WEEK03-COMPUTER CONTROLLED CUTTING

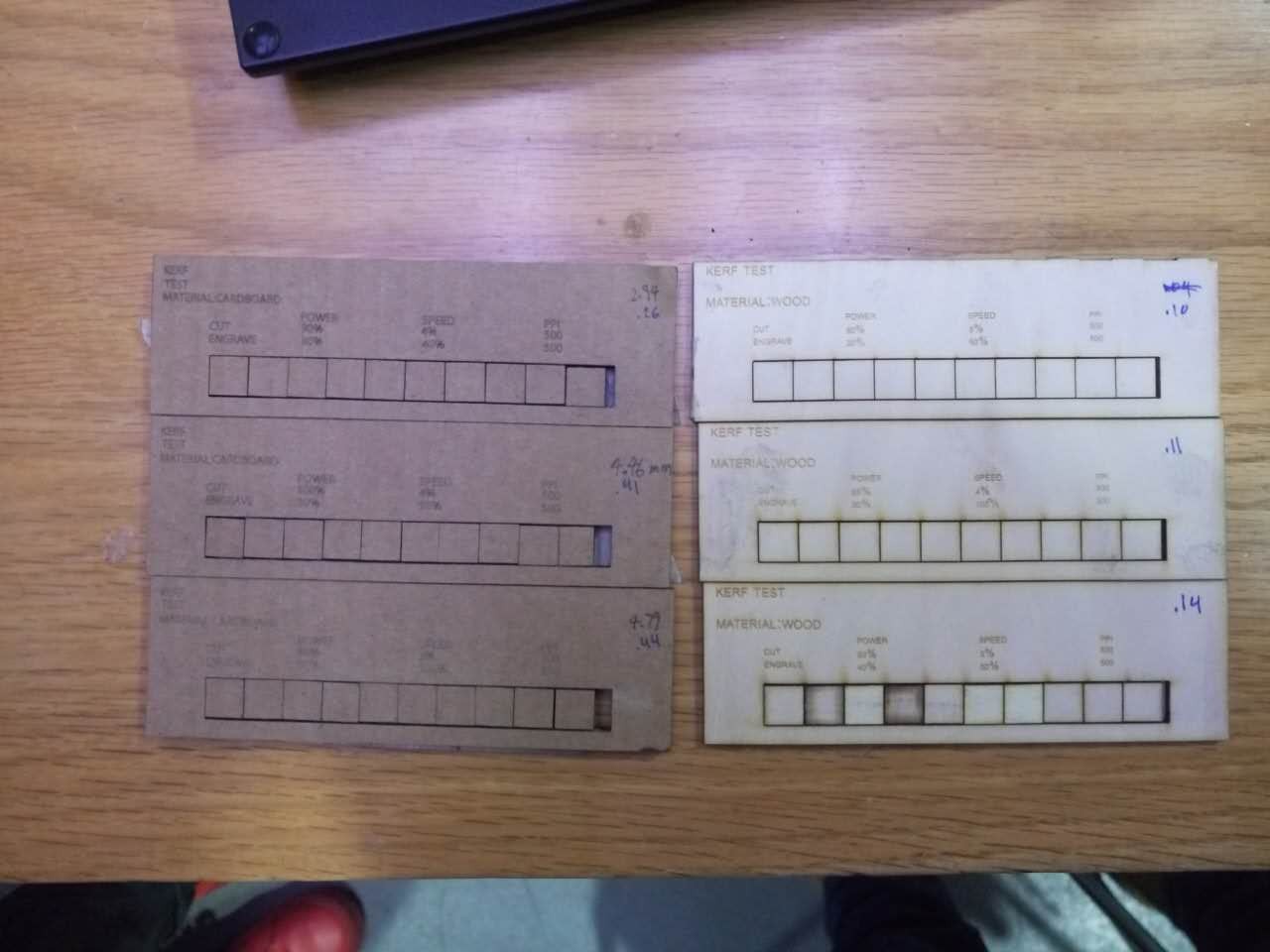

Part 1 Kerf test

- 1. Design a kerf test.

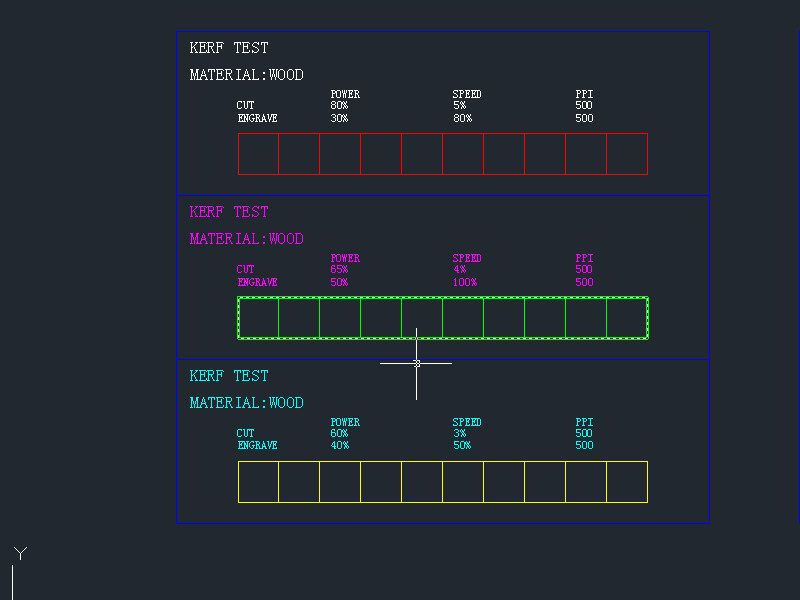

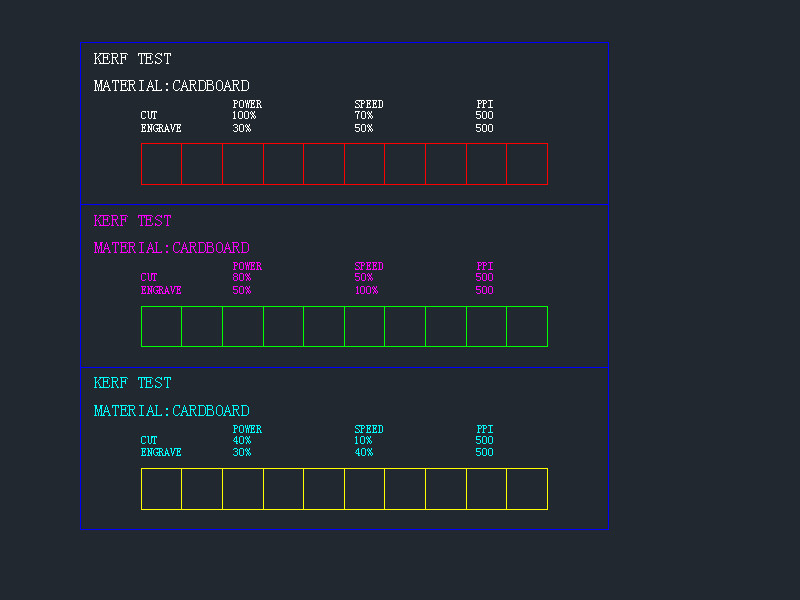

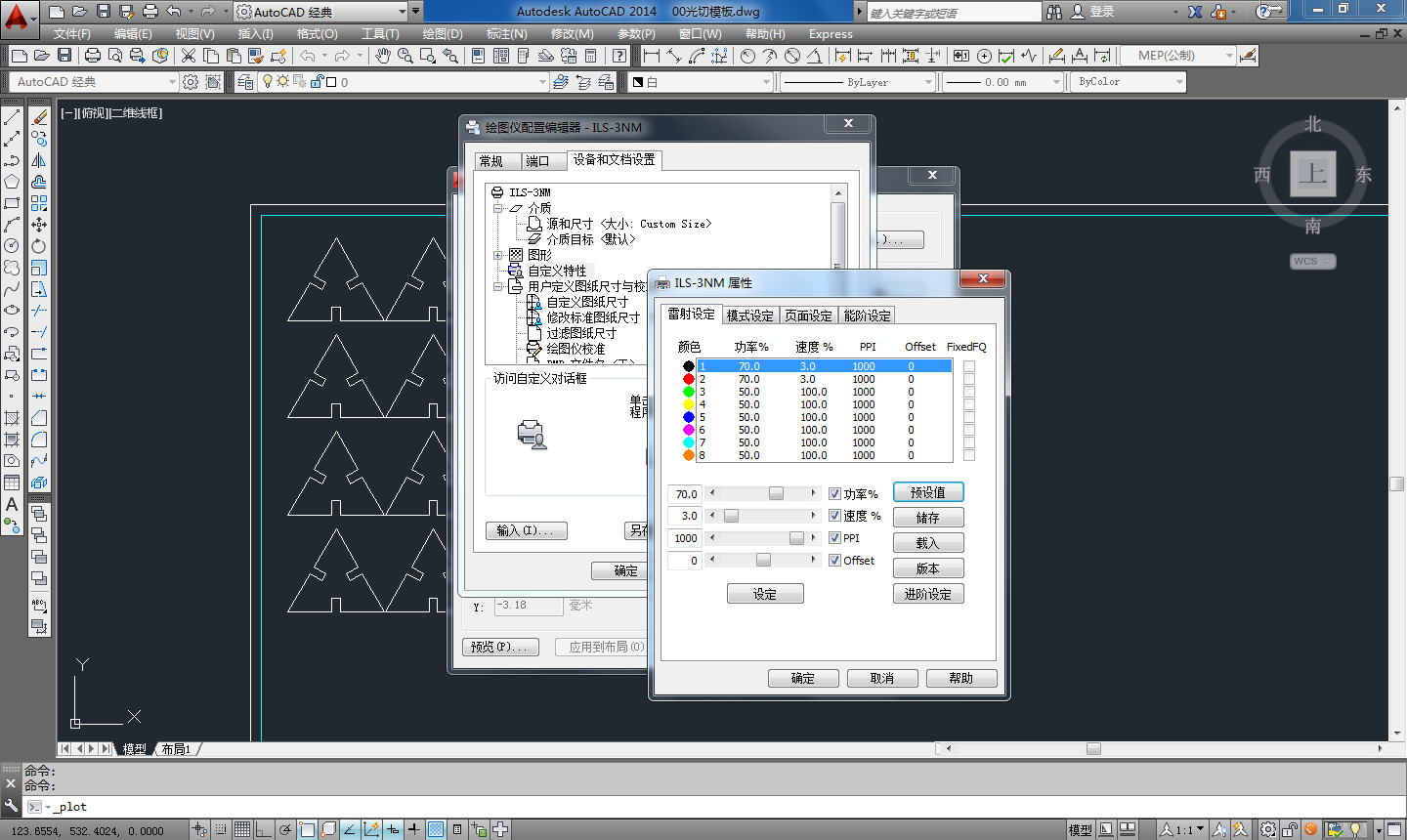

- We design a test for different parameters of laser cutting and engraving, also test two materials like wood(2 mm thickness) and cardboard(3 mm thickness). We use AUTOCAD 2014 for desining.

