WEEK07-COMPUTER-CONTROLLED MACHING

Part 1 Design

- 1. Design a chair.

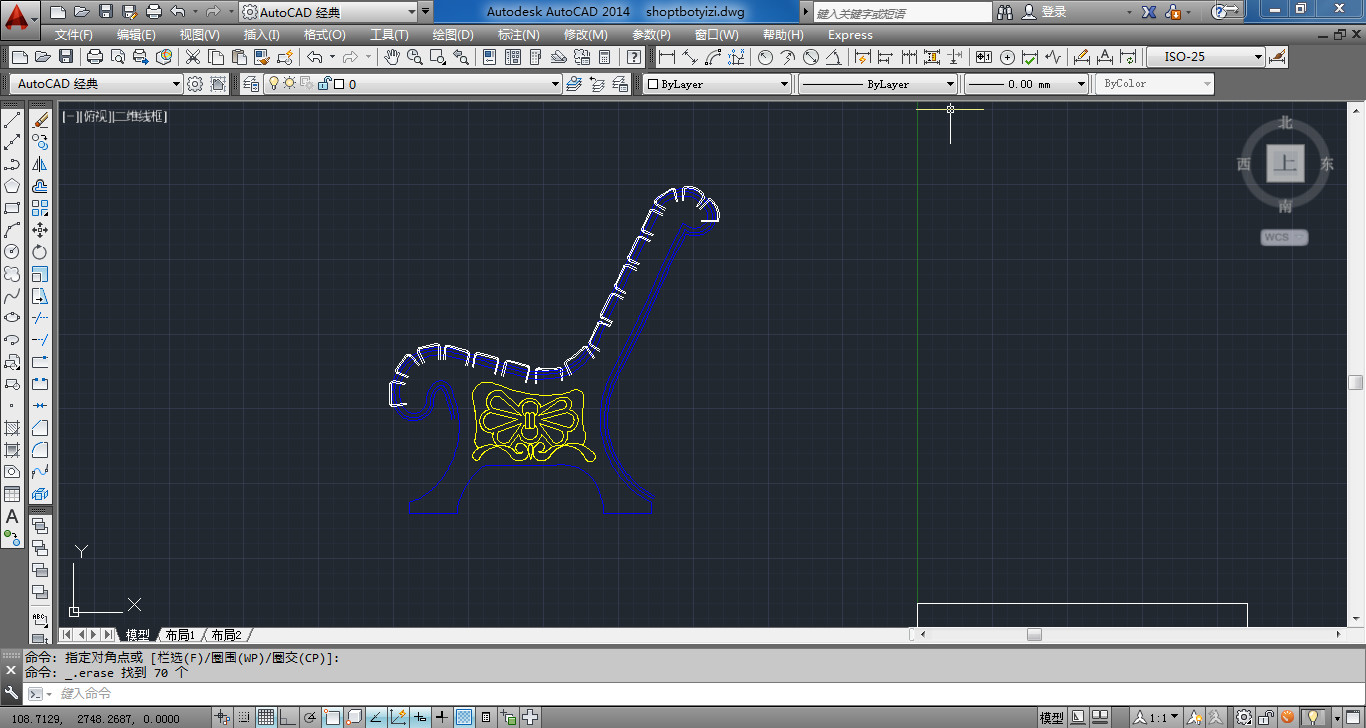

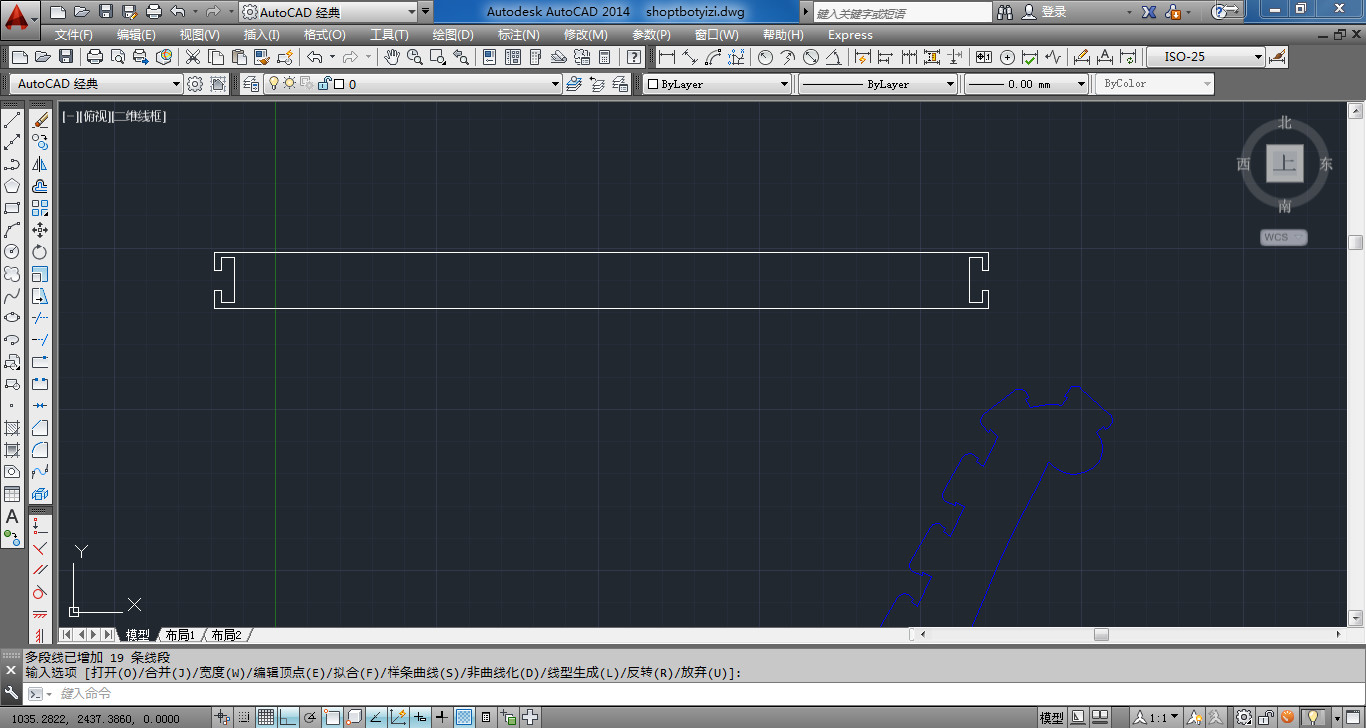

- The assignment of this week is make something big. Use big milling machine make big thing whatever you want. I like to design a chair. For the milling machine is good for cuting 2d model I design with 2D software. I prefer AutoCAD, and the format dwg or dxf can be recognized by almost all other software and the data won't lost. Design the side borard like this.

- The blue line is the shape of chair, yellow line should be engraving and the white is the joint for thwart.

- The line should be closed when cutting. The size of chair is 1100 mm X 1100 mm.

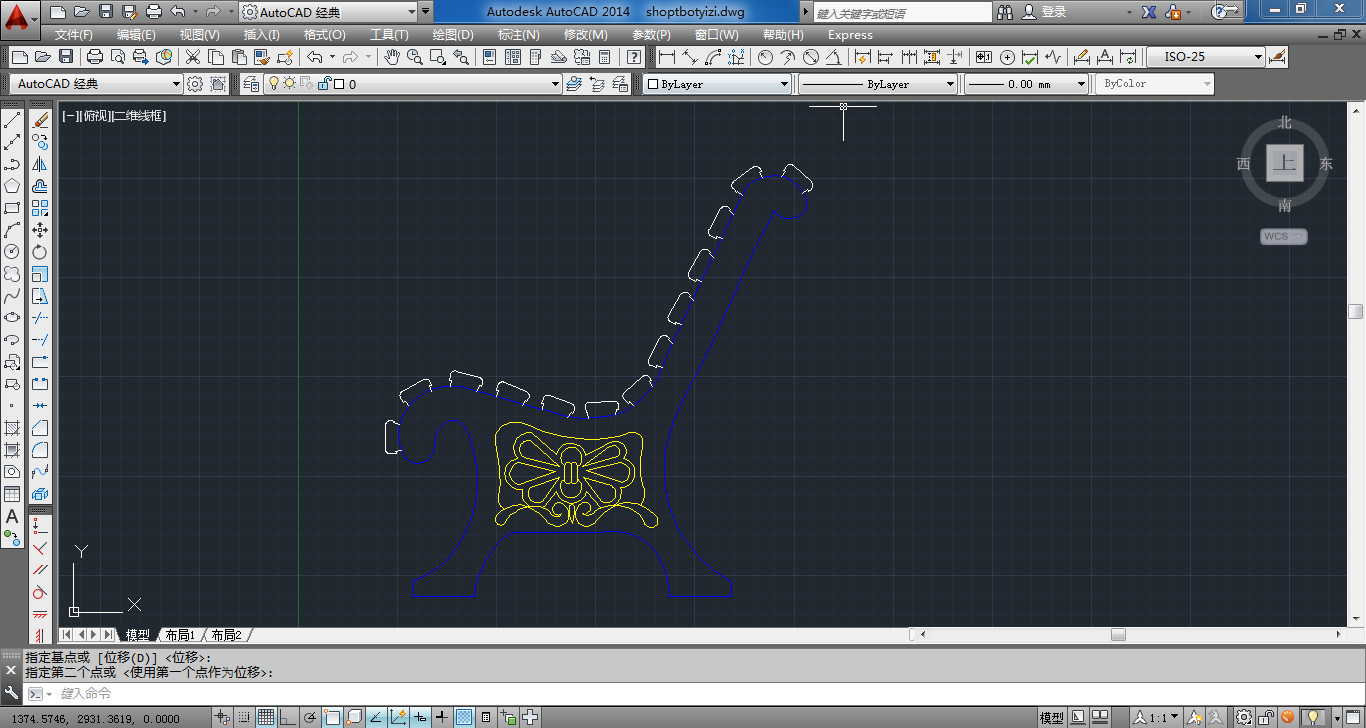

- 2. Thwart desgin.

- The chair has 13 thwarts, and the size is 1200 mm X 65mm.

- 3. Support board design.

- Two support boards will be assembled in the foot of chair.

