|

Groupwork

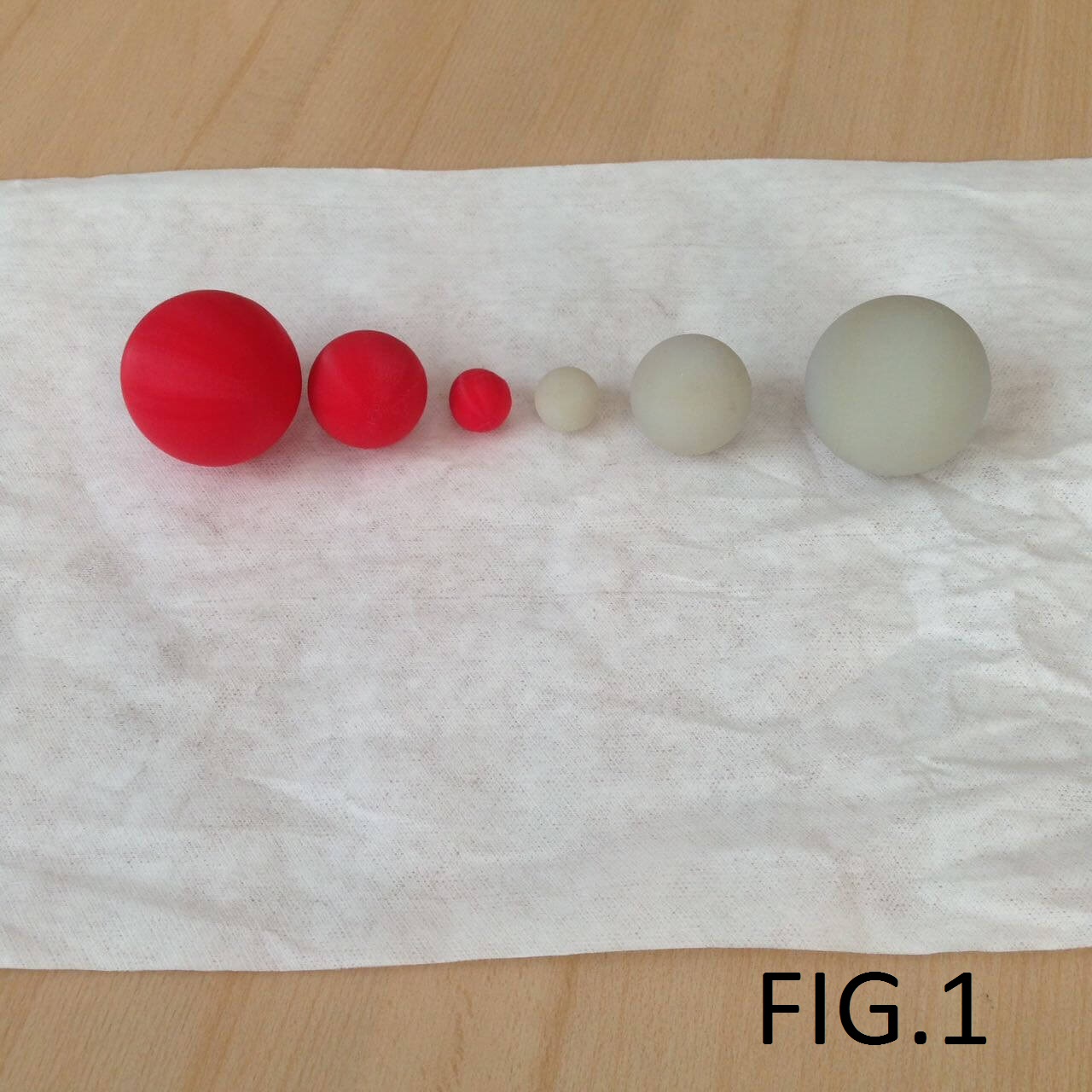

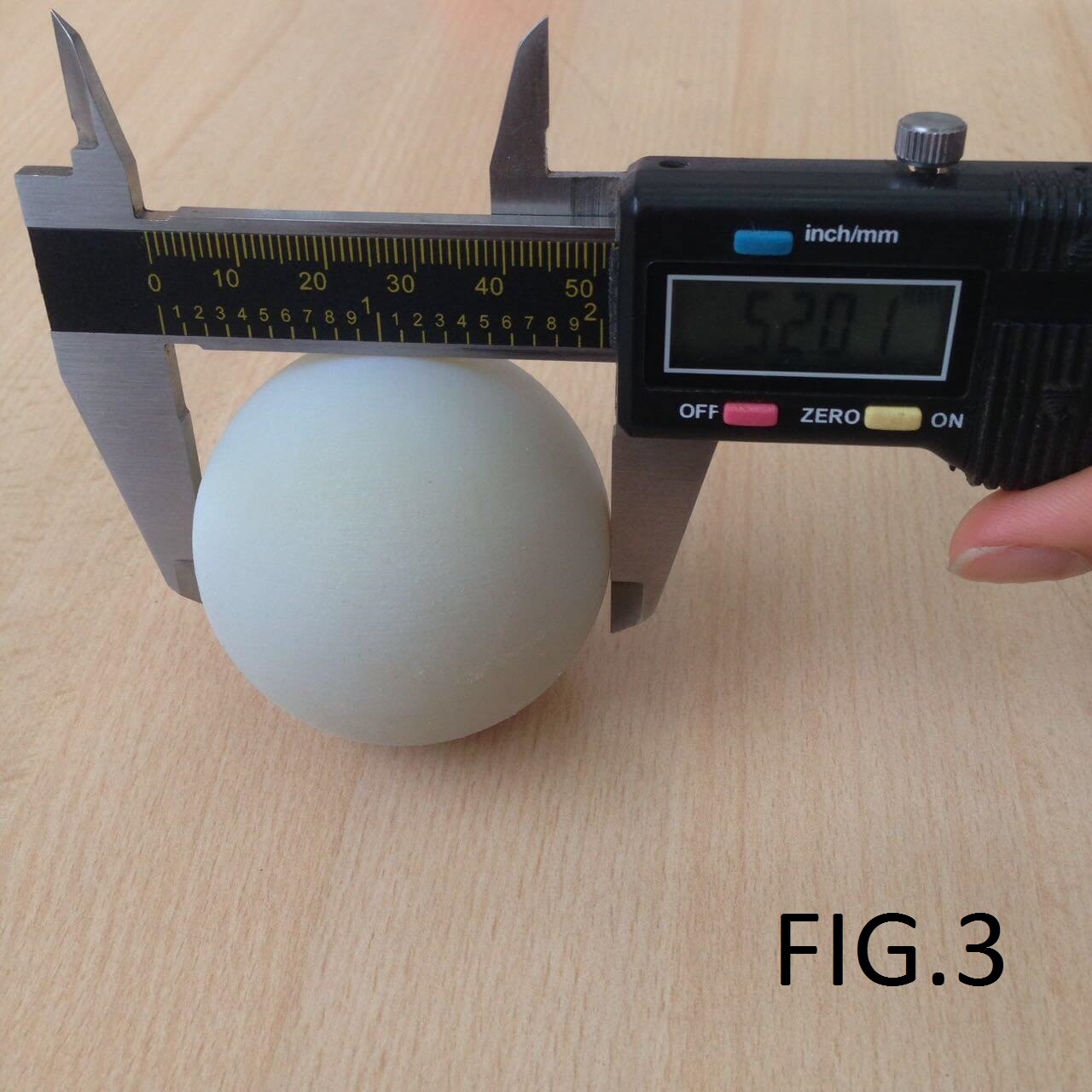

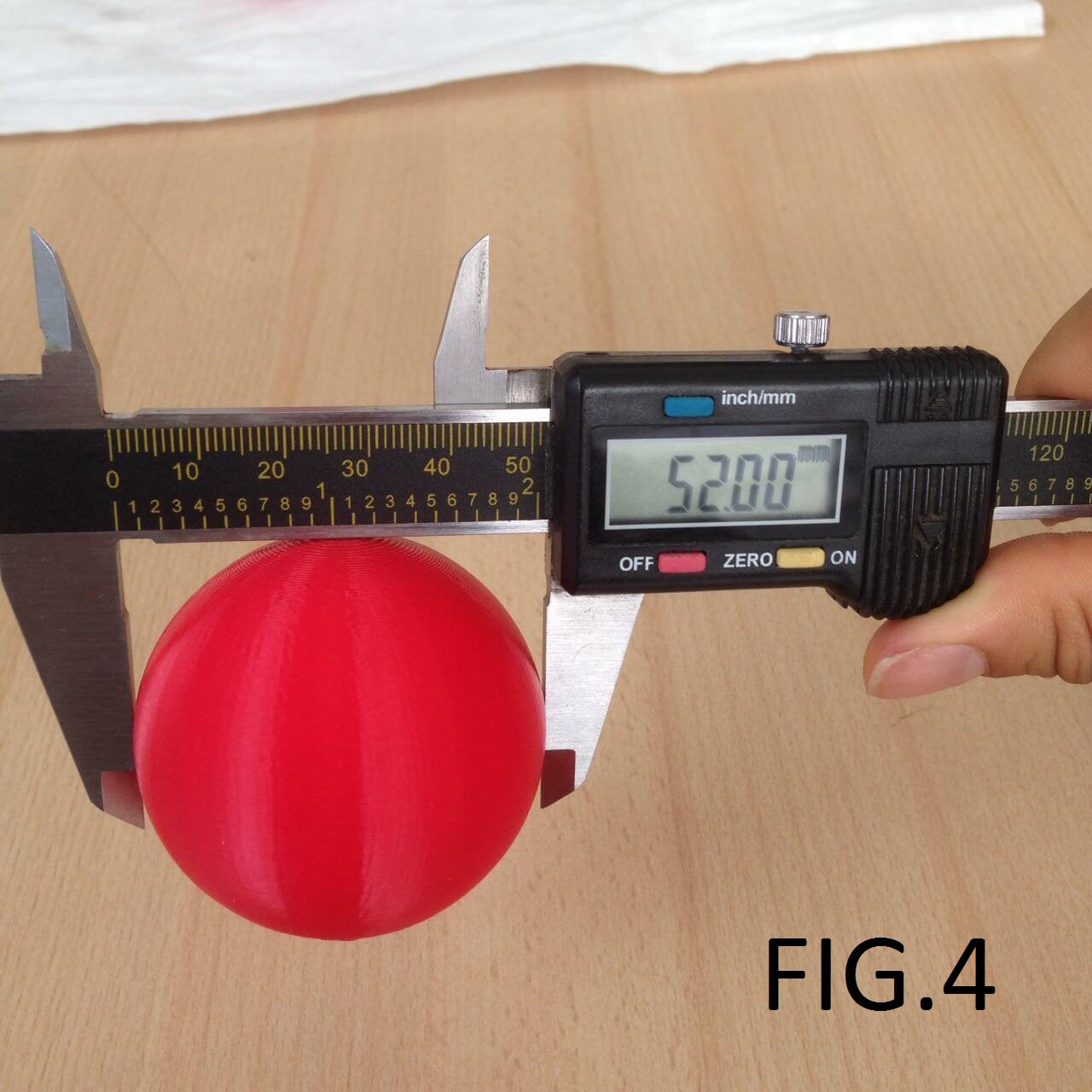

In this workgroup we printed different diameter spheres, both in resin and filament. We were looking for difference in finishing, weight, strenght, accuracy and support creation.

We used a Stratasys Objet 30 and Makerbot printer for resin (Vero Grey Material) and filament (Red ABS filament). Here are the results:

Finishing: Resin materials are really beatifull. The Objet30 prints thickness down to 26µ, allowing to have smooth organic surface. On the other hand, filament material

is not the best option for complex surface having rought surface and a stair-like form (Figure 5).

Weight: Here filament is the best. The Objet 30 printer doesn't allow to create inner structures (like filament does) to reduce material consumption but a solid piece,

this makes this kind of technology really expensive. Even if we design the piece to have an inner structure to save some material, this "hole" would be filled with support material,

in this case, a gel-like material.

Strenght: Resin materials like Vero, are very fragile. They are hard enought for low stress application, but will break if hit the floor for example. In this case, ABS material is

better suited due its mechanical properties.

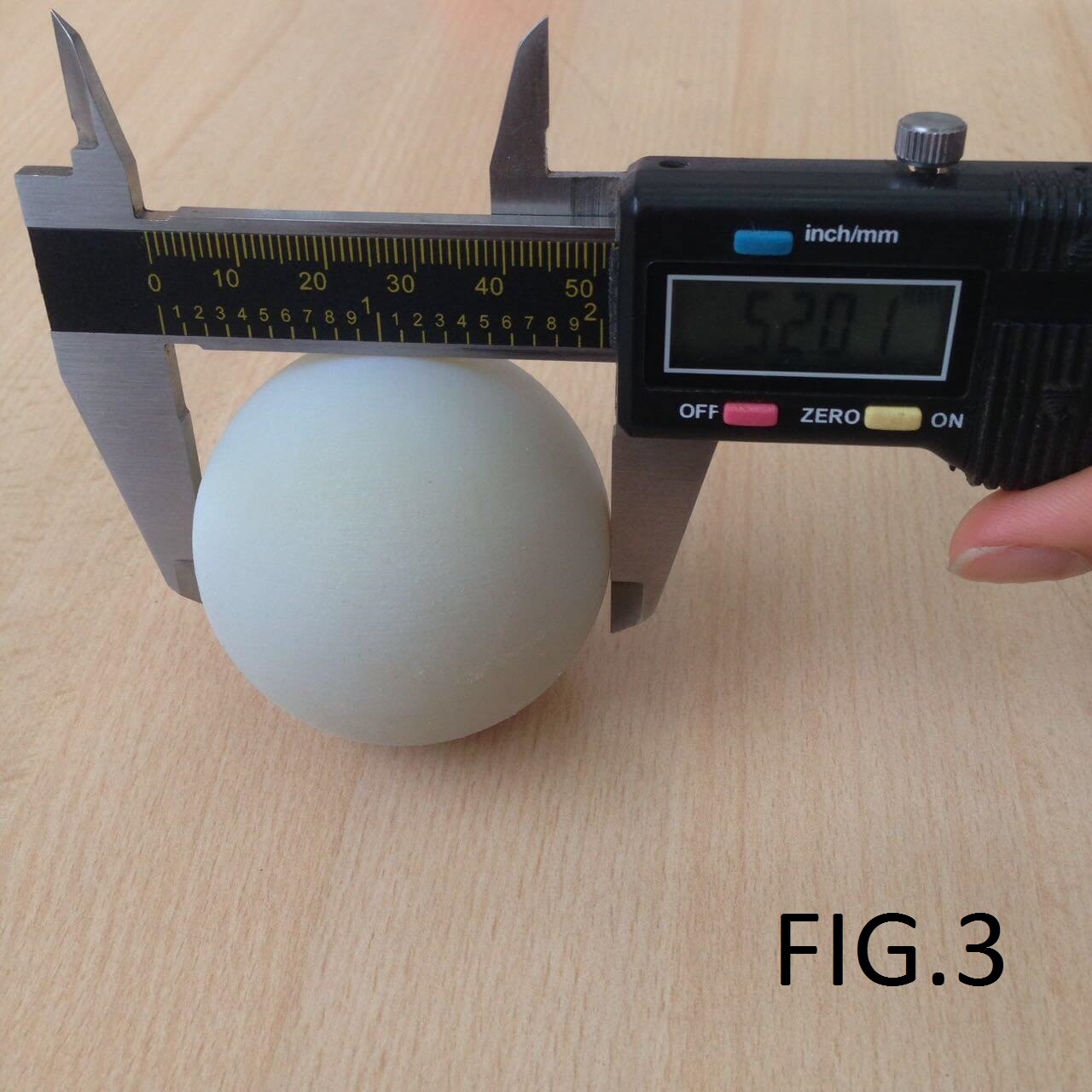

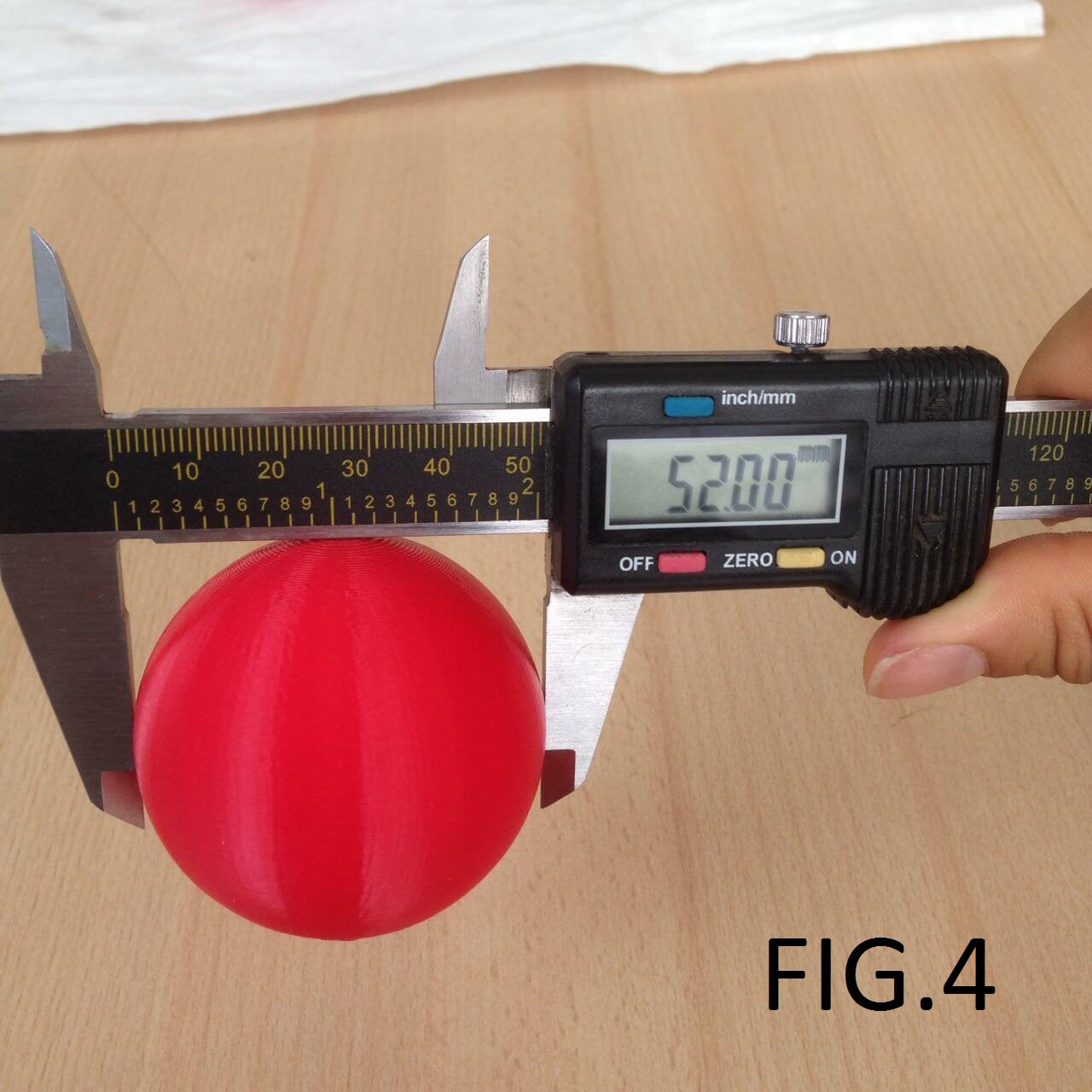

Accuracy: Usually, this topic is more related to the printer rather than the material. The Objet printer is much more accurate than the Makerbot, but for small pieces its not a big

issue.

Support: In Makerbots printers, the building filament serves as support material. The printer usually will decide to put supports where there is a "roof" or a wall have less than 45

degrees (measuring from the floor). In some cases (like this one), support material is no necessary because each layer of filament can support the next one. For resin things are different,

the printer will put support everywhere there is a hole between the material and the floor or other material; in other words there will be material in every angled wall and/or "roof".

|

3DPrint

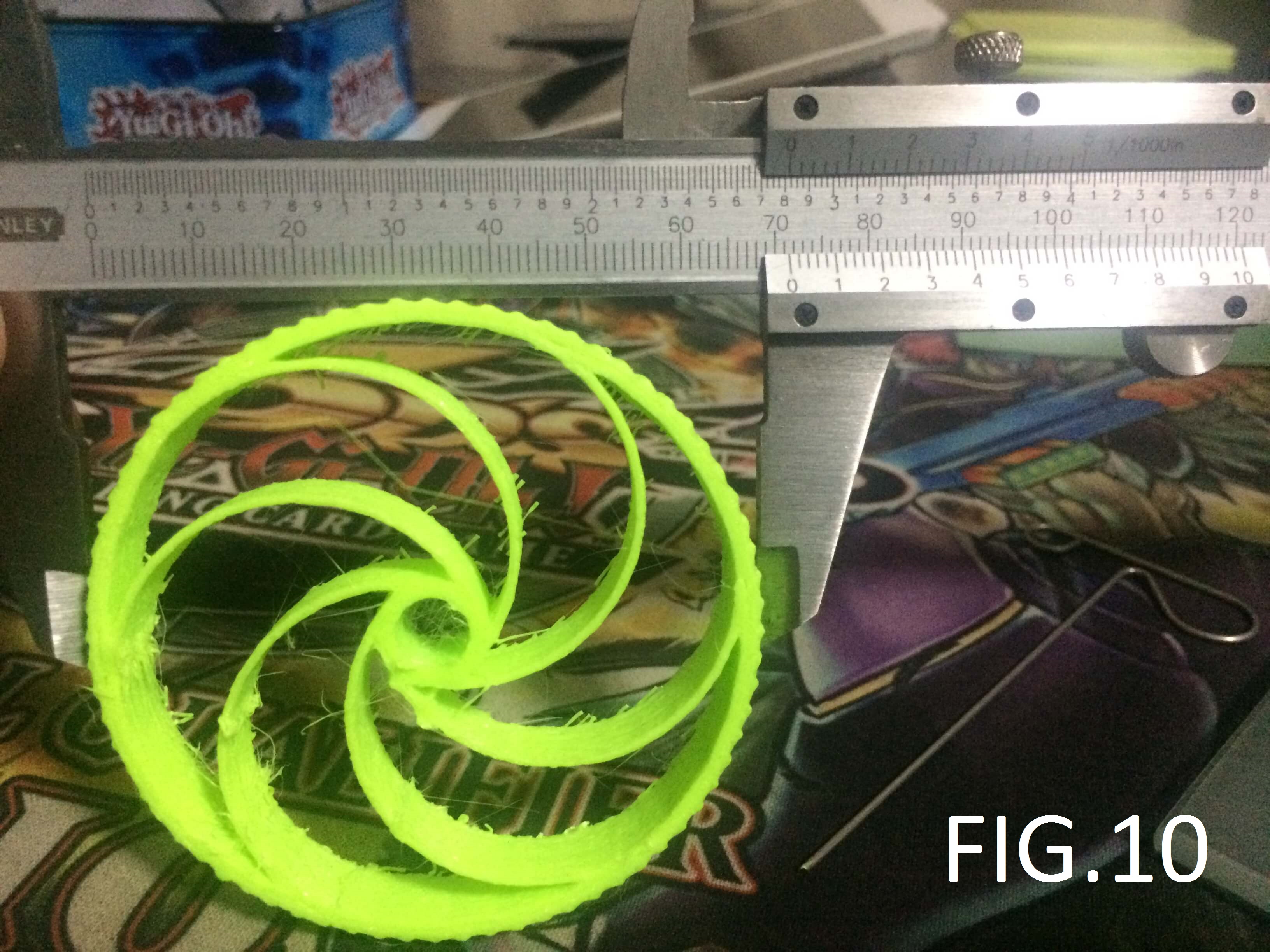

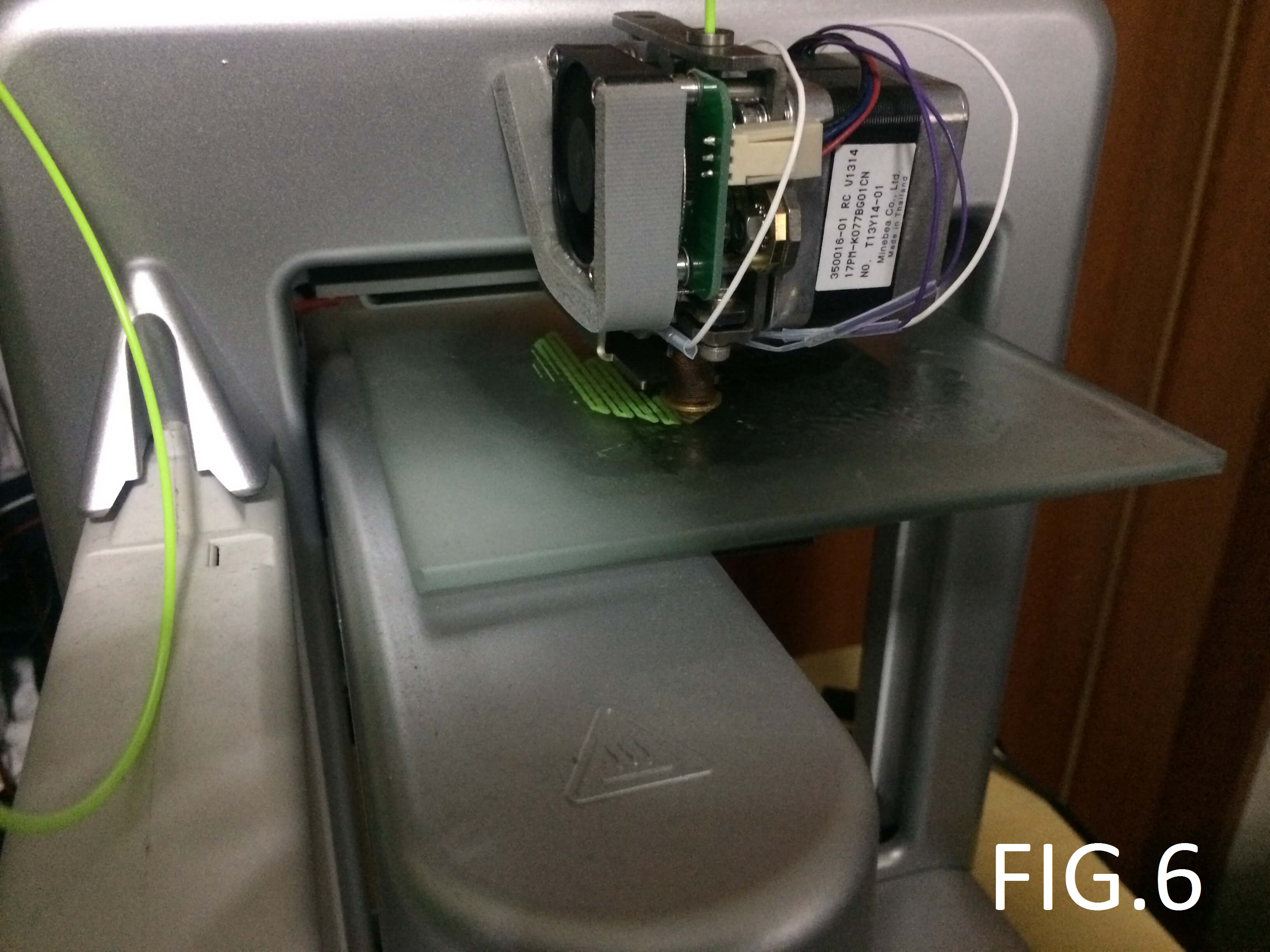

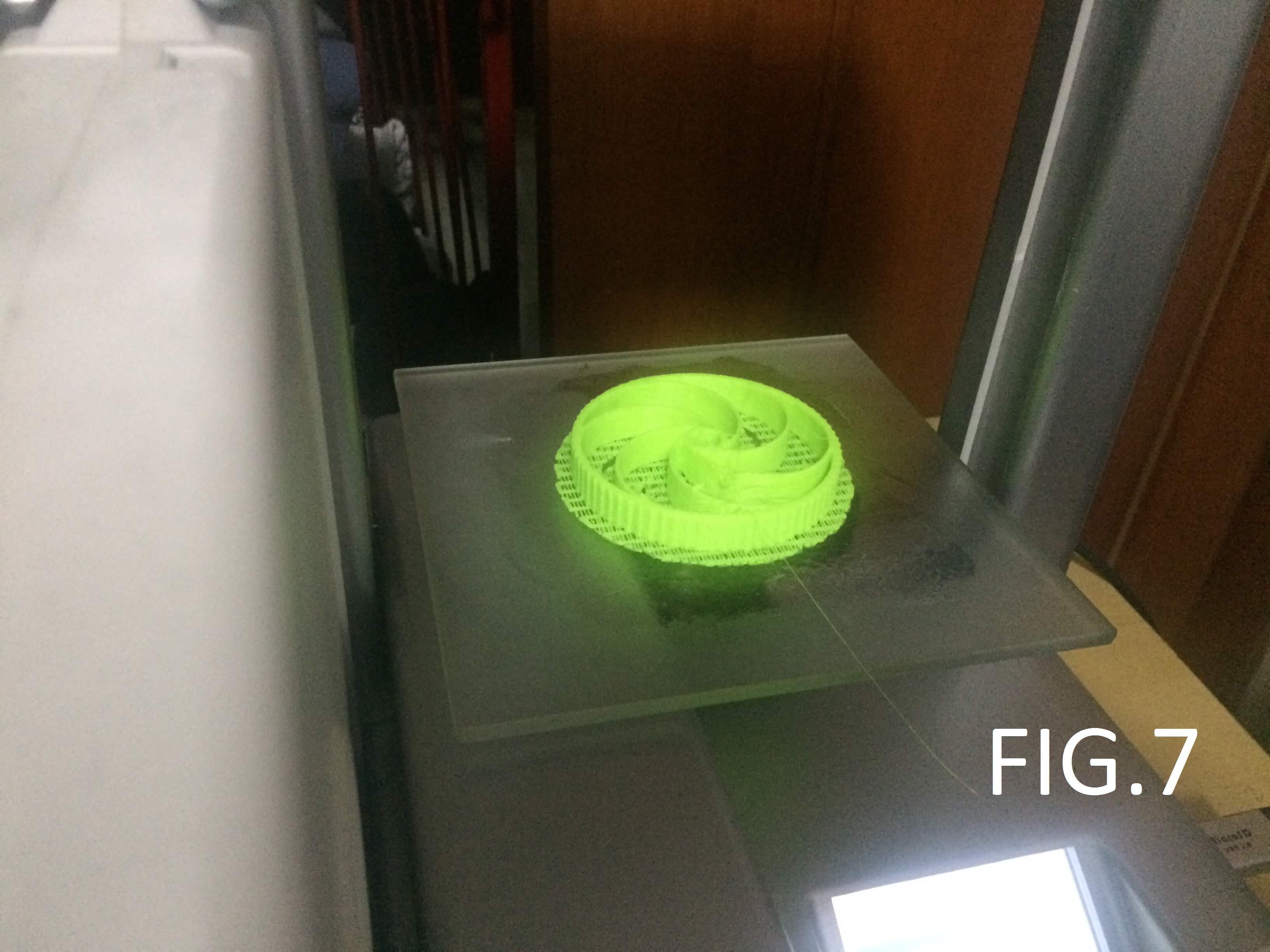

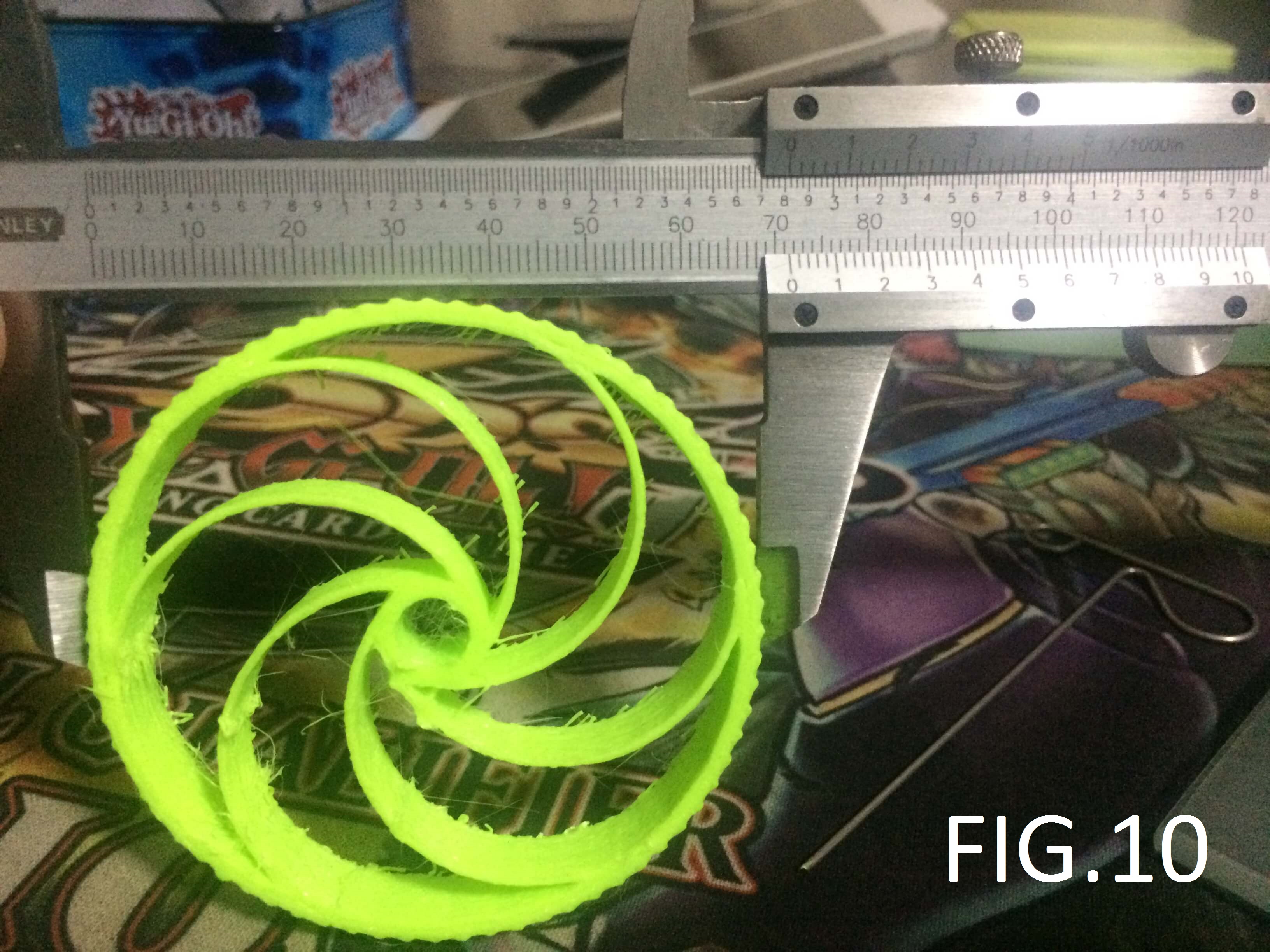

In this week, I'm going to print one wheel for my final project (you can check it here). I want to explore different ideas for every component of my RC car, and

wheels is one thing really want to be different. I went to thingiverse and looked several ideas for RC car wheels and choose one that looks simple but interesting. After download it,

check it using 3D builder (a pre-installed STL viewer on Win10) and confirmed it have a desired dimensions. Load it to my printer and started. Click here for download.