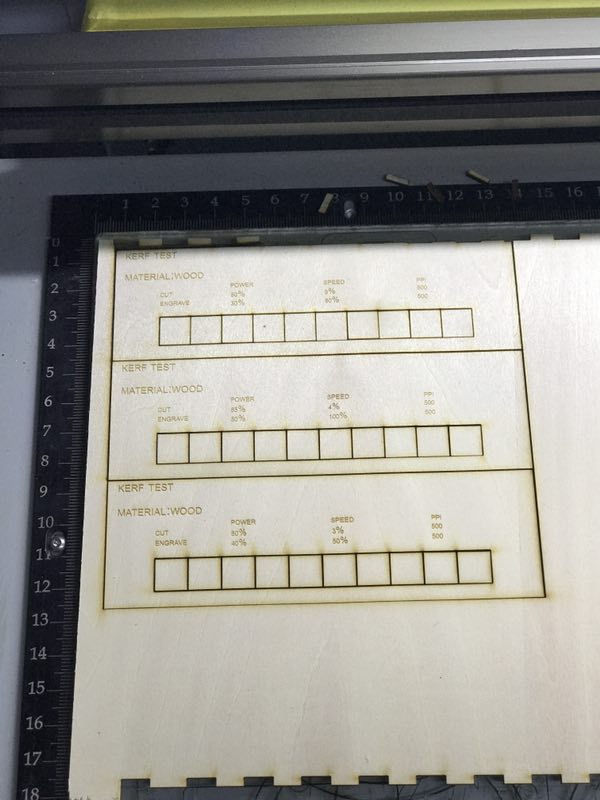

- We designed ten cubes, the width of kerf can be known. We set three kinds of parameters for wood first, changing power speed and PPI.

- We also set three kinds of parameters for cardboard.

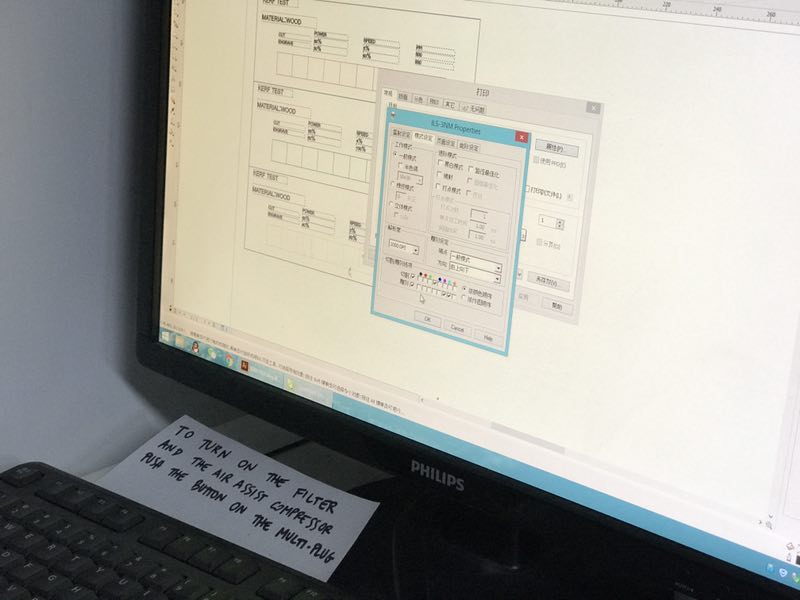

- 2. Open laser cutting machine, setting parameters.

- Open the laser machine, open air compressor and air fliter is very important. The operating software in the computer is Adobe Illustrator. We set parameters and click print.

- We set the parameters same with we design.

- 3. Engrave and cut it..

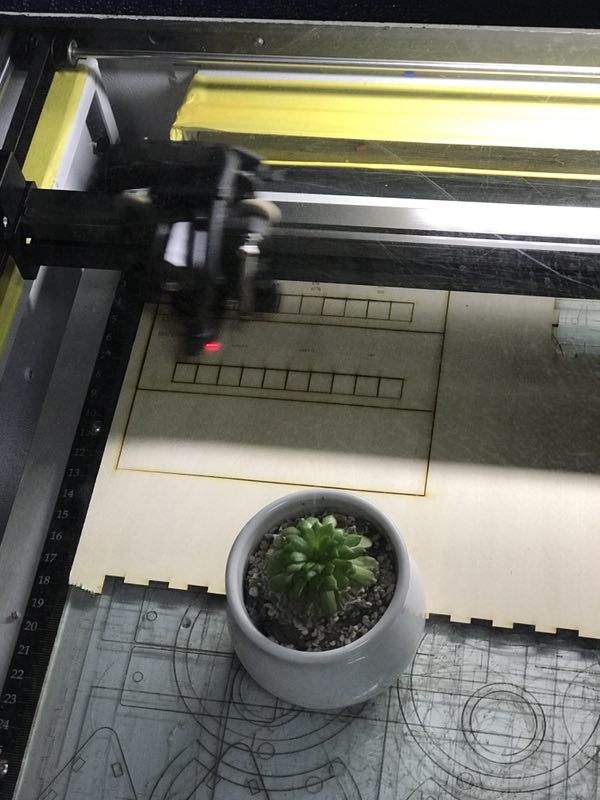

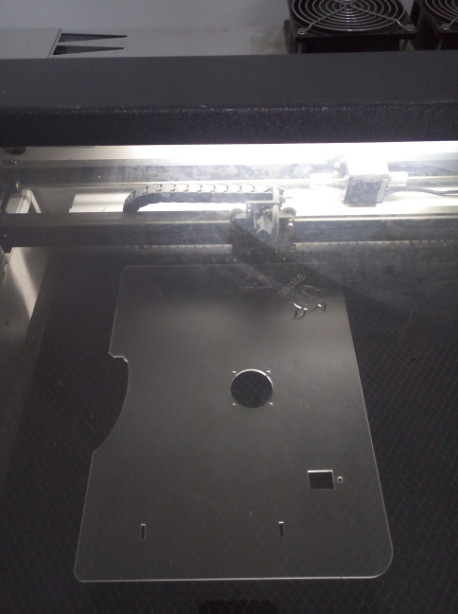

- Press RUN on the machine after checking.

- 4. Check the works.

- Engraving needs more time than cutting.

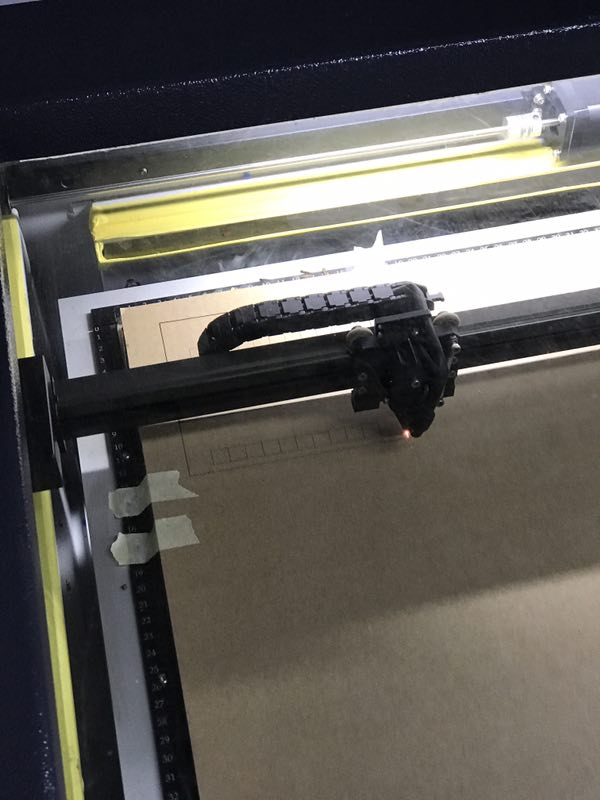

- 5. Change materials.

- We make some change of design, we don't use engrave, we cut outline of words but not cut through. We used almost 6 mm cardboard , power is 100%, speed is 3 and PPI is 500, the cardboard can't be cut through, when speed is 2 it was cut through but it's edge was burned. That's because the power of this machine is not powerful, if you want to cut it you should reduce the speed, actually the power should be large and speed should be fast when cutting cardboard. Enough power can make cardboard gasification in a flash, and there is no time to heat the edge of kerf, so we get high quality kerf.

- 6. Measure the gap of laser cut.

- My cooperator measure the wood works. The kerf width of wood ranges from 0.1mm to 0.14. It's a little difference at different process parameters.

- I check the gap of cardboard. The kerf width of cardboard ranges from 0.29mm to 0.48mm. There is a great difference at different process parameters.

- 7. Comparison of kerf.

- The kerf of cardboard is much bigger than that of wood. It is showed in the picture.

- 8. The processing of laser cut and engrave.

- Dynamic graphics of processing.

Part 2 Design cutting file with parametric software

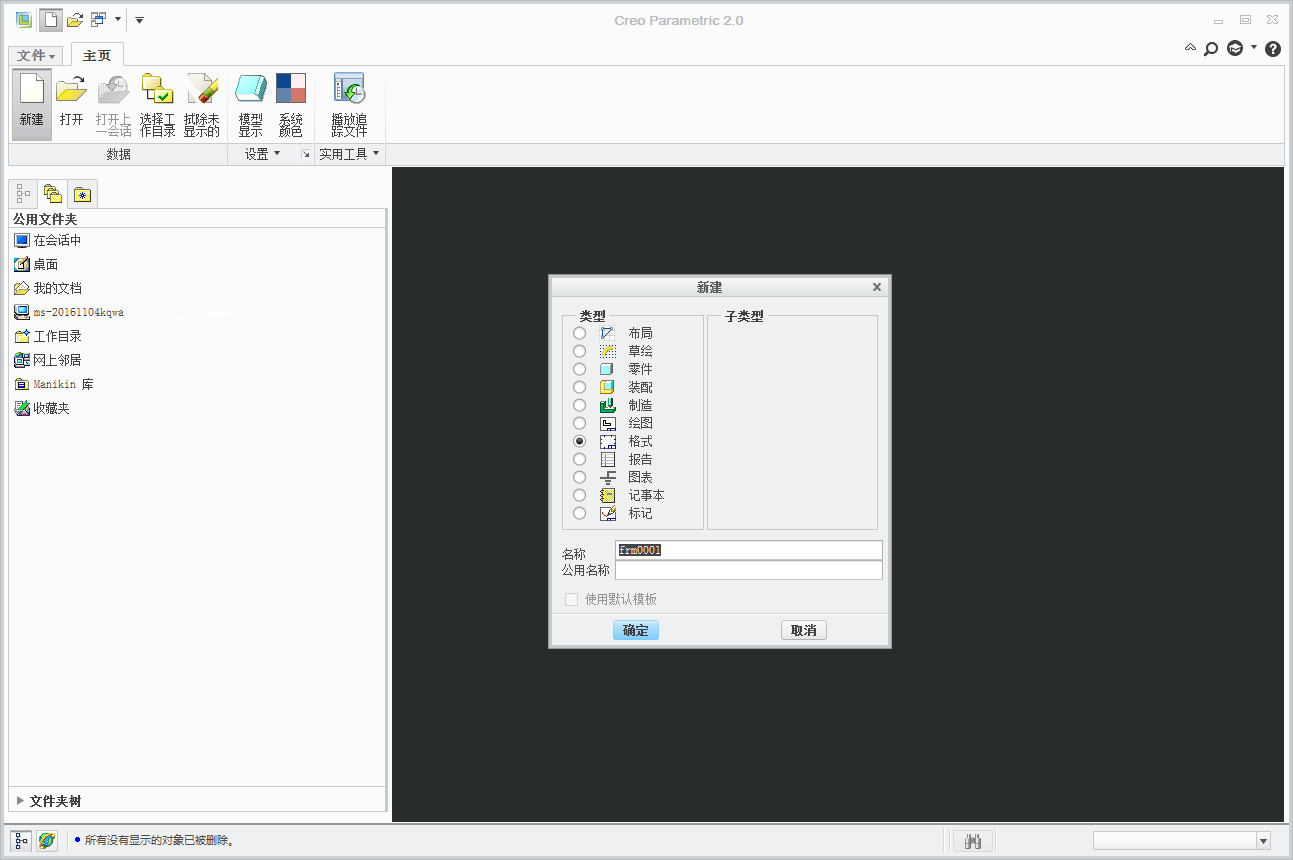

- 1. Used Creo 2.0 to design a simple vector picture

- Open Creo 2.0 and create a new sketch file.