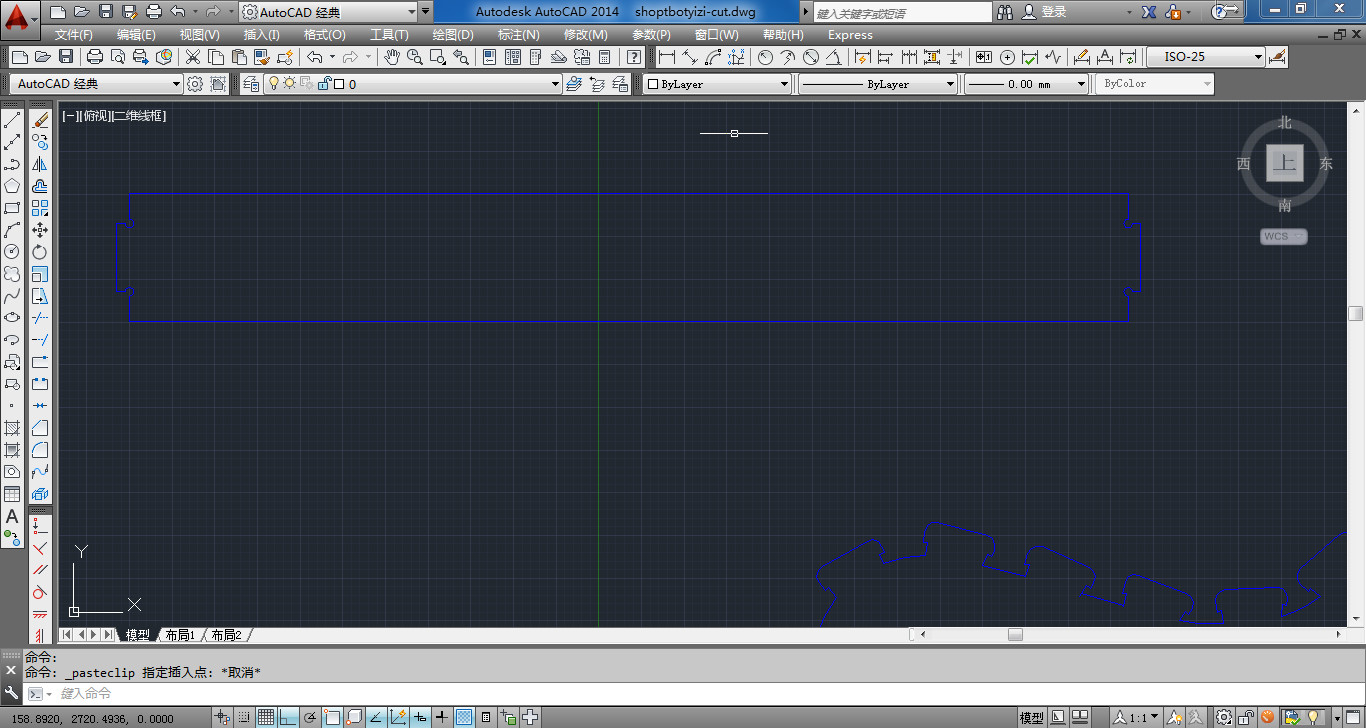

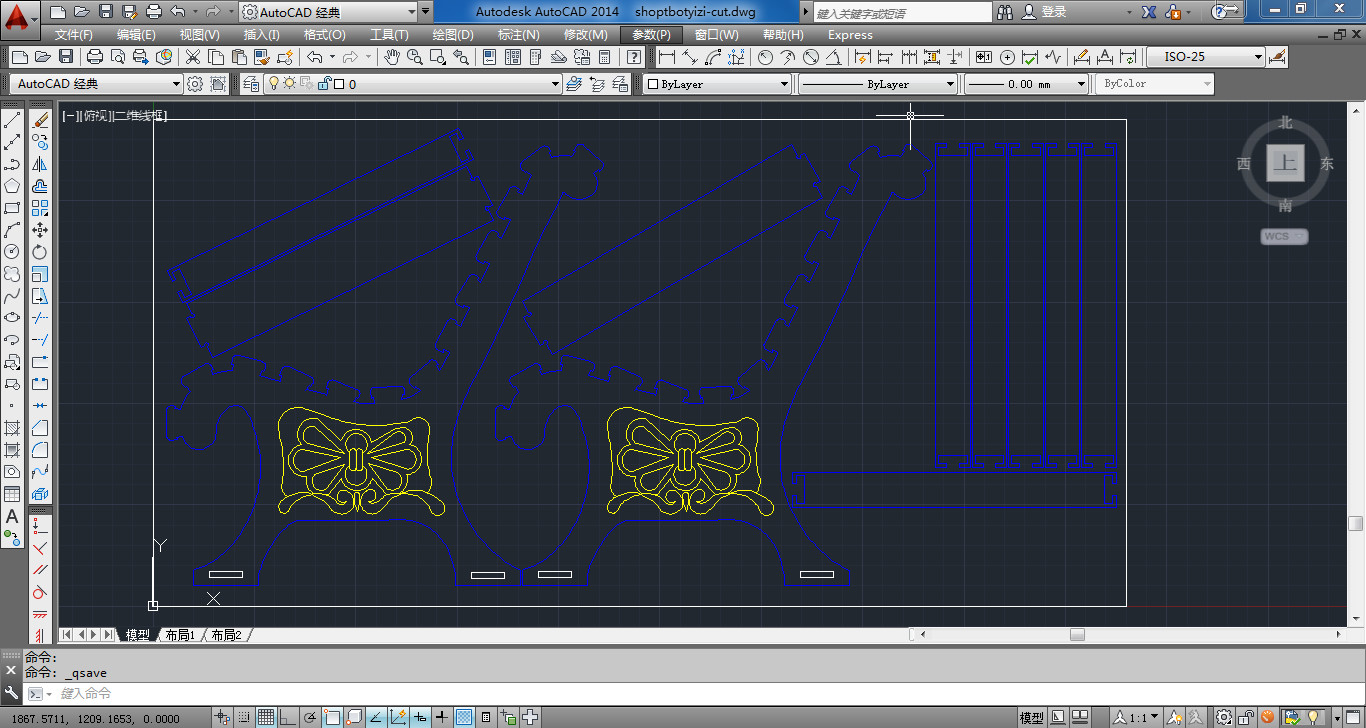

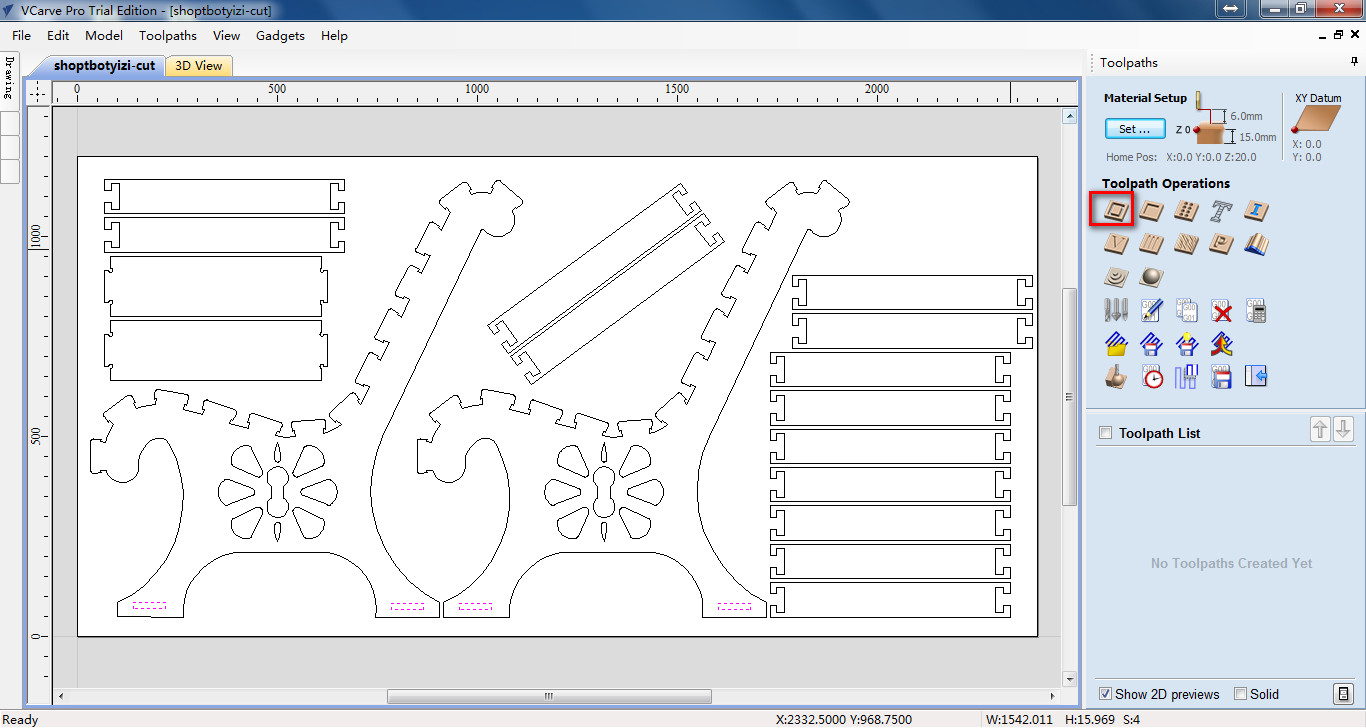

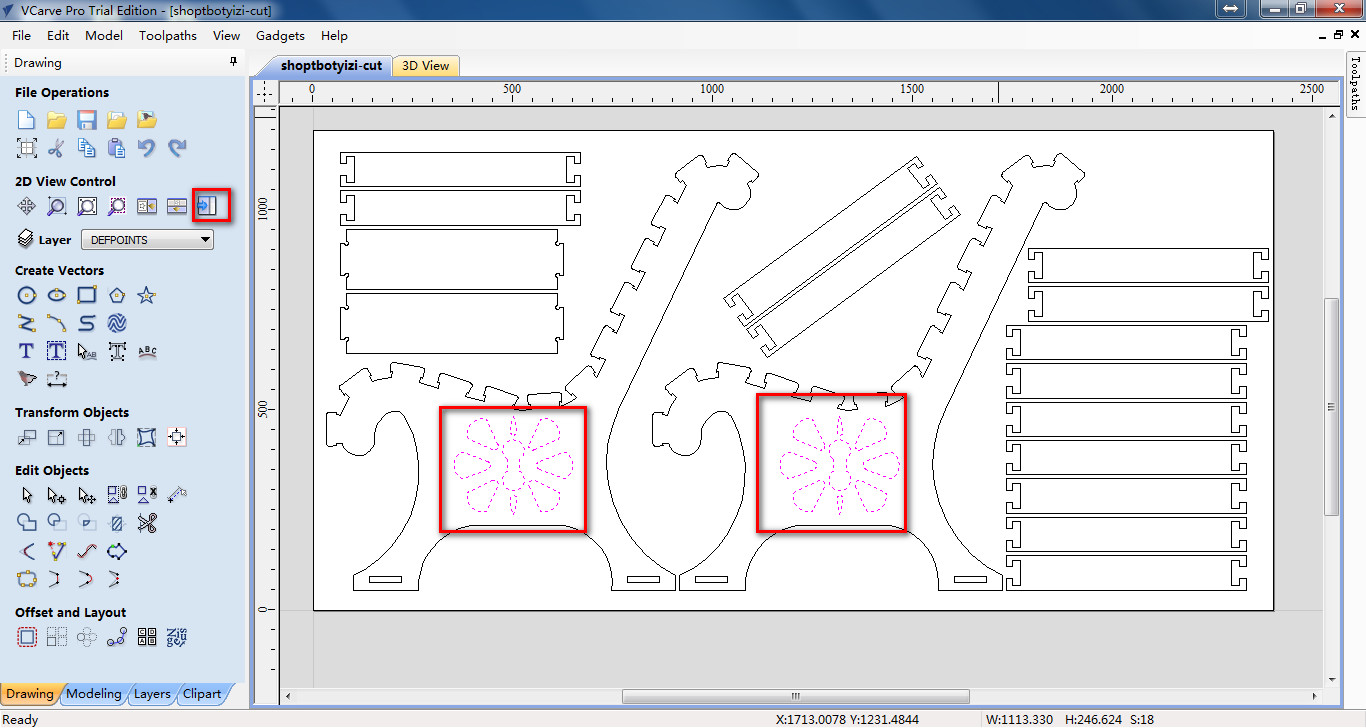

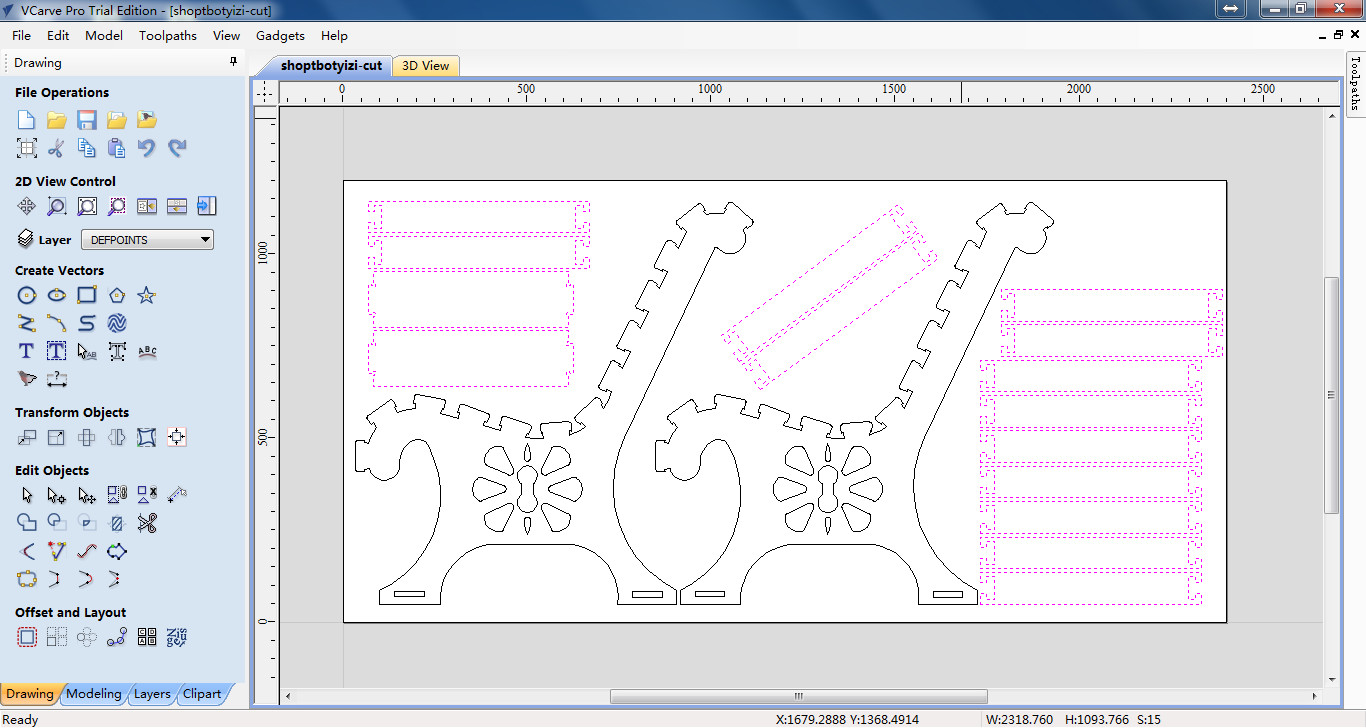

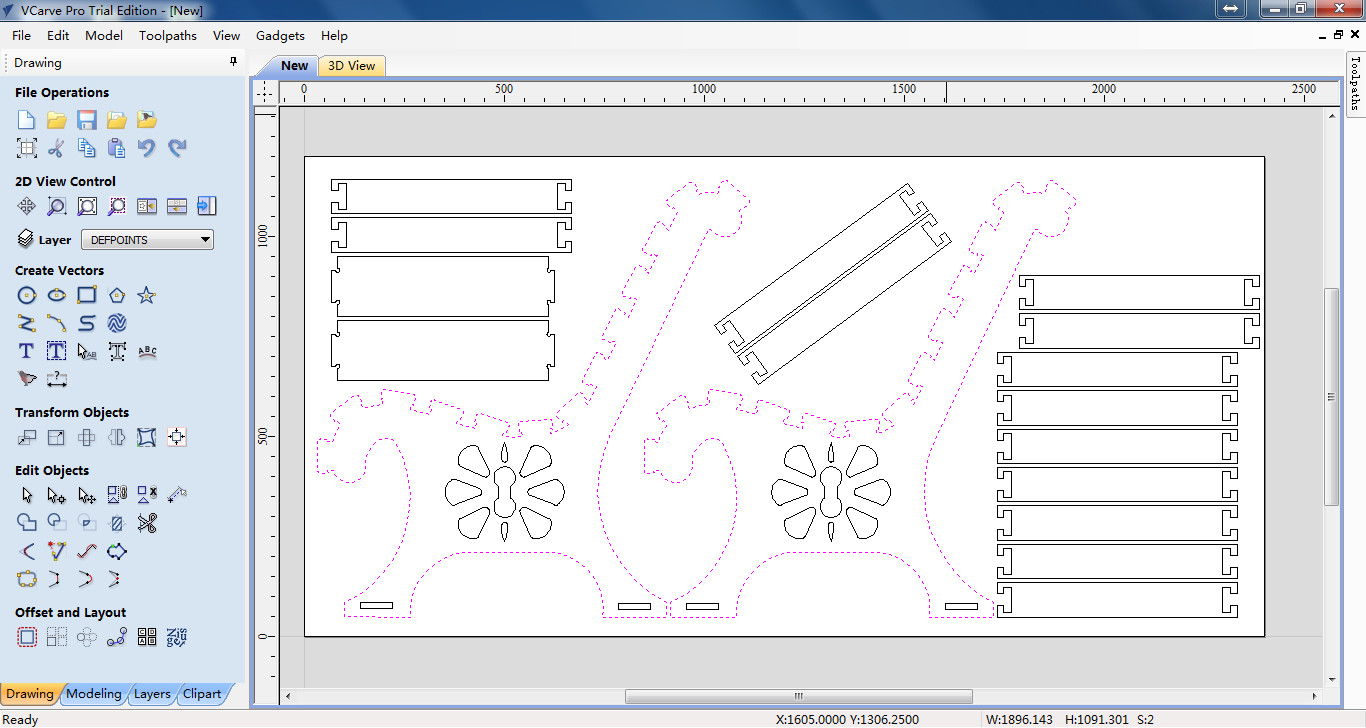

- All of elements of chair were design showed in picture. And they were arranged in rectangle which is 2400 mm X 1200 mm.

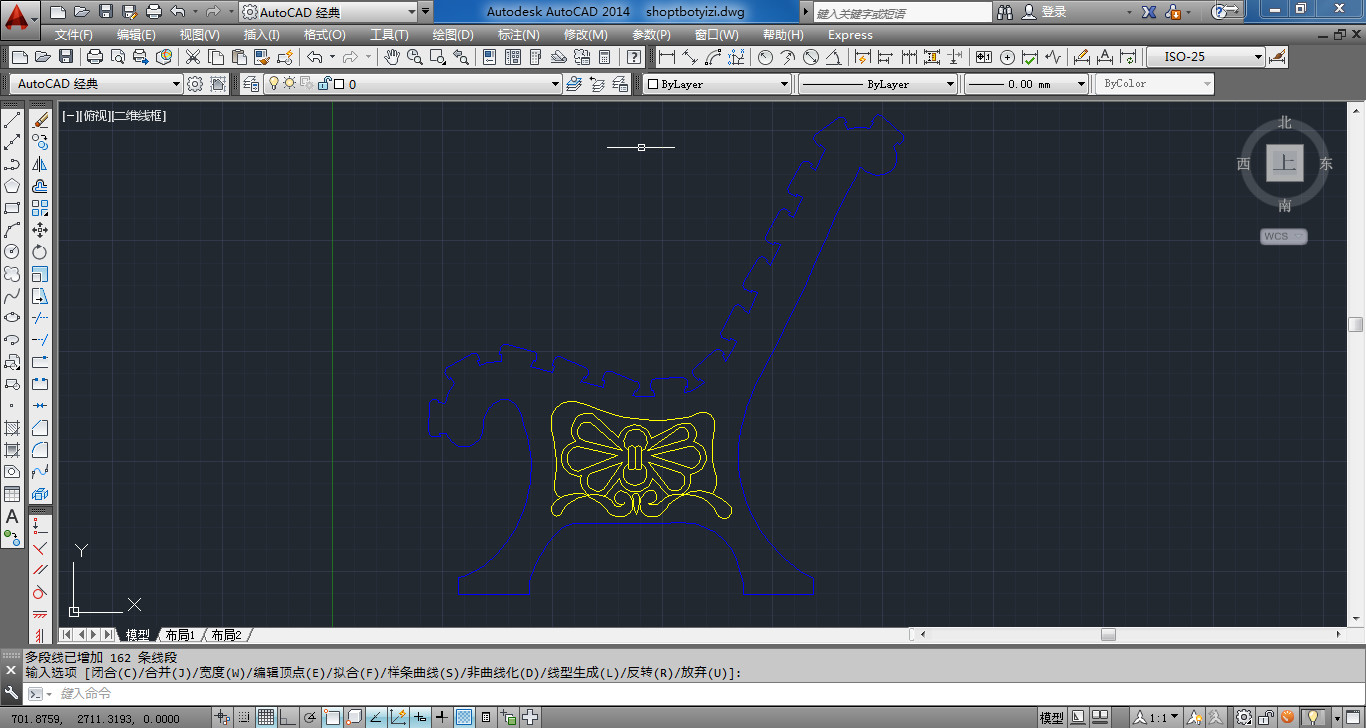

- 4. Adjust the size.

- It was found these components can be cut in a piece board. I changed the size of thwart and support board.

Part 2 Milling programming

- 1. Download Vcarve software.

- Vcarve software is suitble for shopbot and it is widely used in milling, it can generate many kinds format code.Go to vectric website and download Vcarve pro software, and install.

