In this week we have to make something big using CNC machine.

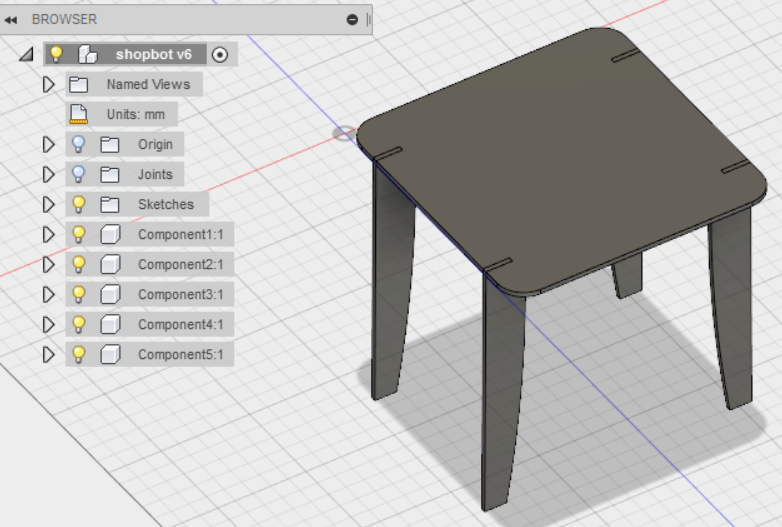

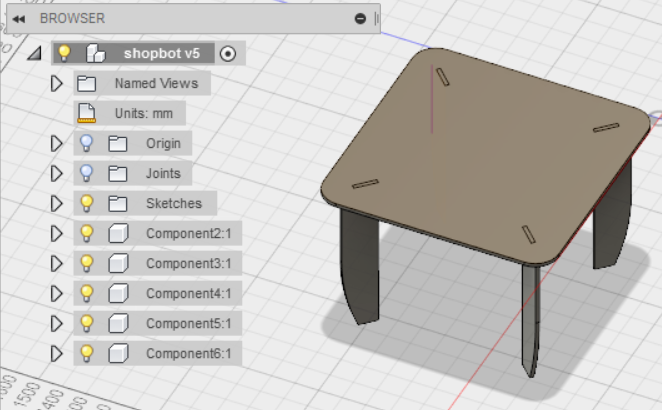

I wanted make a table, so I made the design using fusion and it was parametric. Here is the design.

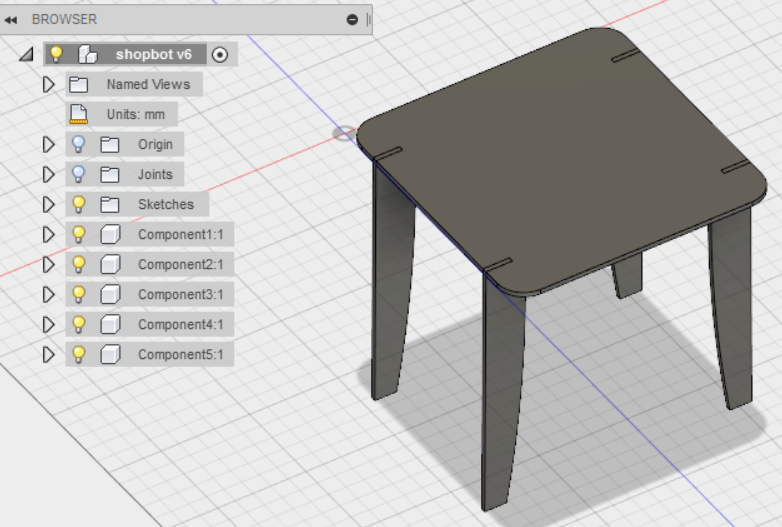

This was my initial design, then I cut it with laser cutter to test it

I found a problem which is that the table is not stable in one direction, here is the a video showing the problem

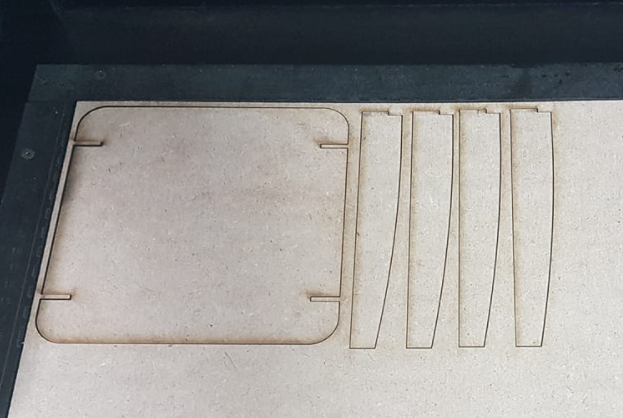

So I modified the design, and here is the new one that I made to solve the problem.

