This week we are going to make a mold and cast something inside

Molding and casting v3.0

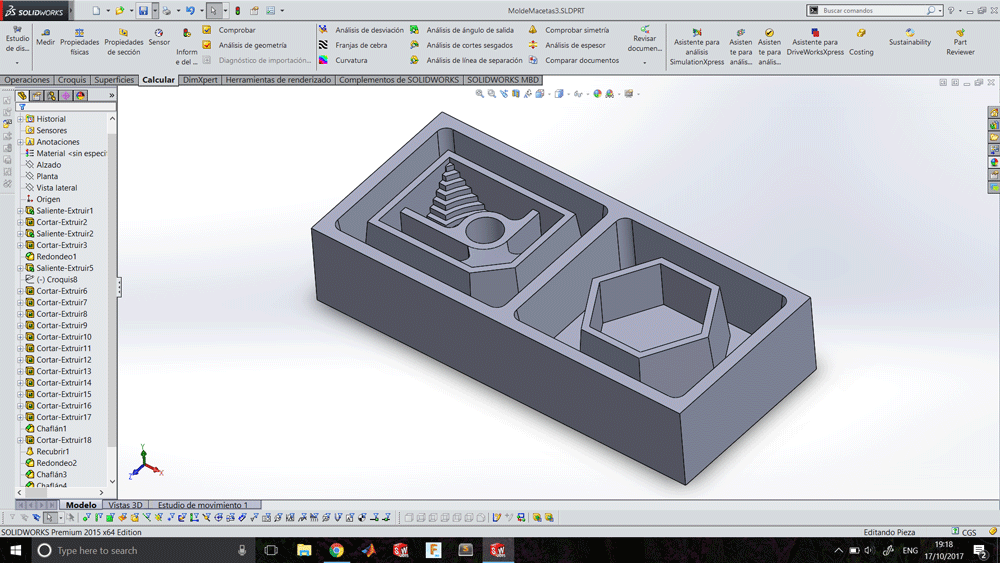

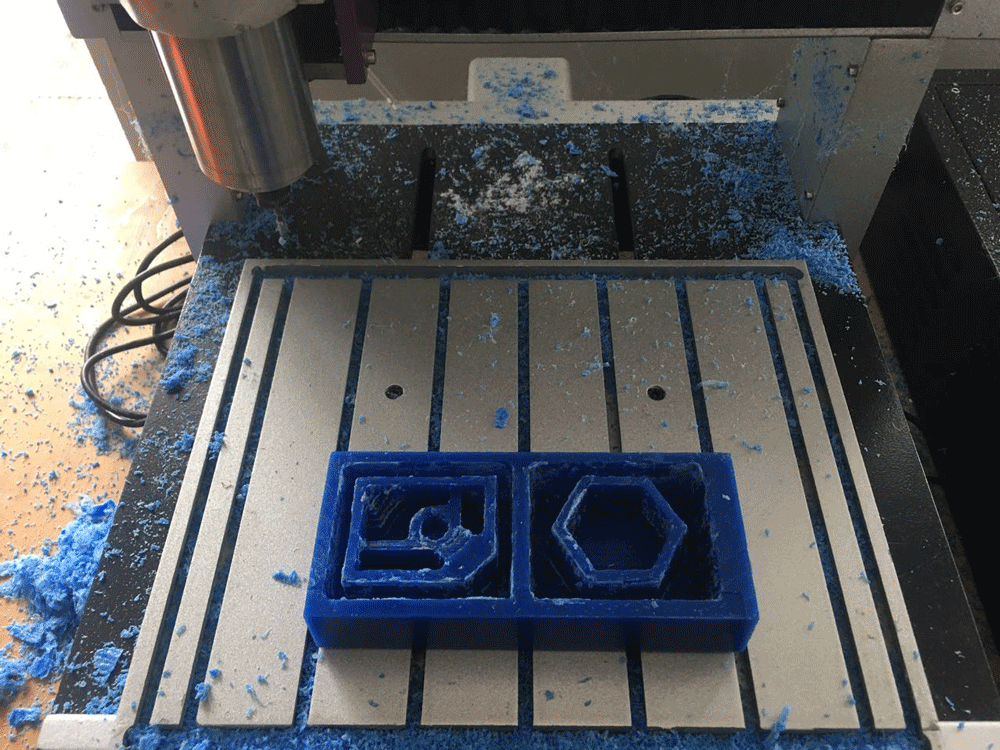

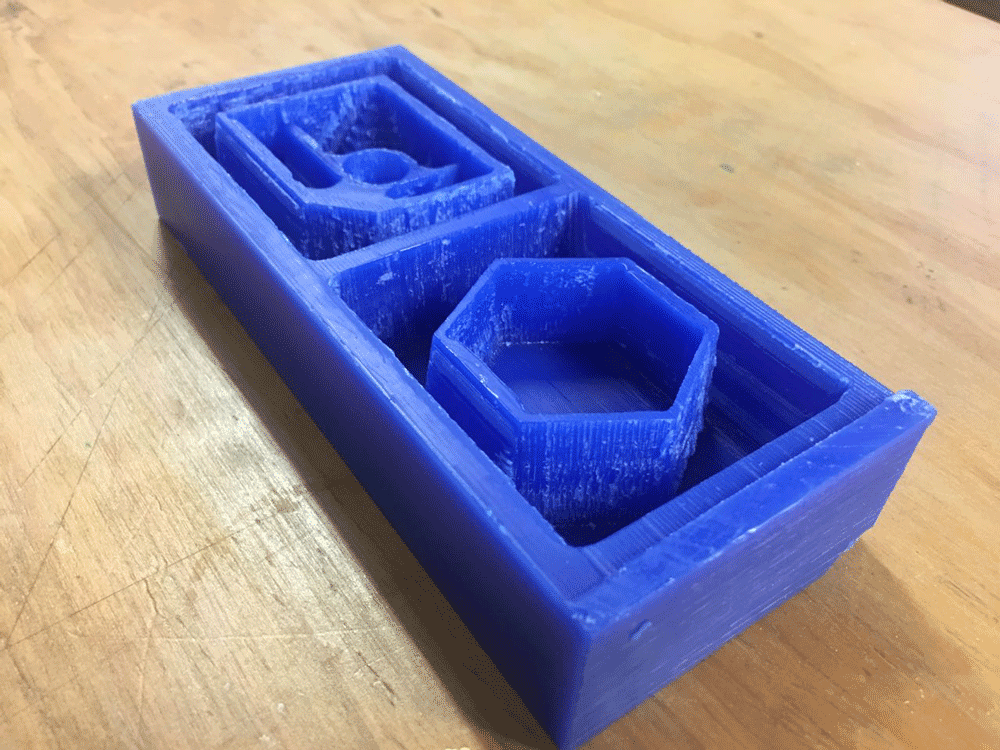

For the third try I designed this little flower pot countermold on SolidWorks

