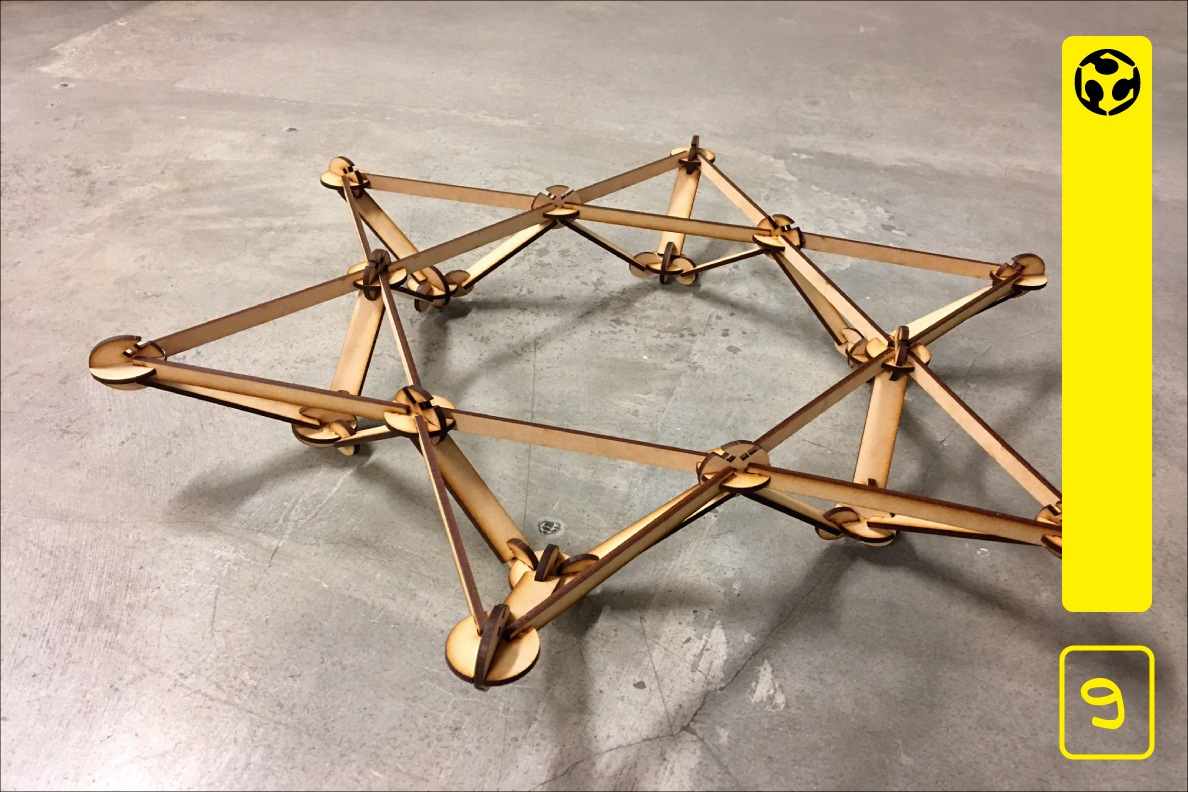

9. Process of arming the entire three-dimensional geometric structure.

10. As a group group decided to develop a base for laptop, made in cardboard box. As a main idea we developed a profile-type piece, to be able to use it repeatedly and to create a mesh structure that in turn had rigidity and also had ventilation for the computer.