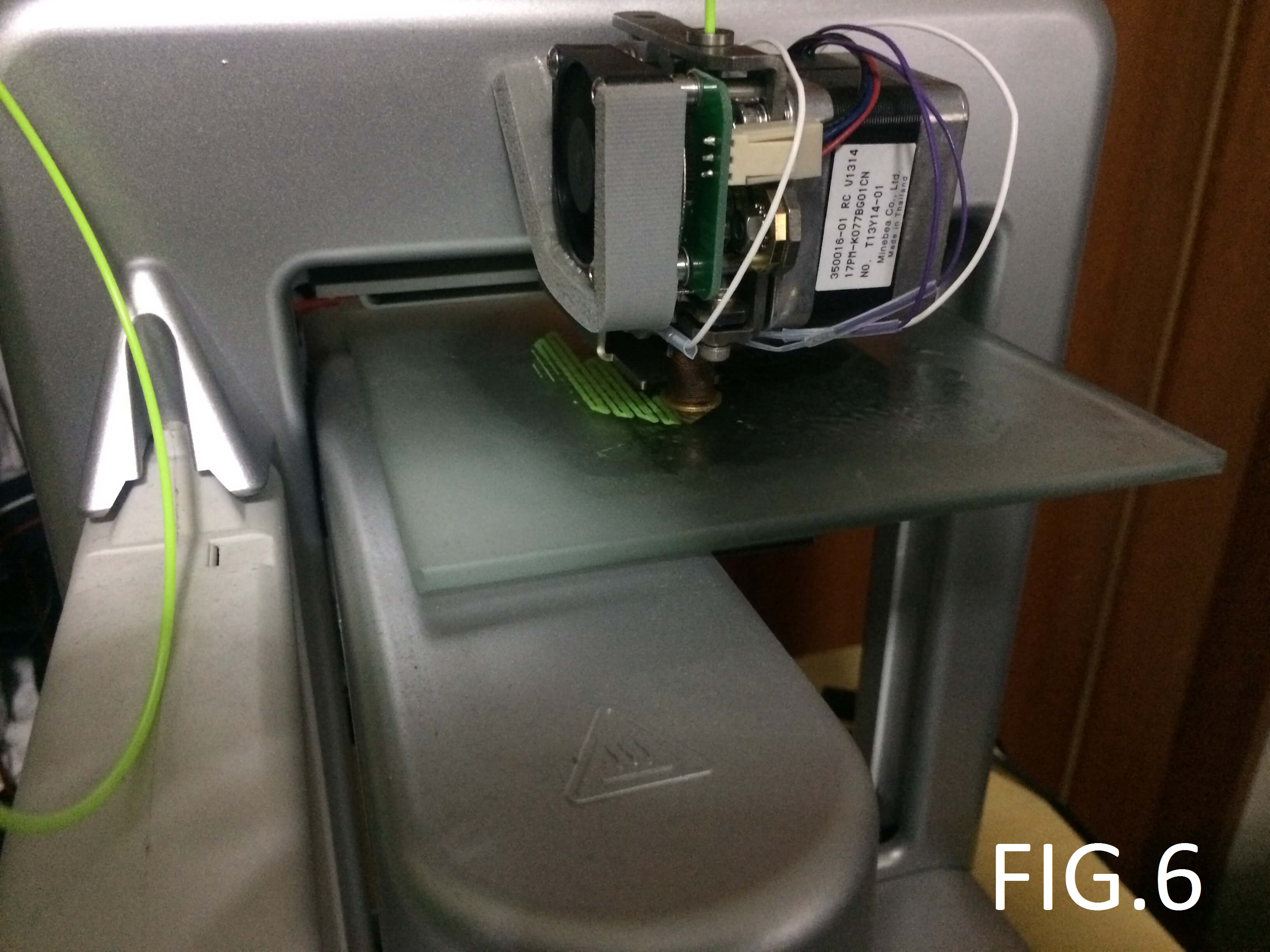

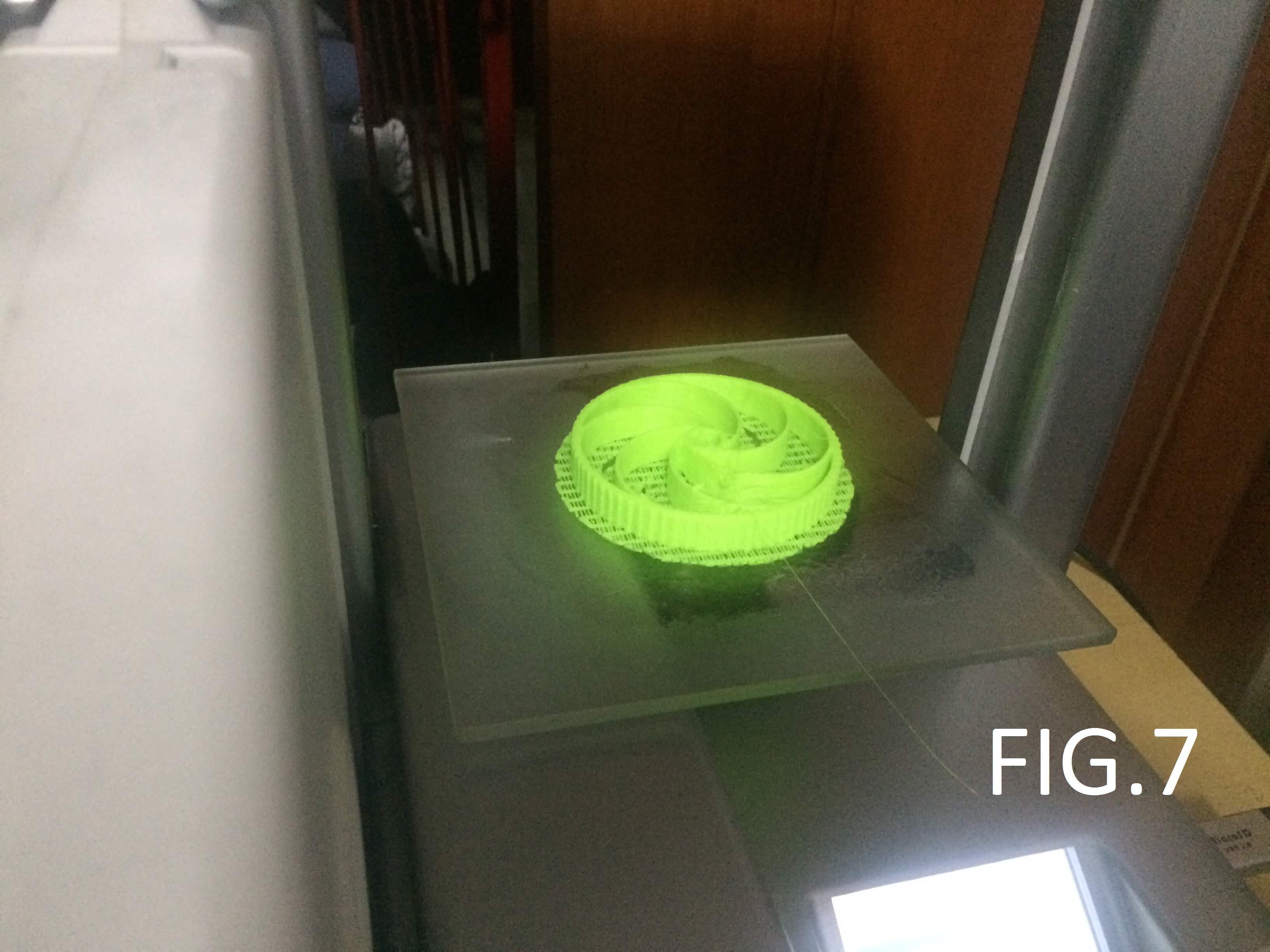

For this assignment I'm using a 3DSystems Gen 2 Cube printer with PLA material. This printer allows me to select between PLA and ABS materials and also to add raft and support. Also allows to

select 3 different infills for your project. Selected raft creation and "almost solid" infill. After 1 hour and a half, I had my print

Comments

It was a easy piece. Most of it is self supported, which makes easier for clean (only need to take off the raft). Due to it simple form, filament was perfect for the job.

The print measure marked 70.8 mm, that means a 0.01% error of its desing value.

|

|