Tenth week's Assigment

For this week, the assignments to be accomplish are:

- Add an output device to a microcontroller board you've designed and program it to do something

- Learn something new

Getting inspired

Summer was in the corner and I saw my instructor make an cardboard frame surf board and I decide to test if it can be done in the CNC (my instrocture reply: that's how they are made.)

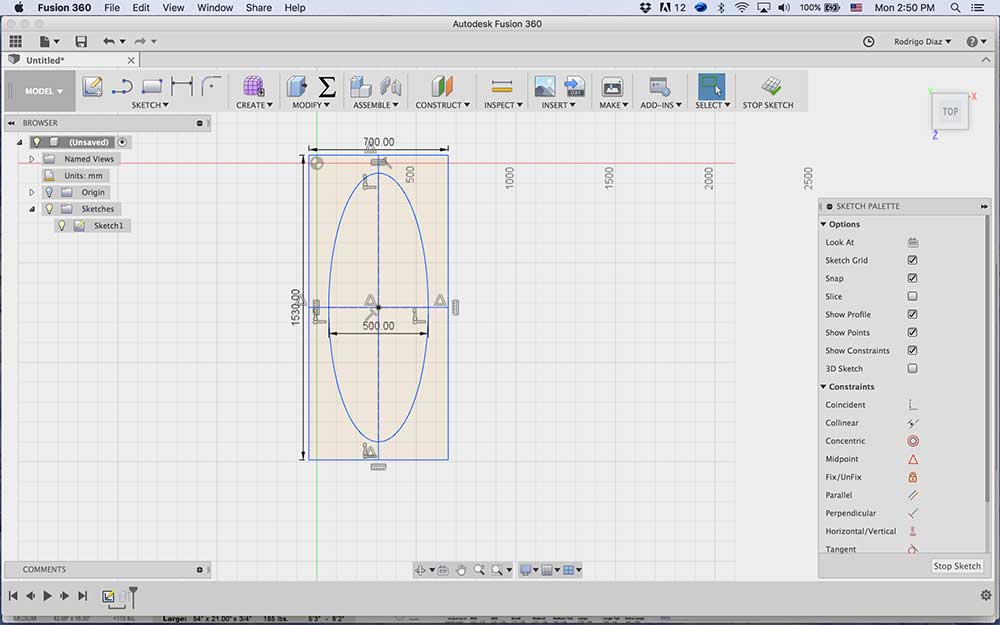