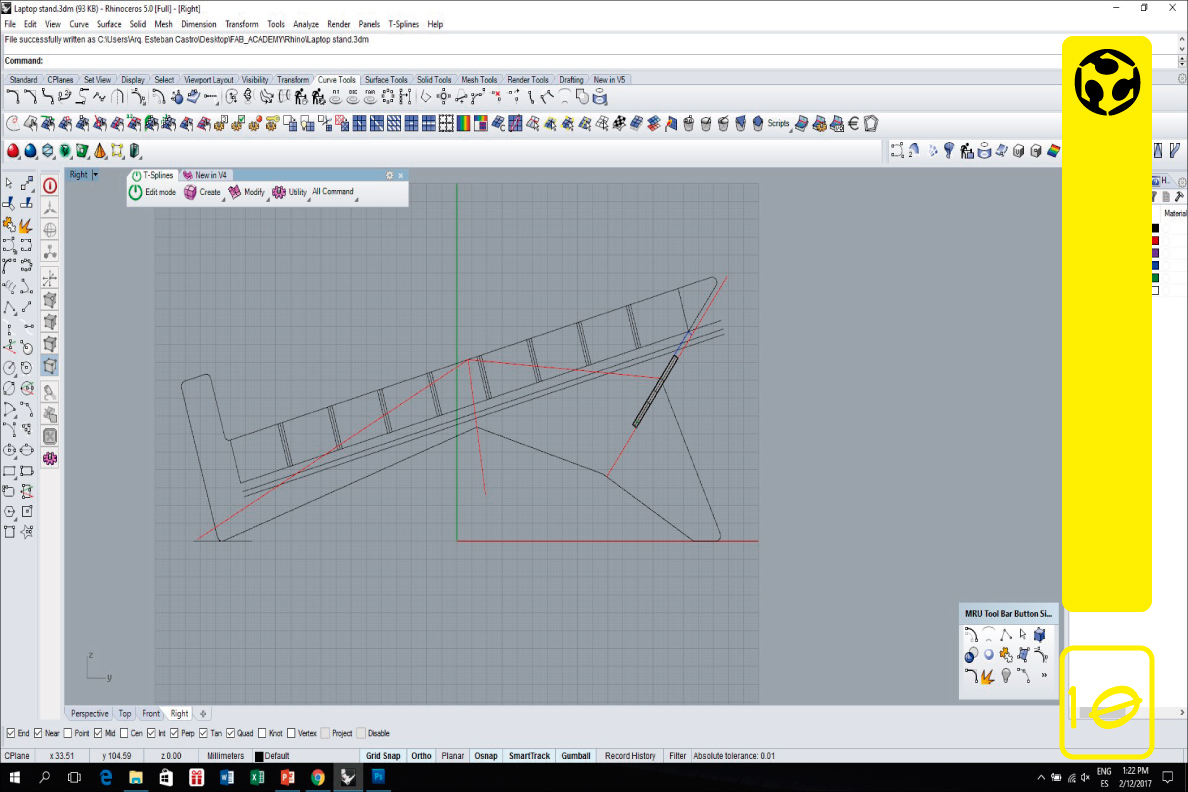

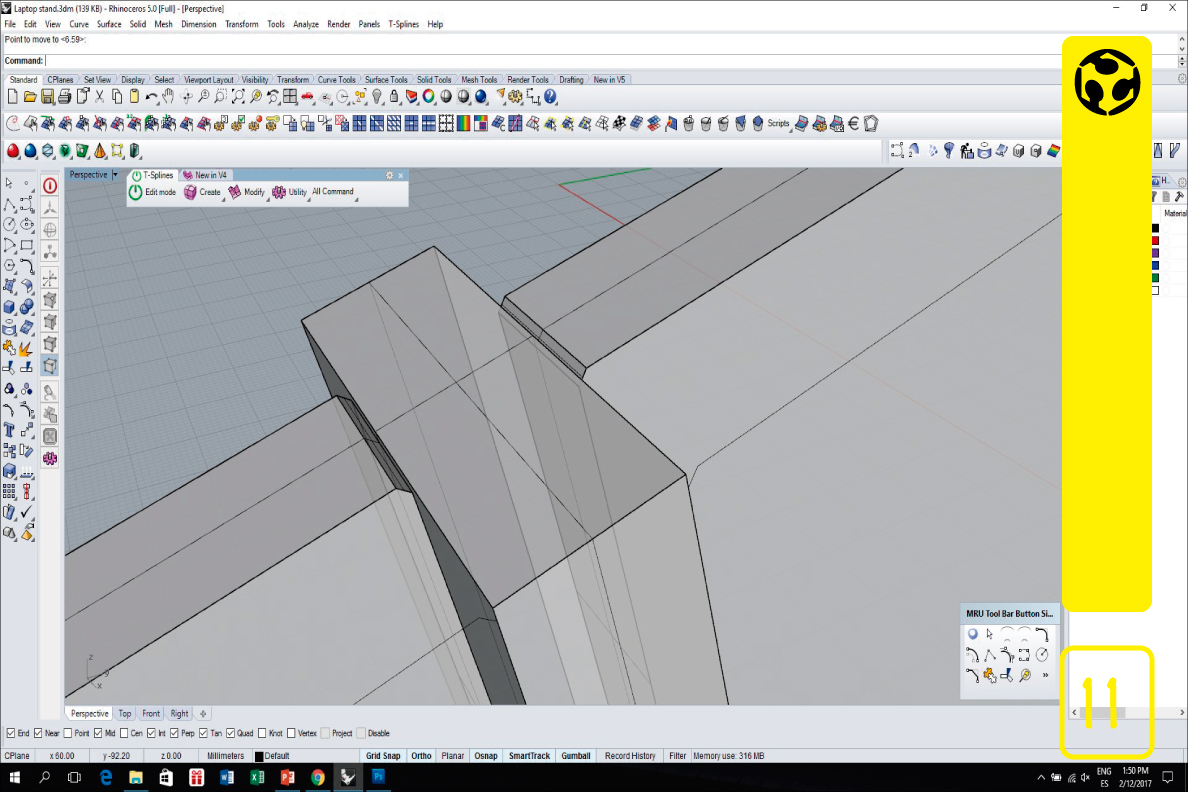

11. We work on the details of the assemblies of each piece so as not to have problem when assembling the different parts.