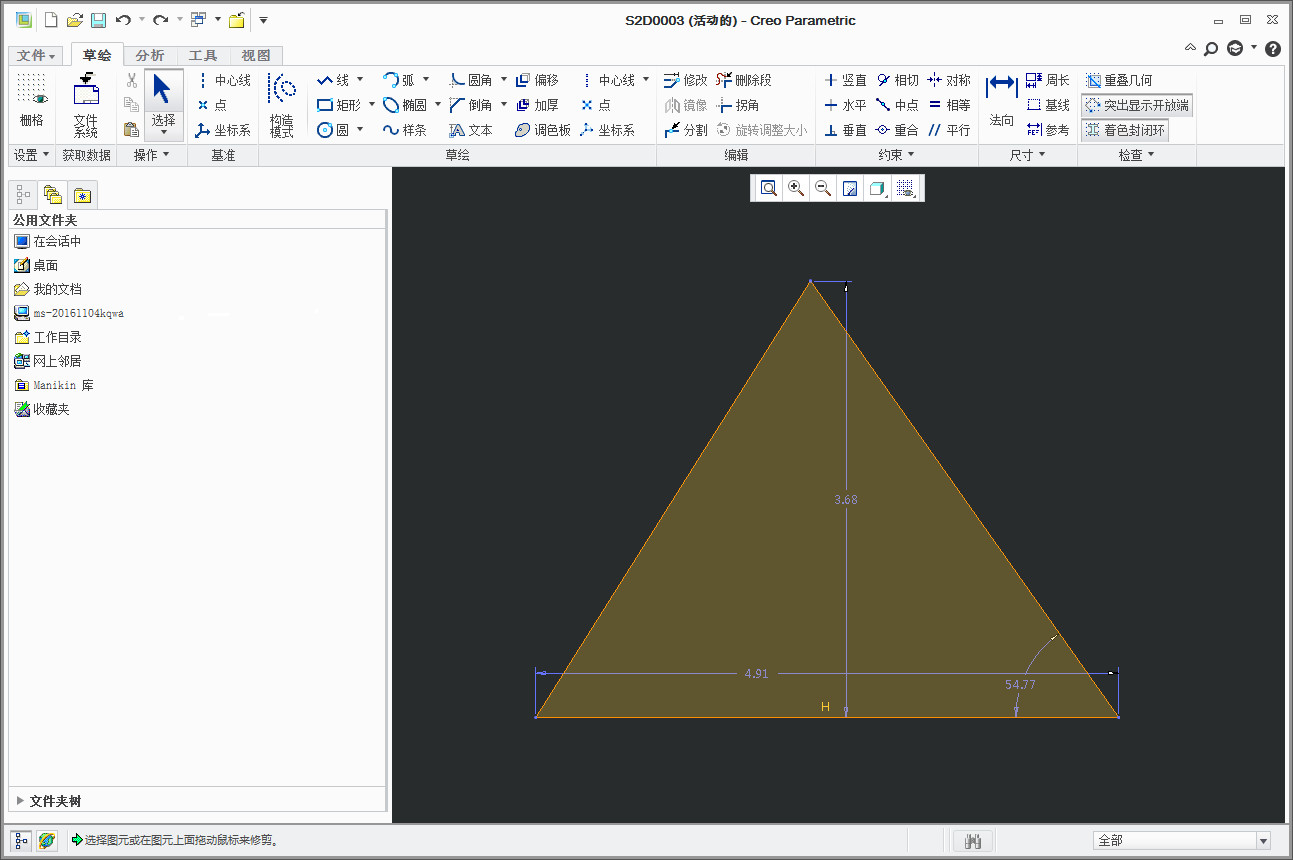

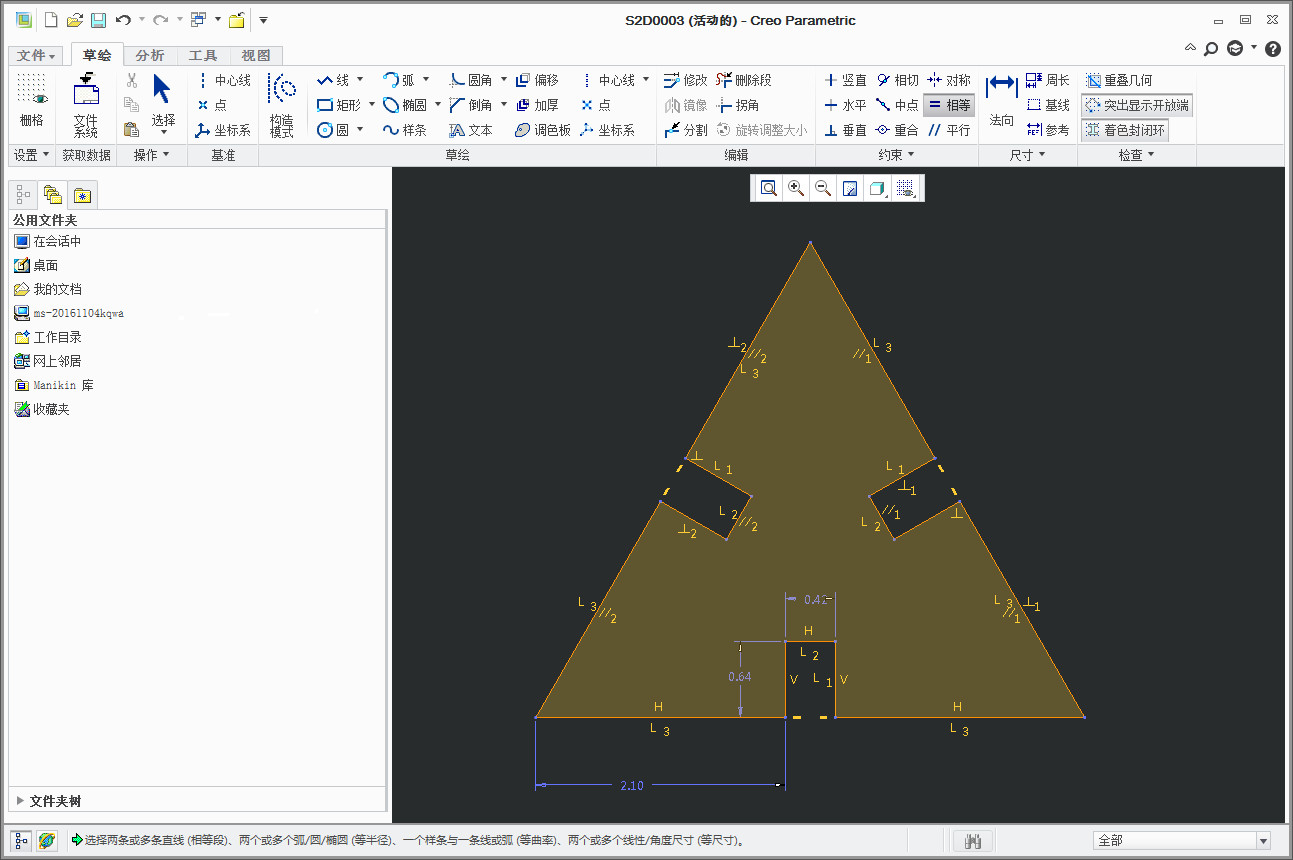

- 2. Create a triangle

- Create it with the order "line".

