17. APPLICATIONS AND IMPLICATIONS

Index

- Assignment

- Question & Answer

- Summary

A. Assignment

-

Propose a final project that integrates the range of units covered, answering:

- What will it do.

- Who has done what beforehand?

- What materials and components will be required?

- Where will they come from?

- How much will it cost?

- What parts and systems will be made?

- What processes will be used?

- What tasks need to be completed?

- What questions need to be answered?

- What is the schedule?

- How will it be evaluated?

B. Shapey, multipurpose hotwire CNC

My final project is a multipurpose CNC machine called "SHAPEY".

I want to make my own cnc machine to learn how they work and to get a deeper understanding

into control mechanisms and fabrication procedure. Making a CNC will involve a wide range of

skill set so i take this as an opportunity to polish my skill sets and add new skills.

I dont want to involve any commercial boards or even existing code libraries for the project. I am

planning to

build the controller circuits, stepper controller boards and all the power control circuitry as

well as the sheilds my myself. Also i wont be depend on any commercial or open-source firmware and will

make one by myself.

I understanding that is a too huge a work considering the time i have. So my consideration will be to

make

it as simple as possible and later add of features following a helical development pattern.

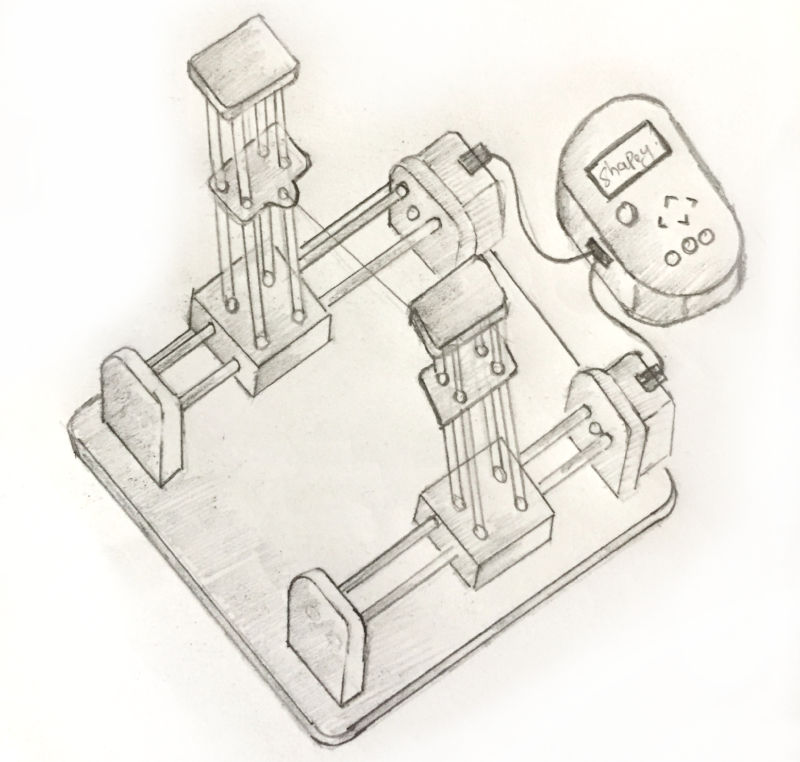

Initial drawing of SHAPEY

c. What will it do

Shapey is beyond the normal foam cutters because it is multipurpose;

- It can cut shapes send from a computer

- It can do lathe

- It can do complex shape cuttings

d. Who has done that beforehand

There are lots of foam cutter available, but the one i am making is spcial due to its lathe feature and more degree of freedom.

e. what materials and components will be required?

e1. Mechanical parts and machine body

The base of the machine will be made with plywood and the main body will be made in acrylic. I will use the aluminium rods, spaces and threaded rod steppers as the guide rail and motion system.

e2. Electronics and control circuitry

I will use a atmega328pu based control circuit. I don't have dedicated stepper control IC in the lab so i am planning to use simple h-bridge IC's to control the steppers. I will make a board with two h-bridge IC's per stepper. This will be mounted on top of a shield board which will be connected to the micro controller board. I am reusing the microcontroller boards i made in the output week and networking week for this project also.

f. Where will they come from?

As you can see most of the components i am using are part of fab lab inventory, i am using them. a few components will be purchased from outside.

g. How much will it cost?

- Cost of plywood: 200 Rs

- Cost of electronics: 600Rs

- Cost of stepper, spaces rods etc: 4000Rs

- Cost of nichrome wire: 300Rs

- Total estiamted: 5K

h. What parts and systems will be made?

Almost all part of the machine will be made in house.

i. What processes will be used?

- Shopbot- for the base and some of the mechanical parts

- Laser cutter for main body

- PCB designing with eagle

- modella for pcb milling

- 3d printing for the control circuit housing

- vinyl cutting for logos

j. what tasks need to be completed?

The basic cad design has been make, now i need to cut the parts assemble them, automate the machine.

k. what questions need to be answered?

I have not tried the nichrome wire which i have odered for the machine. I am not sure on what kind of power source will be needed for it. I am expecting it to get enough hot with around 24v.

l. what is the shedule??

I have three weeks in hand. First week will be dedicated for designing and making the parts. Second week for assembly and testing and the final week for final improvements. I am planning to make atleast a basic foam cutting fucntionality if things does not go as planned

m. how will it be evaluated??

It will be evaluated depending on how well i can cut the foam and also on how much progress i an make on a three week shedule.

Bill of material

| Sl.No | Components | Qty(Nos) |

|---|---|---|

| 1 | Atmega328P-AU | 1 |

| 2 | IC A4953 h-bridge smd | 10 |

| 3 | N channel mosfet AE51AA | 2 |

| 4 | Voltage regulator 5 v | 1 |

| 5 | Diode schottky 1A 100V | 2 |

| 6 | Capacitor- .1uF, 1206SMD | 10 |

| 7 | Capacitor- 10uF, 1206SMD | 2 |

| 8 | Capacitor-100uF, 1206SMD | 2 |

| 9 | Capacitor-100uF, through hole electrolytic | 10 |

| 10 | Crystal-20MHz SMD | 1 |

| 11 | Resistor- 1 Kohm SMD1206 | 8 |

| 12 | Resistor- 10 Kohm SMD1206 | 8 |

| 13 | Resistor- 0 ohm SMD1206 | 30 |

| 14 | LED SMD1206 | 12 |

| 15 | LED through hole | 3 |

| 16 | Push button switch SMD | 1 |

| 17 | ISP Header | 1 |

| 18 | Male -Female Header 1X20 | 3 |

| 19 | Push button switch 6mm | 1 |

| 20 | 9V Battery snap | 1 |

| 21 | 16x2 LCD Display | 1 |

| 22 | 9V Battery | 1 |

| 23 | 12v bipolar Stepper with threaded rod | 4 |

| 24 | 12V bipolar Stepper 1 | 1 |

| 25 | Anodized smoothe aluminium rods | 12 |

| 26 | Spacers | 12 |

| 27 | Nichrome wire 32 AWG | 5 m |

| 28 | Chloroform solvent for sticking acrylic | 5 m |

| 29 | Bus wires 10 wire | 5 m |

| 30 | m8 screws | 20 |

m. Summary

- Answered all questions regarding the development of the final project.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.