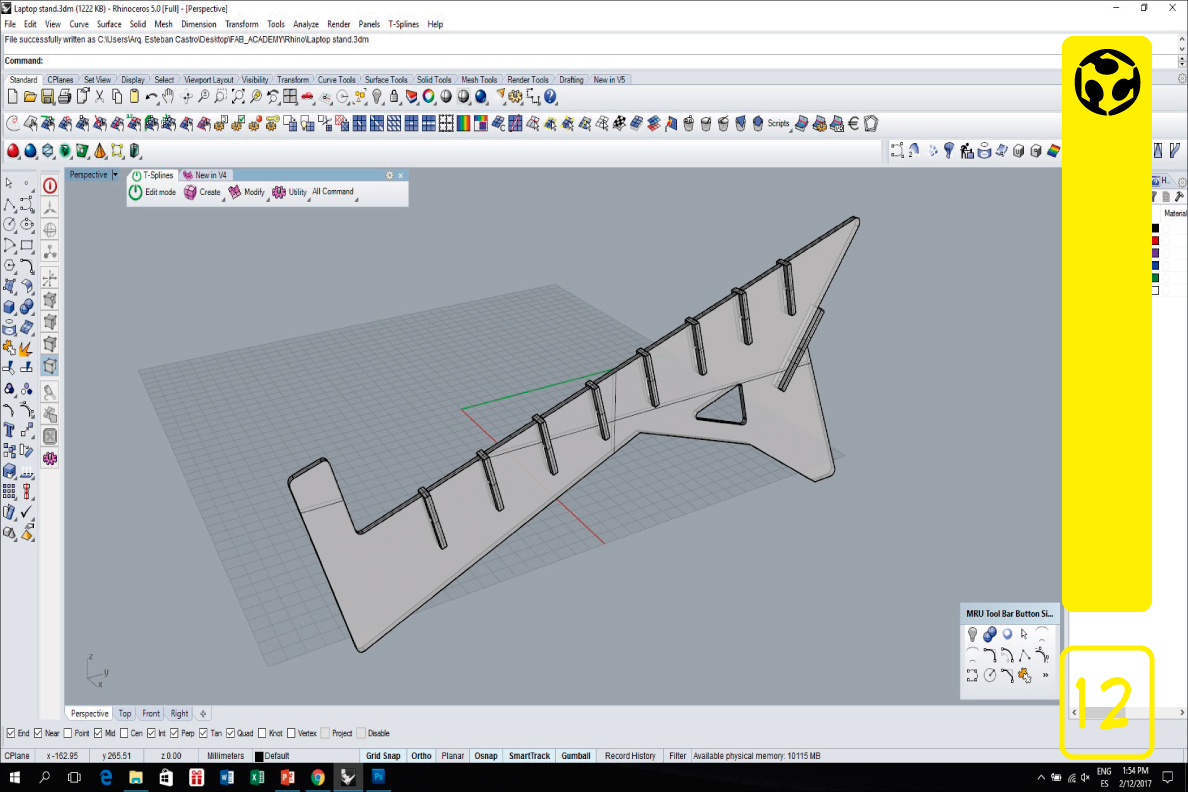

12. We model a profile with each one of the assemblies and then generate an extruction of each piece and so we can repeat the profile "n" number of times.

13. We work on the details of the assemblies of each piece so as not to have problem when assembling the different parts.