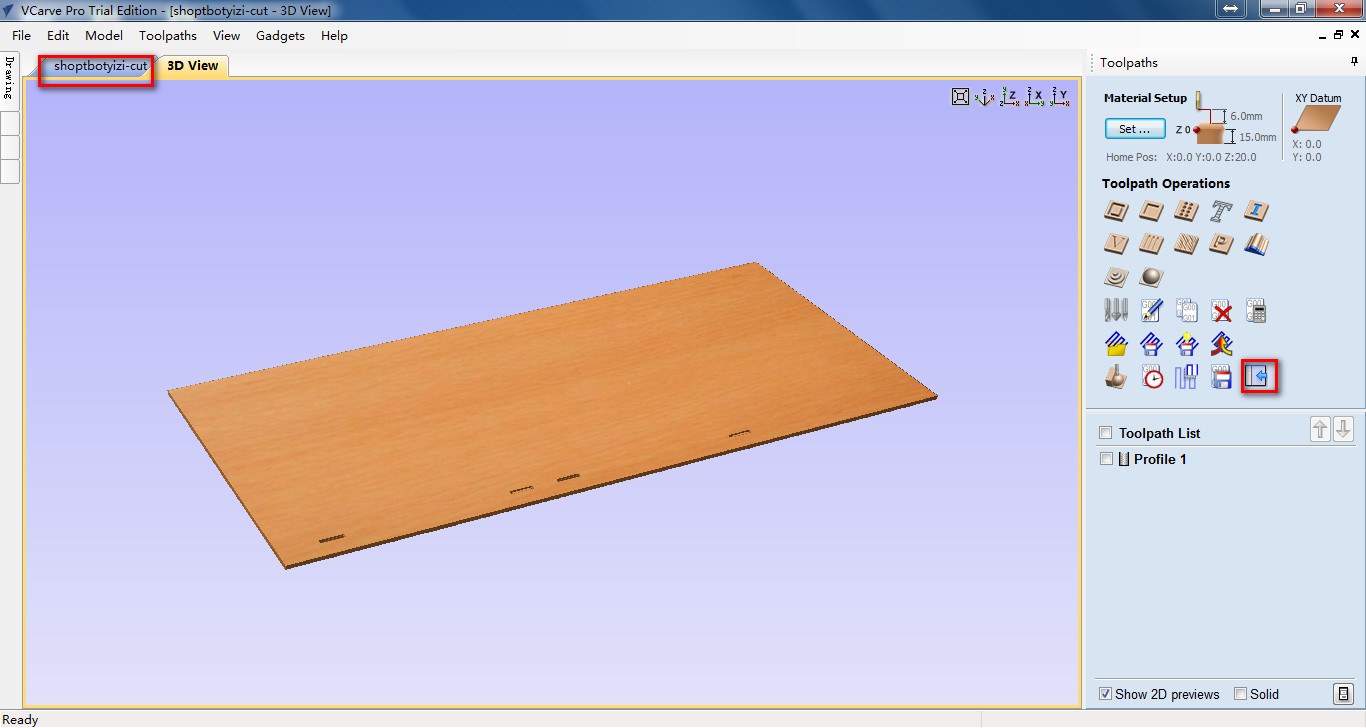

- 2. Create profile1 code.

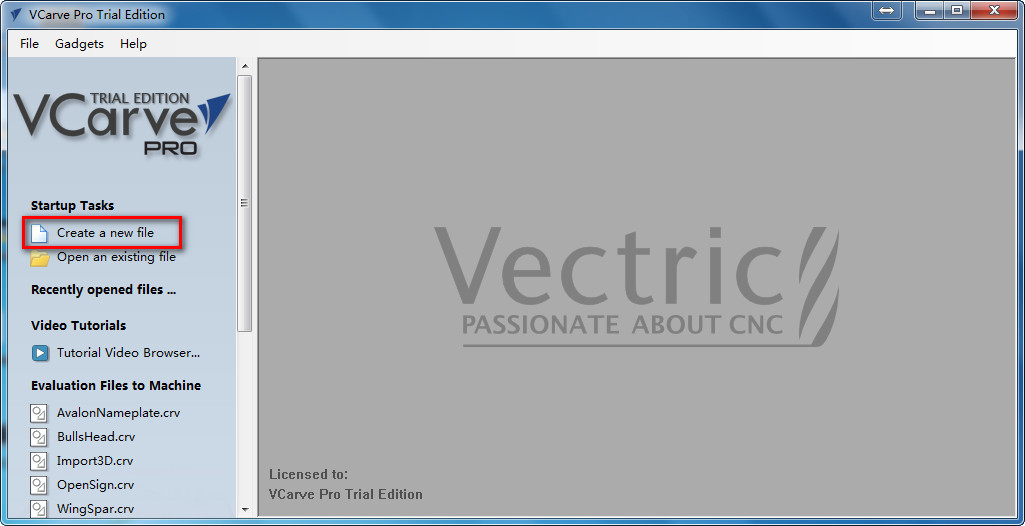

- Open the software click on create a new file.

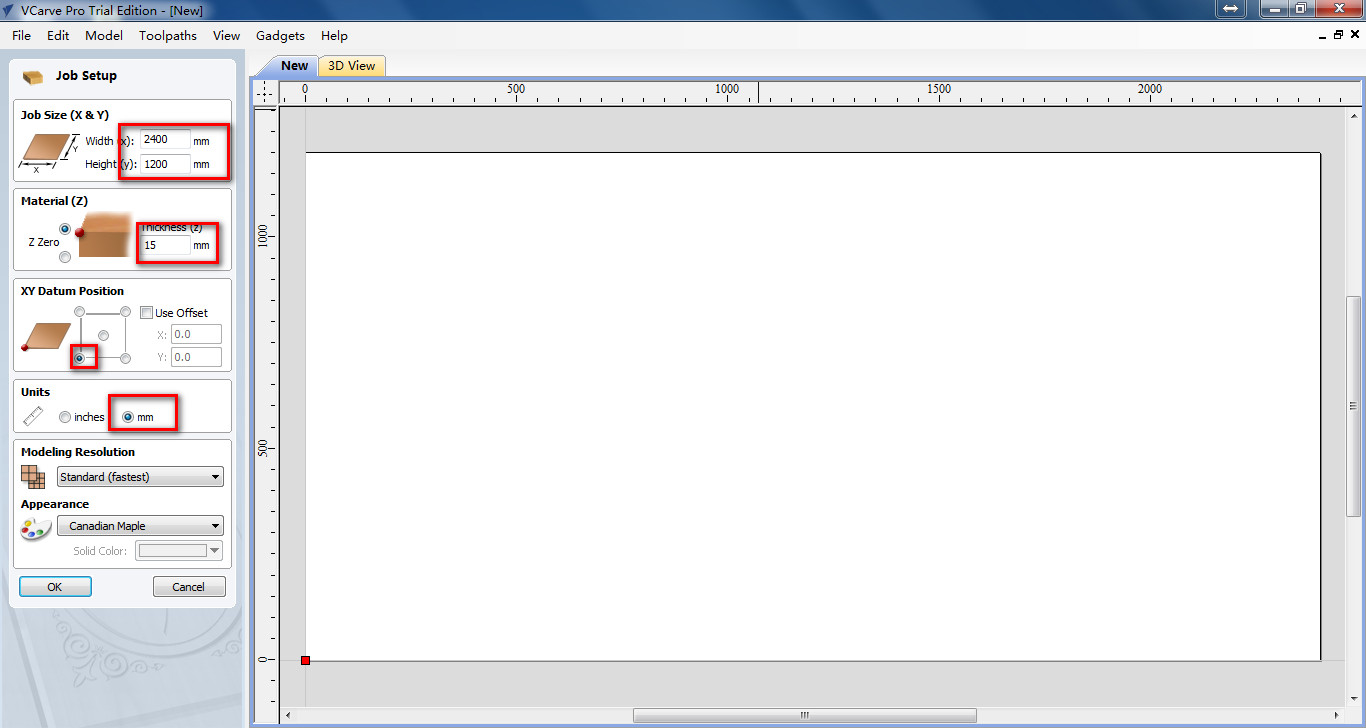

- Set job size, the size of the most common woodboard in China is 2400 mm X 1200mm. There kinds of thickness like 10 mm 15mm 18mm, normally use 15mm. Z zero can set on the surface of board and the bottom of board, set it on the surface. XY Datum position set on the left bottom corner. Units set as mm. Then click on OK.

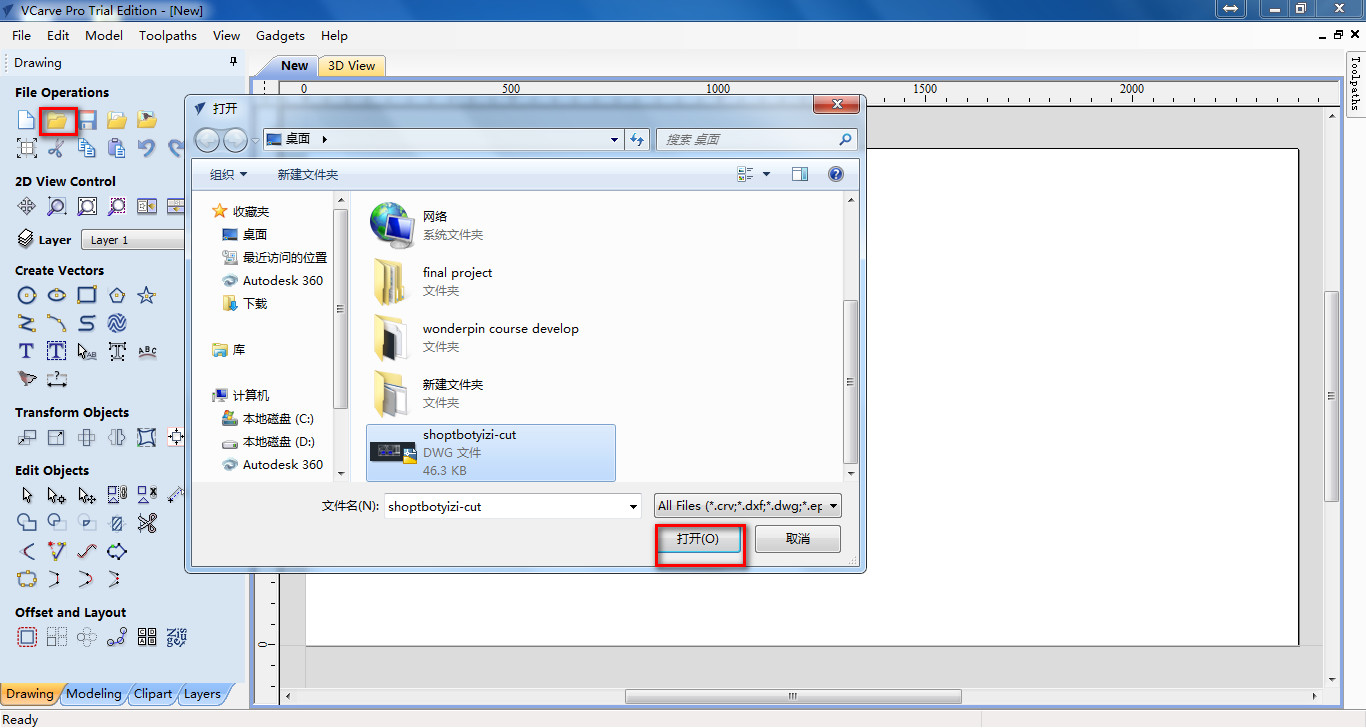

- Click on Open or import, add chair design file.