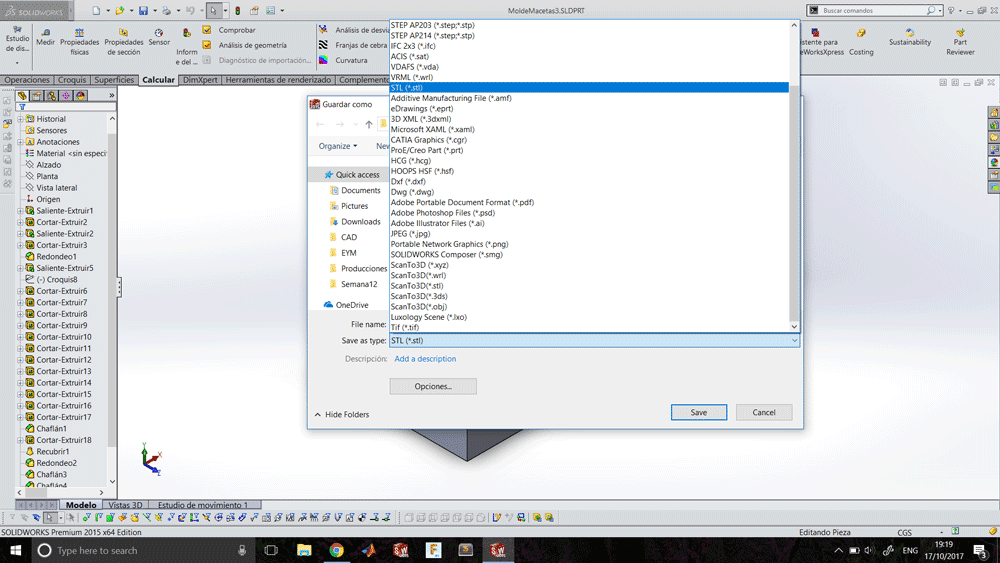

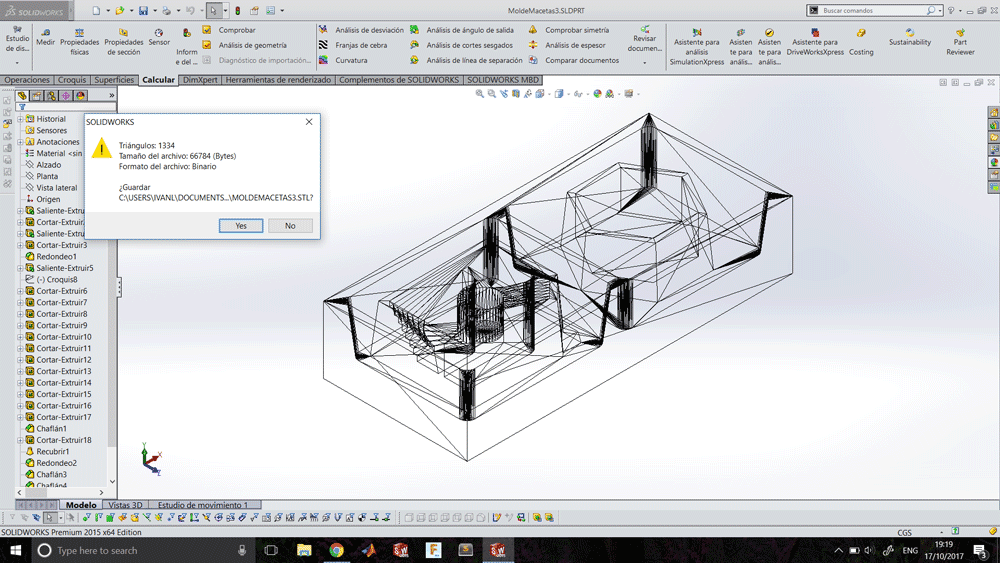

Export as STL

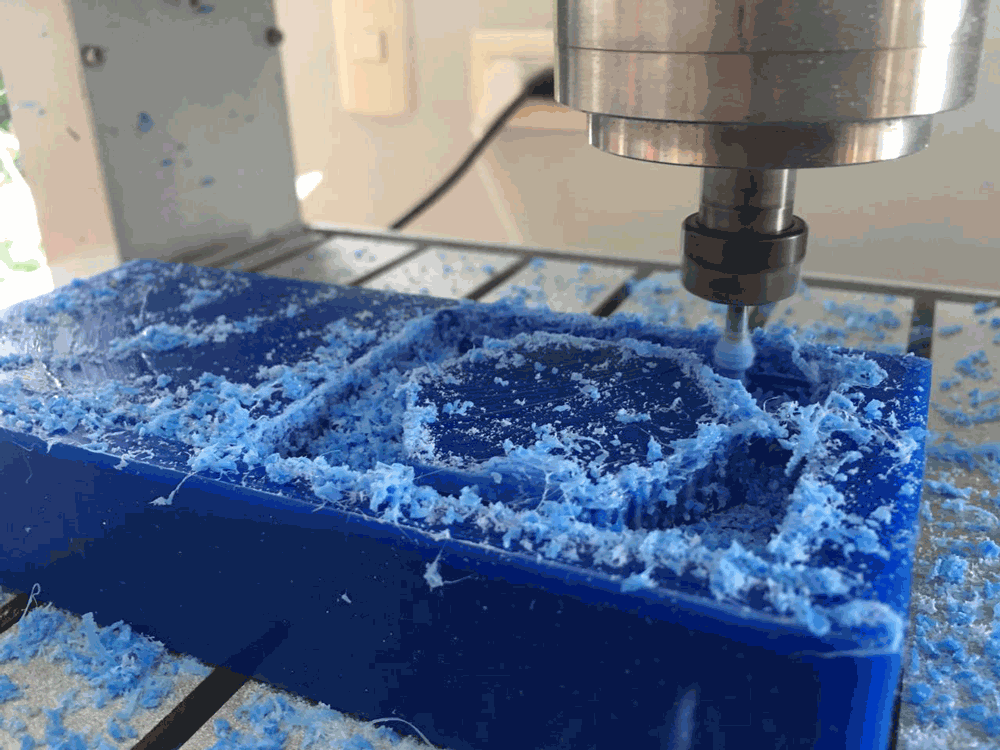

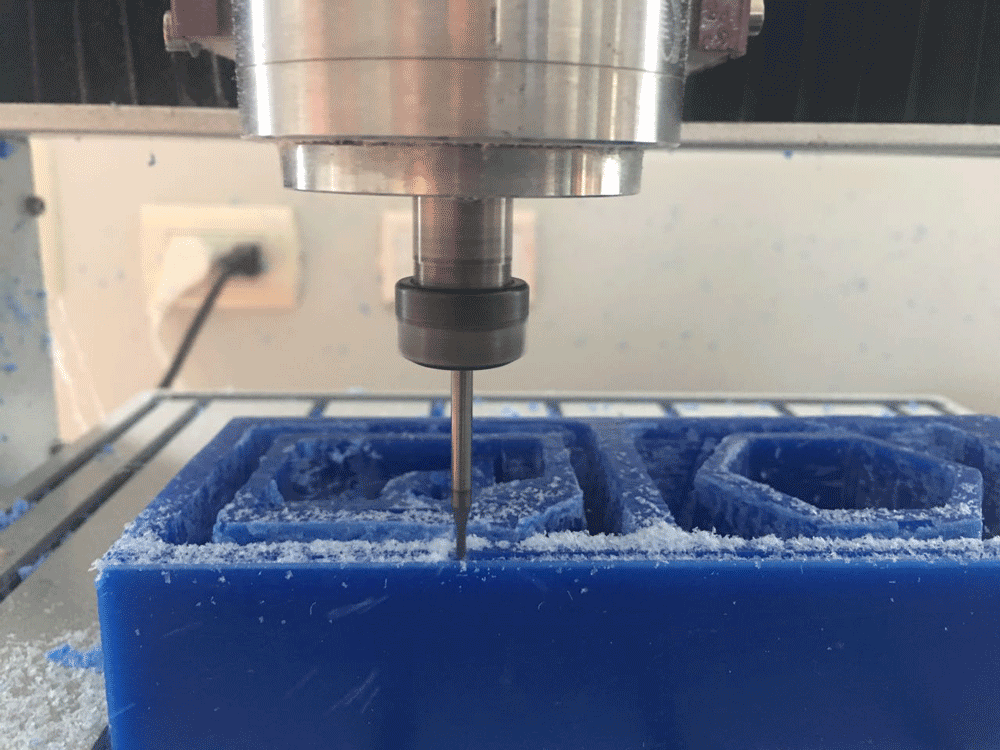

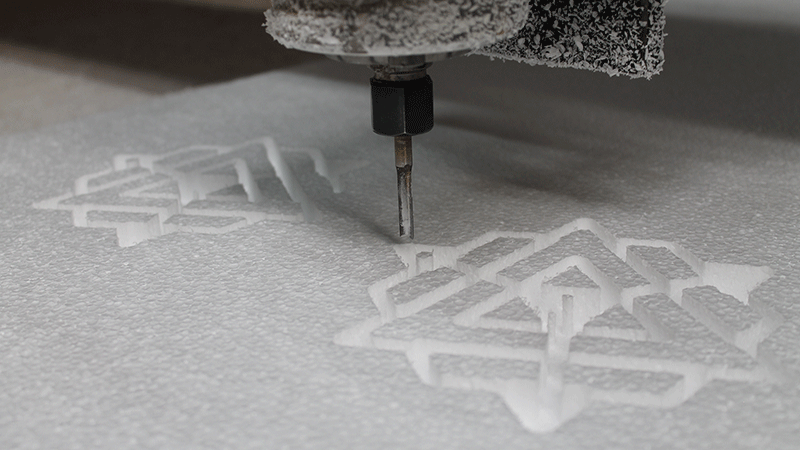

