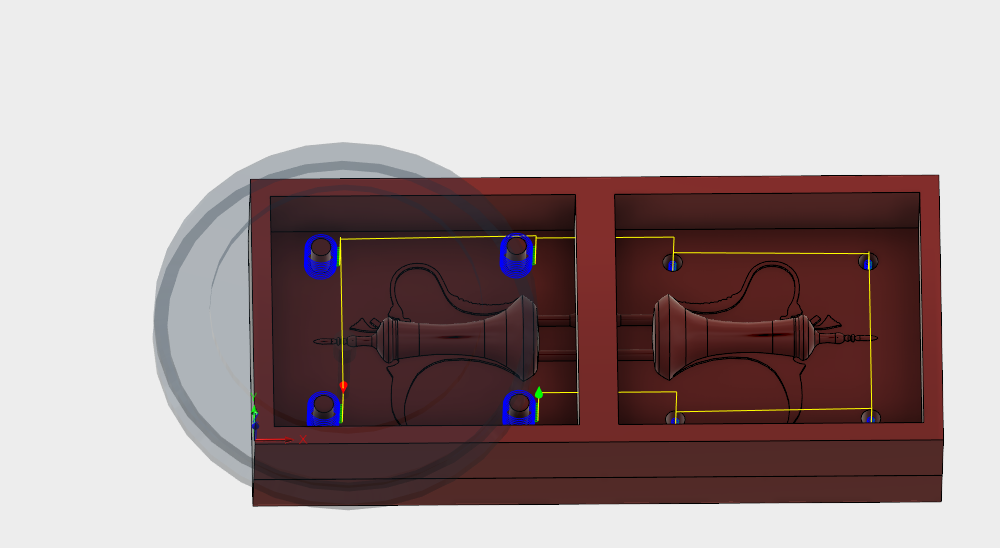

Operation 1/2 | Description: Contour2 | Strategy: Contour | WCS: #0 | Tolerance: 0.01mm | Stock to Leave: 0mm | Maximum stepdown: 0.5mm |

| | Maximum Z: 15mm | Minimum Z: -22mm | Maximum Spindle Speed: 8500rpm | Maximum Feedrate: 1000.001mm/min | Cutting Distance: 5552.69mm | Rapid Distance: 1182.17mm | Estimated Cycle Time: | Coolant: Off |

| | | | T3 D3 L3 | Type: ball end mill | Diameter: 3.17mm | Corner Radius: 1.59mm | Length: 29.97mm | Flutes: 2 | Holder: CT50 - Blank1 |

| |

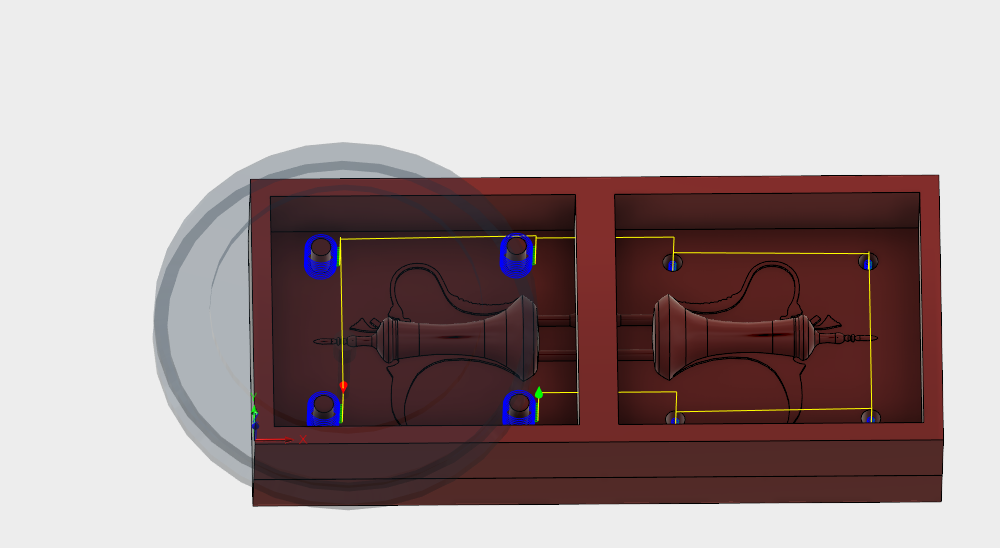

Operation 2/2 | Description: Parallel1 | Strategy: Parallel | WCS: #0 | Tolerance: 0.01mm | Stock to Leave: 0mm | Maximum stepover: 1.59mm |

| | Maximum Z: 15mm | Minimum Z: -22mm | Maximum Spindle Speed: 8500rpm | Maximum Feedrate: 1000.001mm/min | Cutting Distance: 3859.59mm | Rapid Distance: 2366.28mm | Estimated Cycle Time: | Coolant: Off |

| | | | T3 D3 L3 | Type: ball end mill | Diameter: 3.17mm | Corner Radius: 1.59mm | Length: 29.97mm | Flutes: 2 | Holder: CT50 - Blank1 |

| |