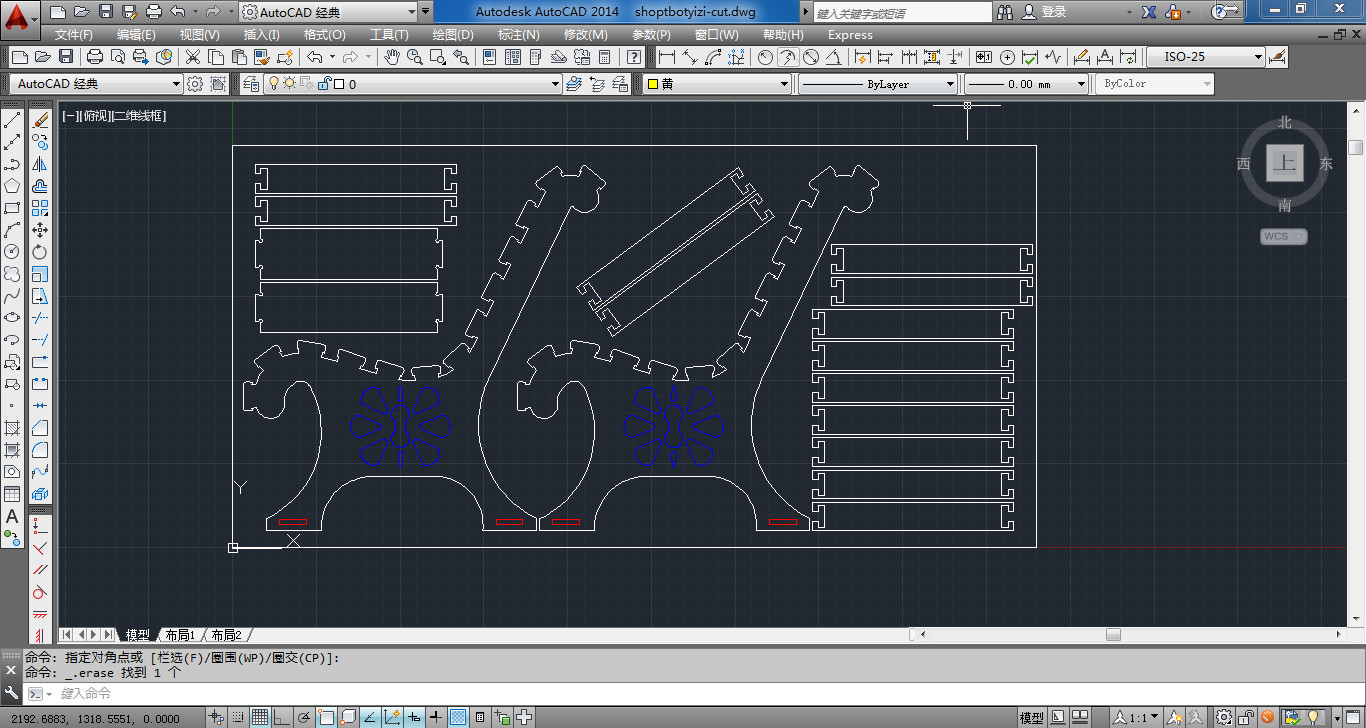

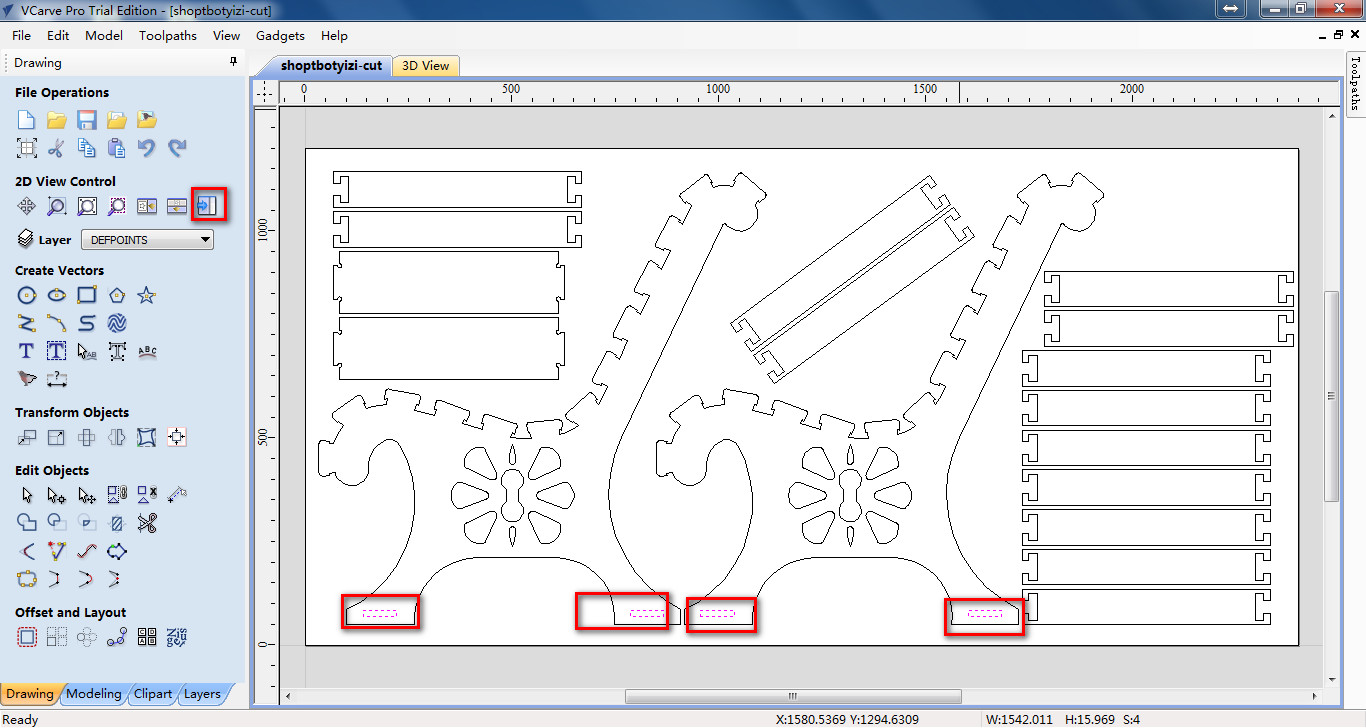

- There are four parts of the chair, the machining is dirfferent. Hold down shift and click on the four rectangle. then click on switch to toolpath.