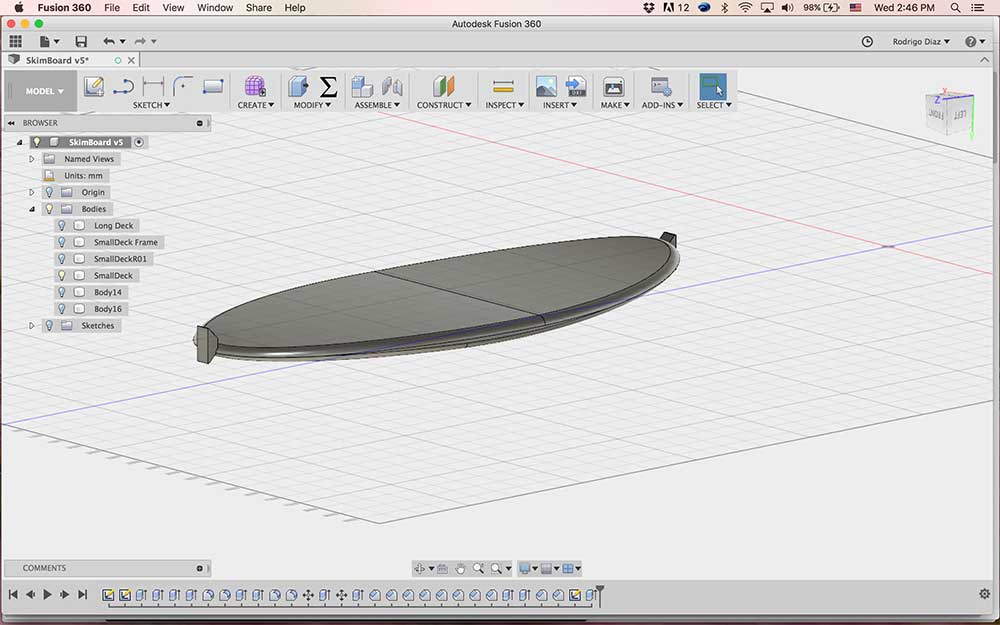

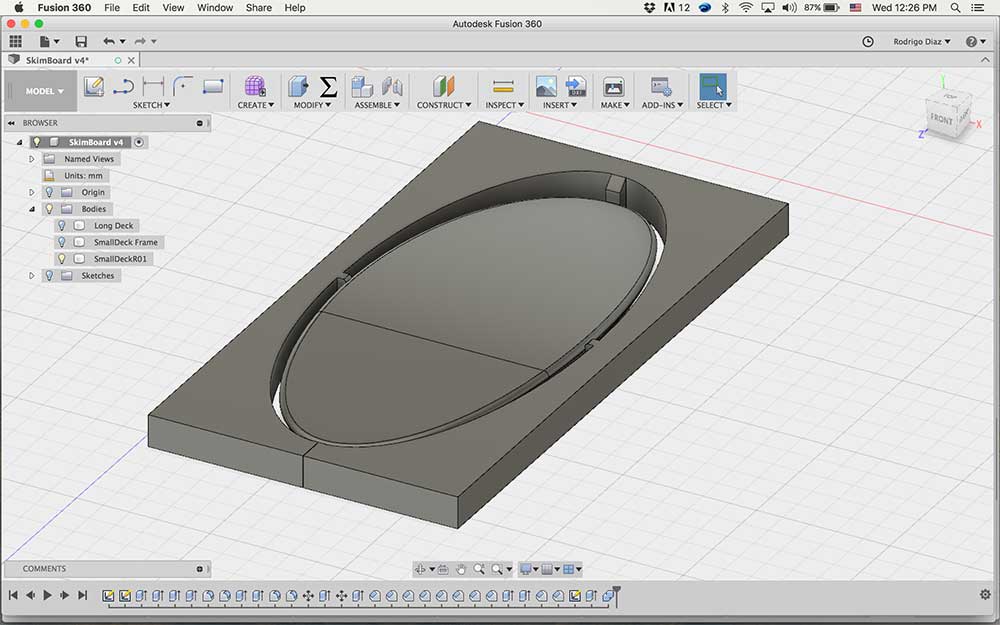

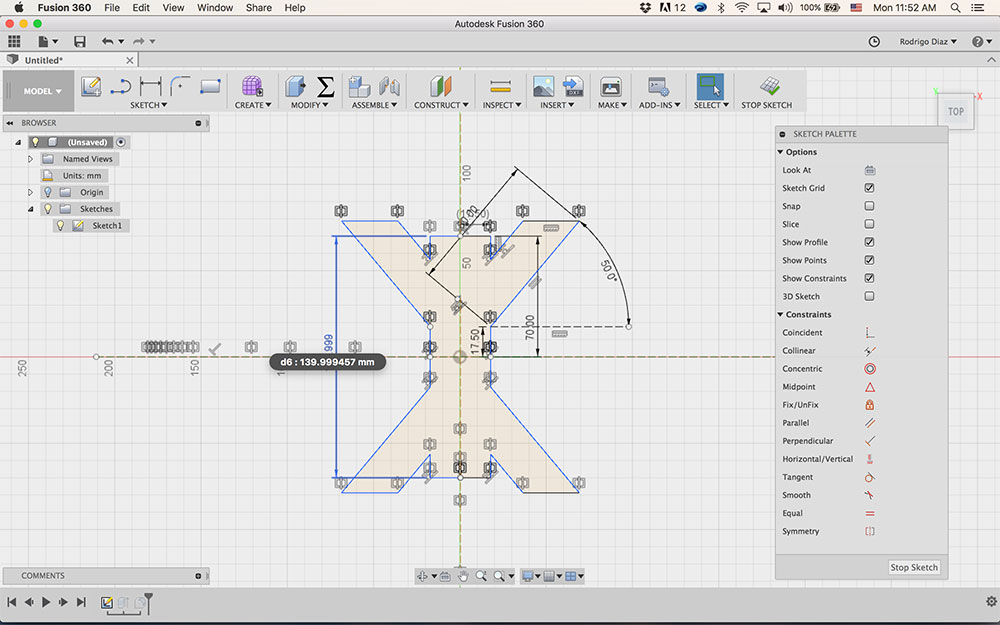

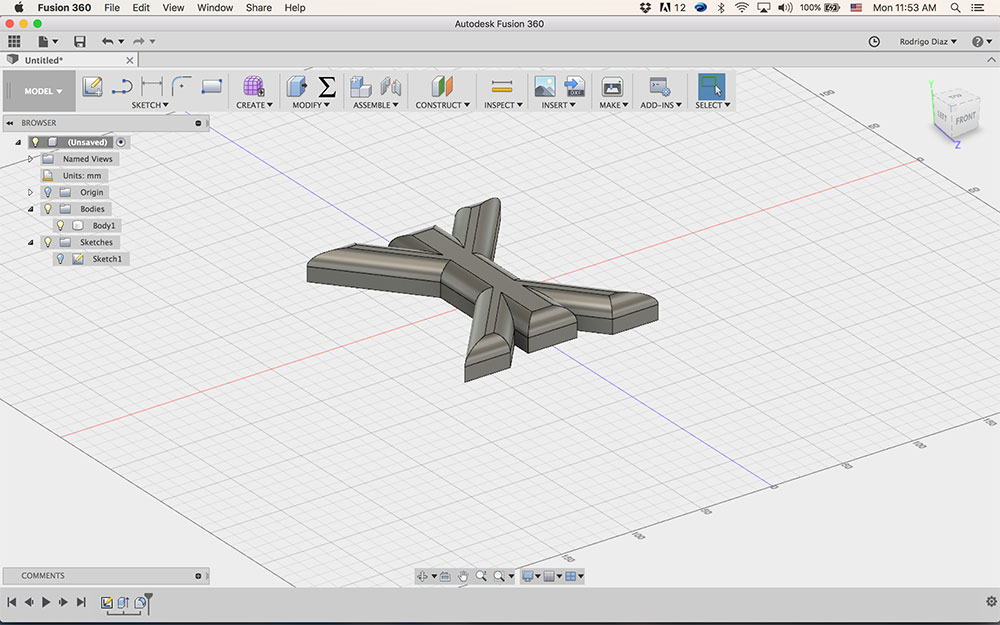

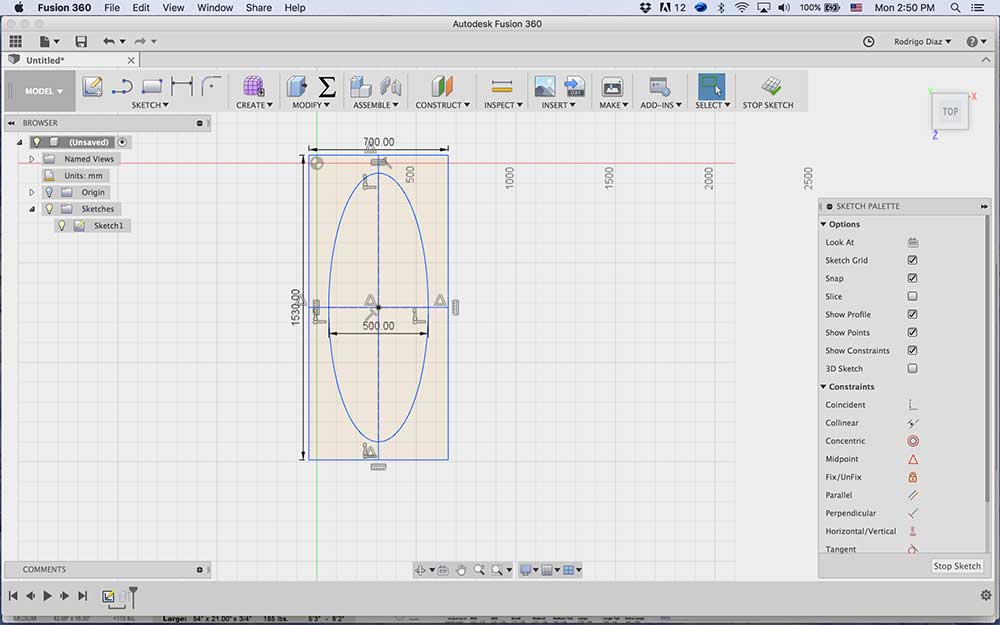

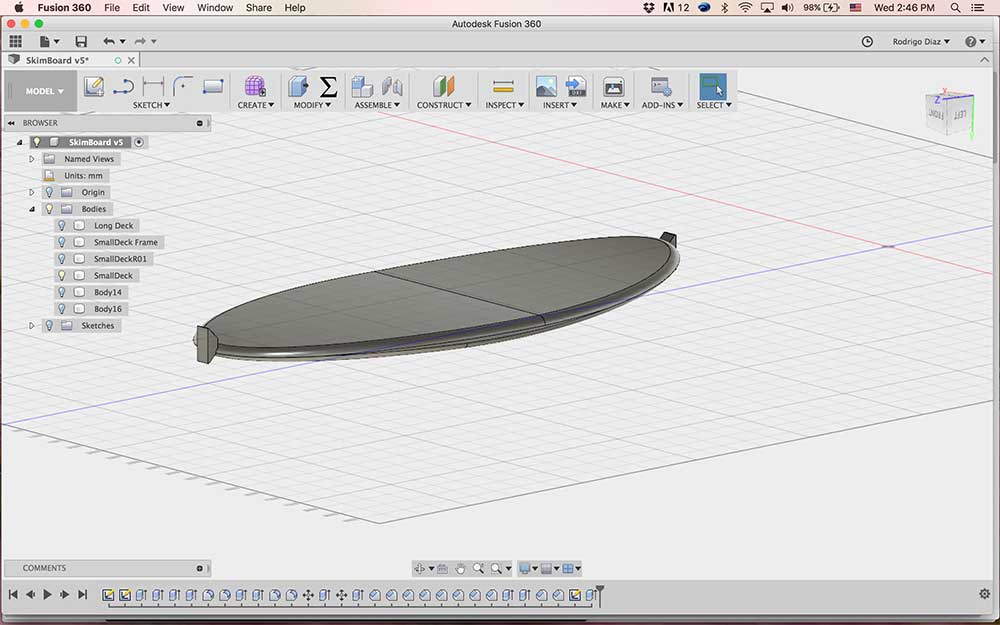