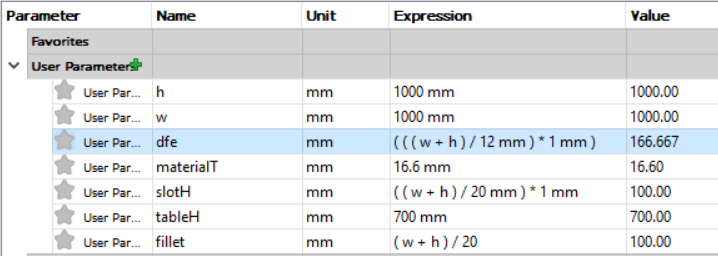

Here is the parameters of the parametric design, dfe is distance from edge.

Actually I couldn't test this design with laser cutter because it wasn't working at that time so I went directly to cut the design using the shopbot.

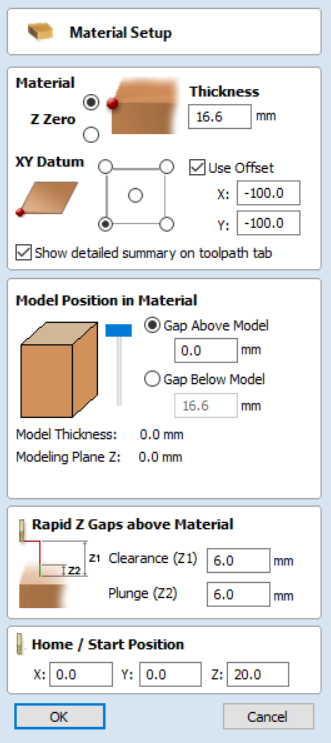

I imported the dxf file to Vcarve. I'm going to cut plywood sheet the dimentions of the sheet is (244 cm * 122 cm) and the thikness is 16.6 mm.

Firstly, I had to do the material setup. I defined the material size and the thickness.

Also, I offset the datum by -100*-100 so I can zero not at the edge of the board because the material surface in the edge is usually not straight.

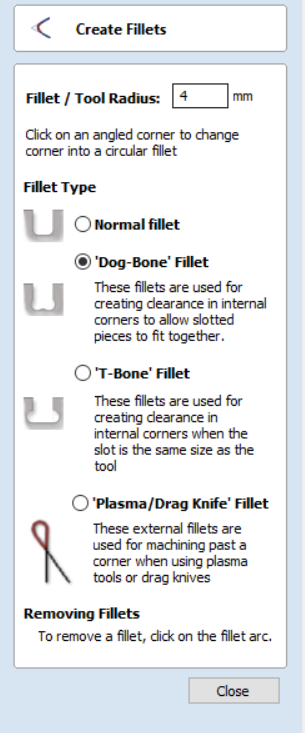

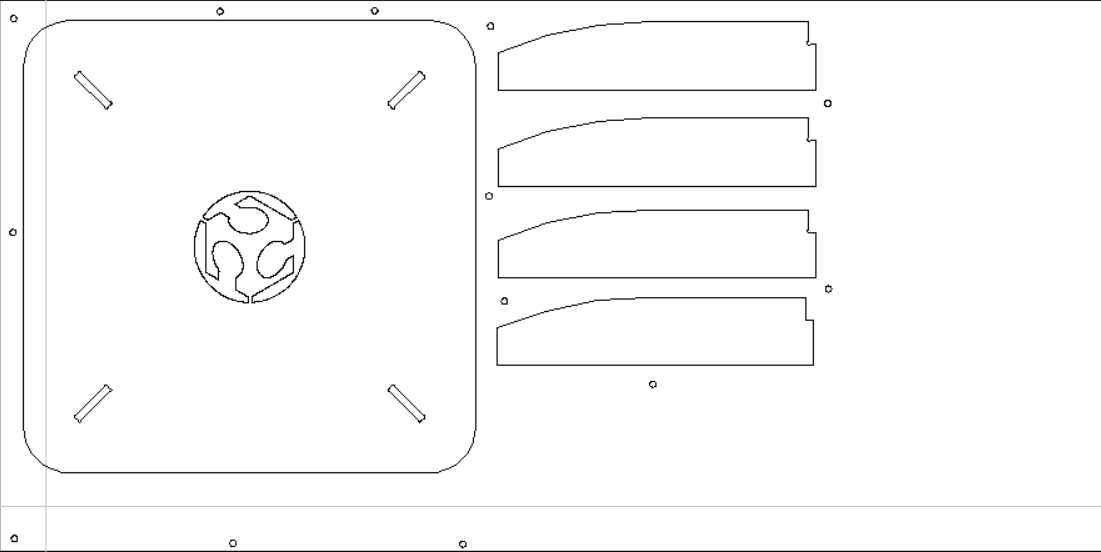

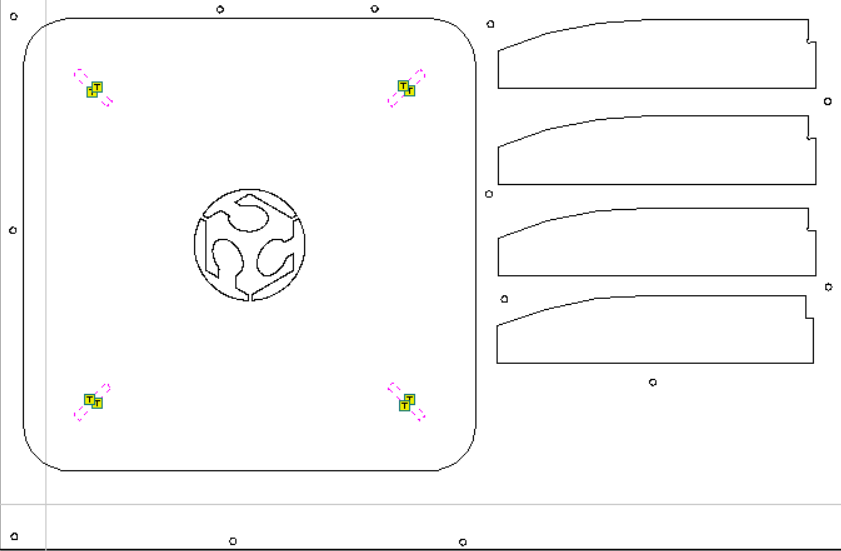

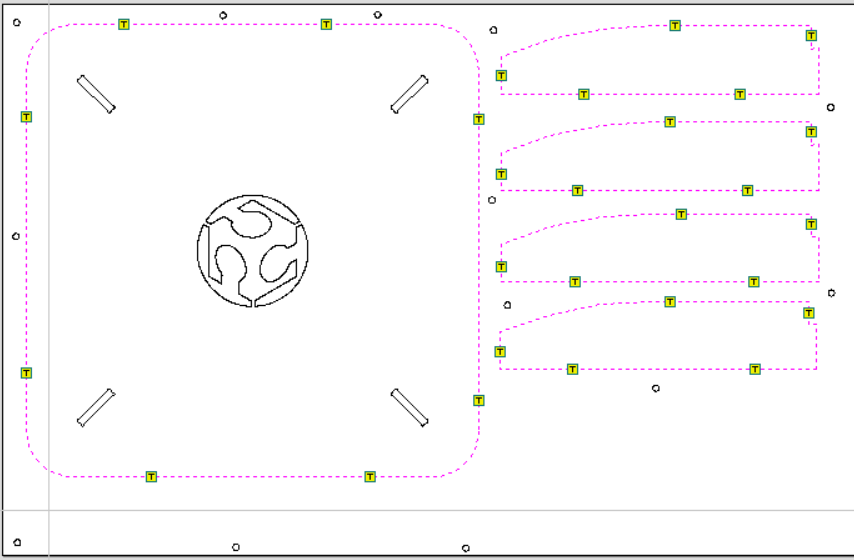

In Vcarve I nested the design and I added the fablab logo to make a pocket in the middle of the table. Also, I added holes to drill them with the shopbot to fix the wood sheet with screws. And finally I added the dogbones fillet.