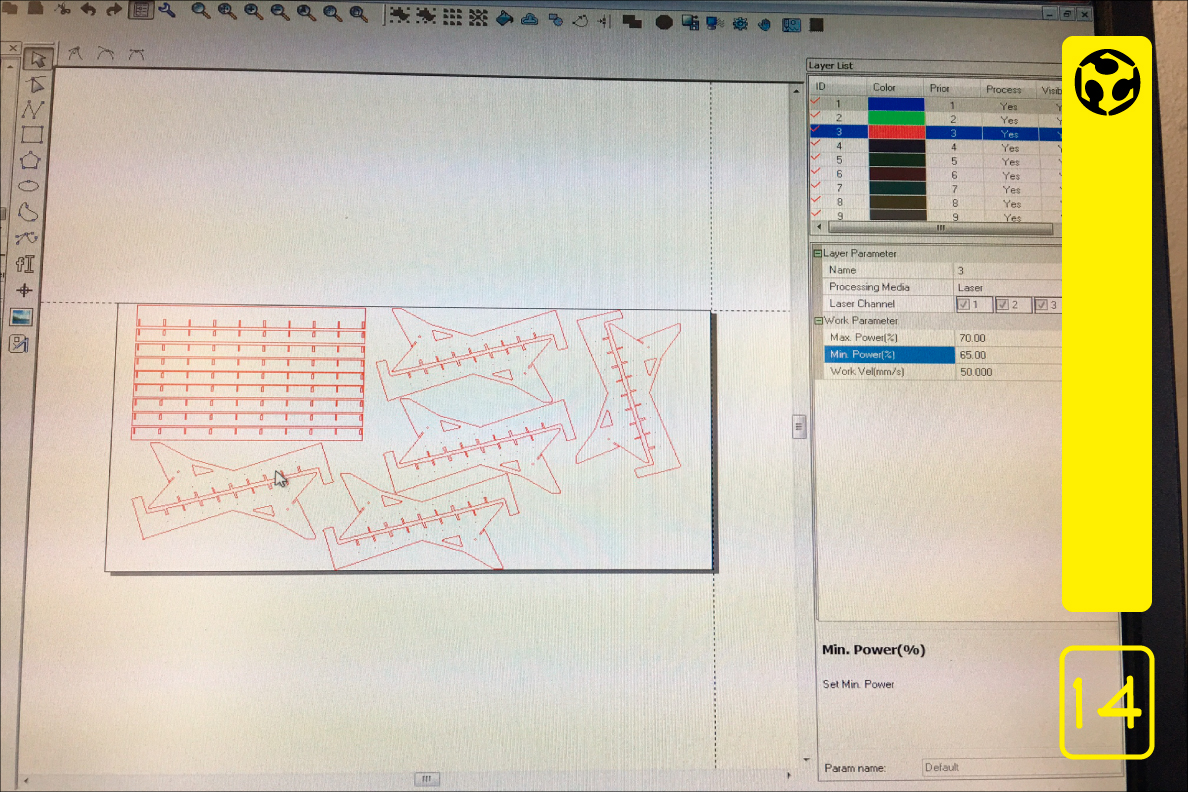

14. We work with different programs like Rhino, illustrator and corel draw to generate the files for the manufacture and laser cutting. The values used to perform the cut in the laser machine were: Max power 70, min power 65 and velocity 50.