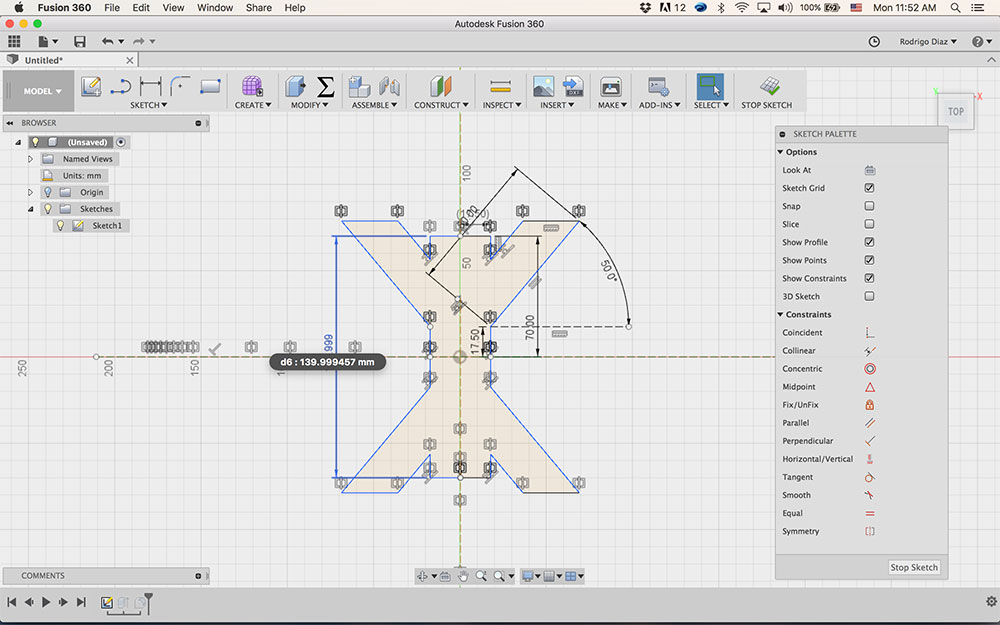

I started drawing in Fusion360 a skimboard because I really wanted to learn how they are made.

I started drawing in Fusion360 a skimboard because I really wanted to learn how they are made.

