In the machine design week I worked on making the three stages of the machine with my friend Mouaz Ali.

At the beginning I wasn't sure how I'm going to make the three axises. AM I going to make the extruder move in the three axises and fix the machine bed, or make the bed move.

I looked into many designs and projects and really liked the idea of making the table move in xy and make extruder move in z, especially that we already made a CNC machine that has an xyz moving head. So I wanted make something different.

Francisco adviced me to look into Nadya Peek, Machine That Make: Stages and then a looked for projects that are using this concept and one of the best projects I found is McNulty Machine. Students from different labs worked on the machine in Fab Academy 2016, and I really liked their documentation and it helped me a lot to design the stages of our machine.

I started the stage design with makercase.

Then after making the box I modified it with CorelDraw to satisfy the stage requirements.

The stage consists of two parts. The stage body which has place where I can fix the stepper motor and the part that moves when the stepper motor rotates.

To make the stages I needed: - RB Stepper Motor 17HD + thread (x4) - 3 mm Acrylic Sheets - 10 mm steel rods - 10 mm linear bearings

When I was desiging I found a problem aligning all the holes together, so what I did is I made a prototype with MDF to make sure that the stage is working fine.

I fixed the stage with super glue and here is the stage operating manually.

After making all that I needed to think of how I'm going to connect xy stages to each other. I decided to connect them by making holes in the moving part in one stage and holes in the body of the other part and connect them with screw. Here's the design of xy.

And the z axis is not connect to any of themm but it will be put inside a base. Here is the design of z axis and the base.

Finall I cut the design in acrylic and fix it with chloroform.

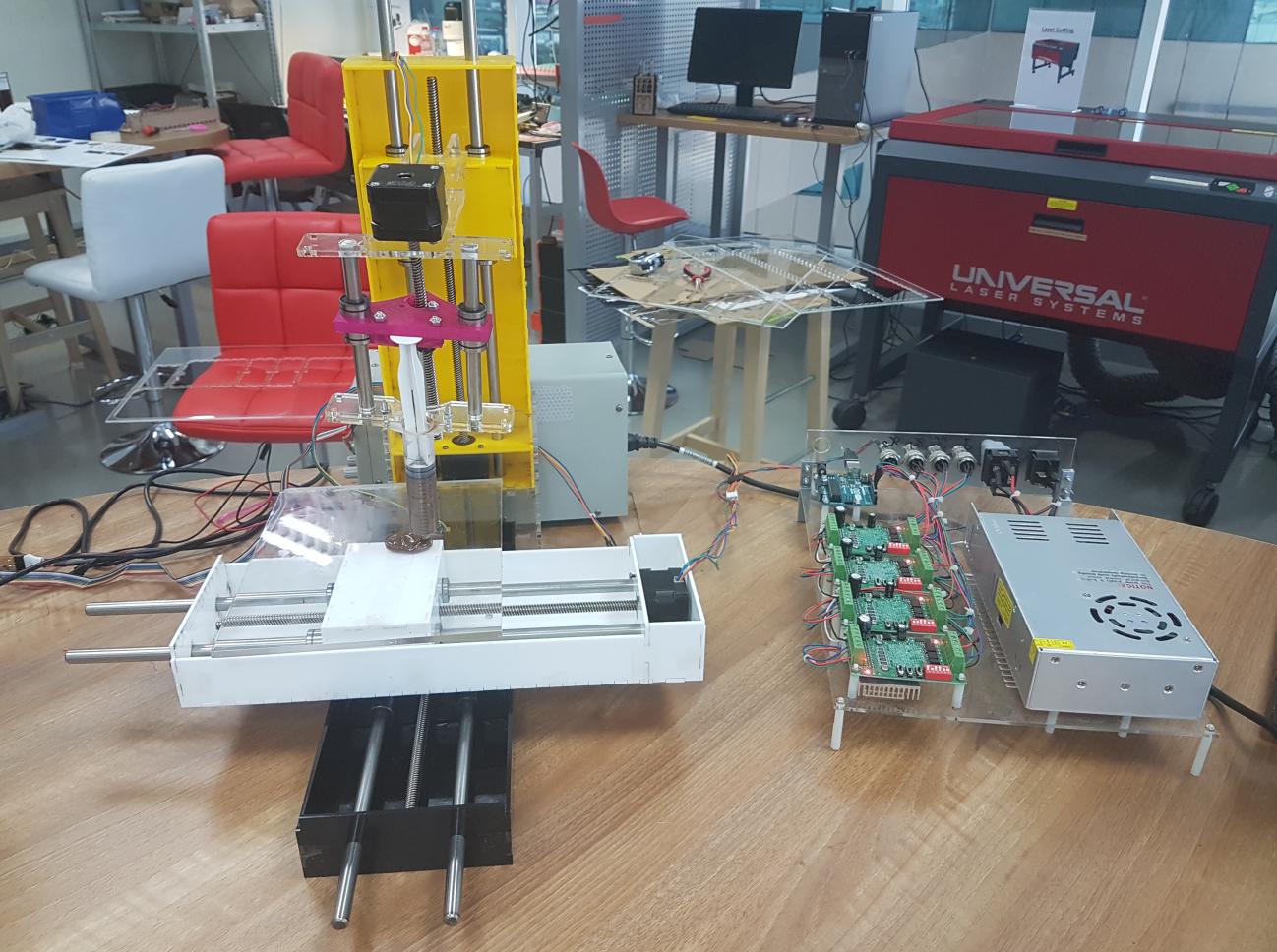

The machine movement will be like this. The build plate will move in xy axises as it attached to xy stages while the extruder is attached to the z stage and it has its own motor for extrusion. The machine building area is restricted to 150 mm x 150 mm x 70 mm.

Finally here is a picture and a video of the machine working.

If you want to know about the other parts of the machine you can visit the machine page.