For this week we need to make a 3D design and print it without support, and to 3D scan an object. And there is a group assignment for testing the 3D printer.

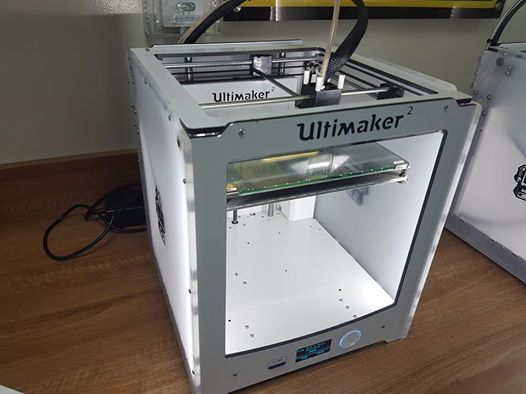

We have an Ultimaker 2 and using Cura for slicing. Ultimaker 2 build volume is 22.3 cm × 22.3 cm × 20.5 cm and its layer resolution is up to 20 microns.

For testing the 3D printer we downloaded this design file from thingiverse.

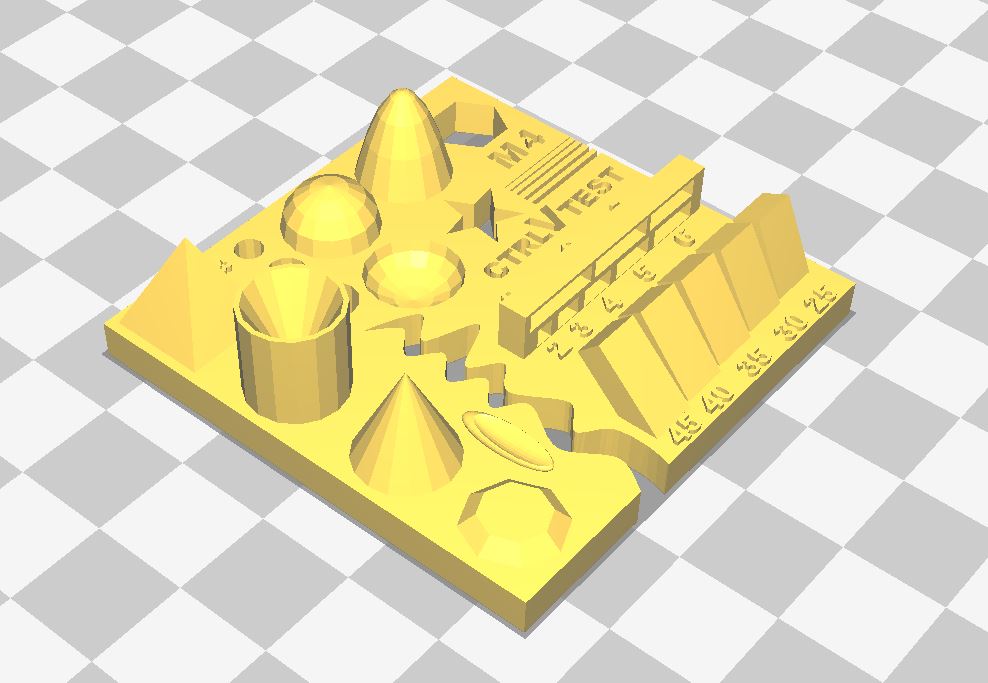

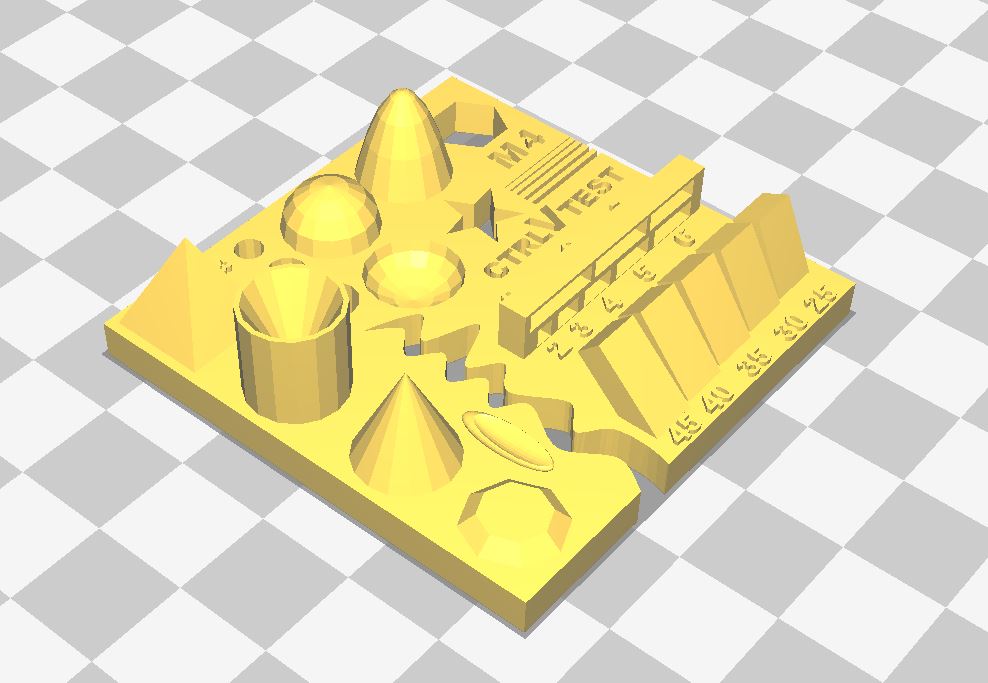

Picture of the design in cura:

The design has these feature:

Printing settings: - Layer hight = 0.1mm - Infill density = 20% - Print speed = 50mm/s - Travel speed 120 mm/s

Here is the design after printing:

The test print design looks good visually. M4 Nut size fit perfectly. Smoothness of all surfaces looks good. We measured the sizes of the circles and they are slightly smaller than the original design but this is expected. Overhangs looks fairly good but with very minor defects.

For this assignment we have to make a design that can't be made subtractively. So I decided to make a design for a phone stand the has curves that can't be made subtractively beacuse they are downward inner curves and the milling bit can't reach them.

I worked on the design using Fusion 360. I Started by drawing two two rectangles inside each other then extruding them.

After that I made a fillet for the corners

Then I drew the parts that will hold the phones, it can't have an angle more the 45 degree otherwise I will need to use support:

After that I used mirror:

Then I exproted the design to stl, and imported it in Cura which the slicing application for ultimaker. Here is the design in cura:

I saved the design in an SD card then I started printing it will PLA filament:

Pictures of the 3D printed design:

Surprisingly, I didn't face any problems printing the assignment. I'm experienced with 3D printing and I know that many things can go wrong while printing, because of many reasons. And this is the second reasone why I don't like this machine, beside the it is very very slow. In Ultimaker 2 the feeder makes a lot of problems and many times the filament stucks to it. Also, because we are printing in a cold room, the temp is around 17-20 C, the object doesn't stick to the printer bed, specially when printing with ABS, this why we only print PLA now. Also some times after finishing the printing taking the object with force misses the calibrate, so we need to re-calibrate it otherwise it will not print well.

For the 3D scanning assignment, I will use sense 3D scanner. What I like about 3D scanning doesn’t apply for the 3D scanner we have in the FabLab right now. But in better and more expensive 3D scanners. 3D scanning can help in reverse engineering. For example, if you have an item and one of its parts broke, instead of buying a new one. You can 3D scan the broken part, and you will have the CAD model which can then be 3D printed. Also, 3D scanning comes in handy when you don’t have the original design document. It simplifies and fastens the design process.

But 3D scanners are expensive, and if you want to do proper reverse engineering using the 3D scanner, you will need to get an accurate 3D scanner which is too expensive, much more expensive than the normal 3D scanner like the one we have in the lab. And what I don't like about the 3D scanner we have is that it is really slow and sensative to any small movement.

For the assignment I decided to scan a Skull my friend Mouaz Ali made.

I put the skull on a table and then started scanning it:

Here is the result:

Then with erase tool I started fixing the skull

After that, I solidified it and here is the final result, Then I uploaded the stl file to sketchfab: