WEEK14-COMPOSITE

I want to make a sea shell this, first is 3D model design, then cut it to pieces in 123d make, the shell was cut by laser cut, the shell was mold by fiber and glue.

Part 1 3D Model Design

- I deceide to cut the 3D model by laser cut, but before cut I need design the sea shell model. Open the 3D model design software CREO, and design it.

- Design the shield. Shell file Download

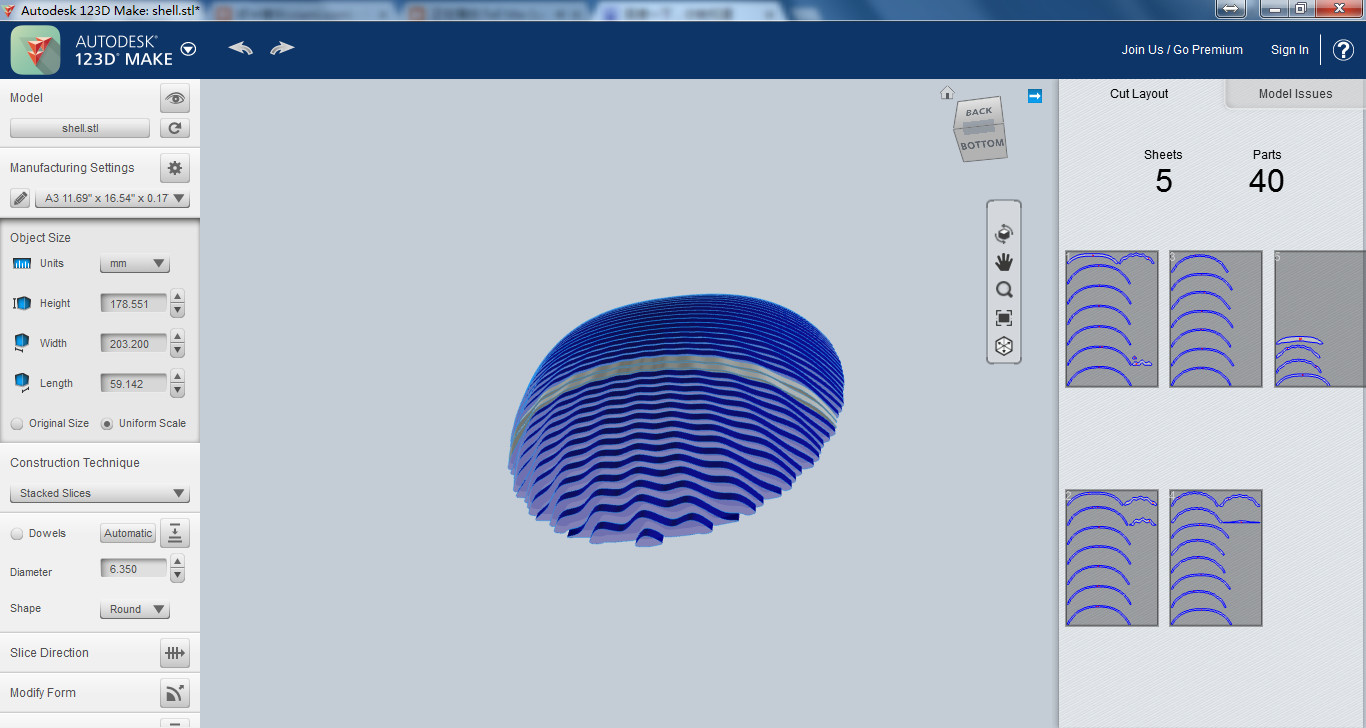

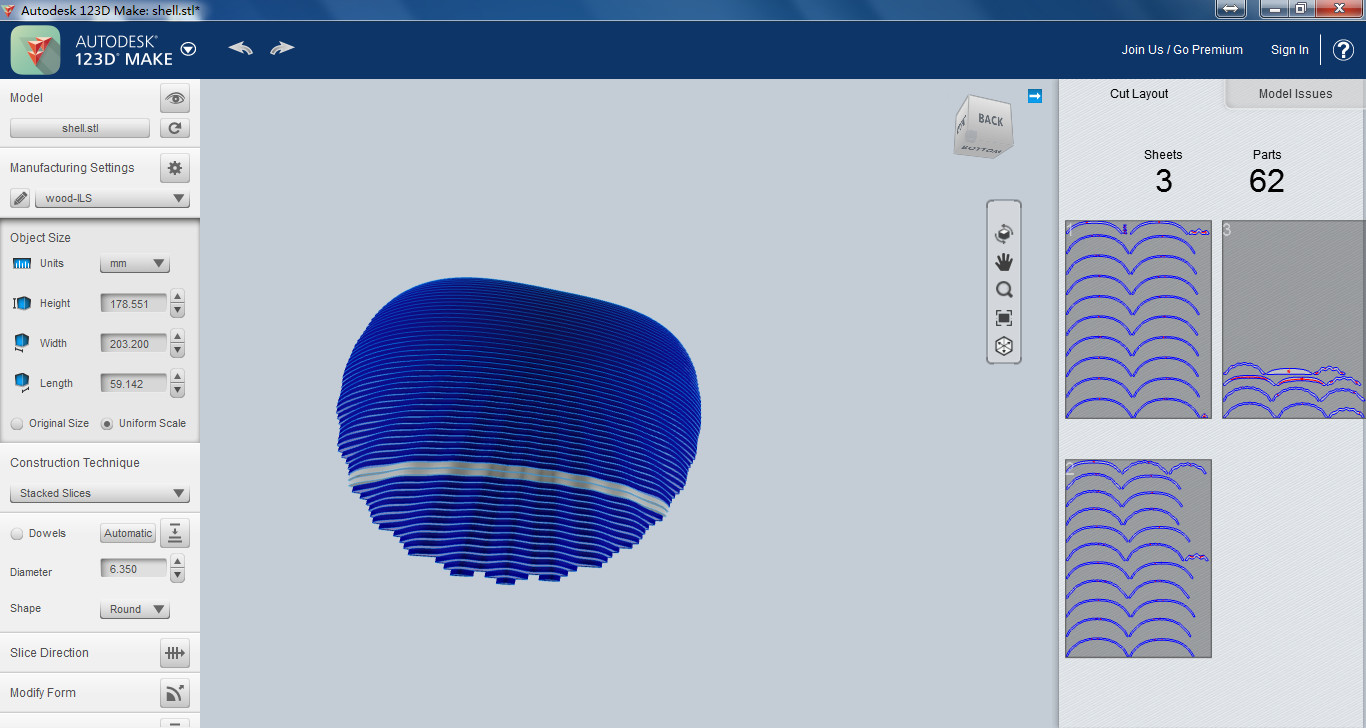

- 1. Open 123D make software it need seconds.

- 2. Click on import, choose shell.stl file.