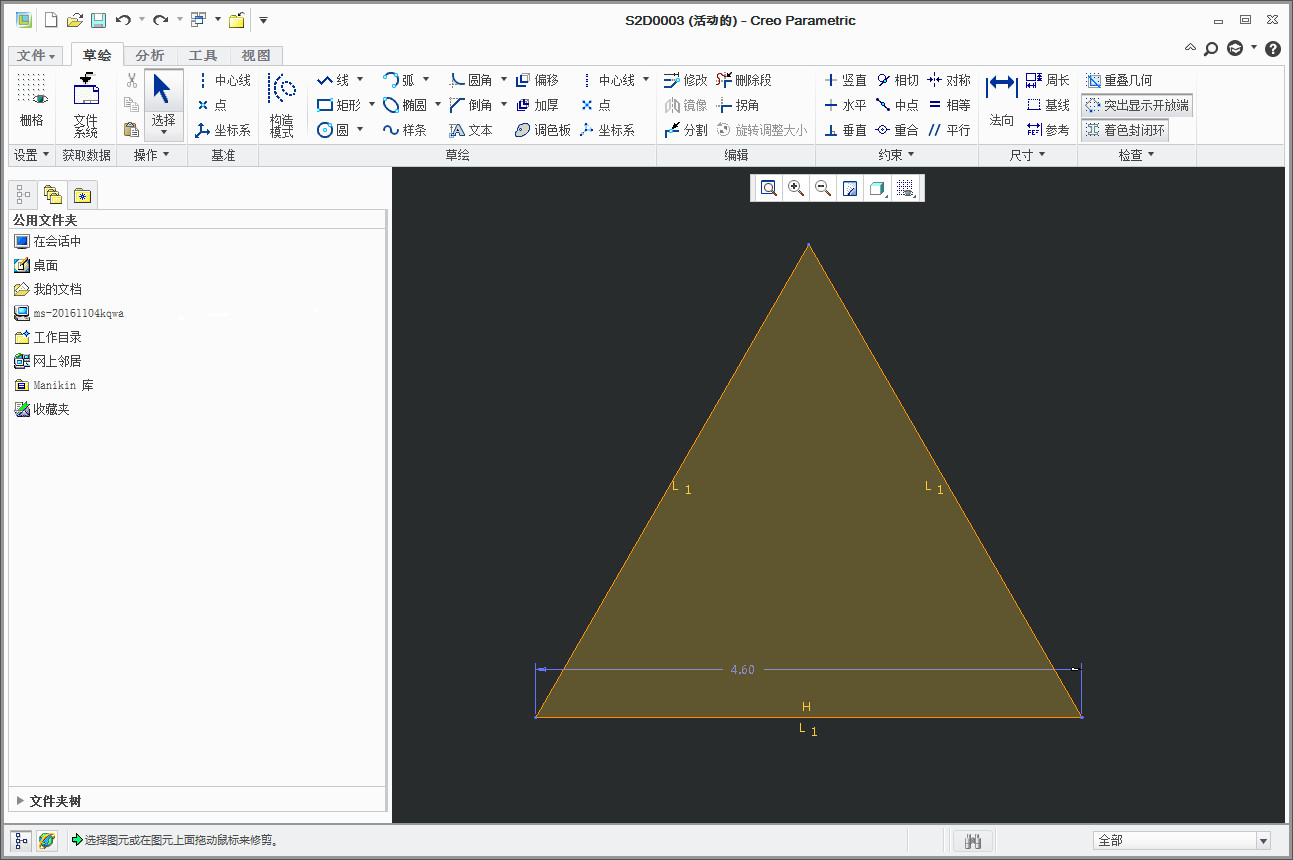

- Make three line equal

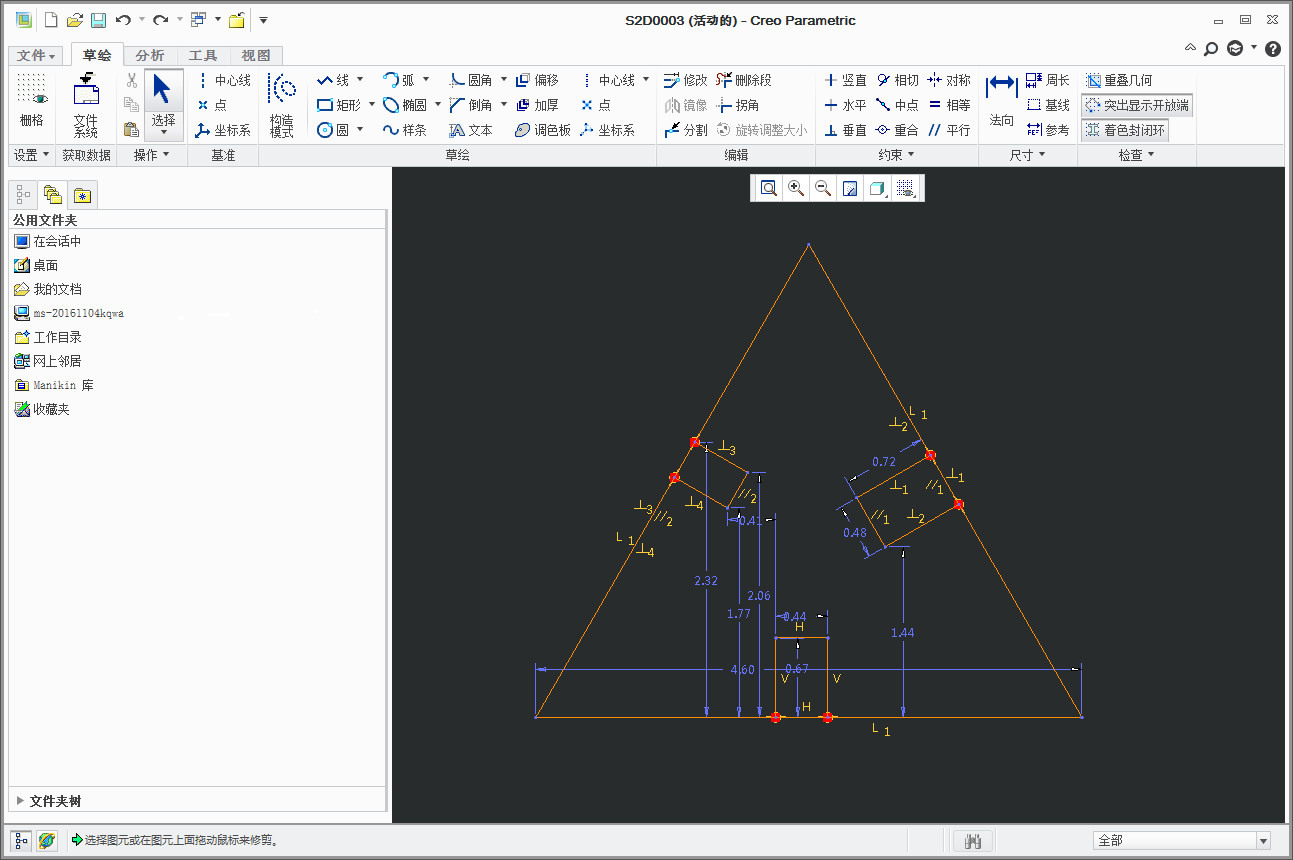

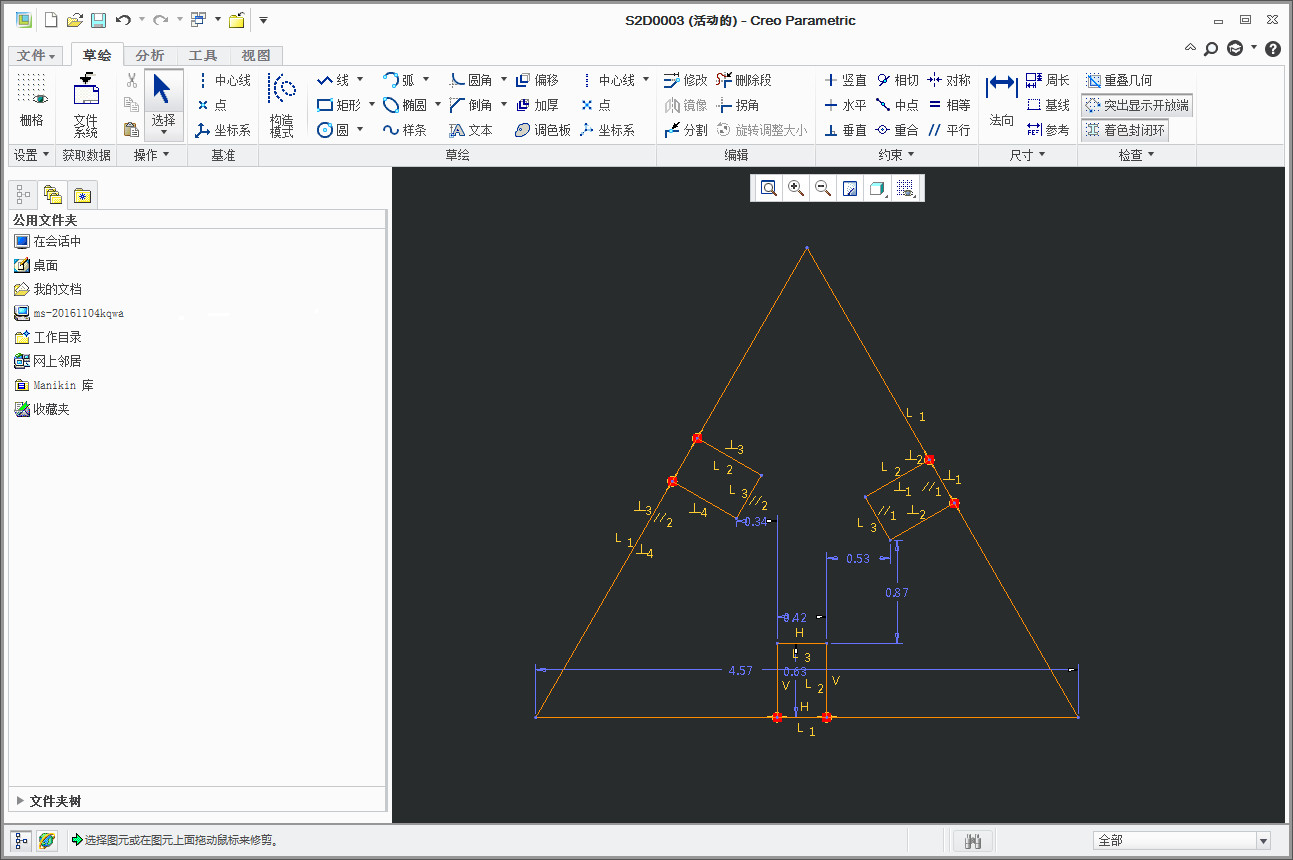

- 3. Create three gaps

- Create three gaps the same.

- Make six lines equal and the other three lines equal

- Delete the line don't need.

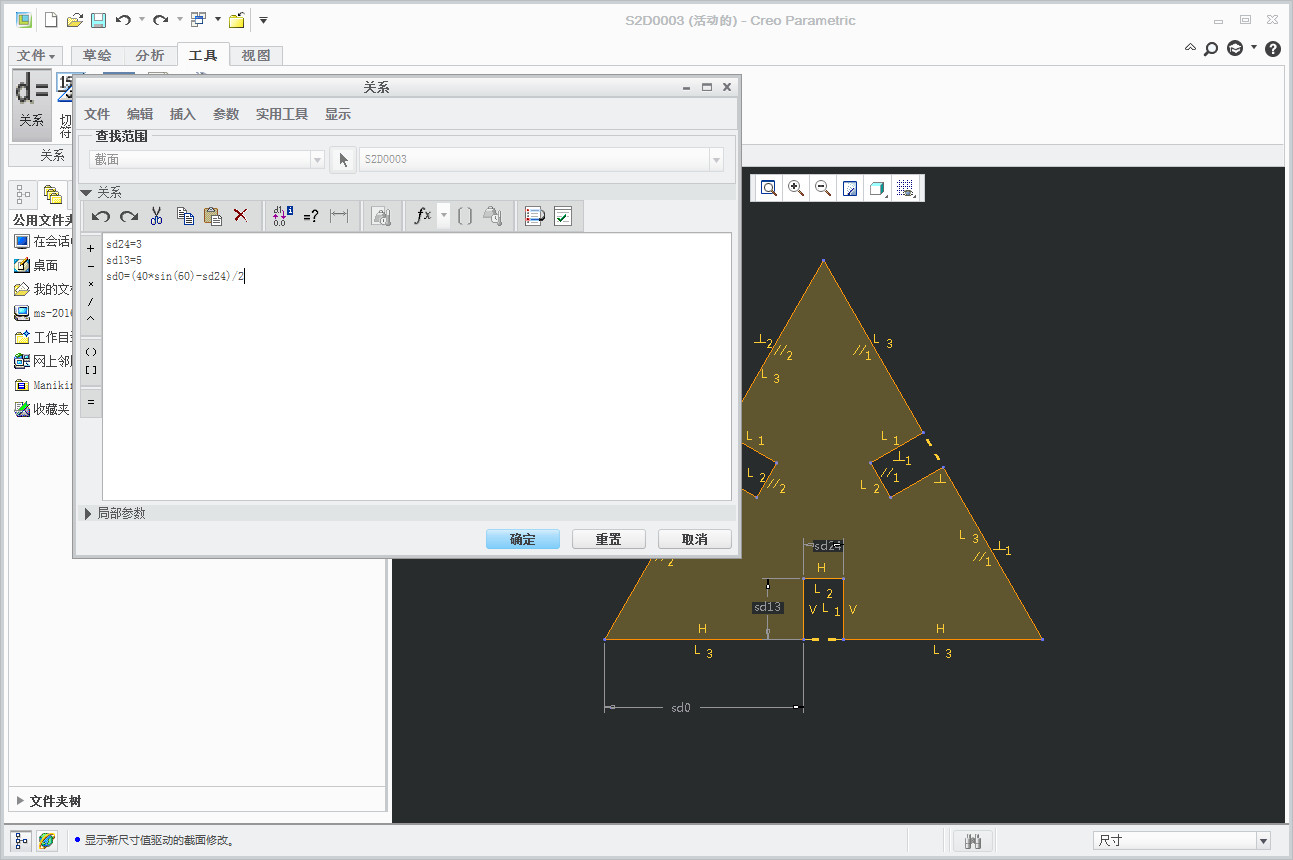

- 4. Set relationships

- Open "tool" - "relationships", and text : sd24=3 sd13=5 sd0=(40*sin(60)-sd24)/2