Here is the design in Vcarve:

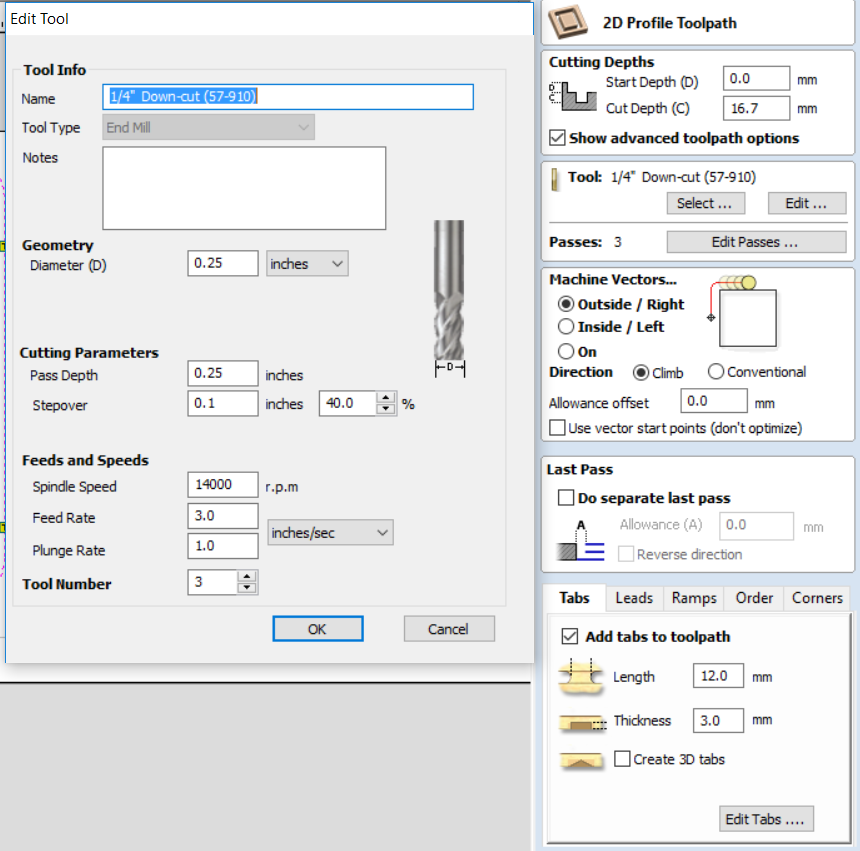

Then, I started making the tool paths. I used 1/4" Down-cut tool for all the tool paths. I made four tool paths, for drilling, pockets, interior cut, and exterior cut.

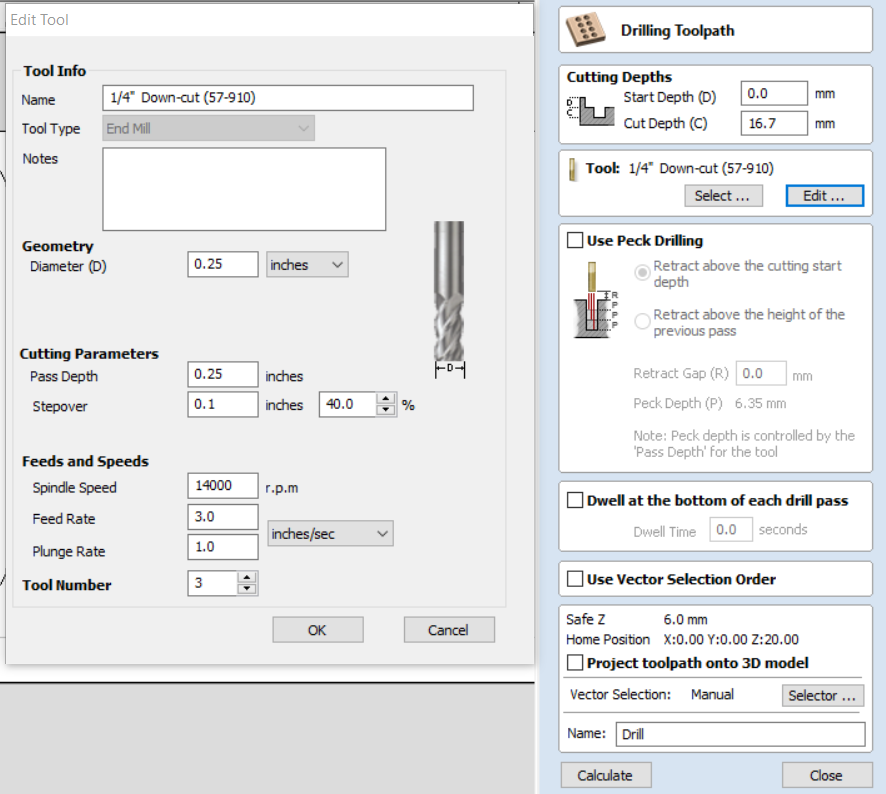

Here is the setting for drilling toolpath.