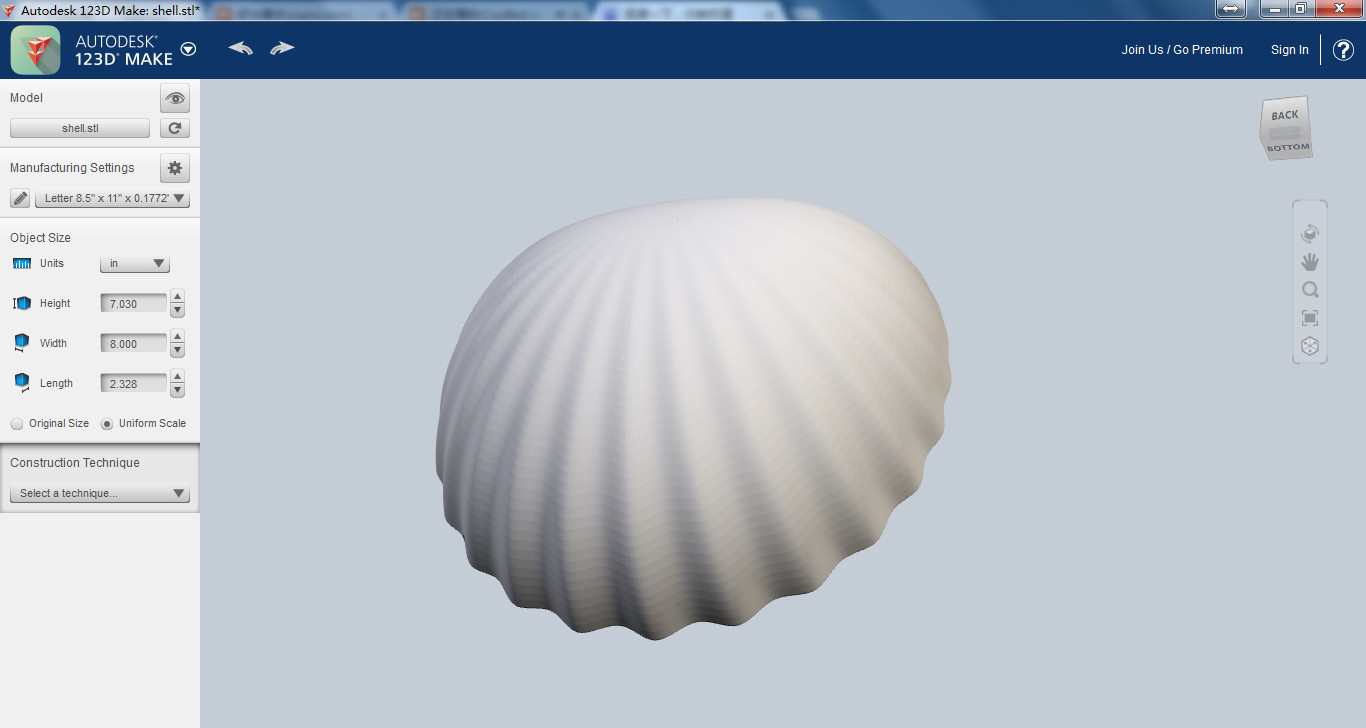

- 3. A nice seal shell was imported to the software.

- 4. Choose the units as mm and set construction technique as stacked slices, the shell can be precisely constructed in this construction .