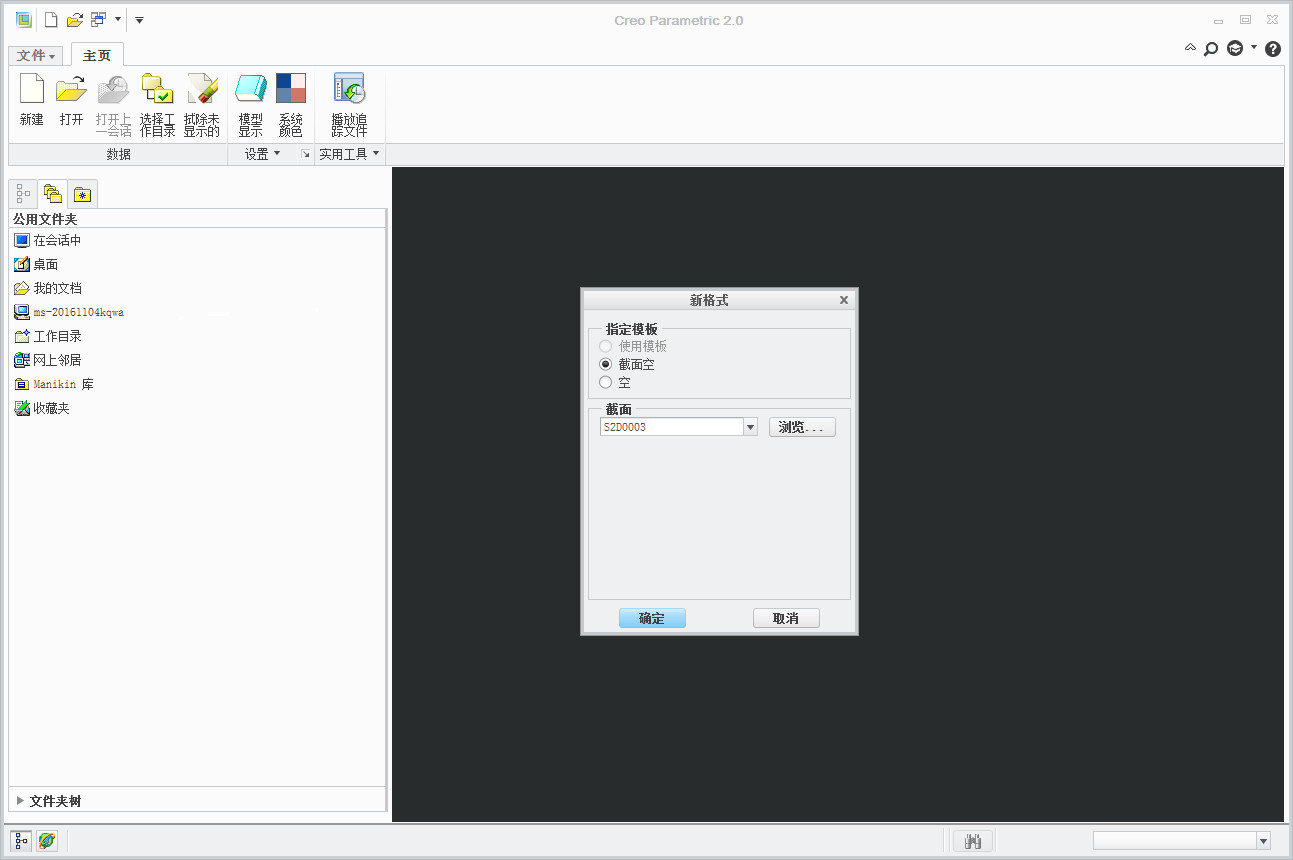

- 5. Create a new file with .fram after save the file S2D003.

- this file was used to change fomat for cutting.

- select the file S2D003 and open it.

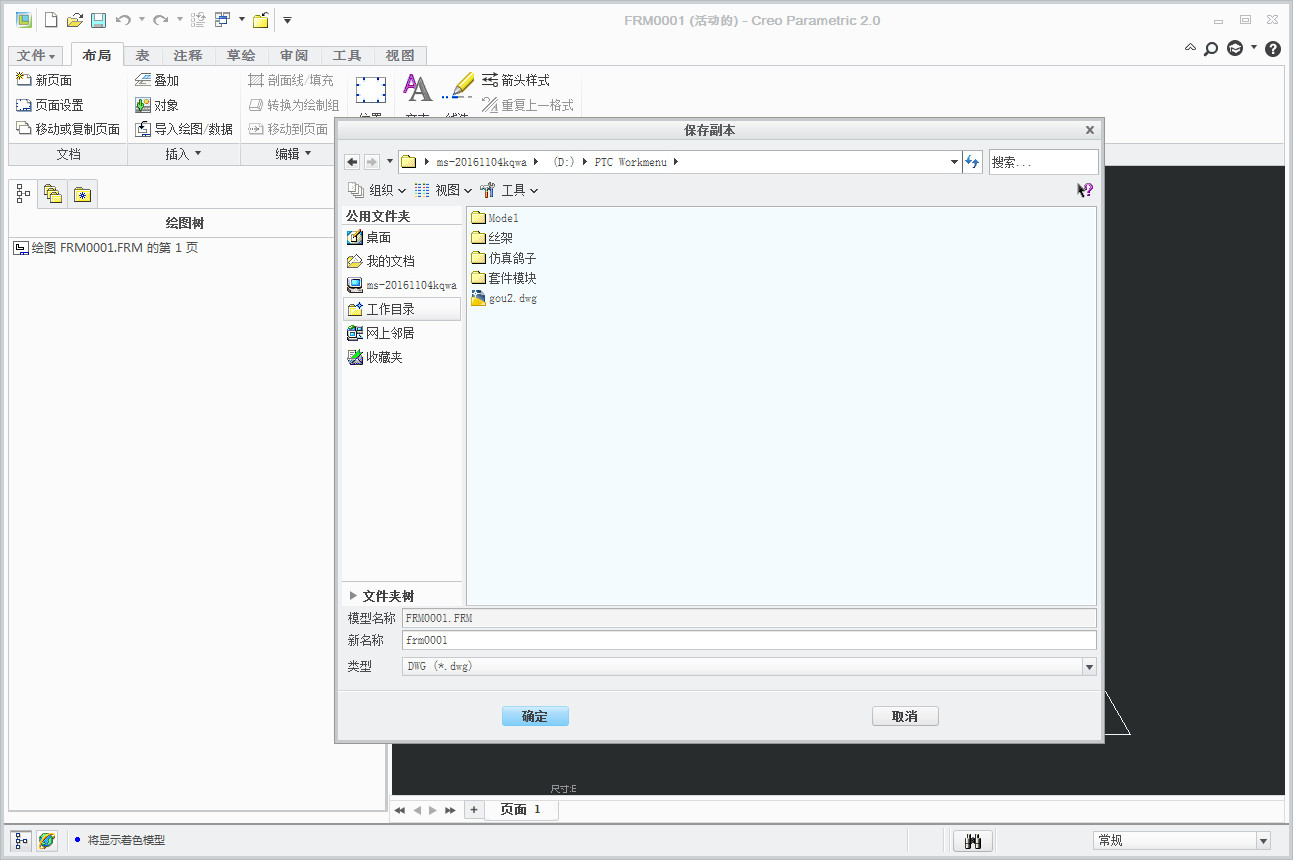

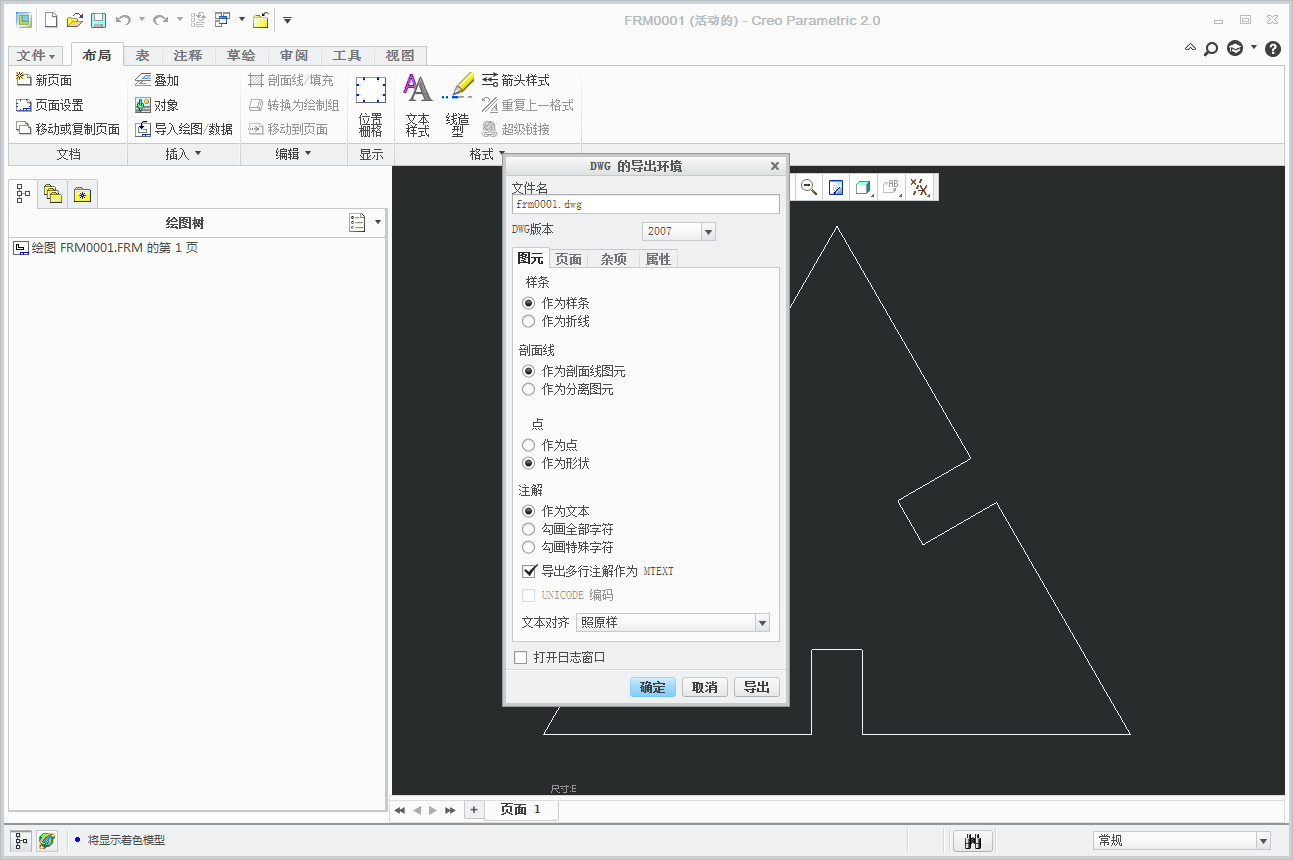

- and save as .dwg

- export it.