Import to ArtCAM, generate G Code to mill with 3mm Milling Cutter

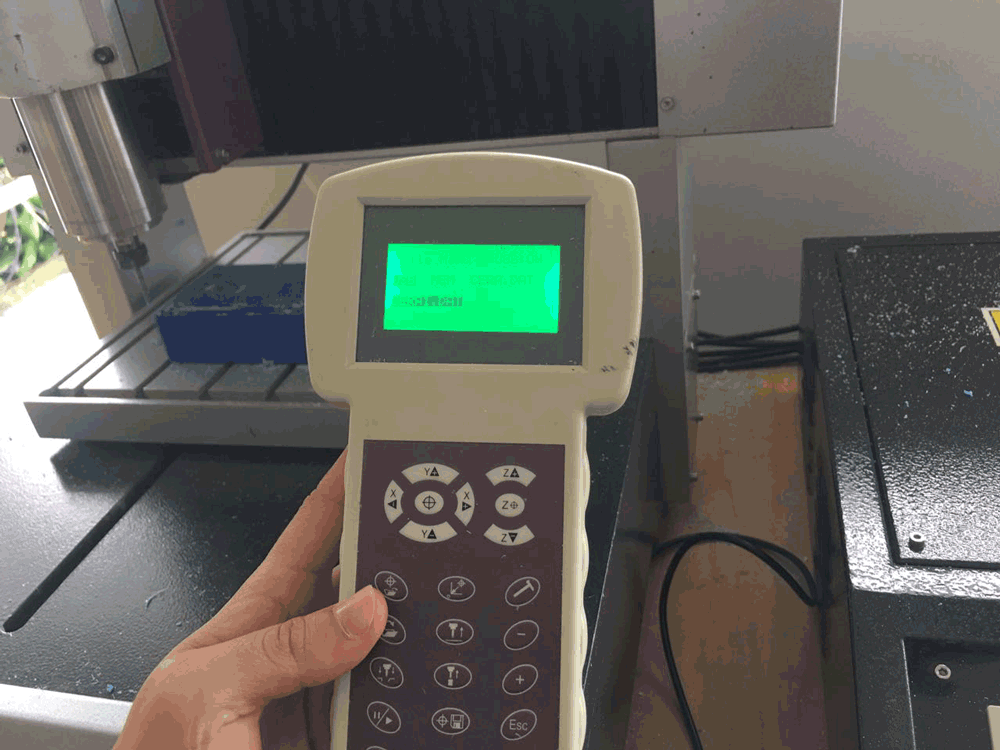

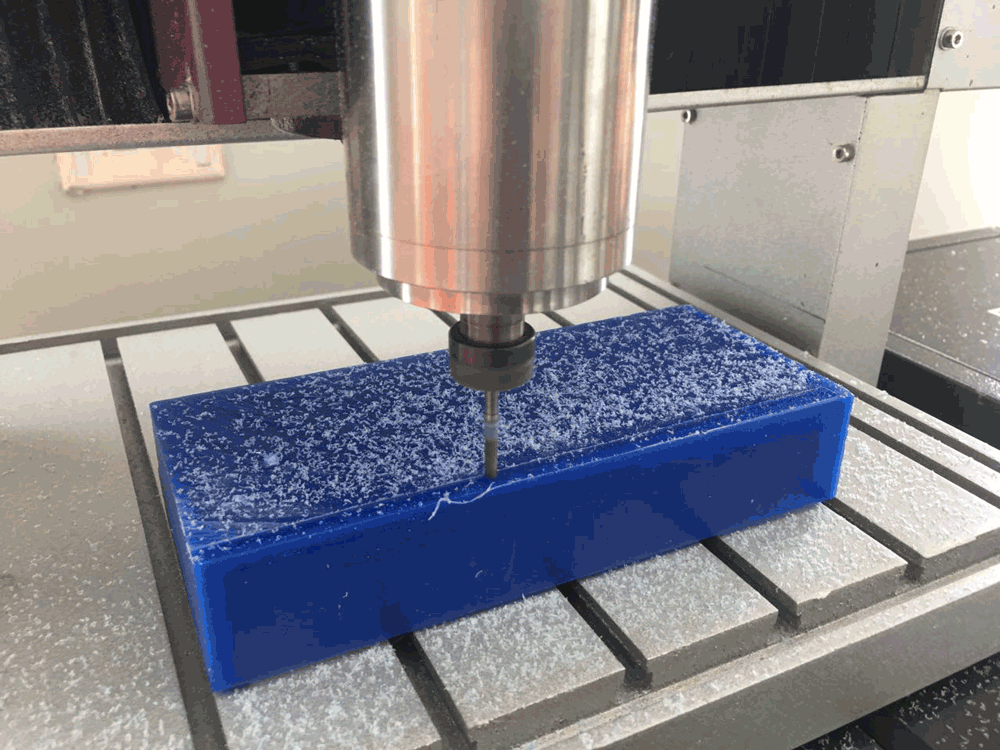

Define zero

Machine it

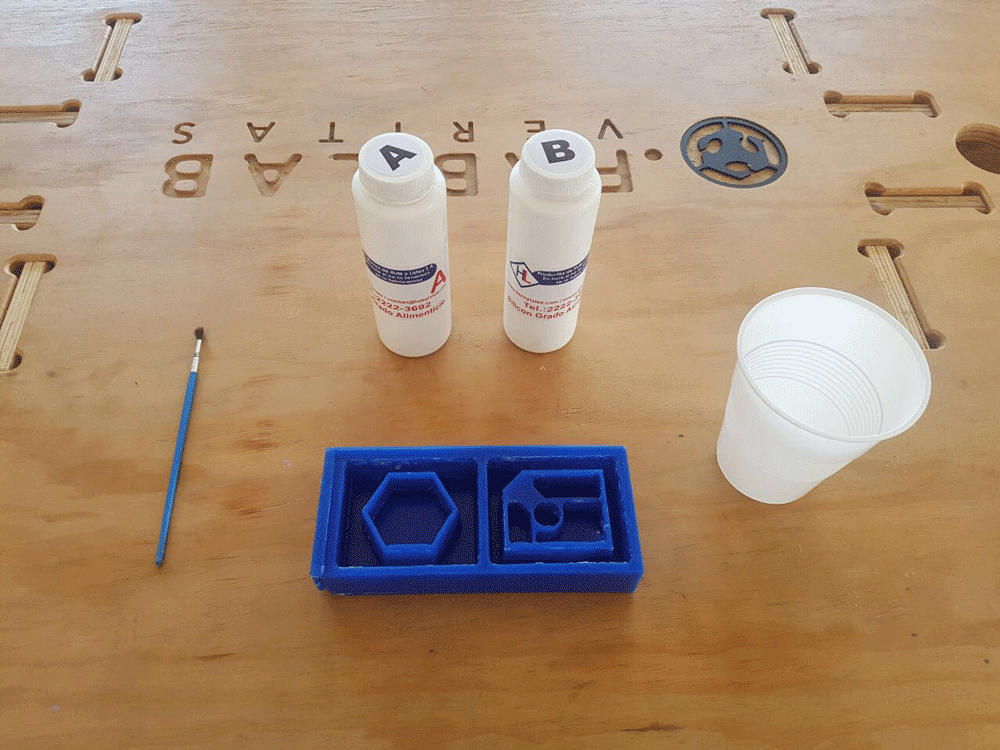

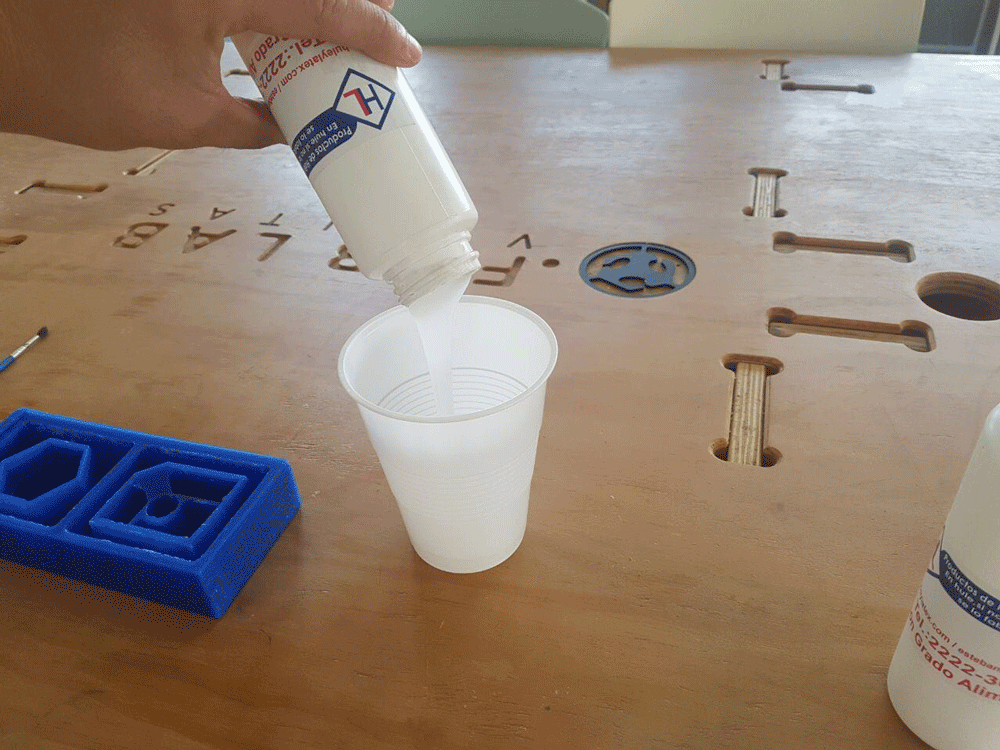

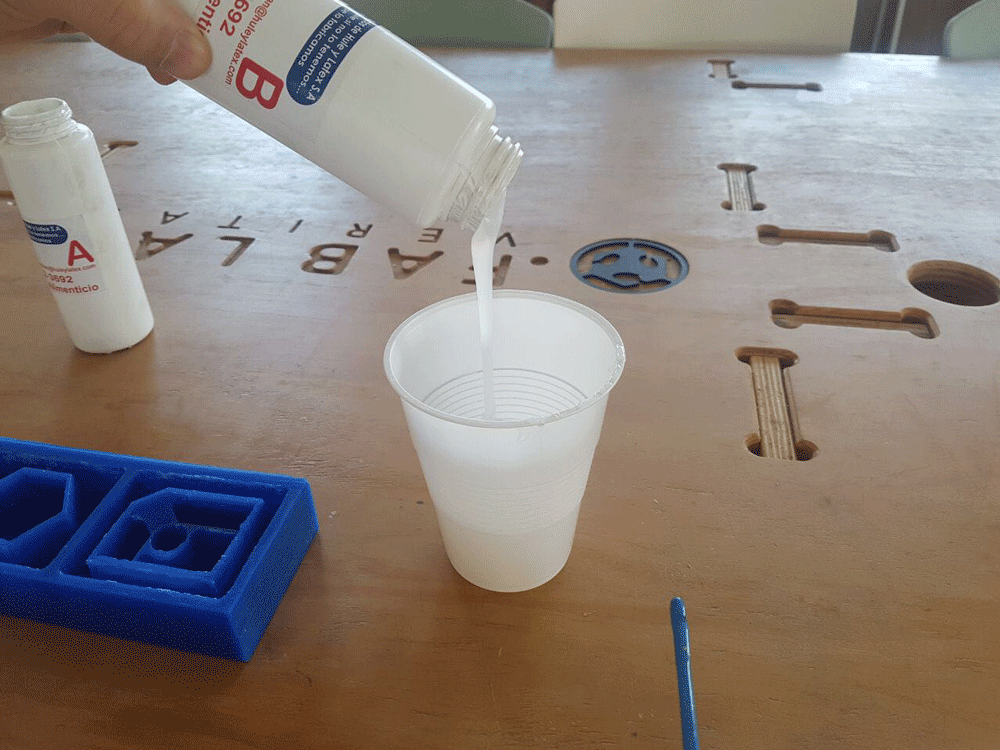