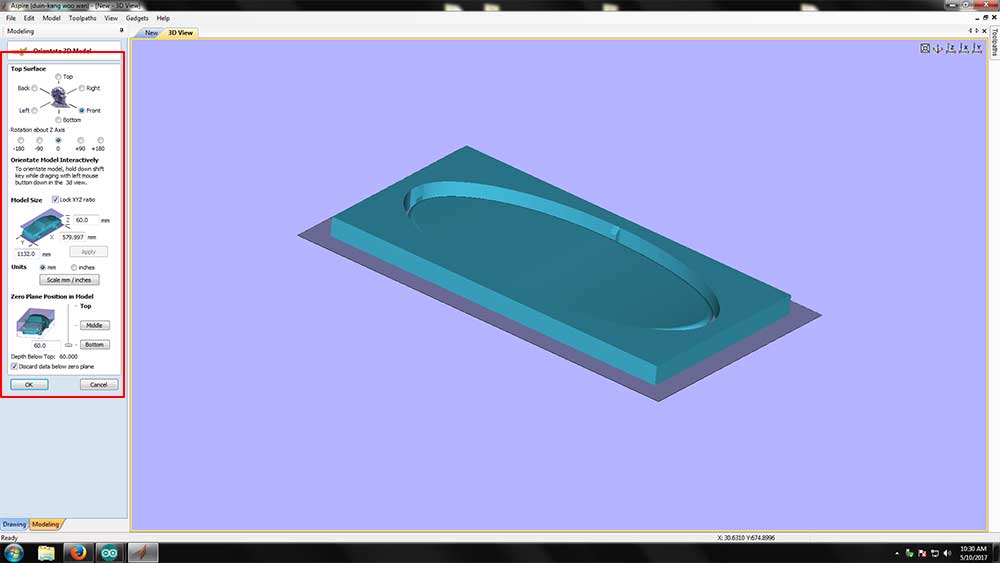

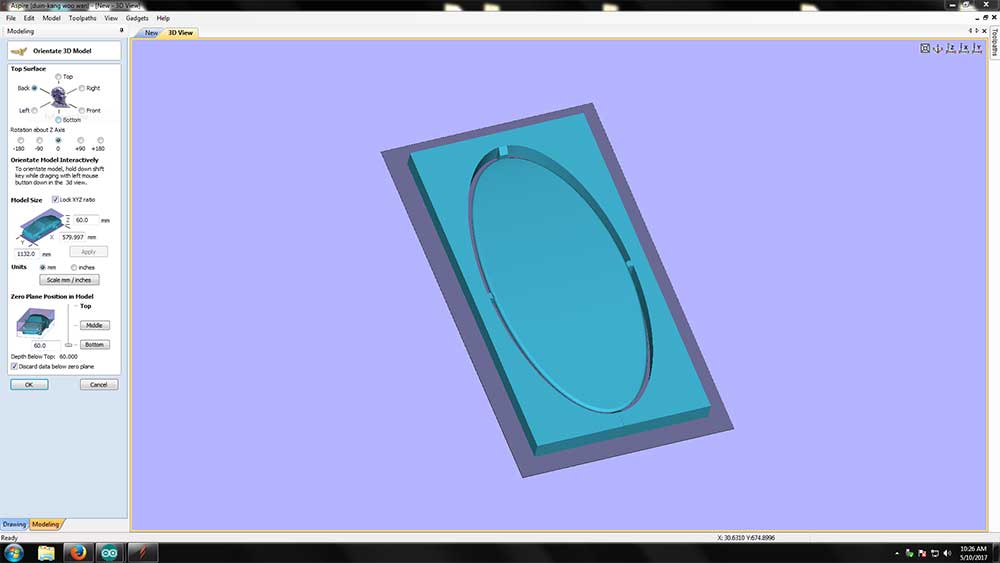

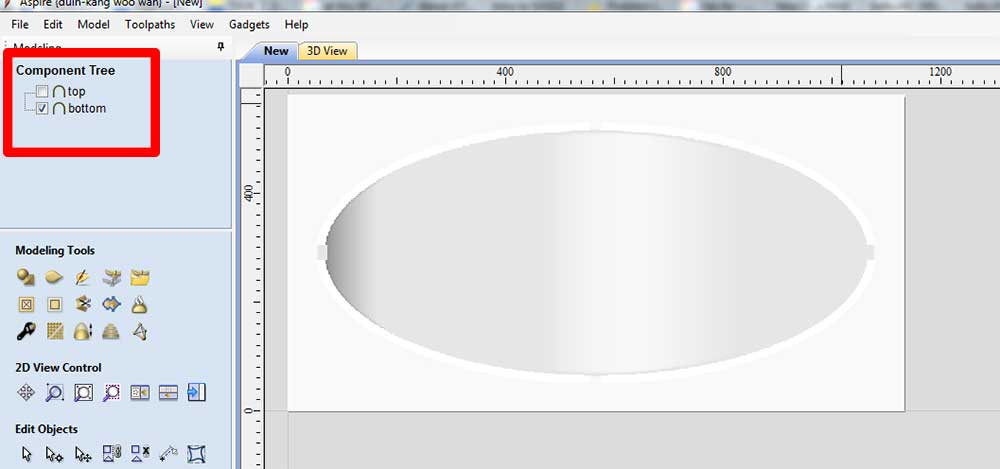

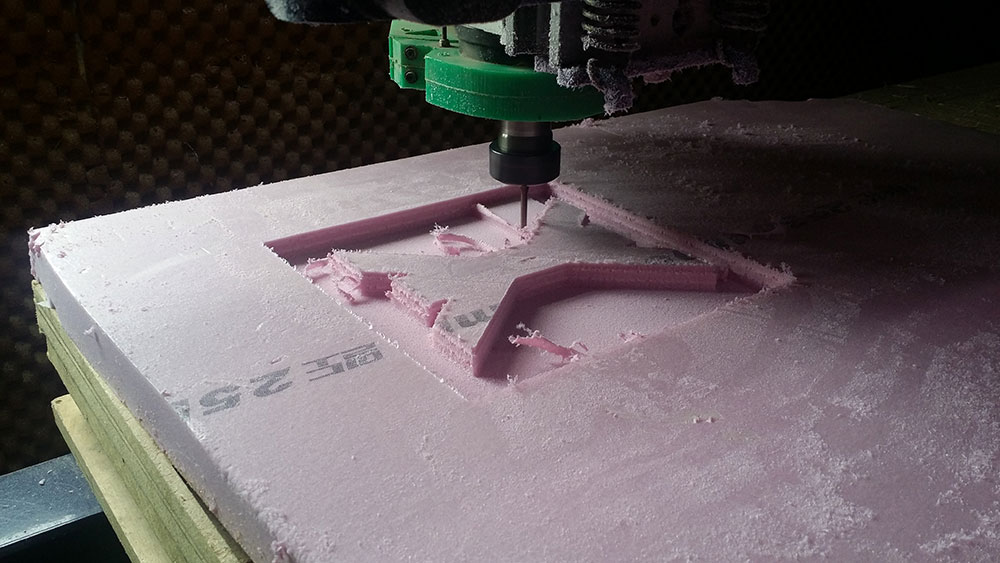