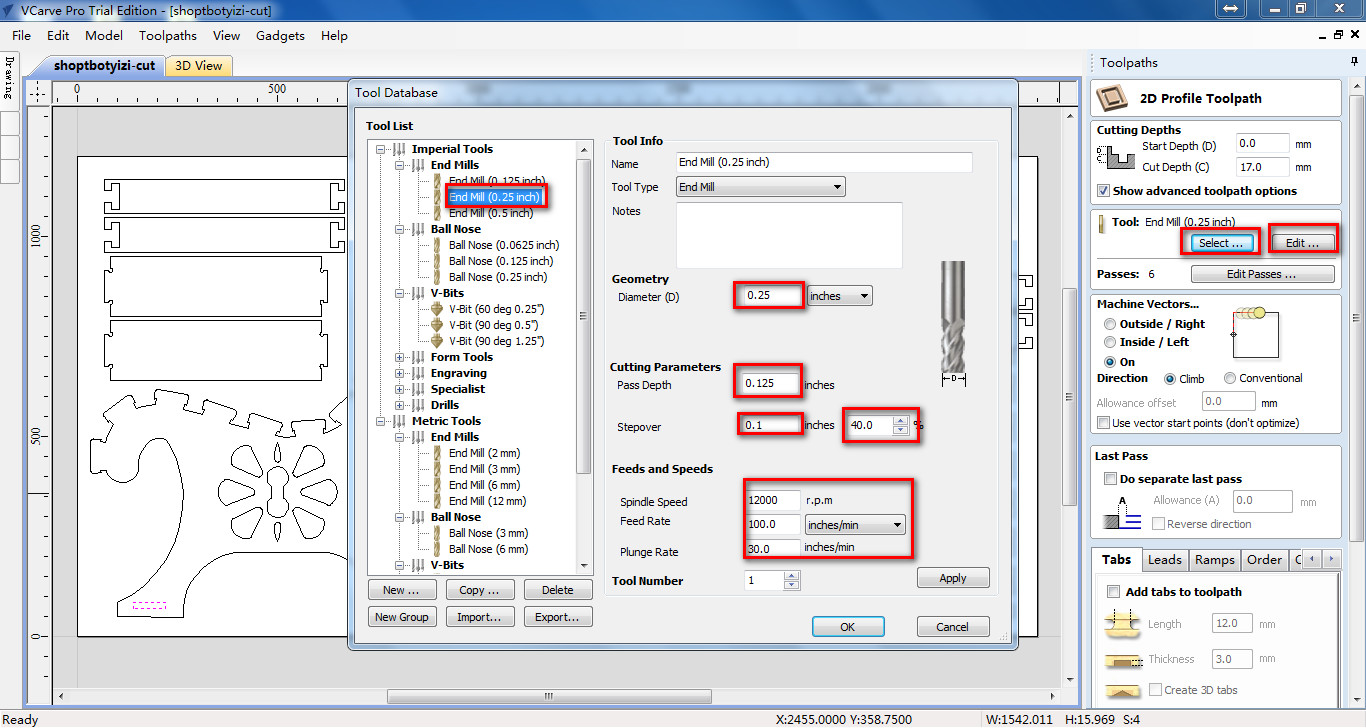

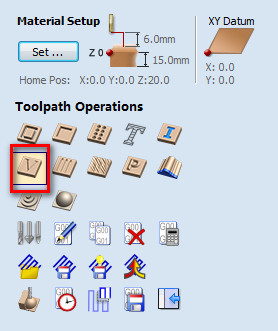

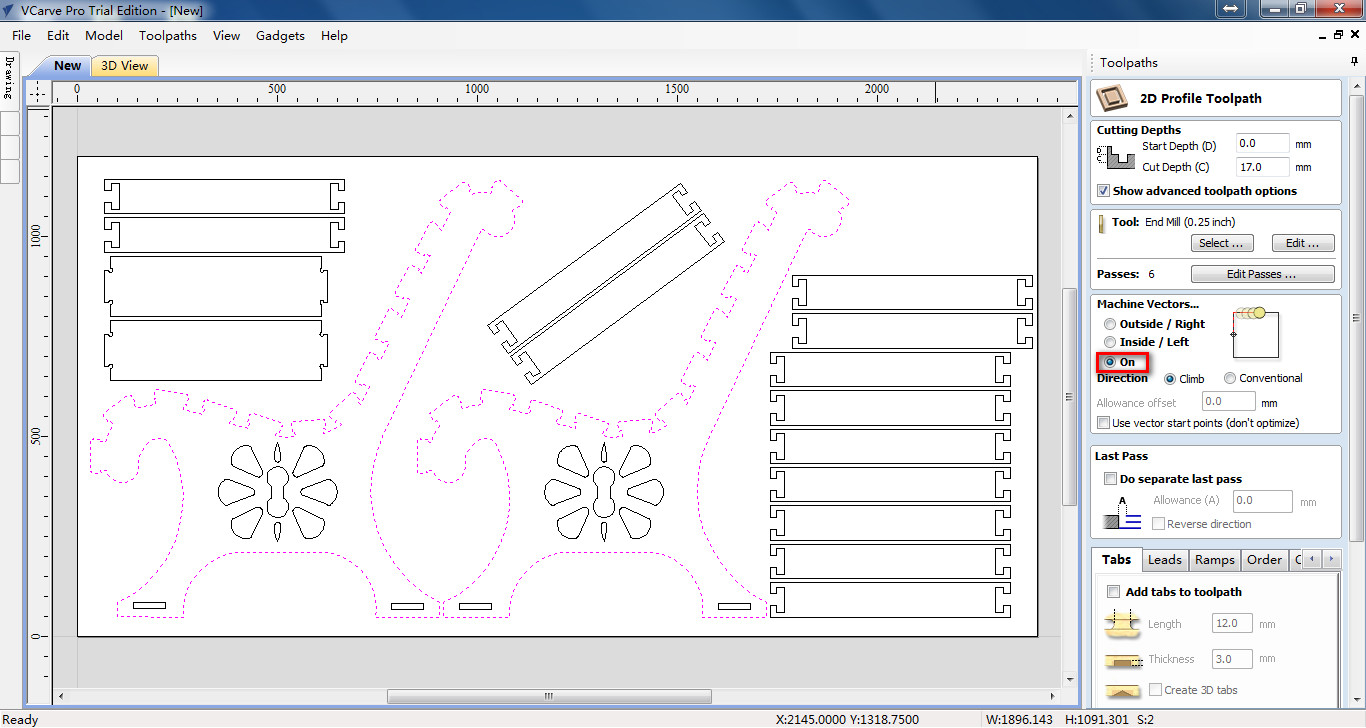

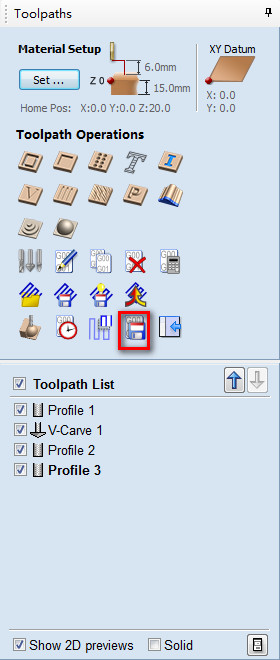

- Choose toolpath operations, 12 toolpath can be selected. For the four recuglars were the hole for support, it should be cut through, so click on profile toolpath.

- Set process parameters. Set cutting depths as 17 mm, it is bigger than the thickness of board, for if we set as 15 mm, it can be cut through. Click on tool select, choose end mill 0.25inch, cutting parameters and feeds and speeds can set.

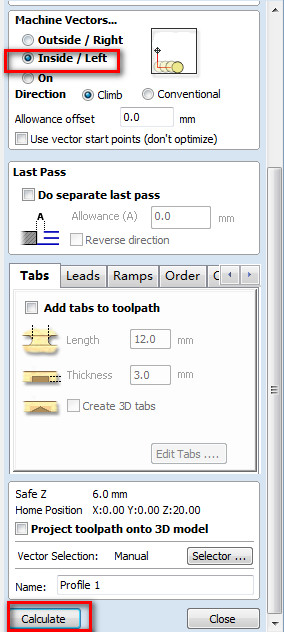

- Set the path of mill, three kinds of them can be choose. Mill can go out of the path inside the path and on the path. If choose outside in this case the supports were loose assemble. So choose inside in this case. Then click on calculate, the code will be created.

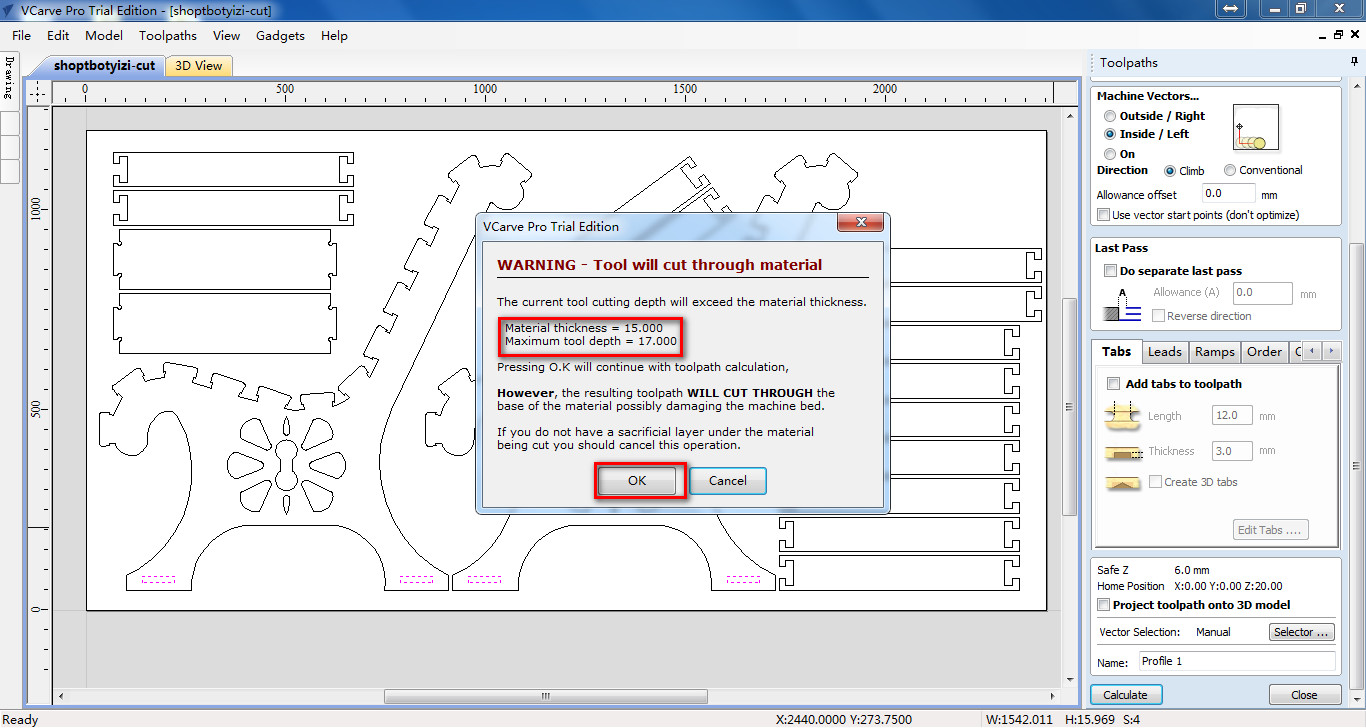

- For the depth was set as 17 mm, warning pop-up. Click on OK.