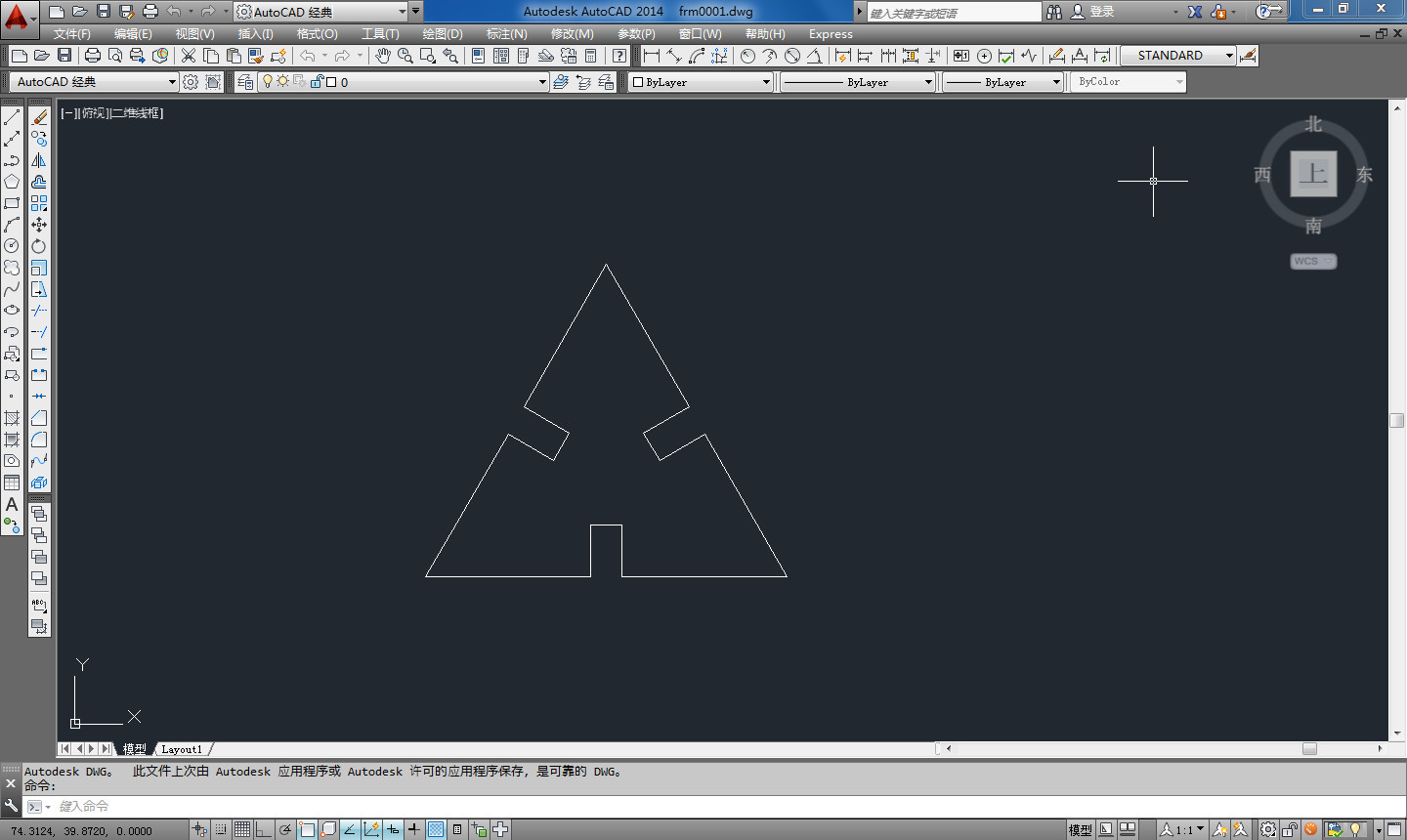

- 6. Open it with autoCAD

- Using autoCAD as a cutting software.

- measure it and I find it's right.