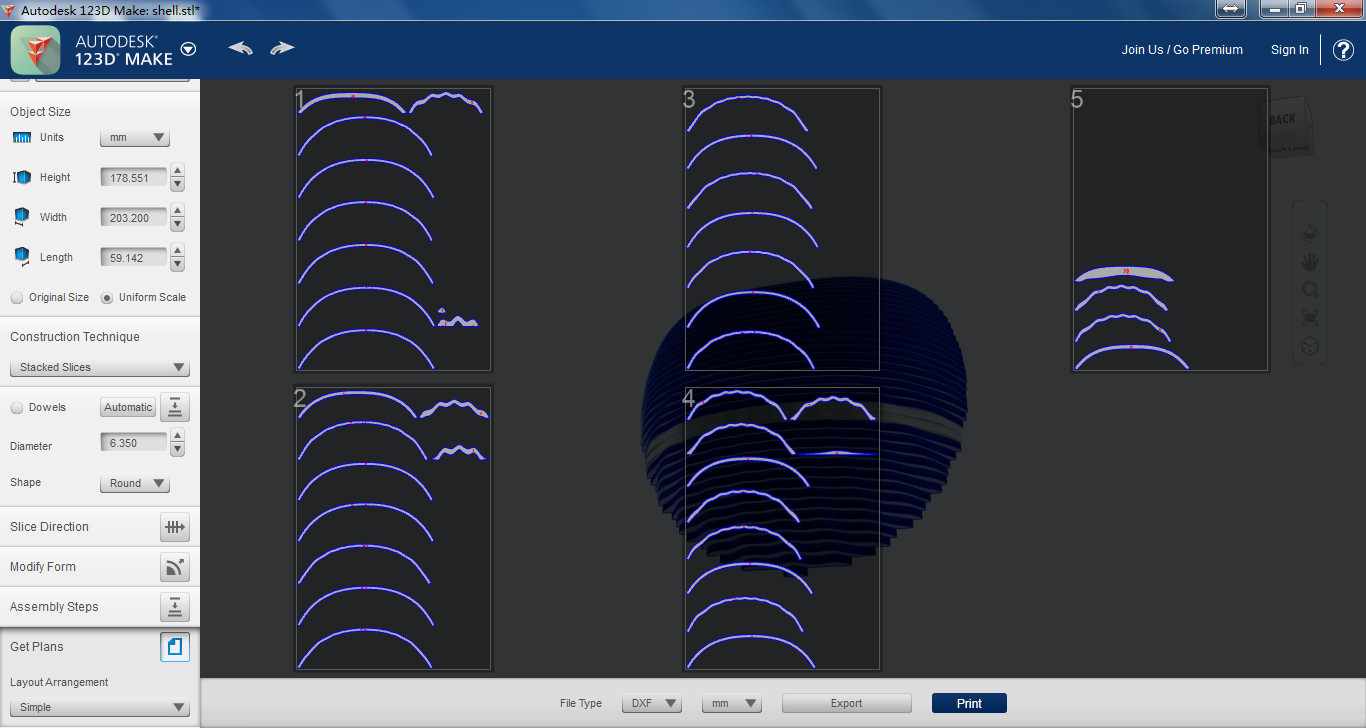

- 5. Click on get plan the software will process a 2d file, choose dxf and export the file, you need login in autodesk account, if not the file can't be exported.

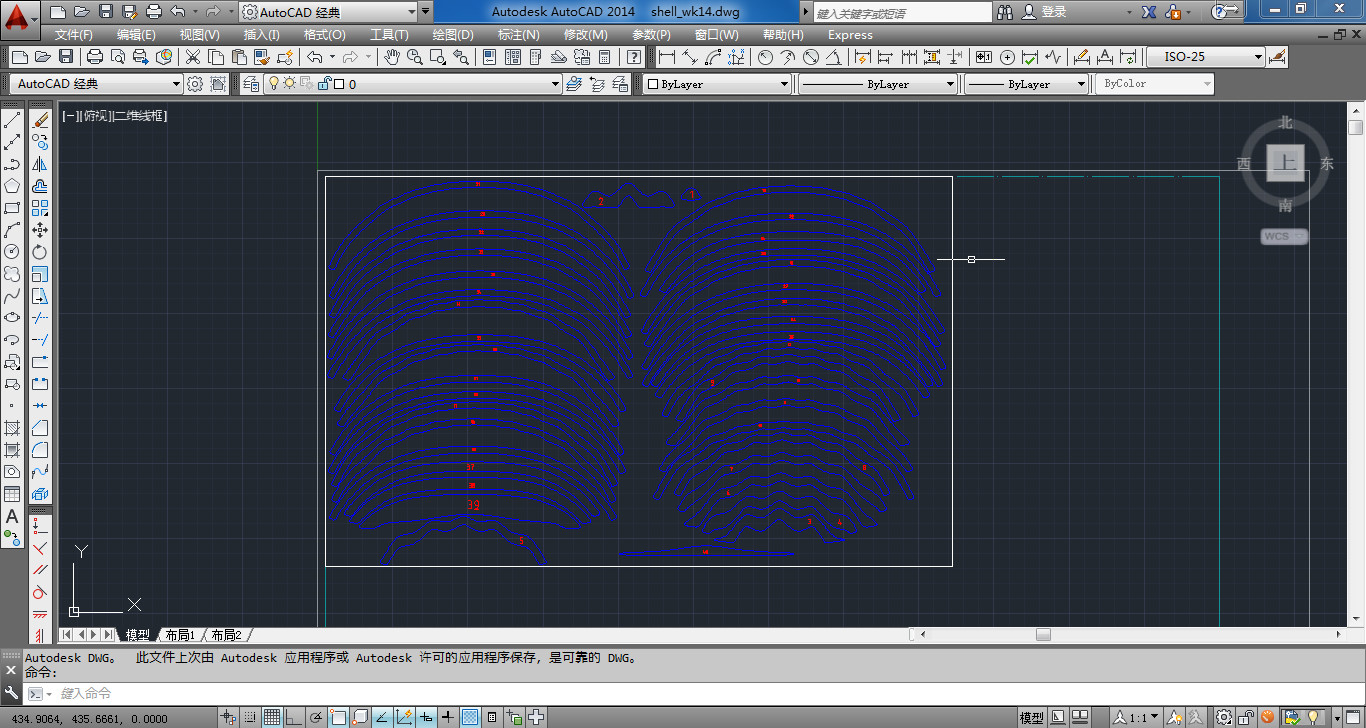

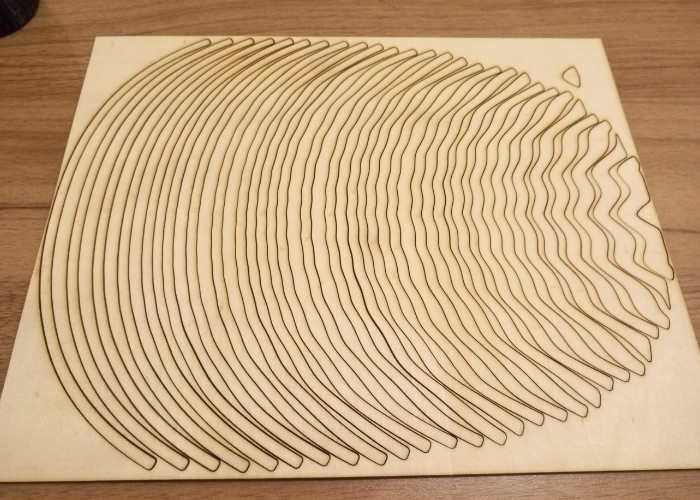

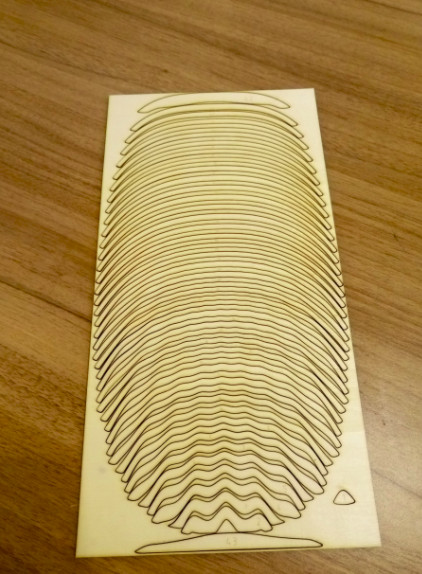

- 1. Open the export file with autodesk, and adjust the positon of vectorgraph.

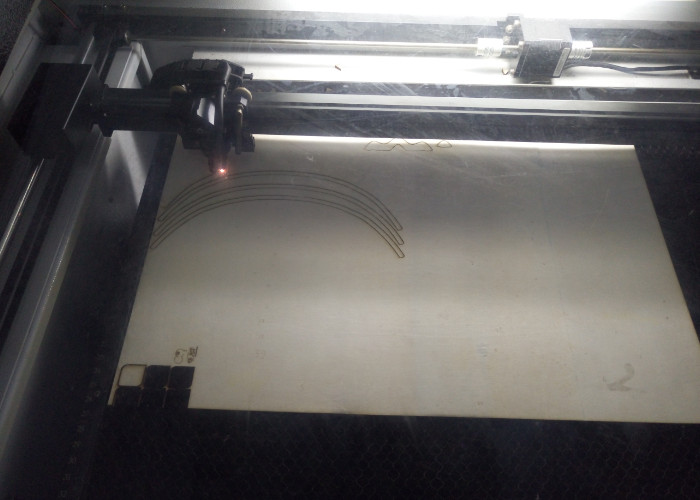

- 2. Set cutting parameters and send the file to laser cutter and cut it.

- 3. Wood was cut smoothly.

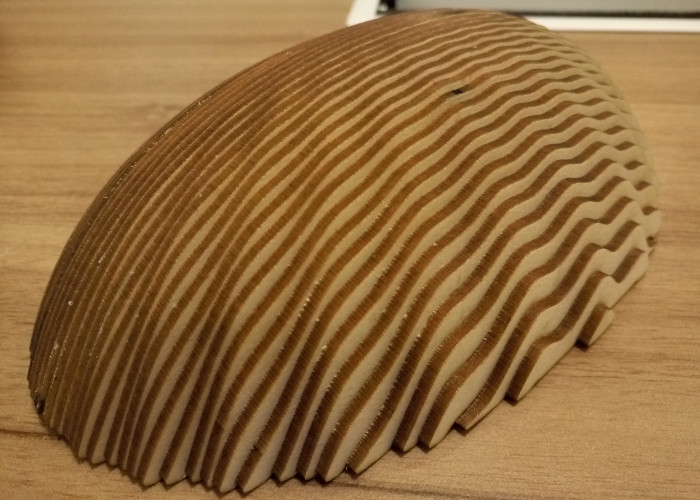

- 4.Need minutes to put the parts together, be patient and careful.