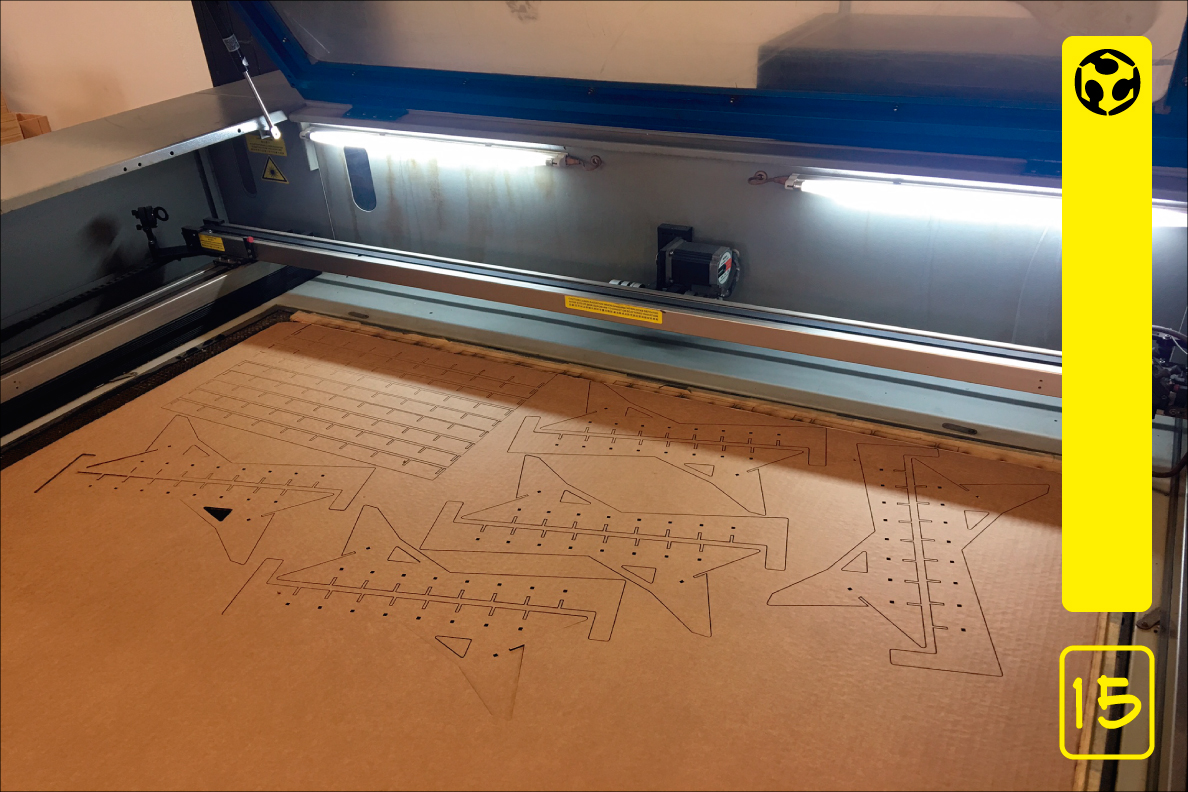

15. The laser cutting process.

16. After performing the laser cutting we are able to assemble all the pieces and form our laptop base.

17. Final product.