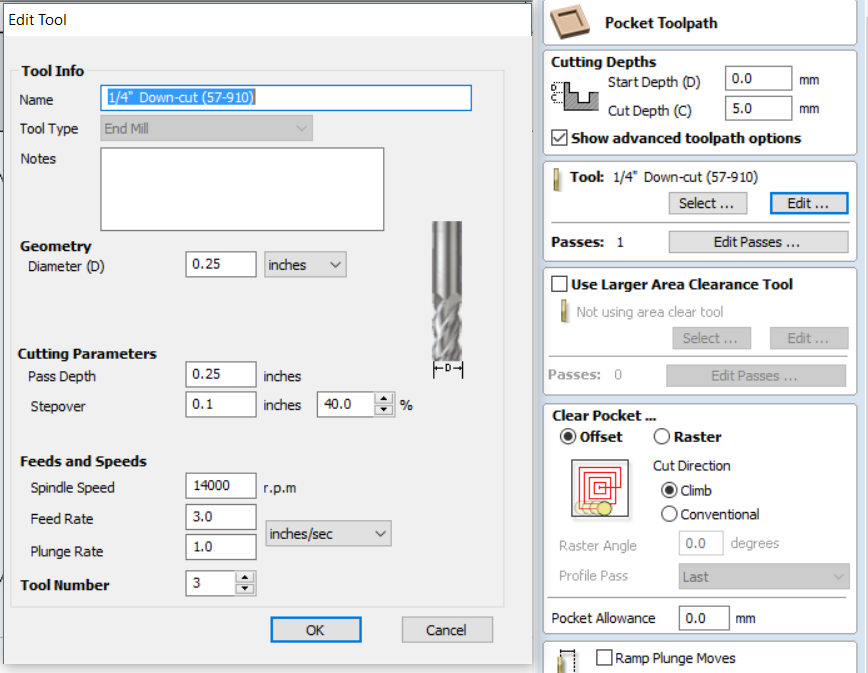

After that I made pockets and here is the setting.

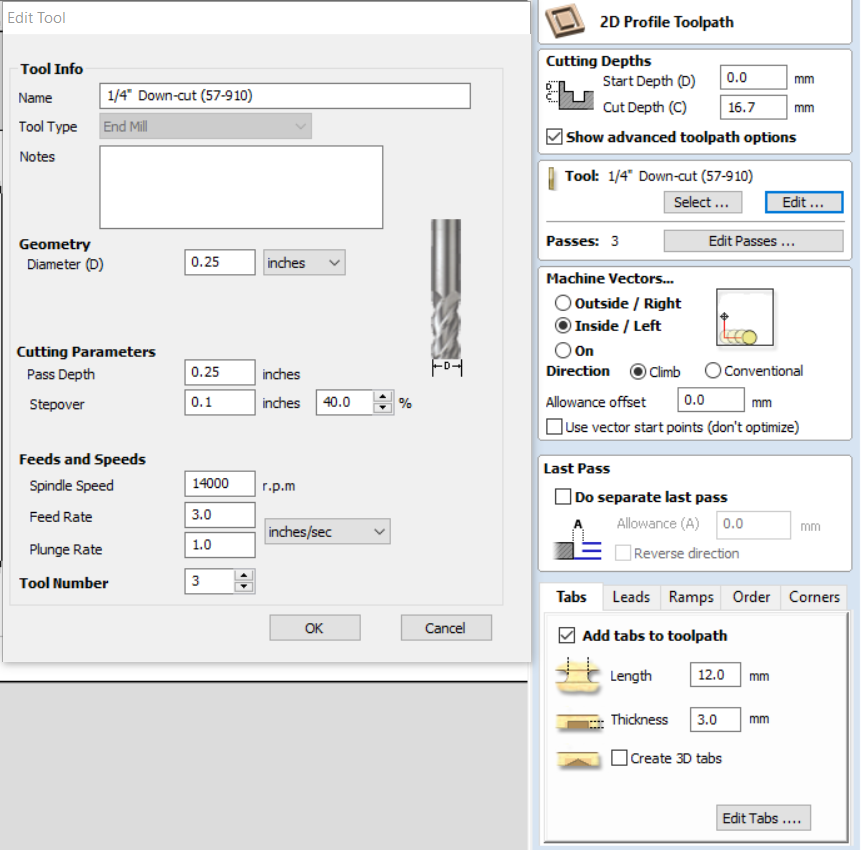

Then I started with the interior toolpath, here is the settings.