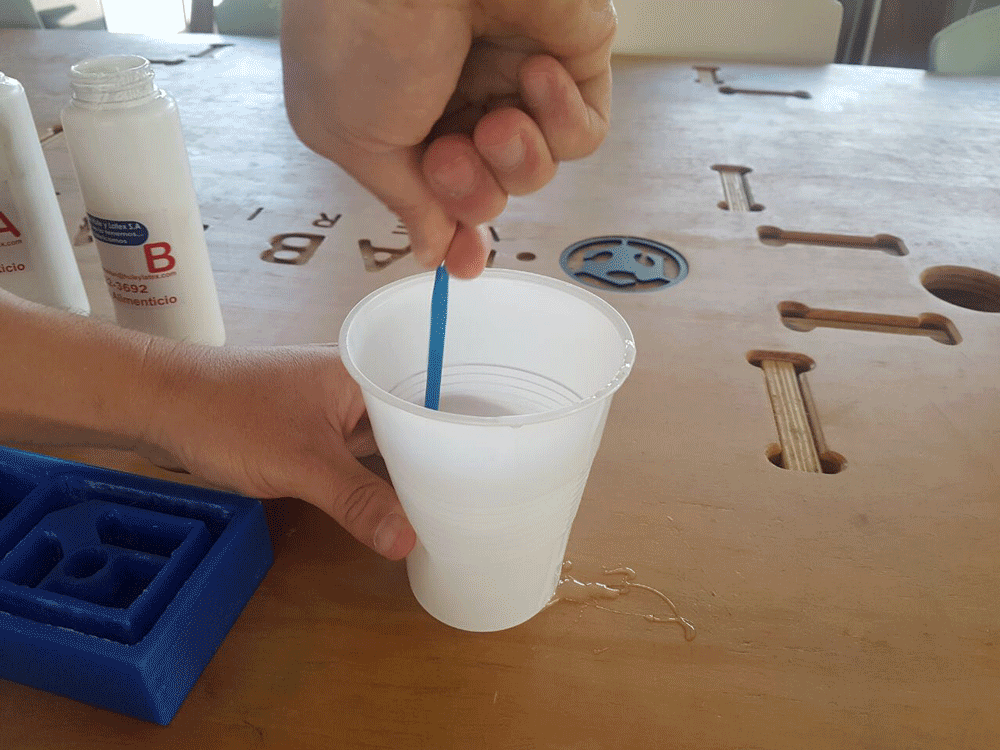

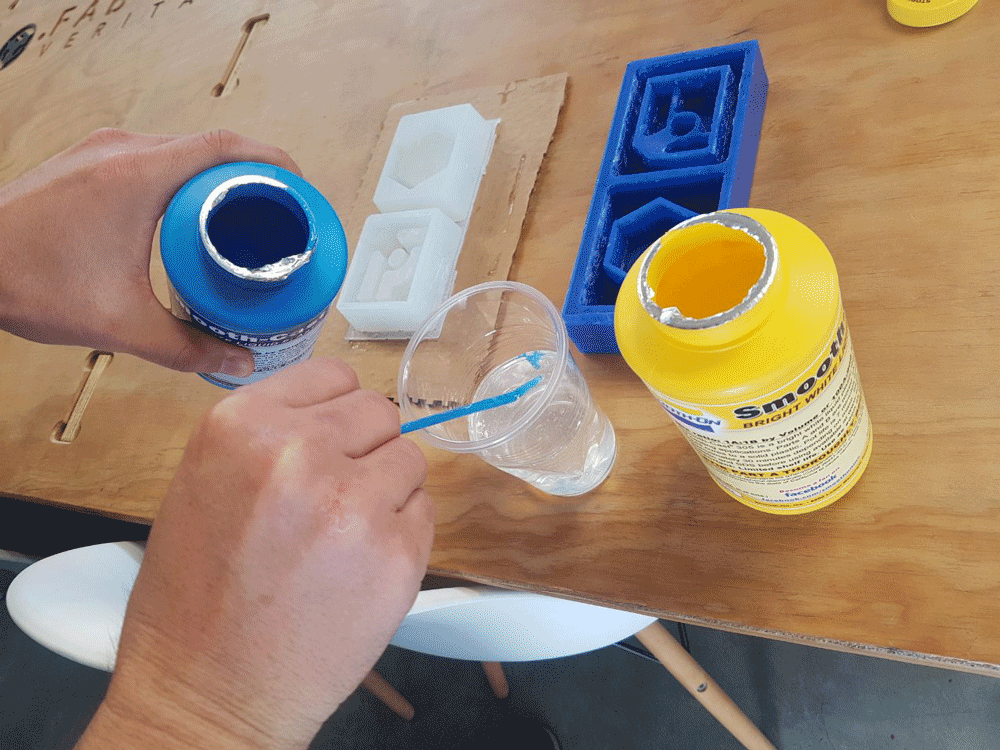

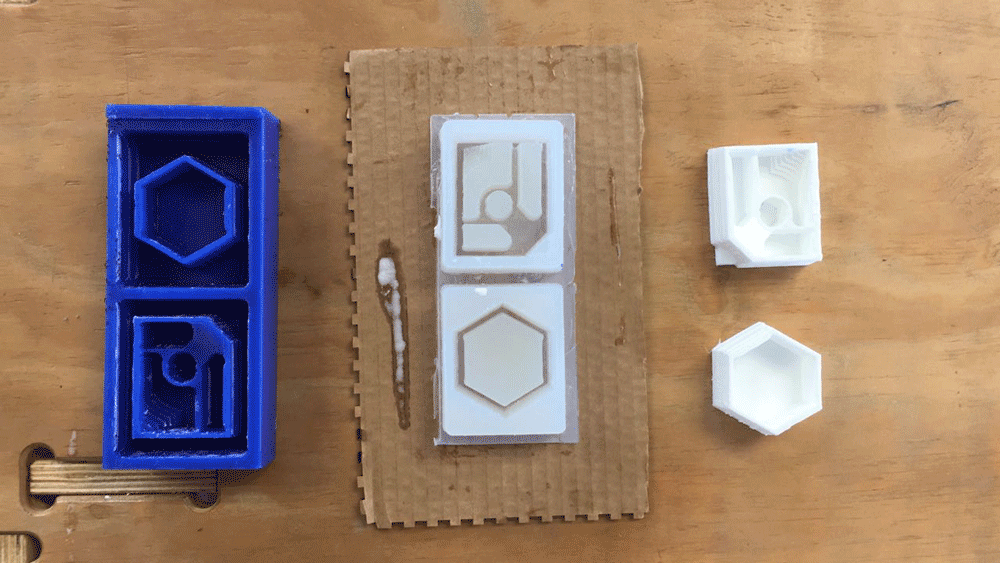

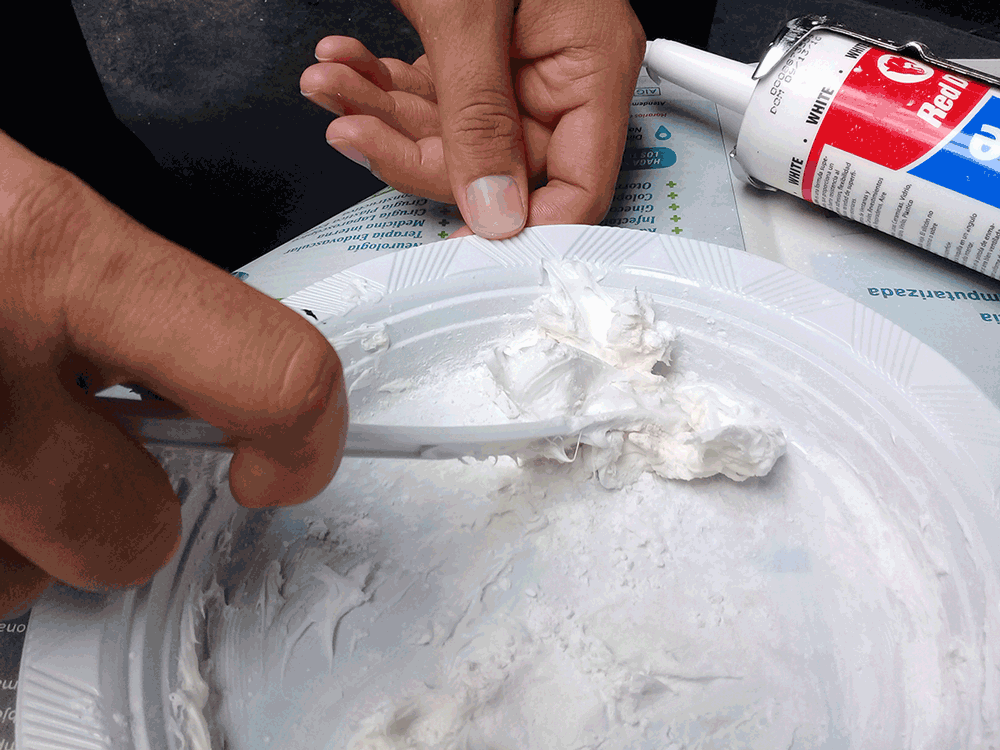

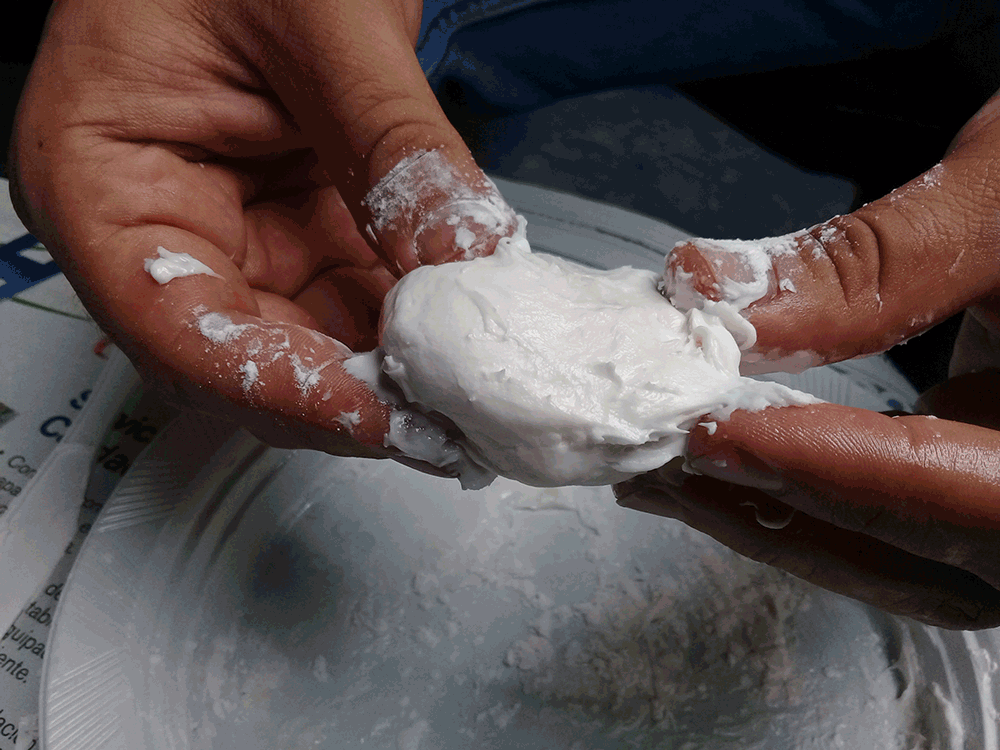

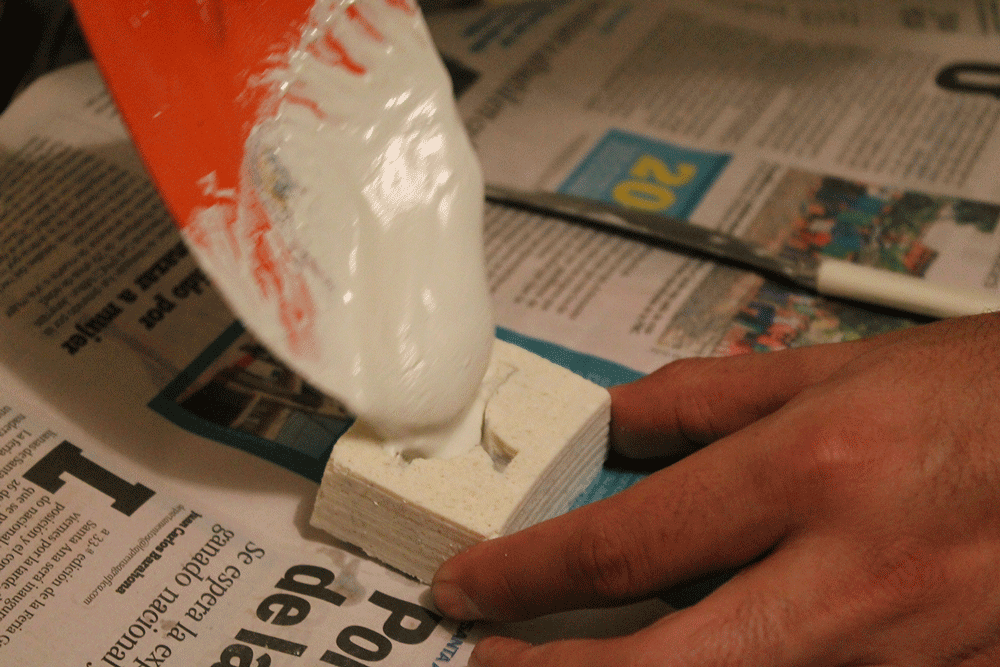

Mix both parts of silicone