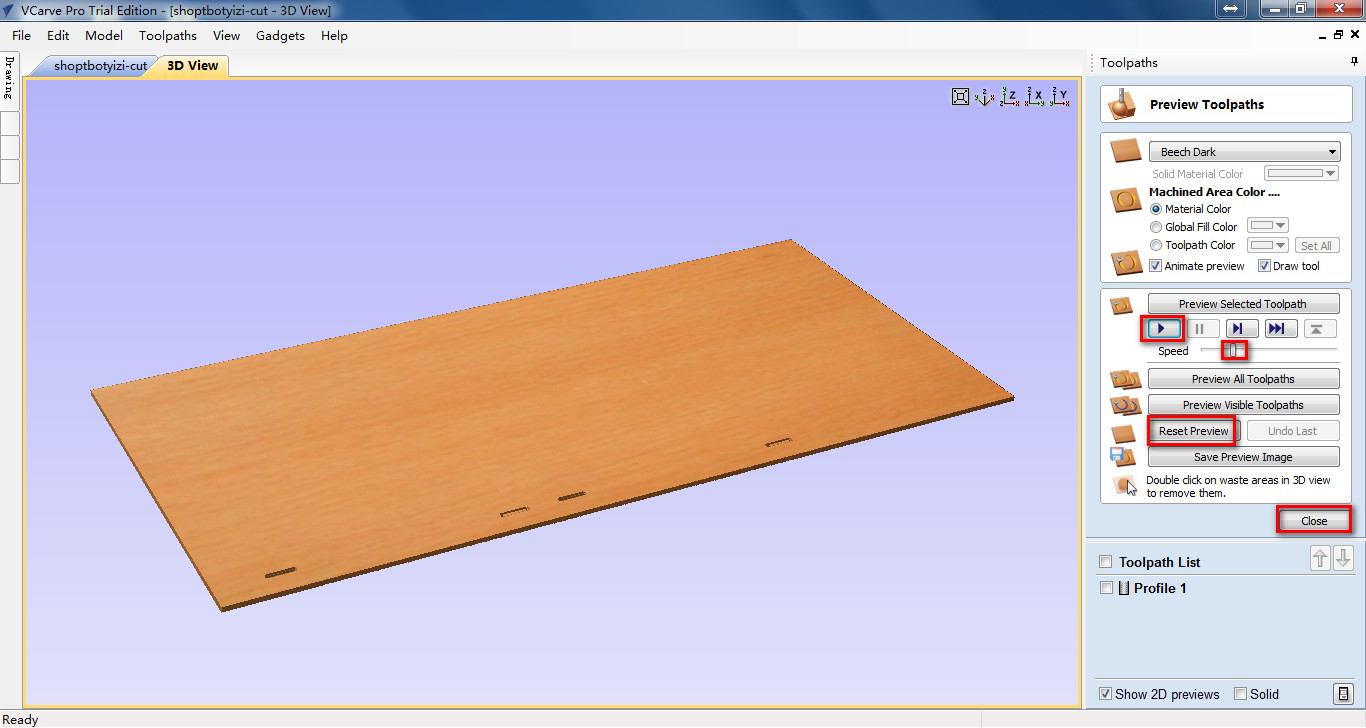

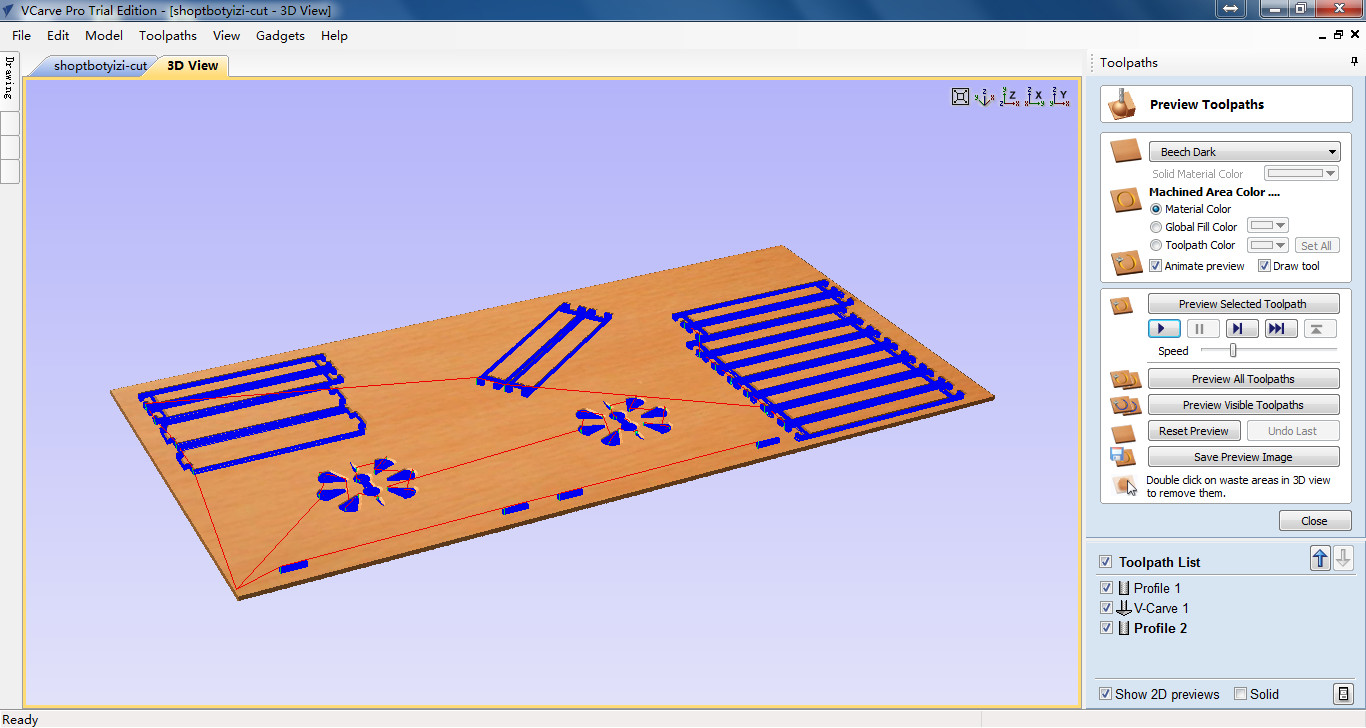

- Click on preview we can see the simulation of maching.

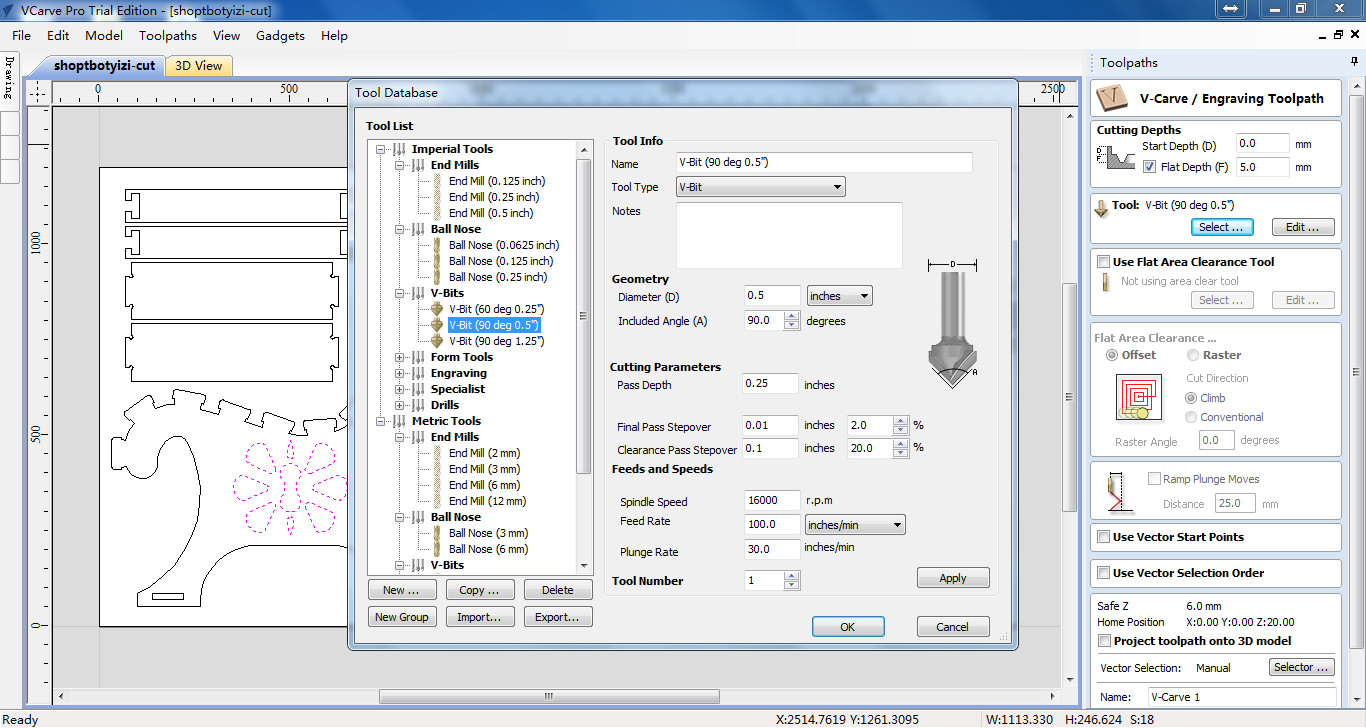

- 3. Create v-carve1 code.

- Click on swtich to drawing tab. Choose the inside path.

- Hold down shift and choose the inside path, this path won't be cut through, a new mill will be used. Click on switch to toolpath tab.

- Click on V-Carve toolpath.

- Set flat depth as 5 mm. Then click on select and choose V-bit, and set the mill parameters. Then click on calculate.

- Preview the milling process.

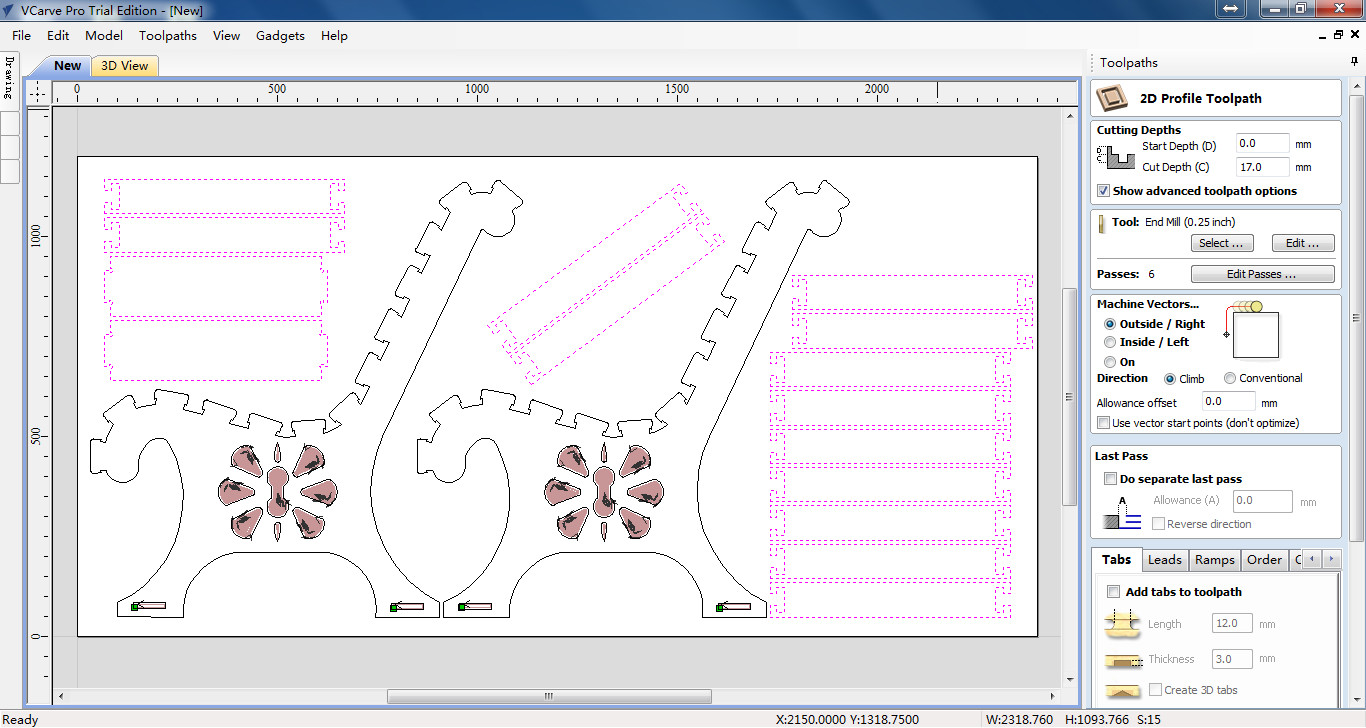

- 4. Create profile2 code.

- Back to drawing tab choose thwart board and support board, then go to toolpath.

- These should be cut through, click on profile toolpath. Set cut depth and mill parameters as the same. Set machine vectors as outside. Click on calculte.

- Preview the toolpath.

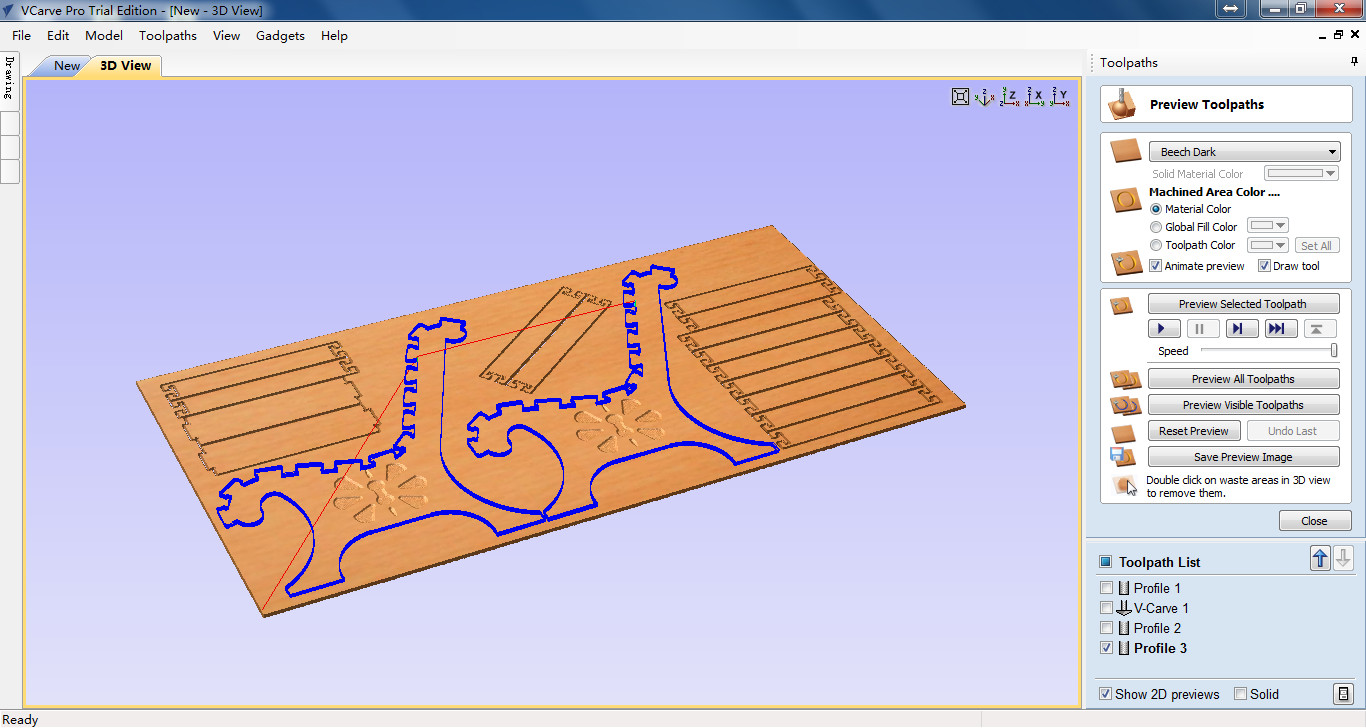

- 5. Create profile3 code.