The tabs:

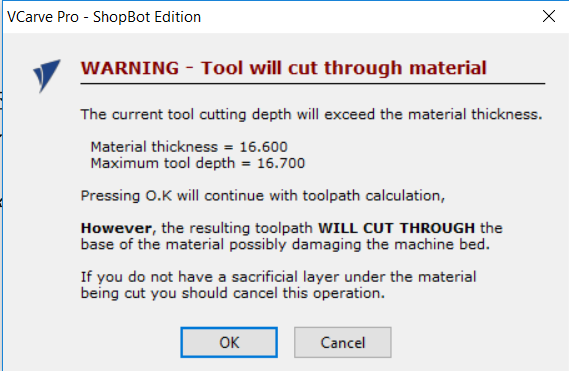

You can see that I made the cut depth 16.7 mm and this is why I get this warning message when I calculate, but I ignore it because I have another wooden board below it.

Here is the exterior toolpath setting.

The tabs:

Then I selected the tool paths, and saved each one of the tool paths separately.

I generated four tool paths, and I will start executing them in order: - Drill - Pockets - Interior Cut - Exterior Cut

The first step was fixing the wood board with clamps and then zeroing xyz according to the datum I defined in Vcarve. I started running the job and here is what happened:

Then, I realized that the units in SP3 is inches and the tool paths are in millimeters. So I changes that and I run the job agian. After drilling all the holes, I put screws to fix the board.

Then I wanted to make the pockets so I run the tool path for pockets but the machine went to one of the drill halls. Apparently, what happened is that I executed the drill tool path again by mistake. Here is the result:

The drill was broken and the collet was damaged.

But I worked with the damaged collet and with a new bit, here is a video of the machine milling:

I was able to make the pockets, the interiors and part of the exterior, but I had to stop because the collet wasn't holding the bit securely, so the bit fell down while milling. Here is what I had at this moment, I had three legs lift to finish.

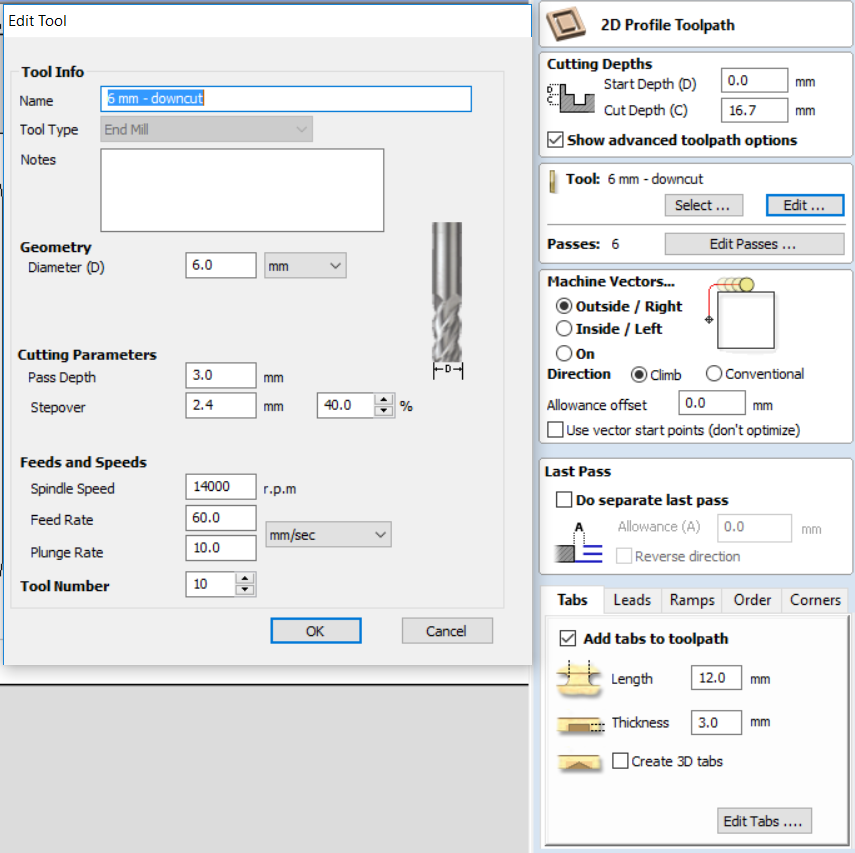

We bought a new bit and collet to continue the job, it was 6mm Down-cut milling bit. I had to make a new tool path for the remaining legs. Here is the settings:

Then, I had to zero at the same place I zeroed before and start cutting:

After having all the parts ready, I started assembling them. Putting them together was a little bit hard, I should have increased the width of the slots. Here is the final product pictures.