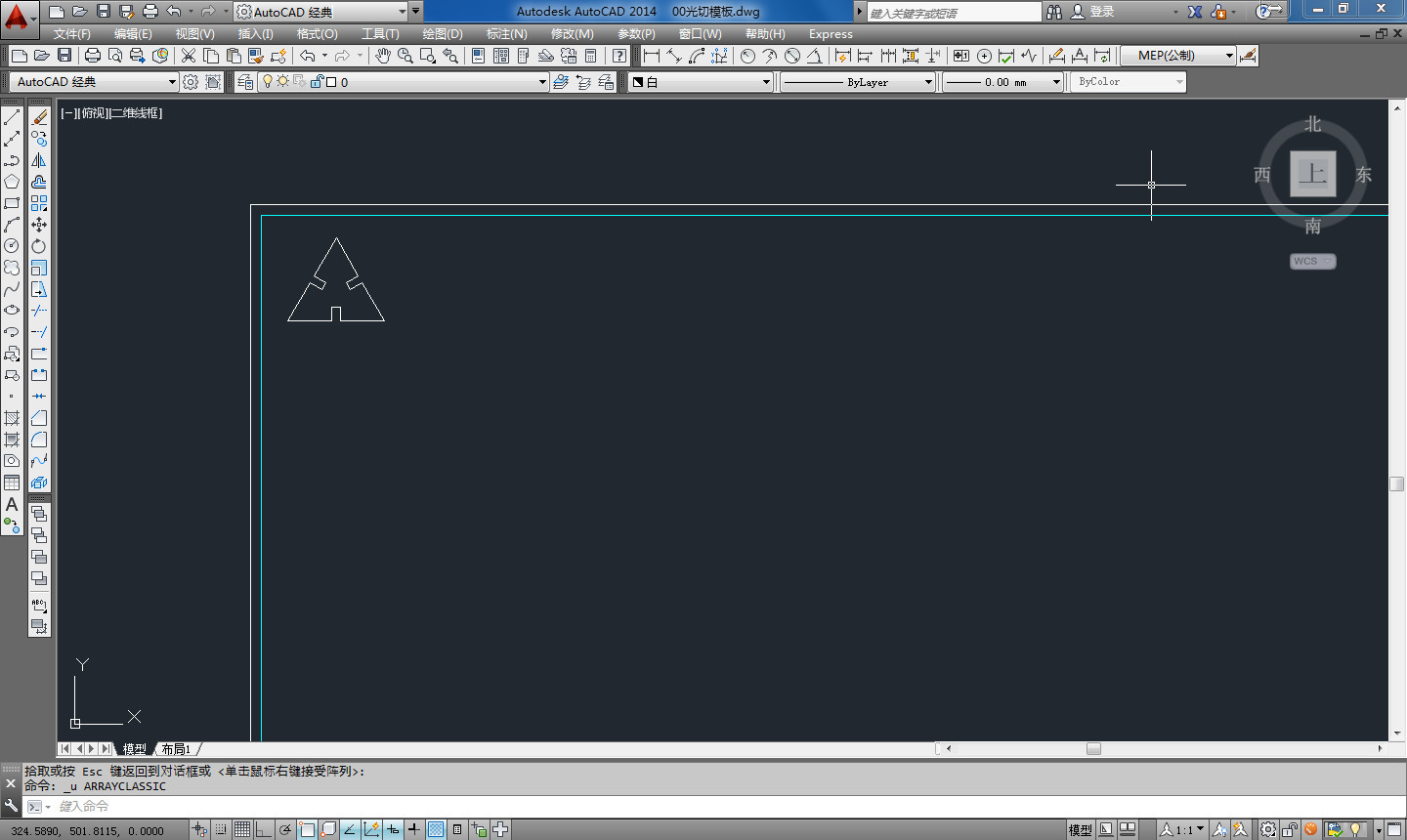

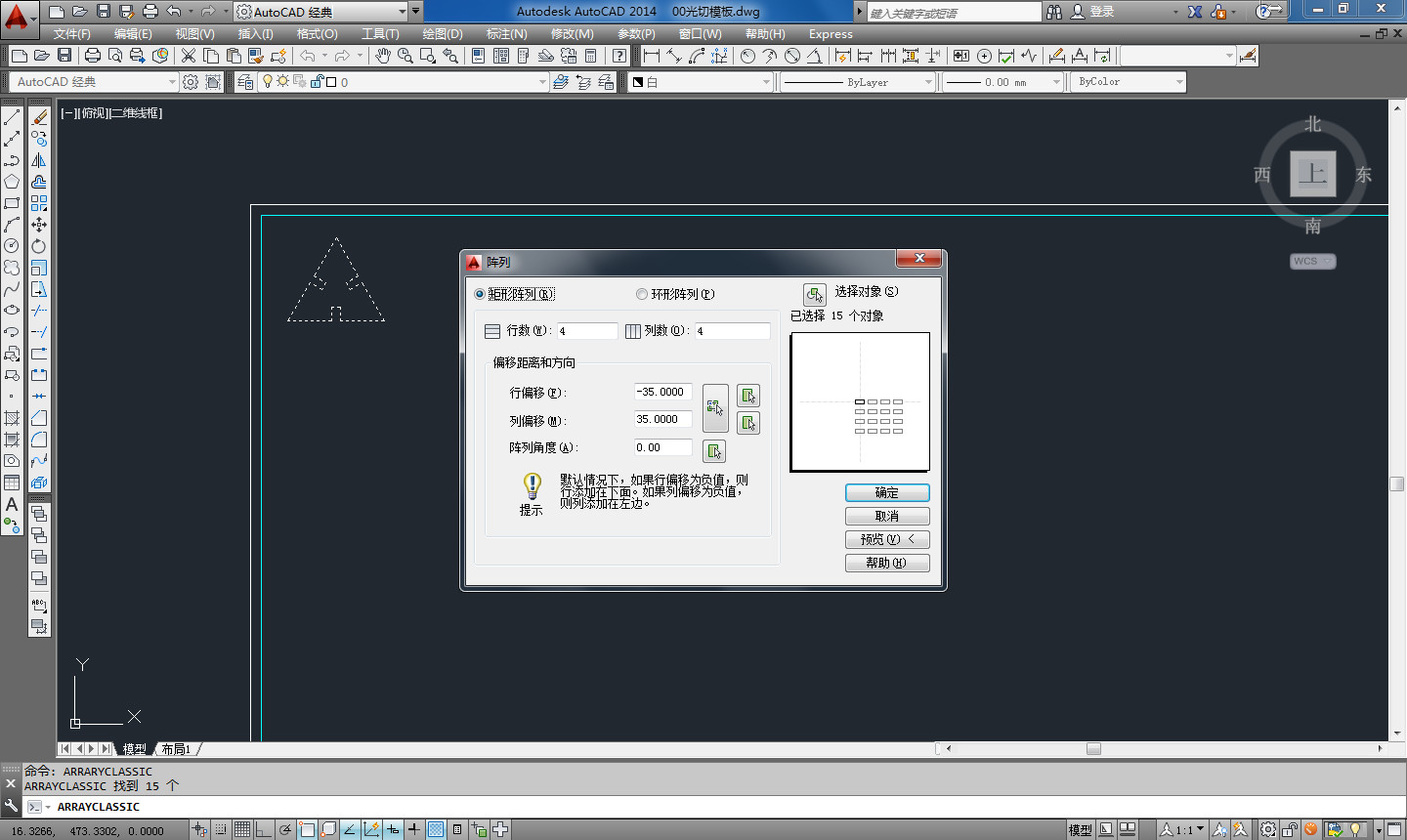

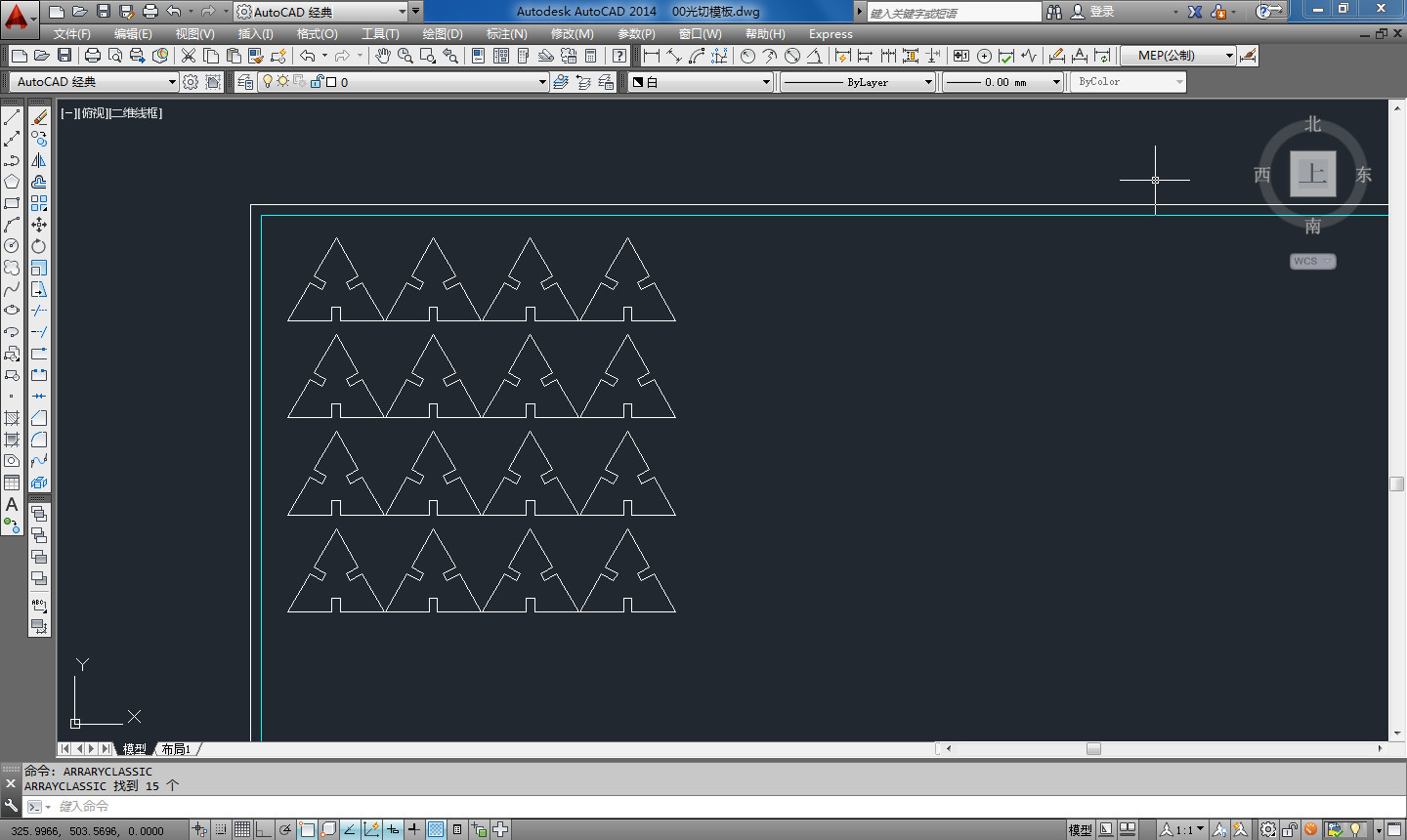

- for I need 16 pieces so I use the order "arraryclassic"

- Then it become like this.

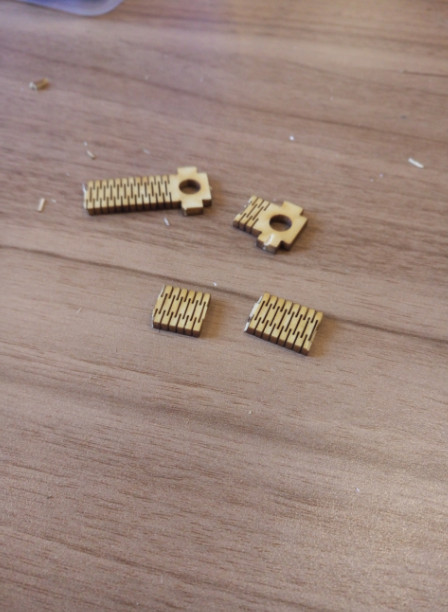

- 7. Cut it

- set parameters.

- 8. The model

- They are been cutting.

- They are combined.

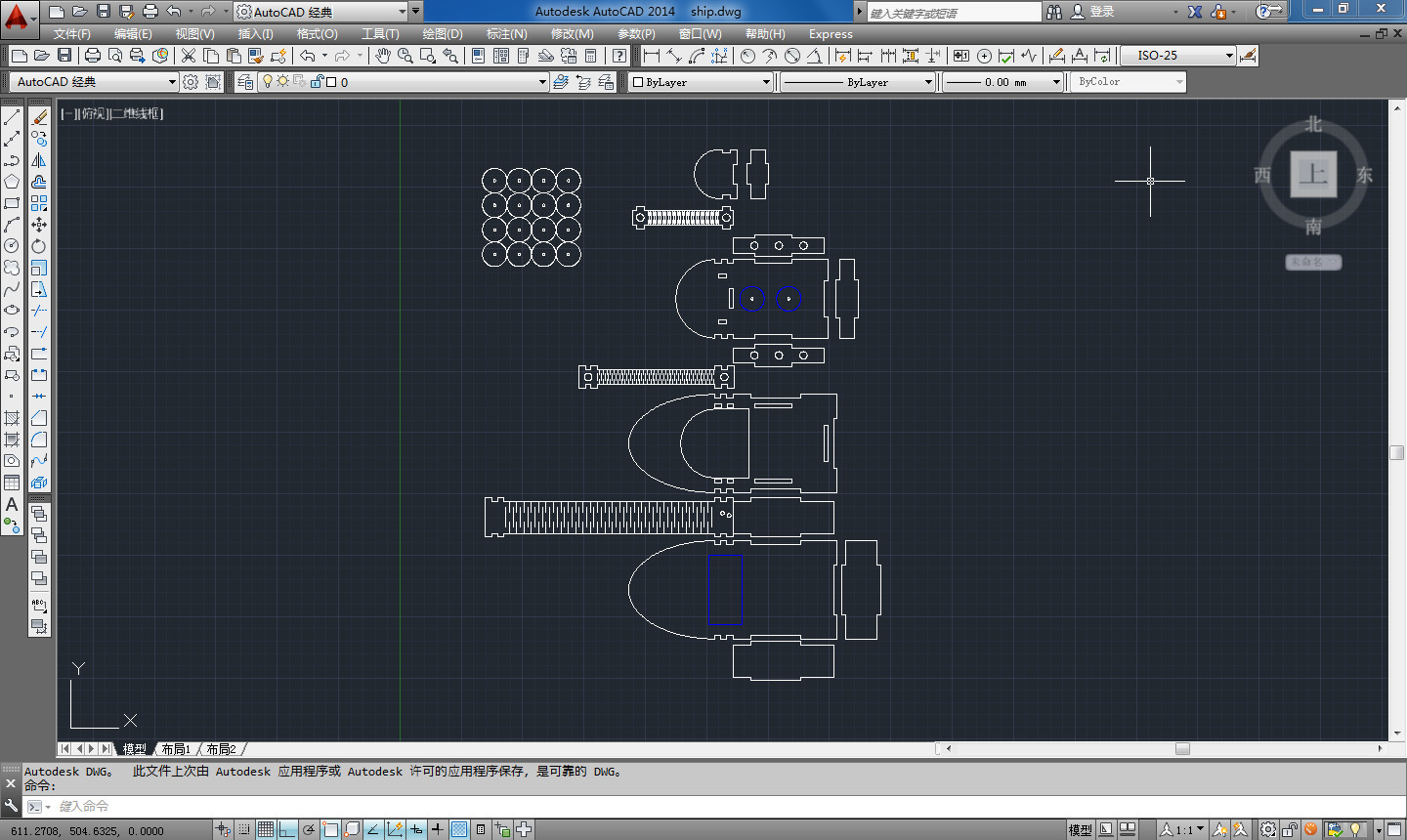

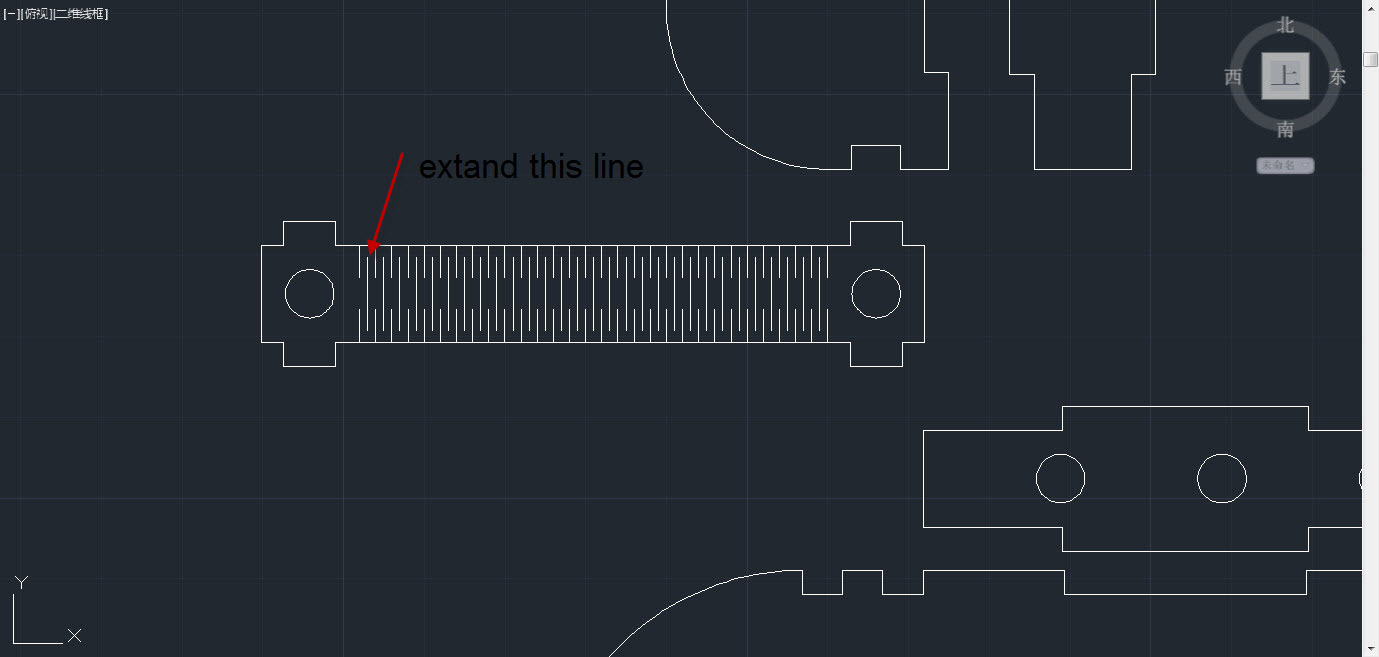

- 9. Design a ship for fun

- design it with autoCAD.

- cutting it, then something happened.

- I extend the line.

- and then it worded.