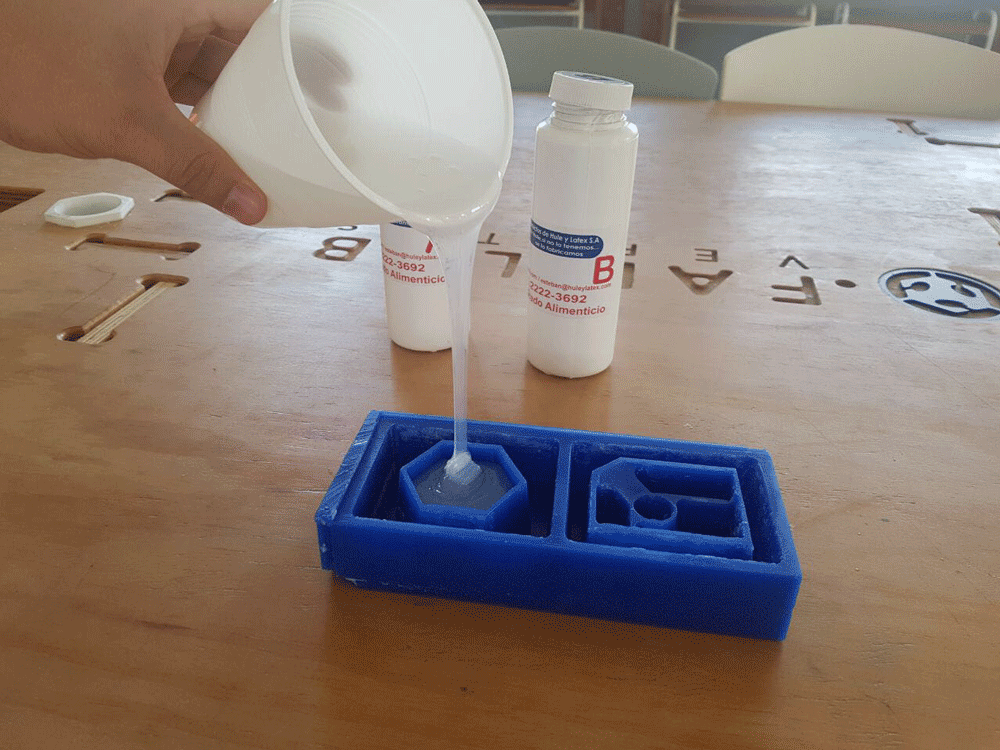

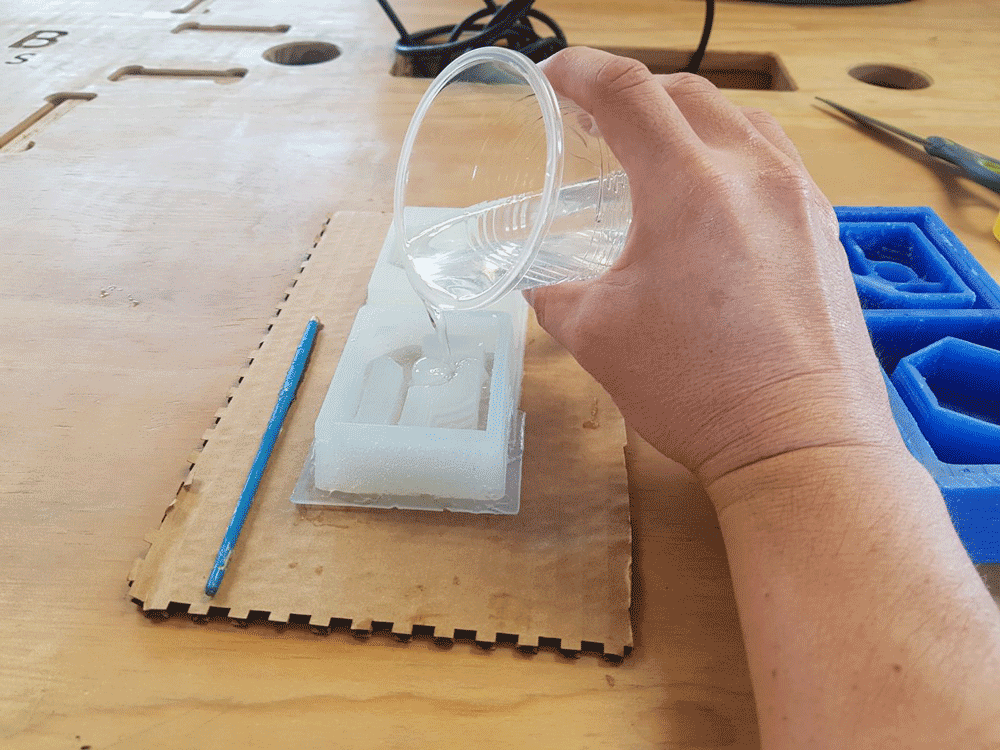

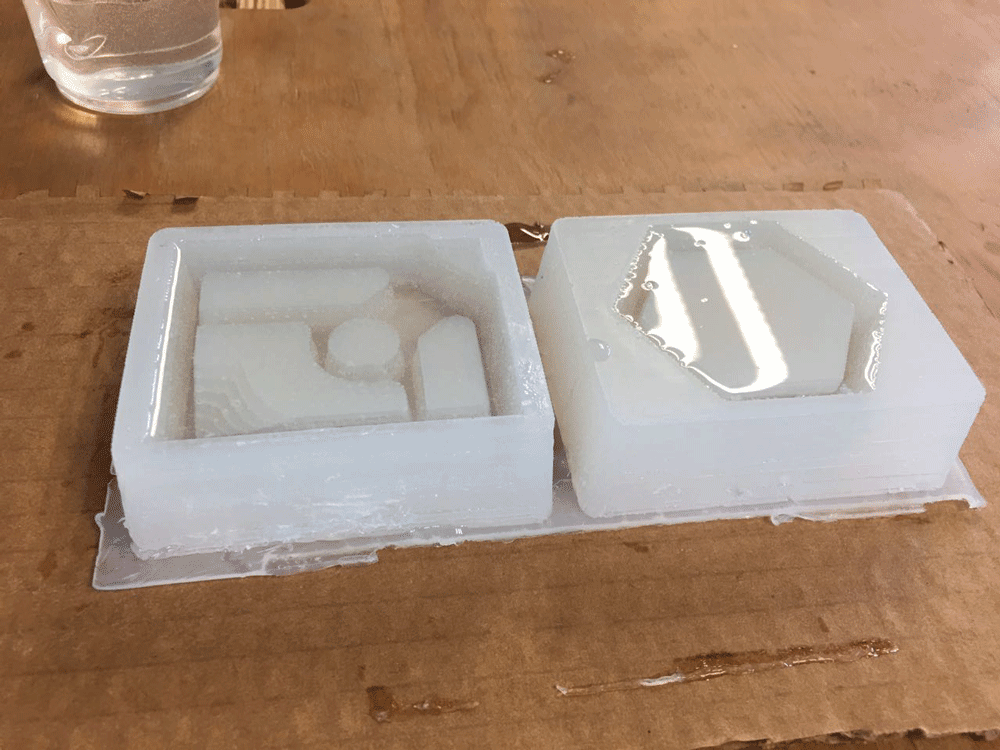

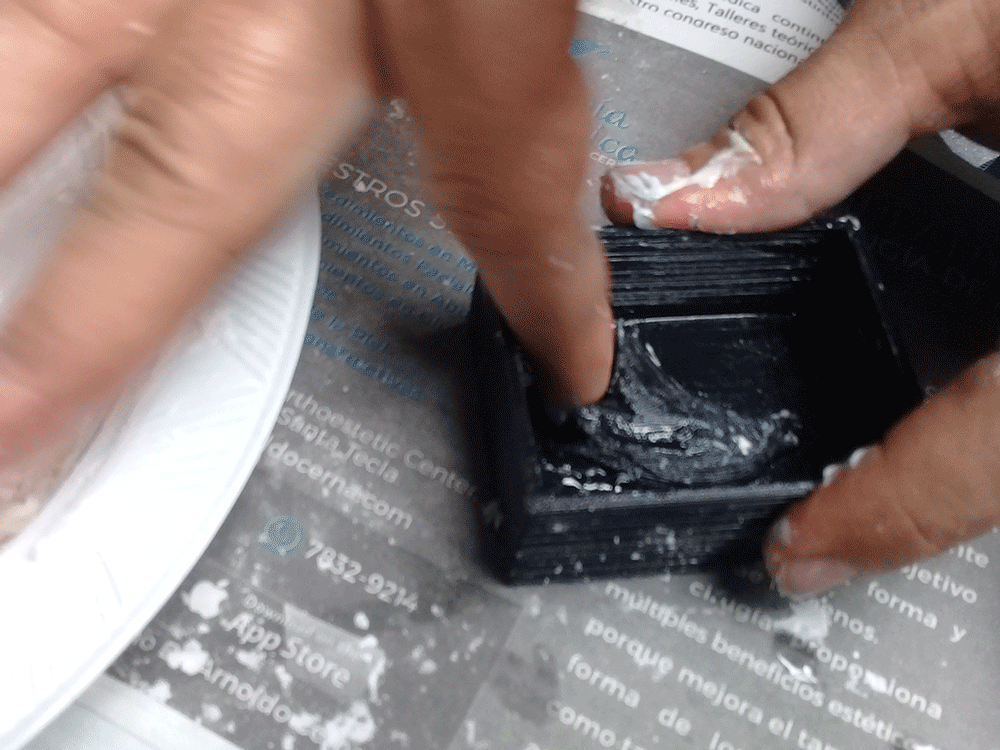

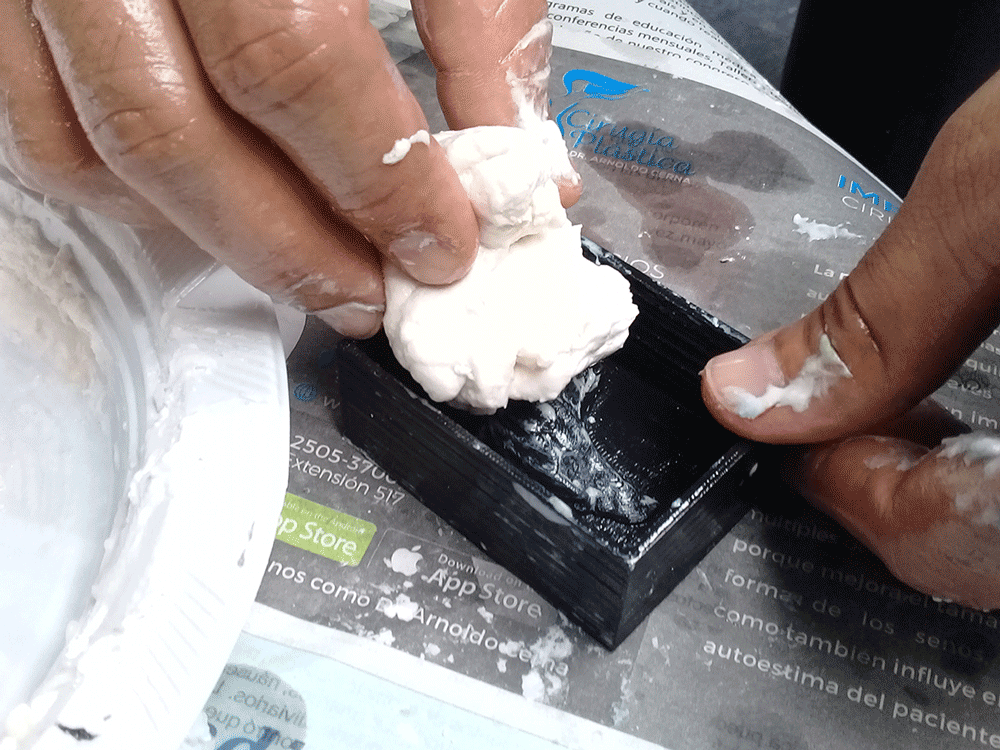

Cast silicone into the countermold. Let it dry.