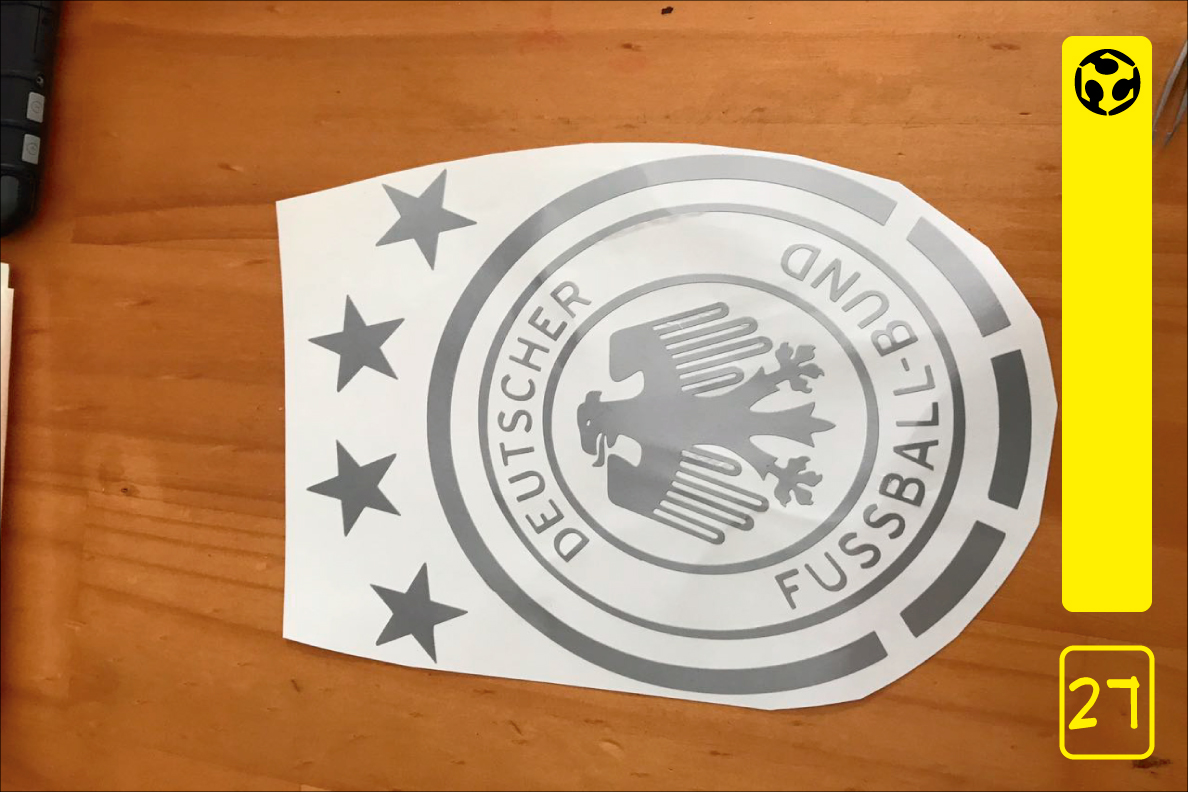

18. For this part of the assignment decided to realize the logo of the federation of soccer of Germany, using vectors to create the routes for the respective cut.