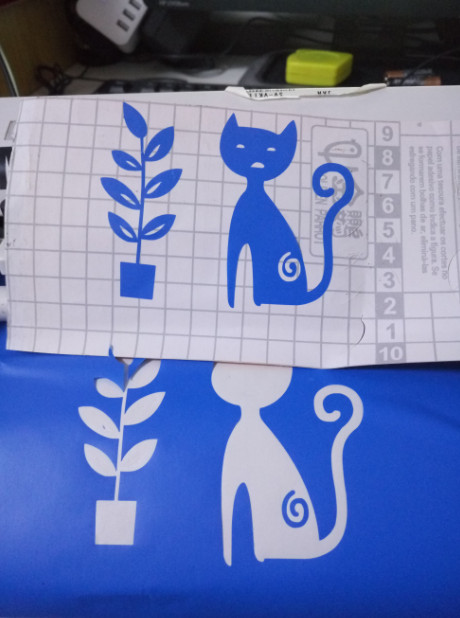

Part 3 Vinyl cutter

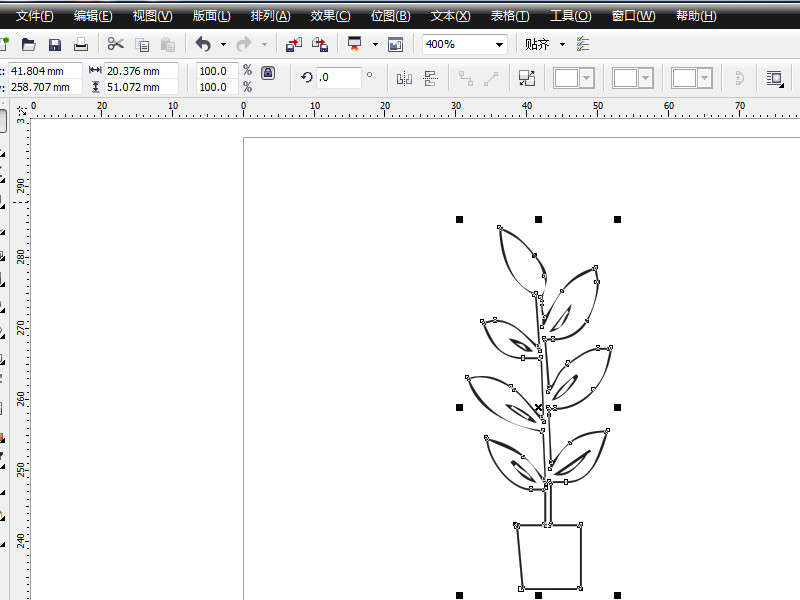

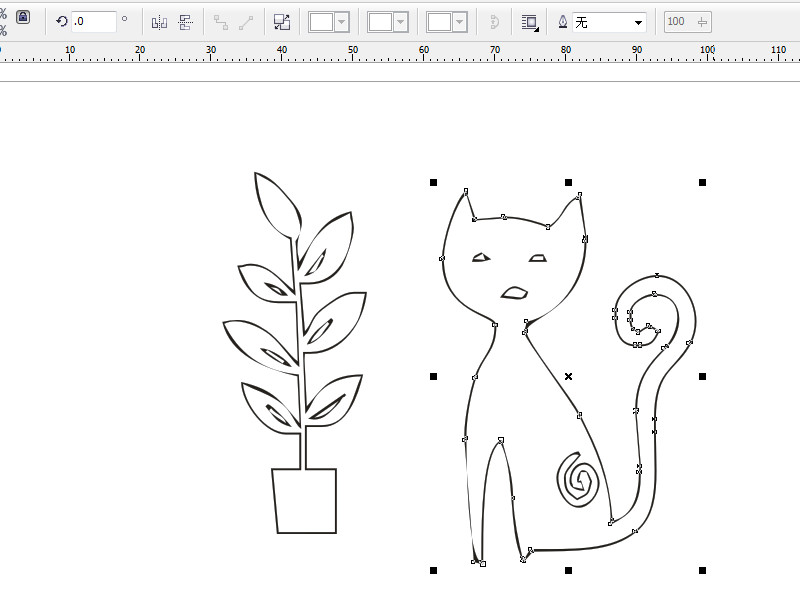

- 1. Design a cat with a pot plant

- Open corelDRAW X4, use "line" and "curves" design plant first.

- Then design the cat

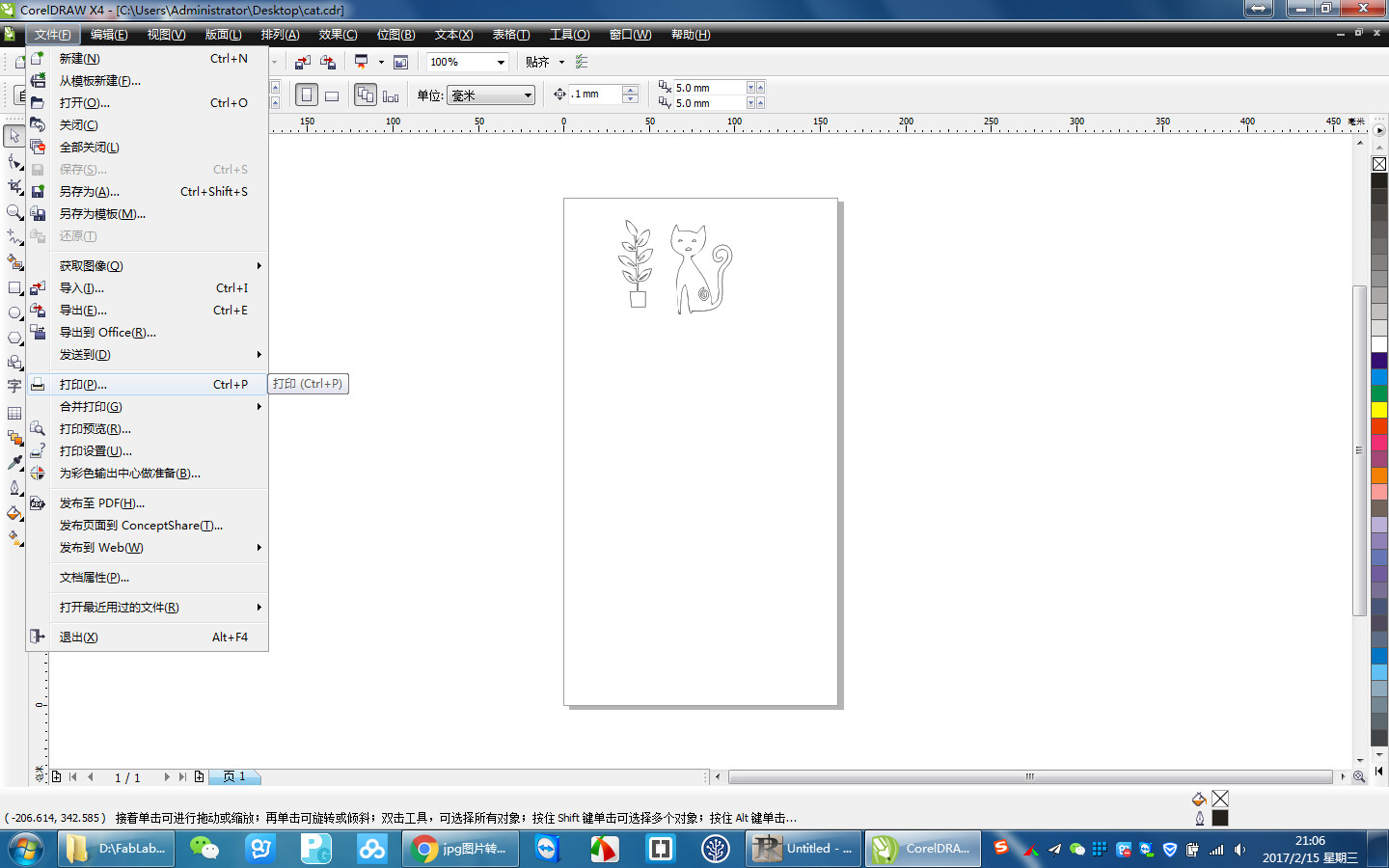

- 2. Print

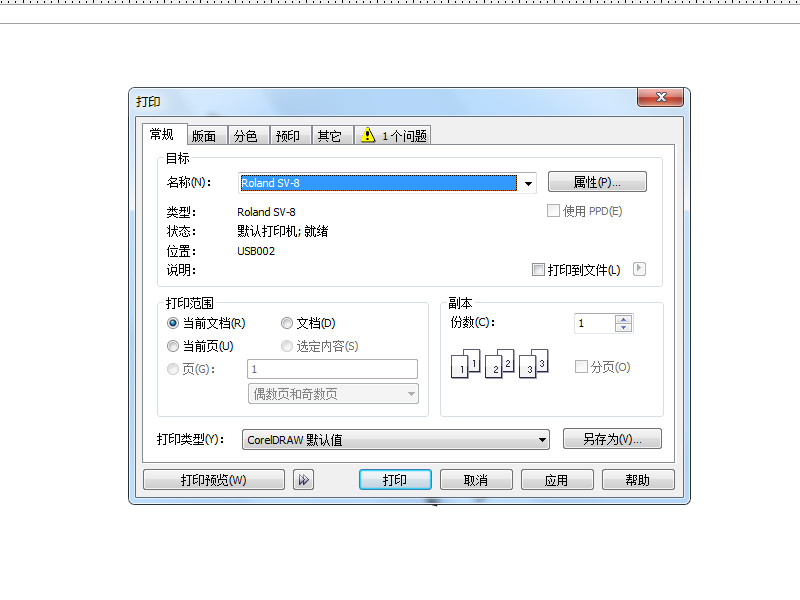

- Print it after design have done.

- Choose the printer - "Roland SV-8" a smaller vinyl cutter

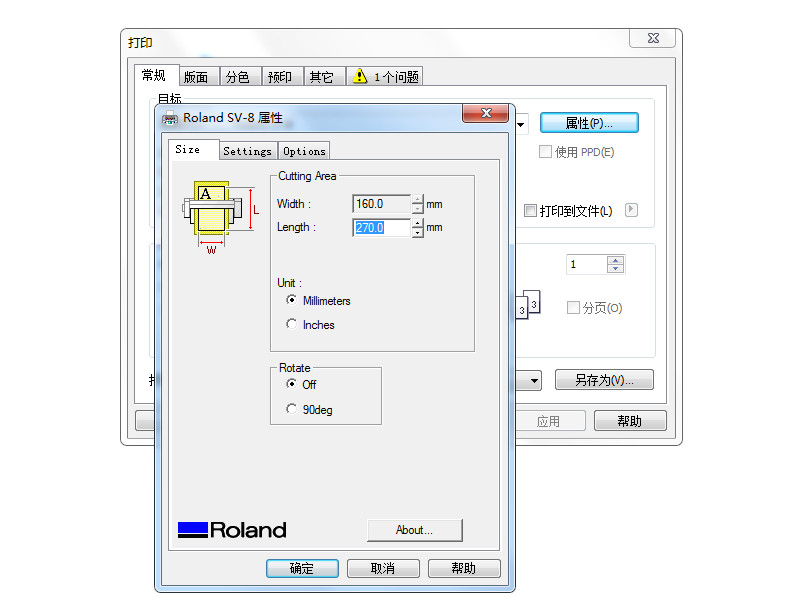

- Check the preference of printer

- 3. Vinyl cutter worked

- It is only 160mm wide, but it is enough for cutting this vector design.

- It is already done, but can't see it clearly for the knife is a little far from the paper, the paper is can't be cut through.

- The knife is a little out of the shell.

- Rotate the shell clockwise, the knife will be out.

- Unfortunately, the paper was completely cut through, that's not I want.

- Adjust the knife and cut it.

- Finally, I get a good one.