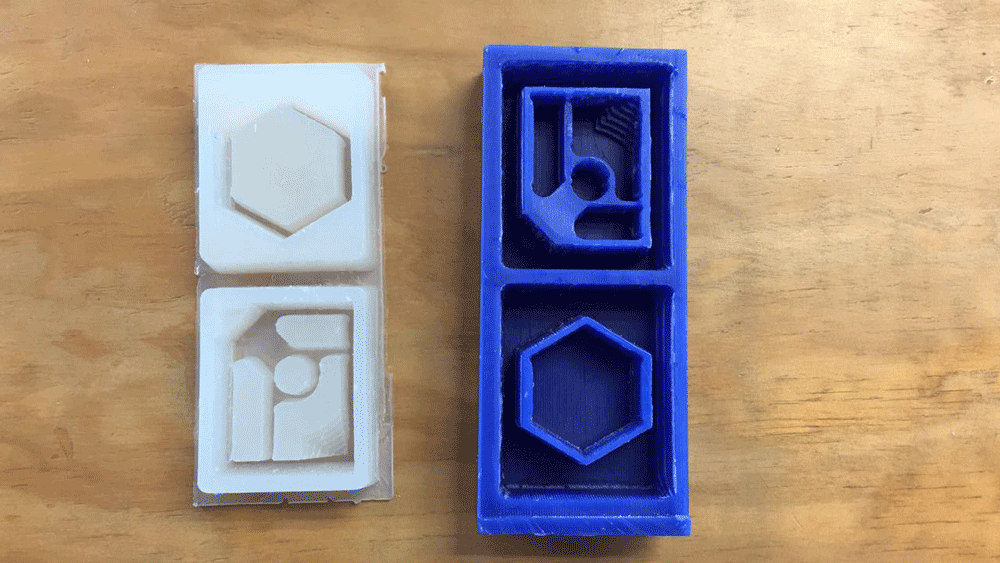

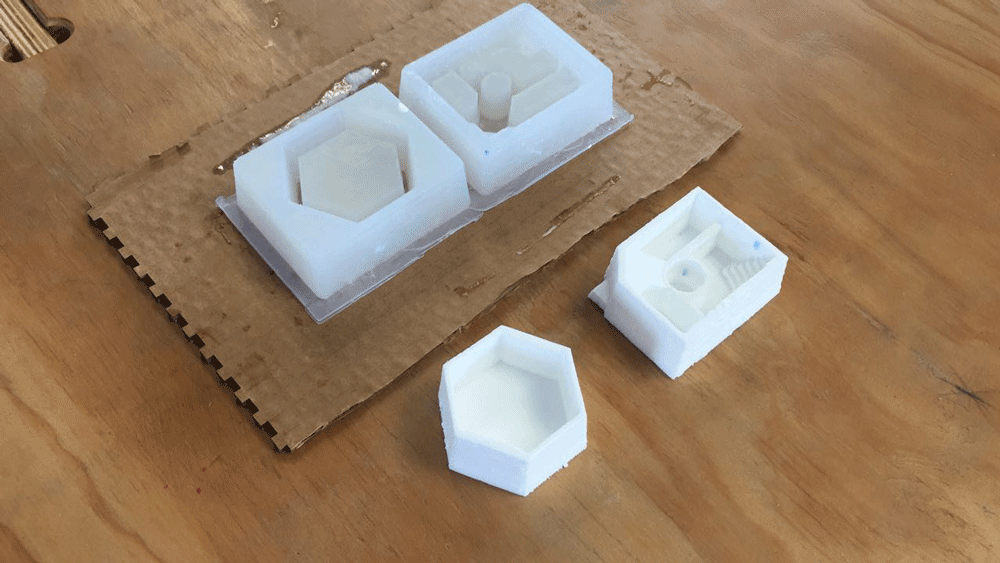

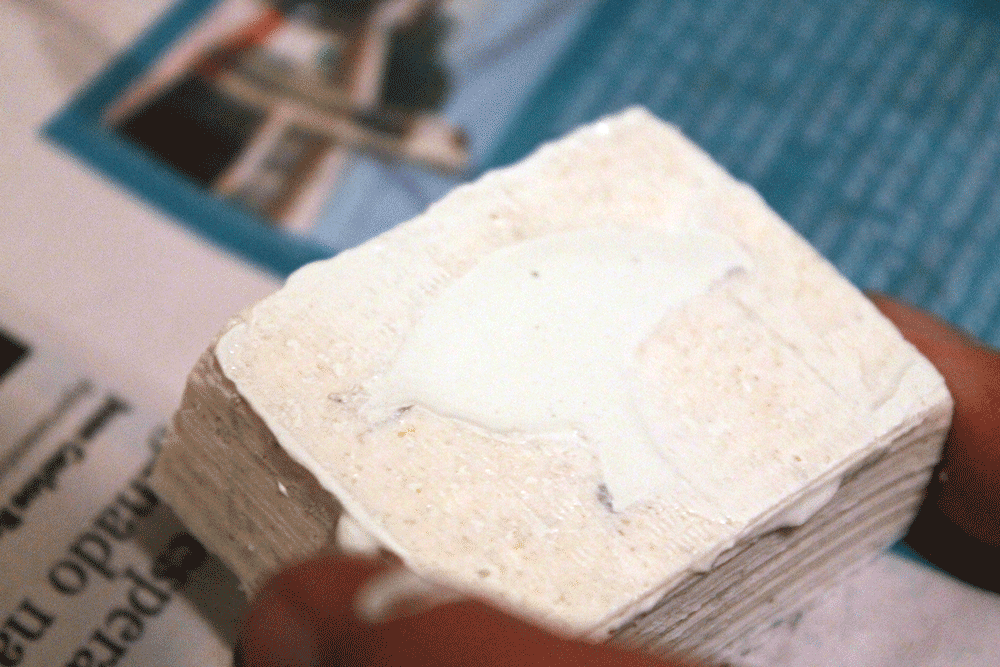

Unmold

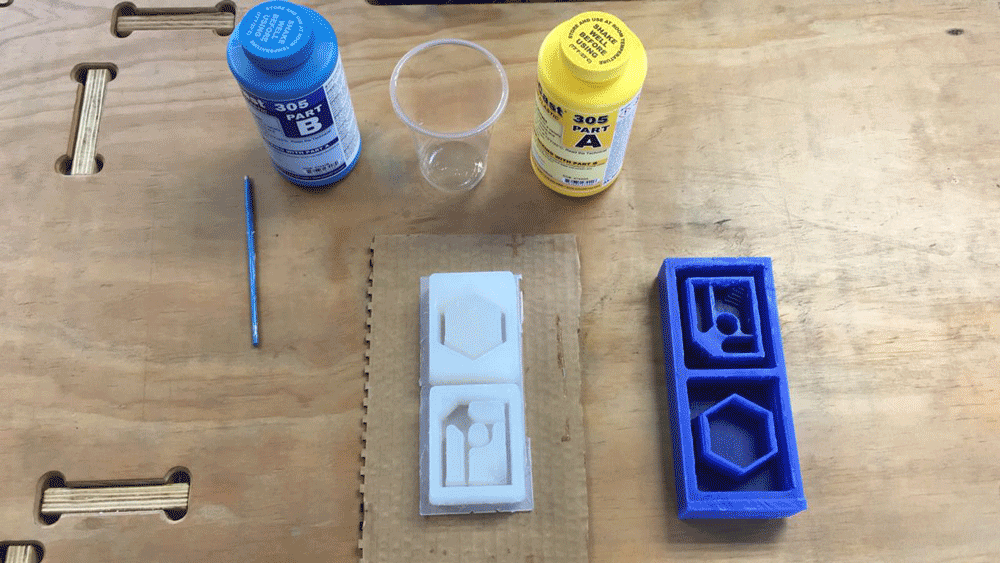

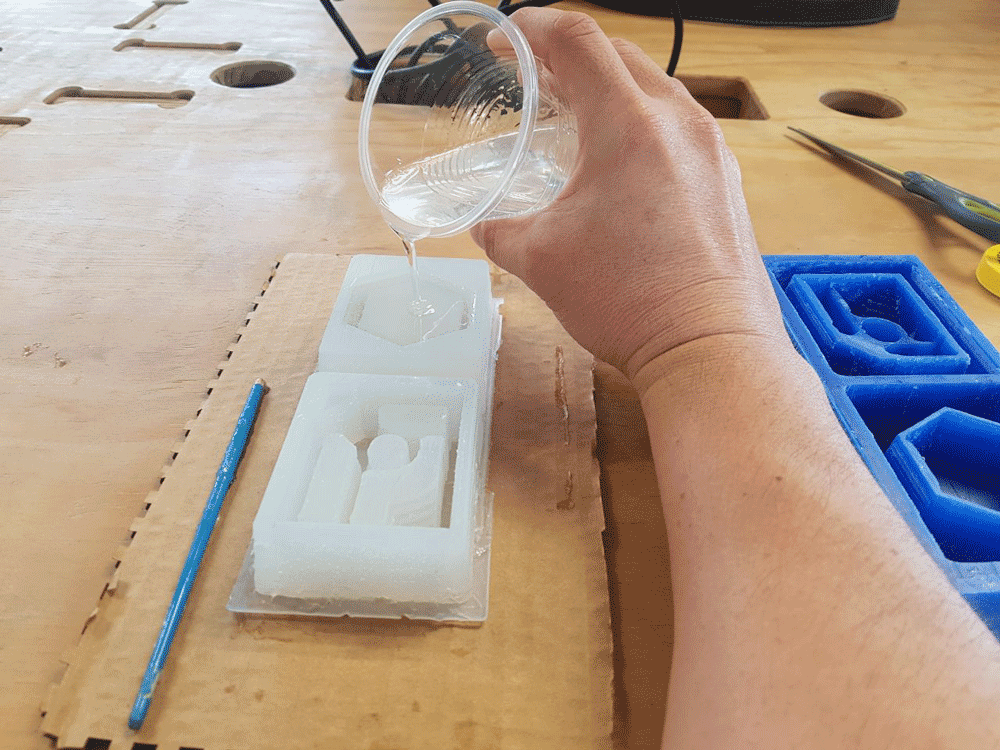

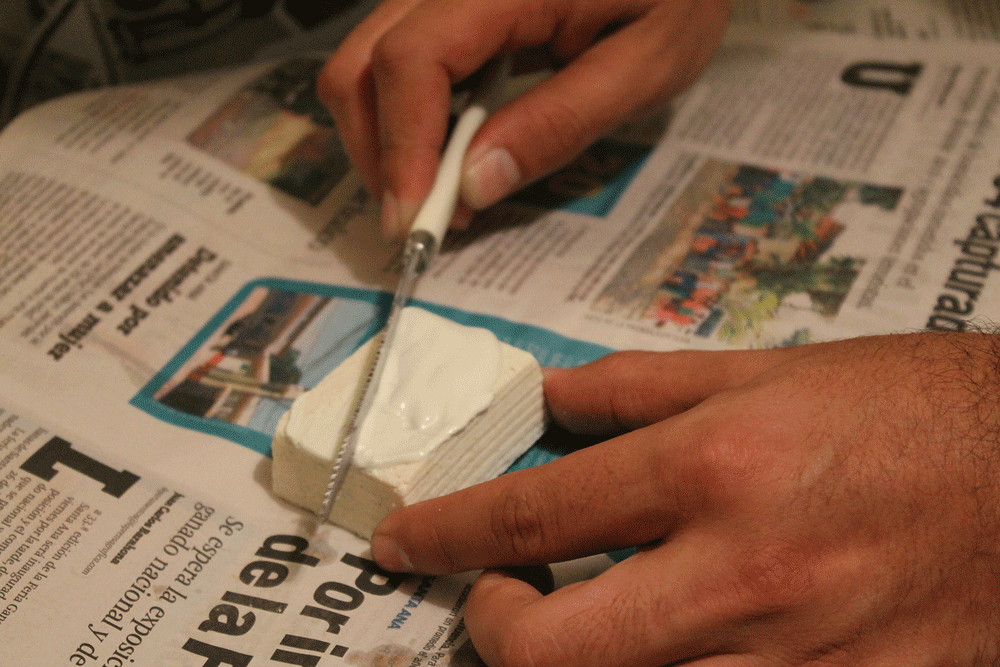

Now we cast resin into our soft mold to get the designed products. Let it dry

Unmold again. We could repeat this process several times, until the mold fails, here we proceed to repeat the process of making a new mold from the countermold.