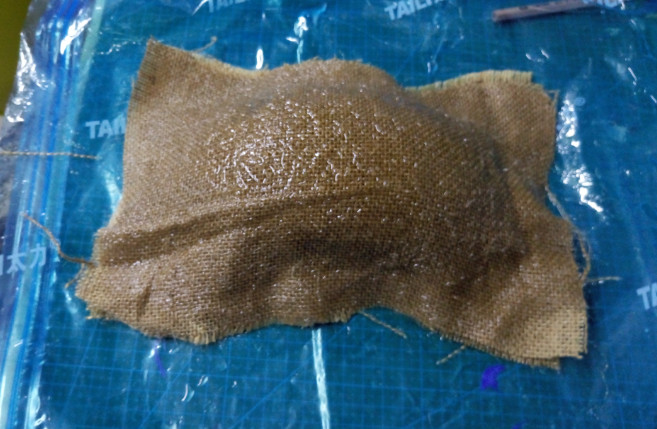

- 1. Prepare for molding cut three pieces fiber for molding.

- 2. Put plastic wrap on the model, this make the model be take off easily after the glue solidiy.

- 3. There are two parts glue for molding, the ratio is 3:1, put them in a cup.

- 4. Stir the glue, mix them completely.

- 5. Put the mixed glue on fiber and put it on the model, then put the glue on the second fiber put it on the first one, then the third one.

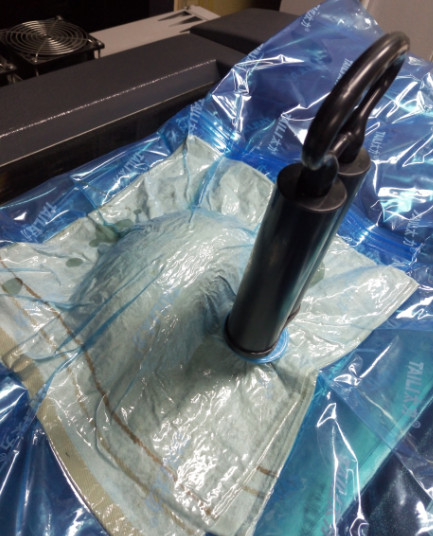

- 6. Put the model to a vacuum bag carefully, vacuumize by a vacuum cleaner or by a hand tool. It need 20-30 mins for initial solidficaiton, take a long time about 5-8 hours for completely solidfication. In first 30 mins check the bag one time in 5 mins, for the bag leakage very slowly.

- 7. Take it out of the bag on second day, it is complete solidficaion.

- 8. Take the model out, I want to cut the edge but it is hard to cut, that's because I put more glue on the fiber and two pieces fiber are enough. the fiber inside get the shape of shell but the outside didn't.

- 9. The edge of model was cut by saw, this make the model looks better.

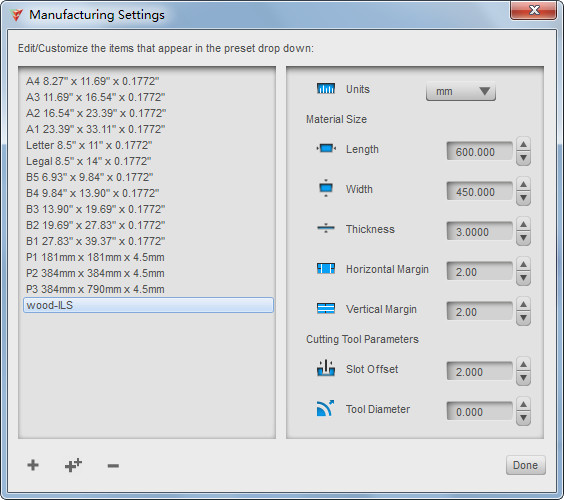

- Another problem about my model is the shell model like be compressed, so it looks like a half rugby. I find the reason at last I have to set the size of board here.

- Then 62 parts were need.

- Cut it by laser.

- Assembly them and stick them by glue.

Part 2 Creating 2D file

Part 3 Laser cutting

Part 4 Molding

The new shape is much better and it was showed in the picture before. But unfortunately I have no time to make a new composite.

The new shape is much better and it was showed in the picture before. But unfortunately I have no time to make a new composite.