- Back to drawing tab and choose the chair. Then switch to toolpath.

- Click on profile toolpath and set mill parameters and choose on the path. Then click on calculate.

- Preview the toolpath.

- All of the toolpath have been created.

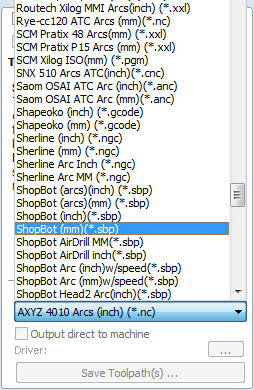

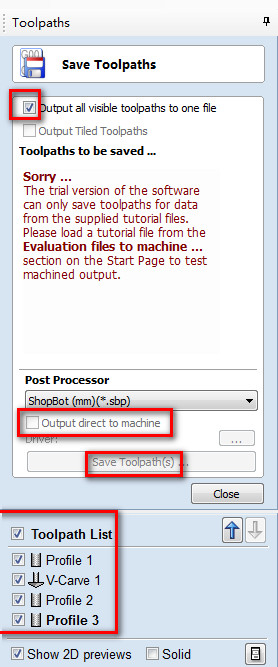

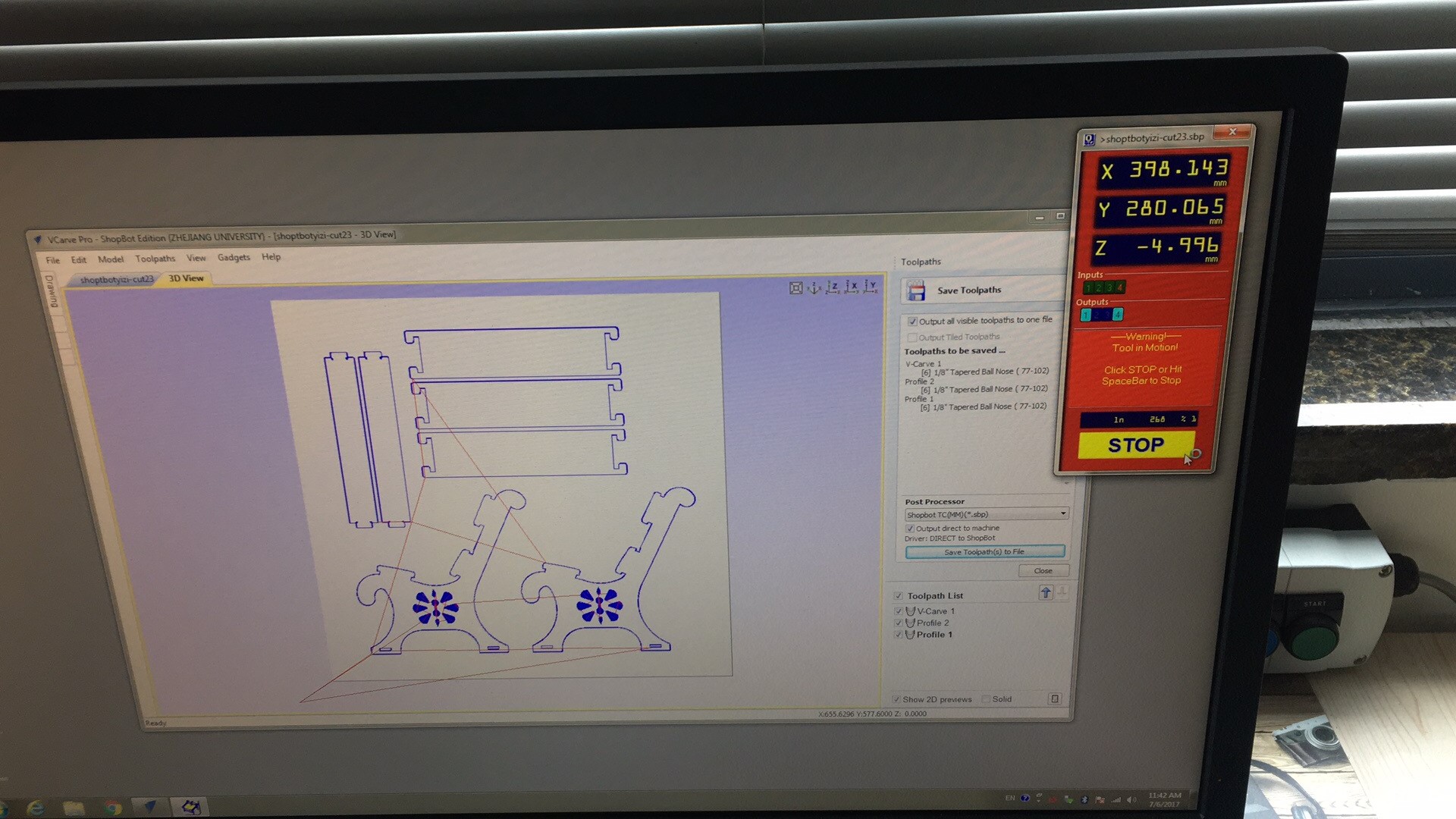

- Save all of them, click on save toolpath.

- Choose the shopbot(mm)(*.sbp) format.

- Check on output all visble toolpaths to one file and output direct to machine. If computer is connect to machine the code will send to machine. We have created four profile, so it will cut four times and we use end mill and v-bits so it should be careful when cutting.

Part 3 Milling

- 1. Preparing.

- The wooden board should be fix on the working plane. and the knife should be checked which I used is 77-102.

- 2. Input code.

- Everything is ok send the code to machine, and click on start.

- 3. Cut.

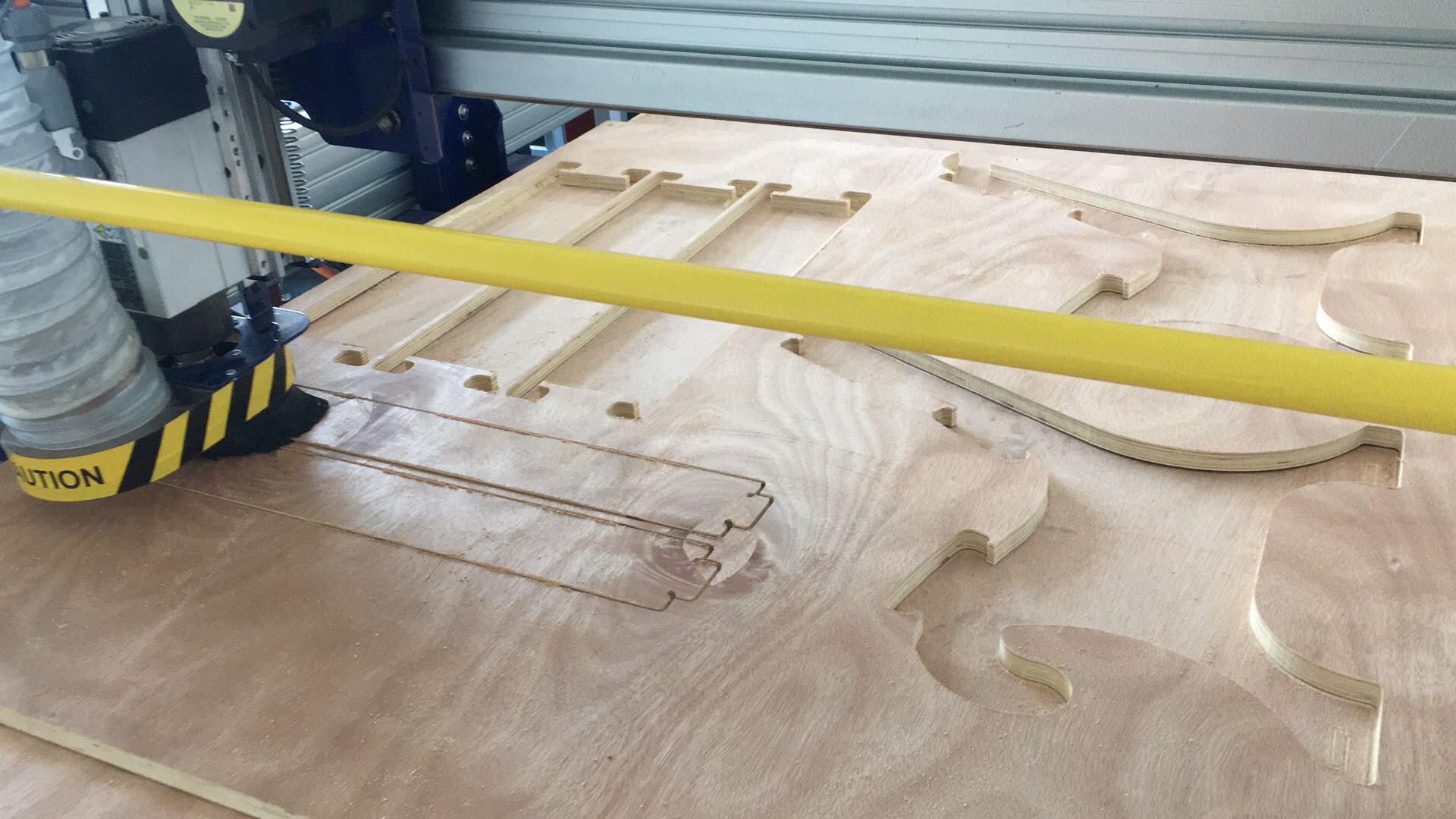

- The machine is working.

- The machine is not cut very fast after an hour most of them were cut.

- 4. Assembling.

- The chair was assembled. And I have a sit on it, it worked.