Results

Molding and casting v2.0

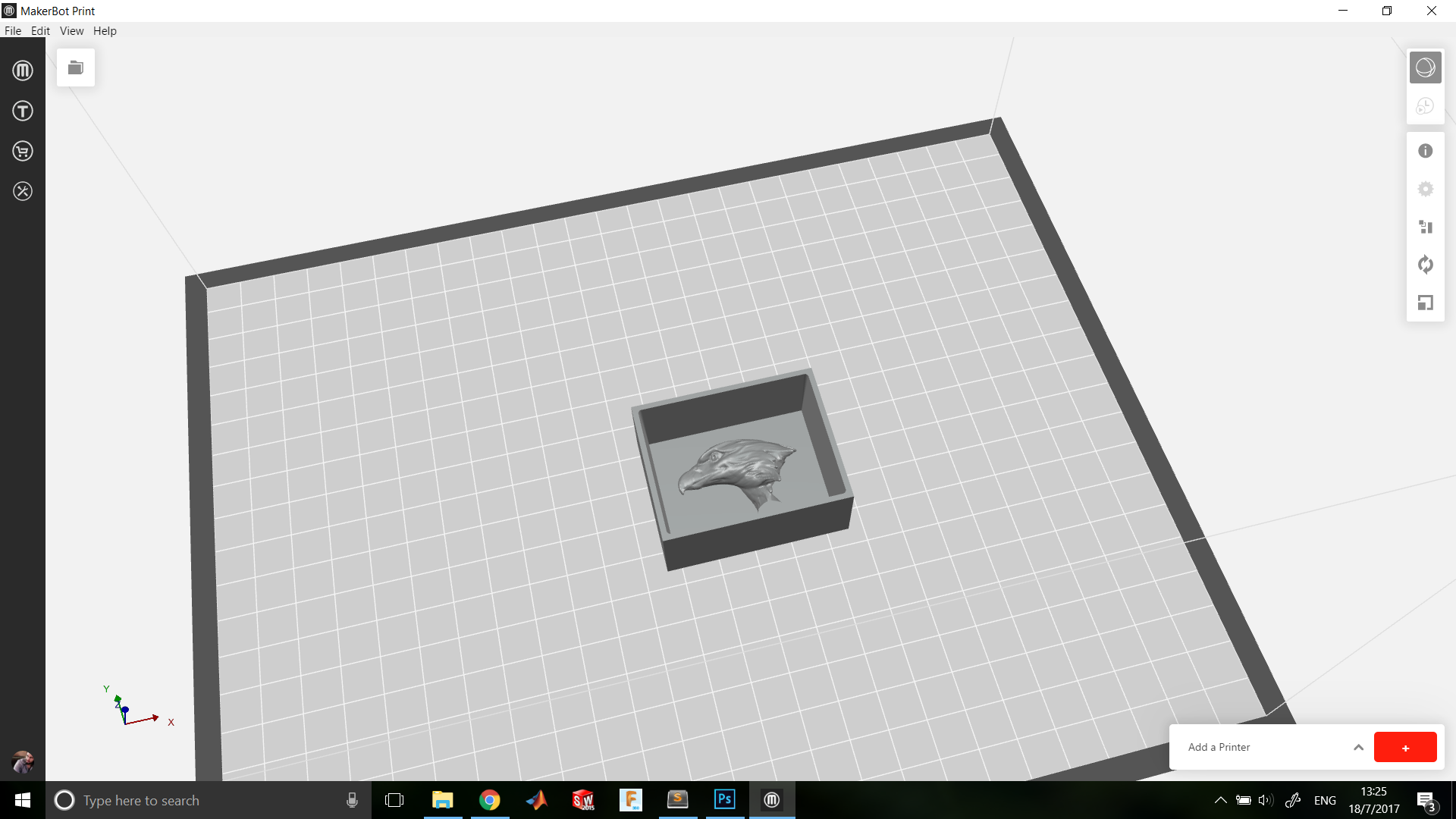

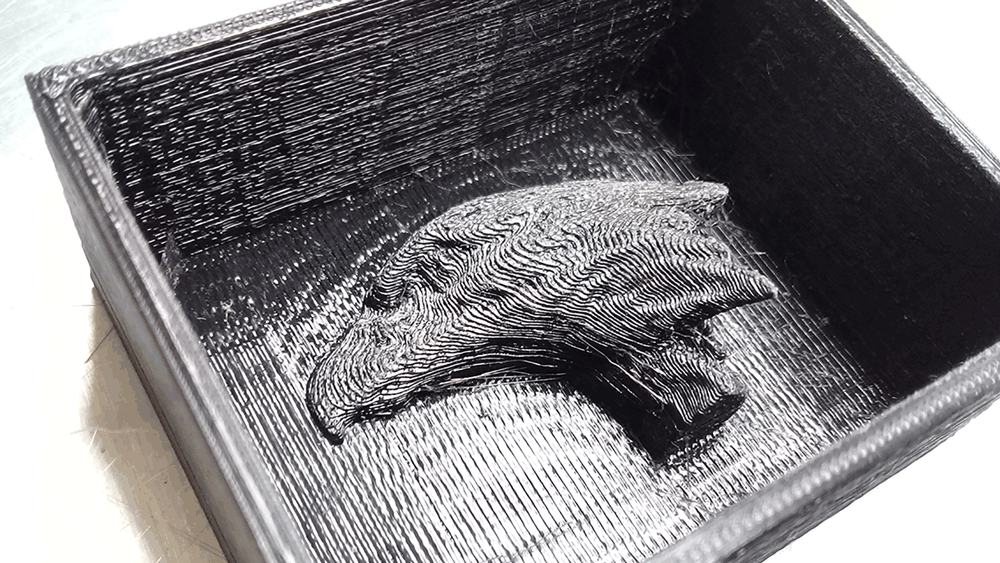

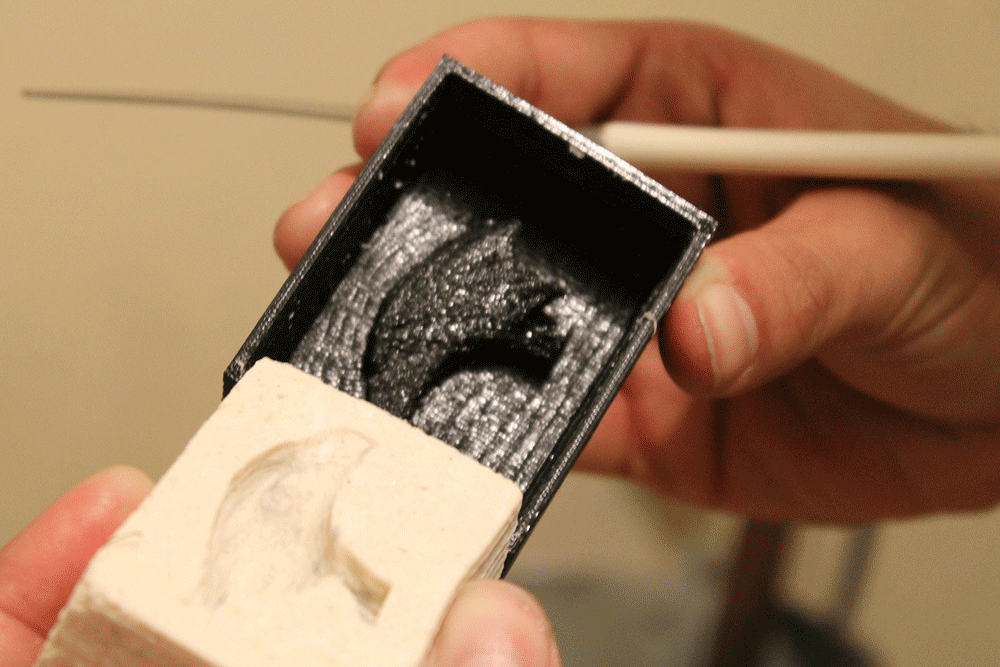

For the second try I downloaded this Eagle Head and modified on Rhinoceros to make the countermold. I cutted the eagle head in half and then surround it with a box with demolding angle.