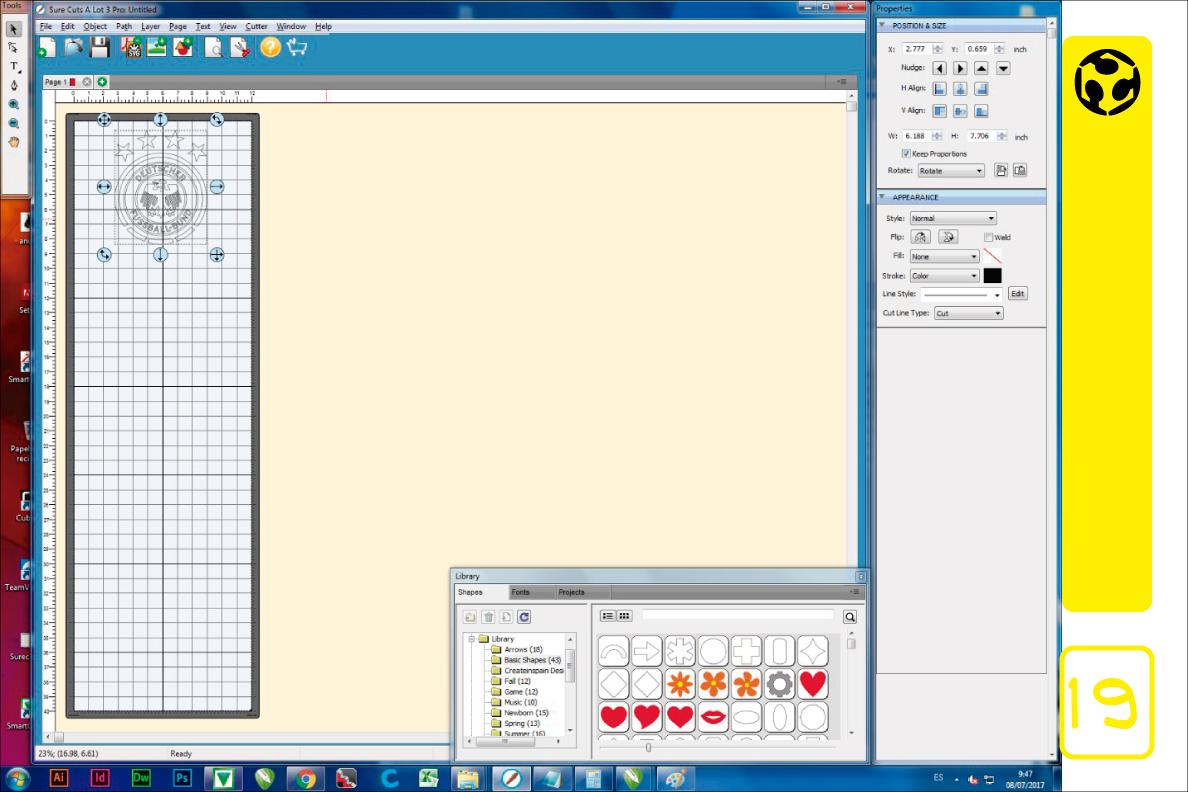

19. Import the file and center.

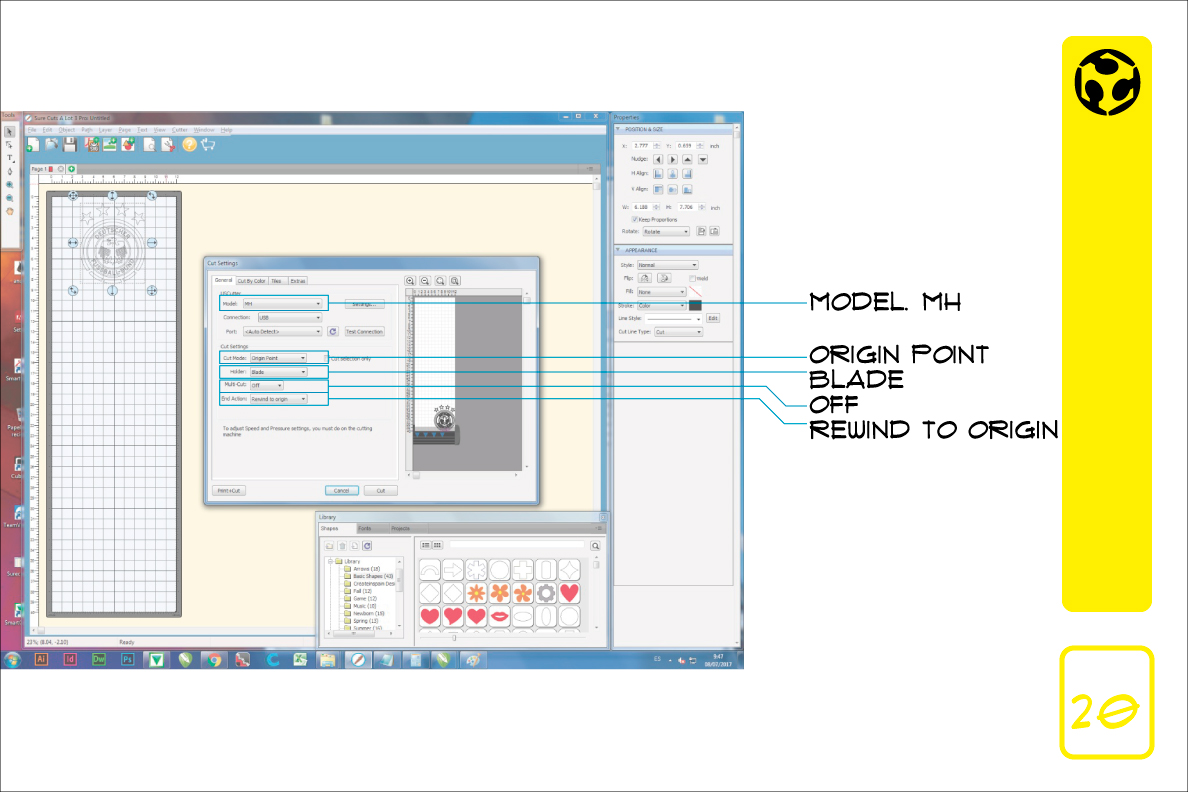

20. I use the software us cutter.

21. Vinyl cutter machine.

22. Vinyl cutter machine and transfer tape.

23. Start button.