Results

Molding and casting v1.0

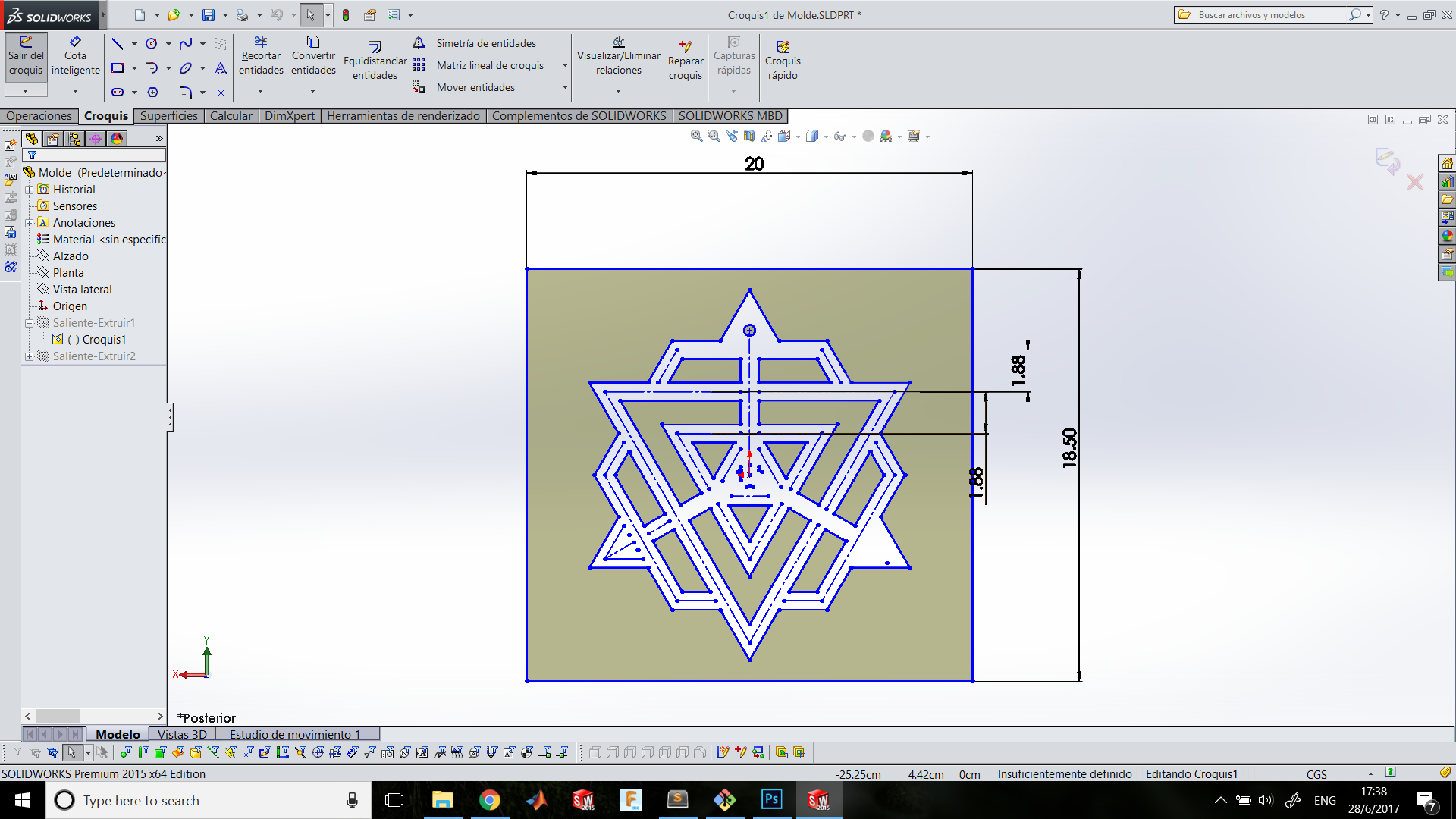

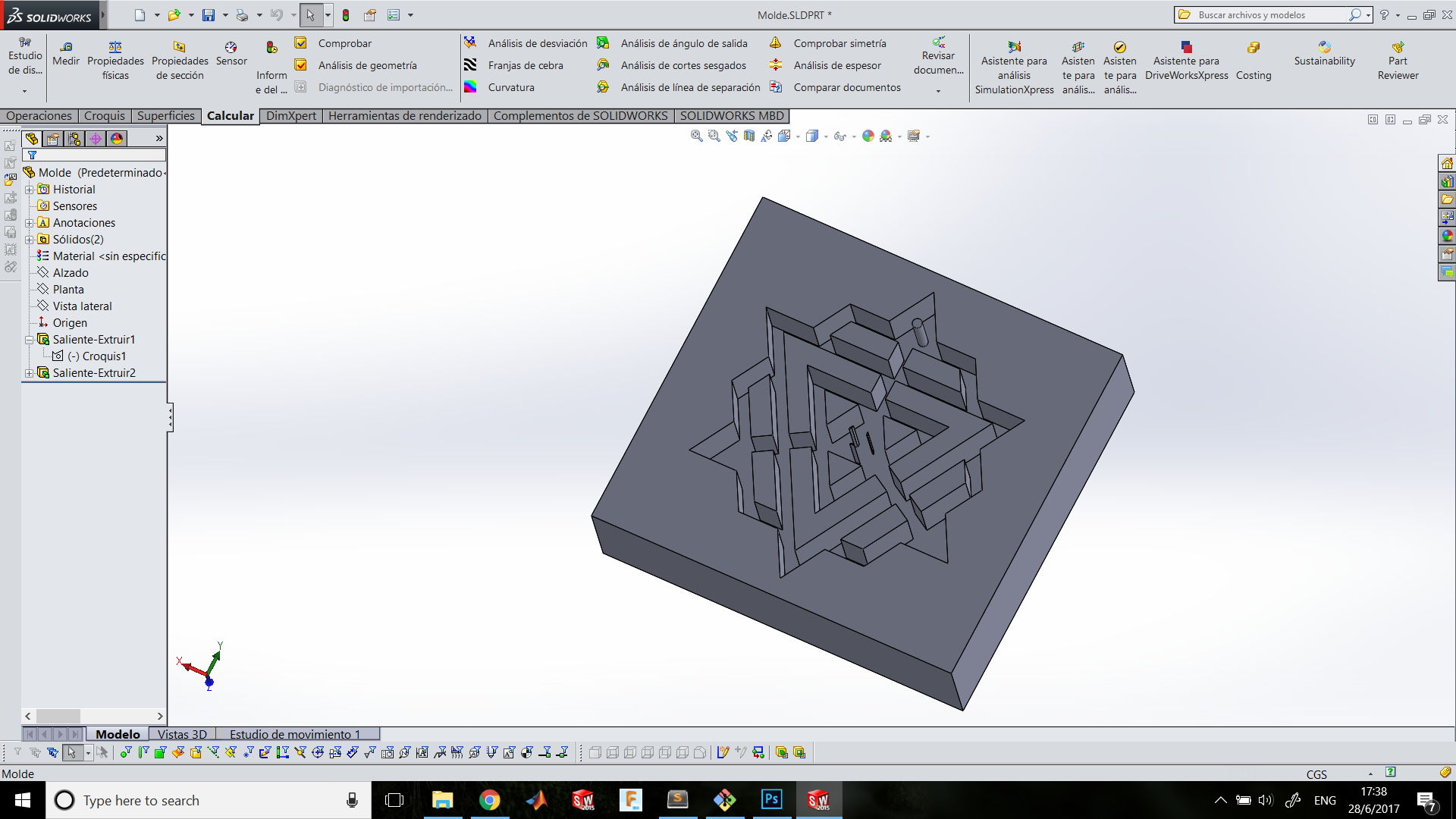

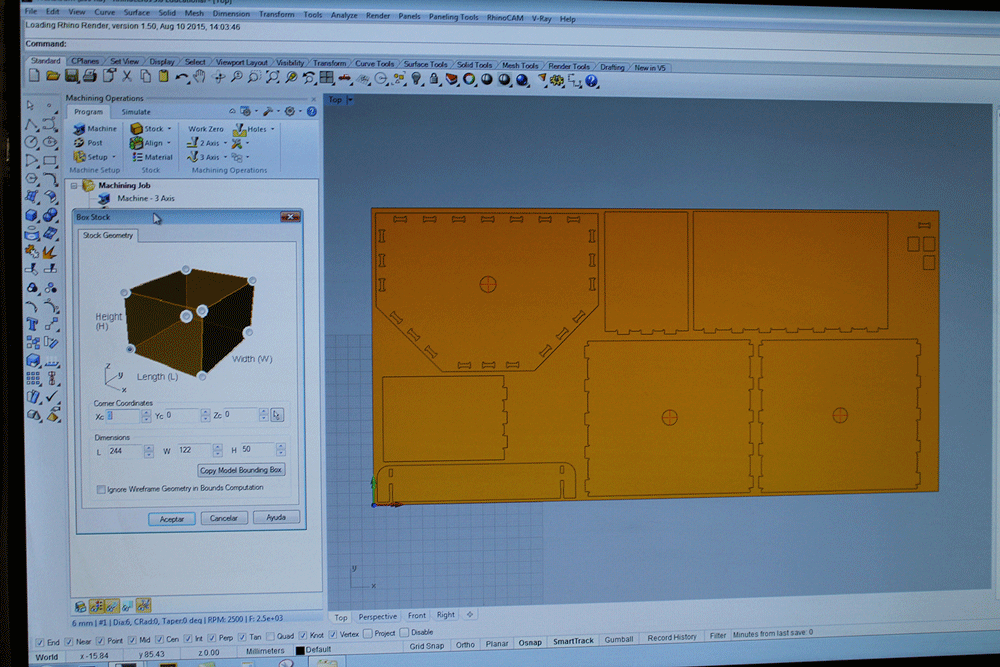

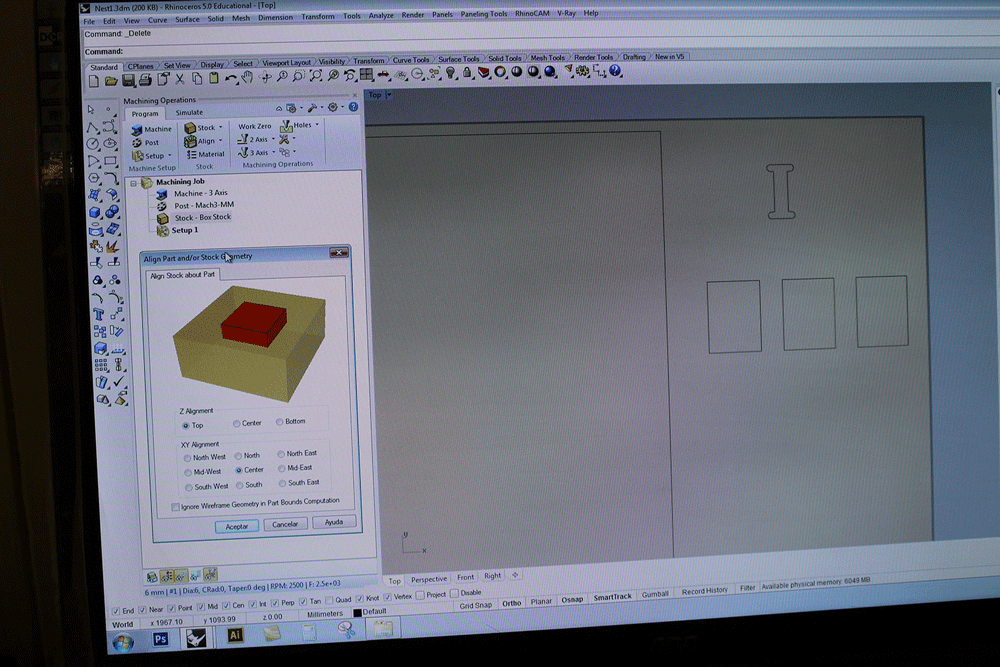

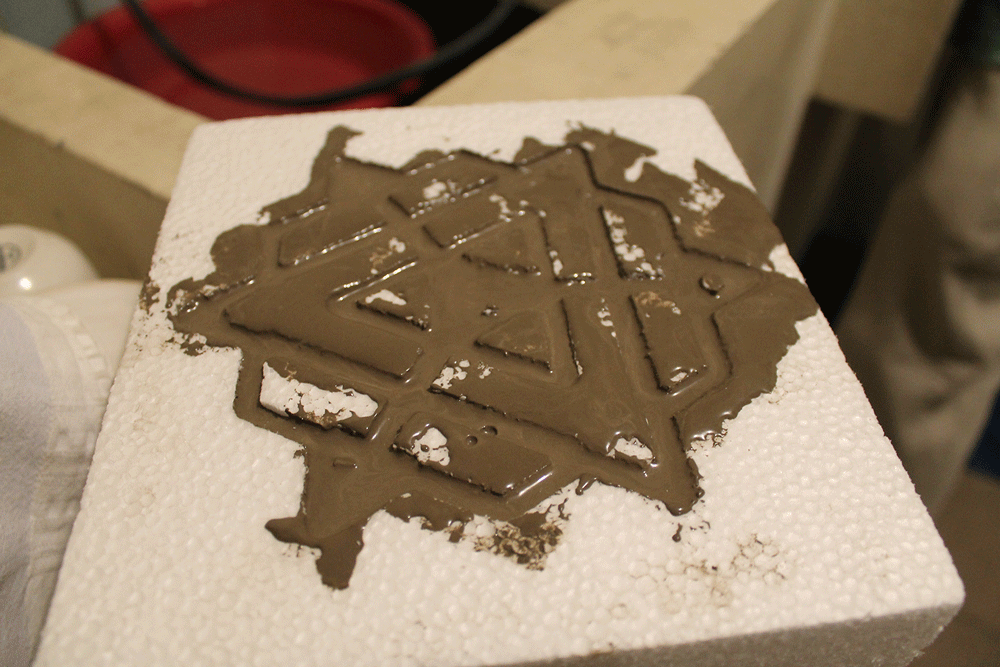

I make a model on SolidWorks and then exported to Rhino to use RhinoNest

Week 12 - Molding and casting from Ivan López on Vimeo.

After this I prepared cement

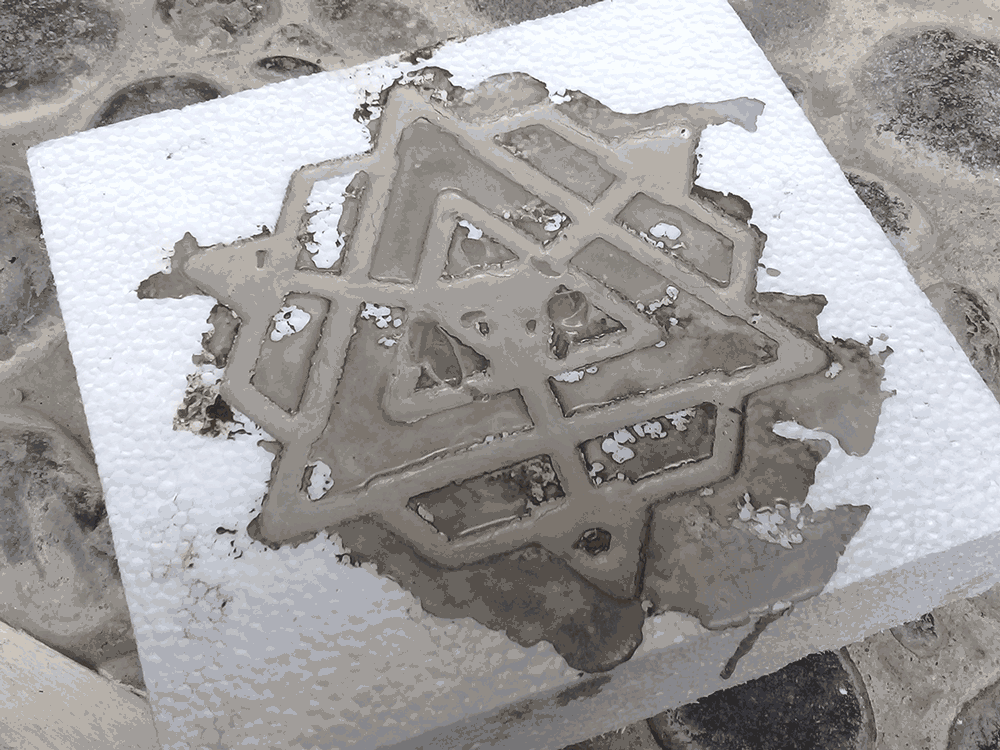

Let it dry

Unmold

Results