24. We use these two supports to hold and align the vinyl.

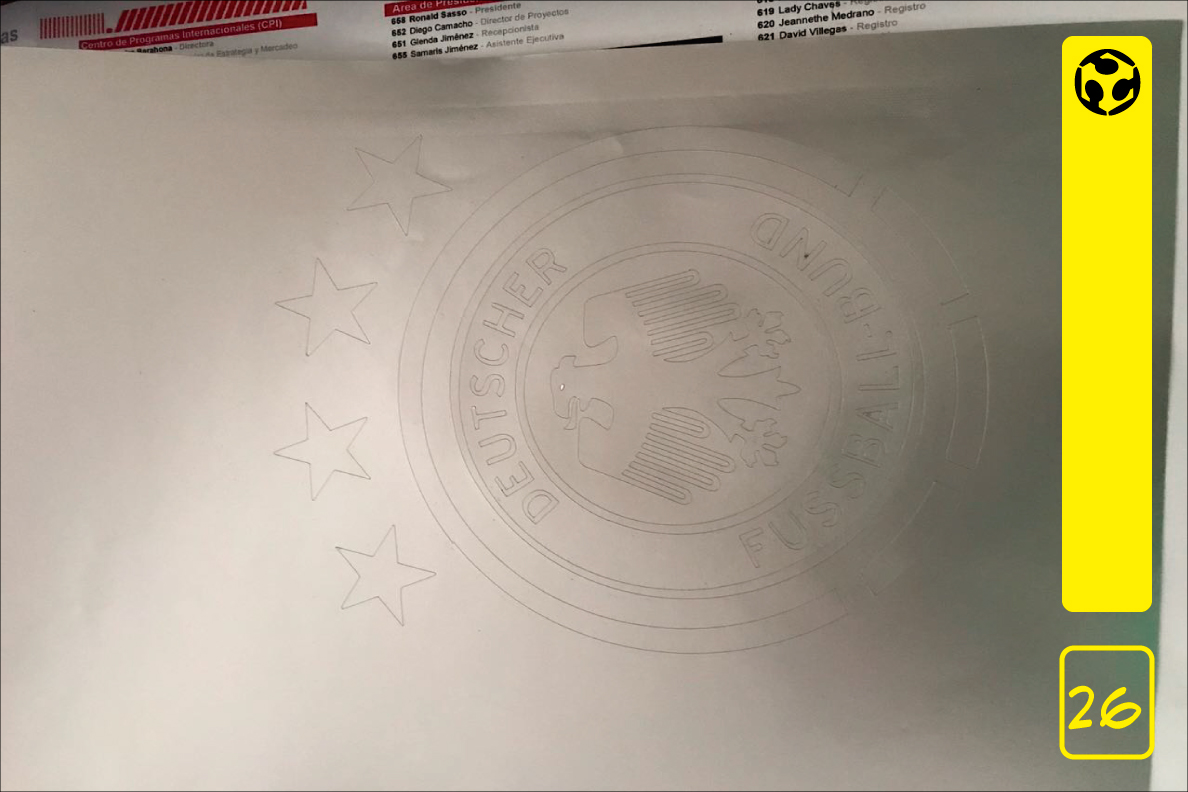

25. The machine cuts the vinyl according to the design vectors.

26. The design its ready.

27. I put the transfer paper and it's ready to stick on the surface.