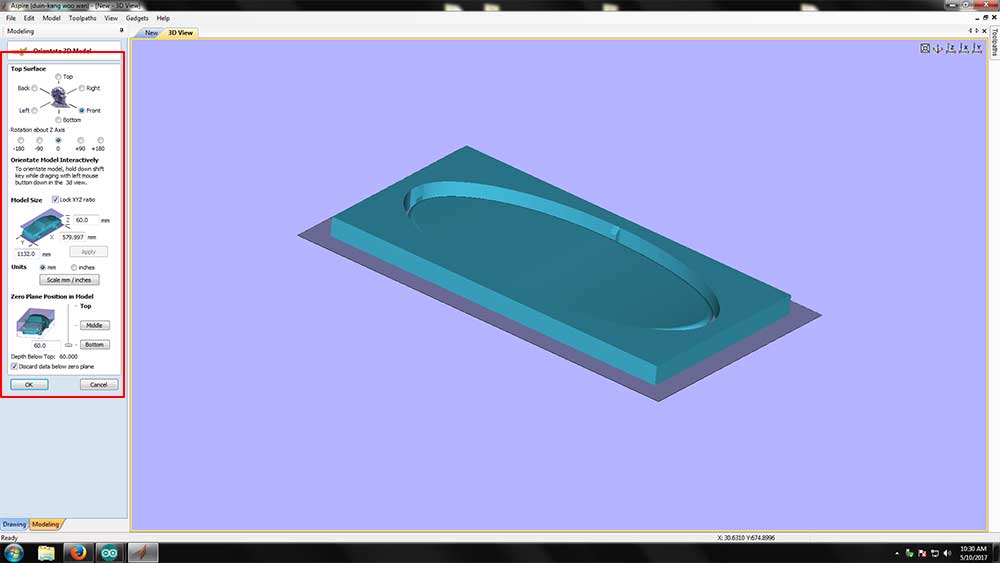

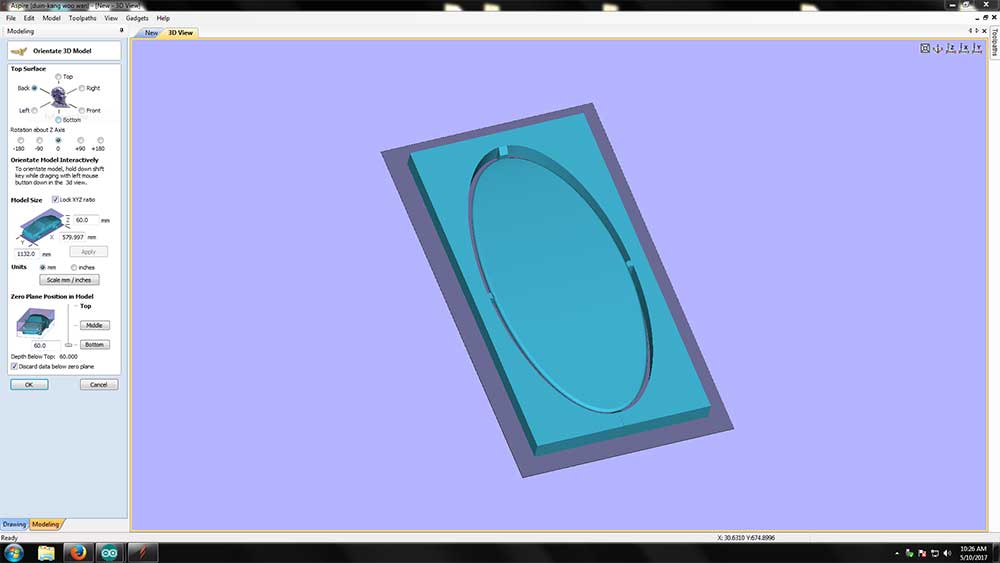

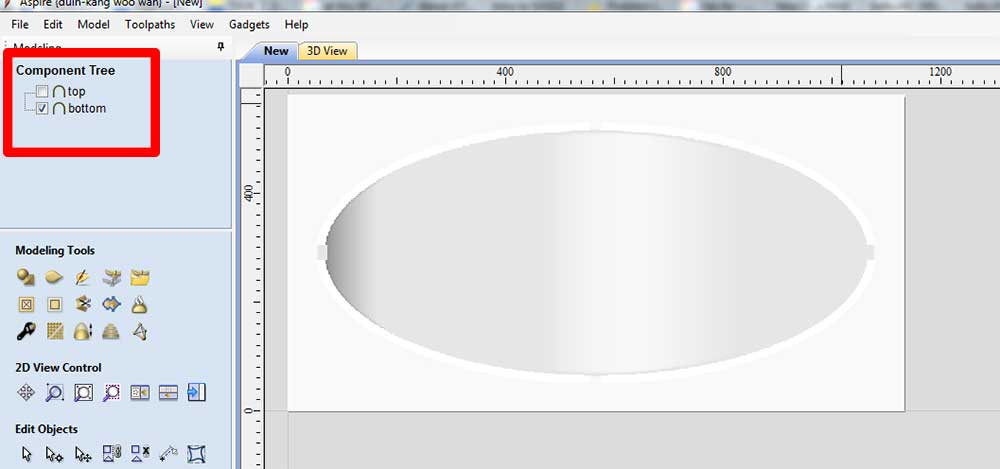

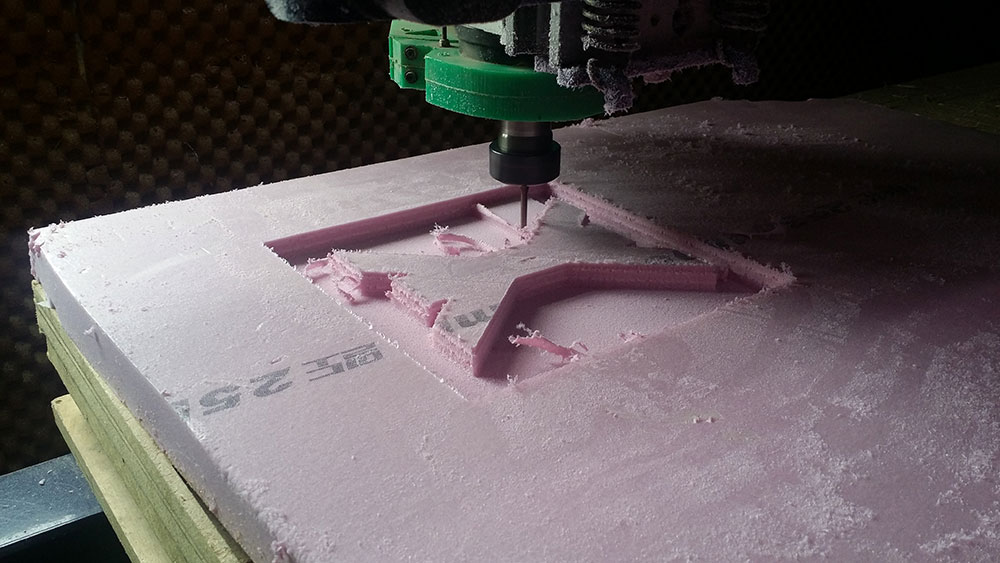

I took my design to the Aspire to create to tool path, on the top left corner you can see that I had to ajust to for the back and front to create both side tool path.

I took my design to the Aspire to create to tool path, on the top left corner you can see that I had to ajust to for the back and front to create both side tool path.

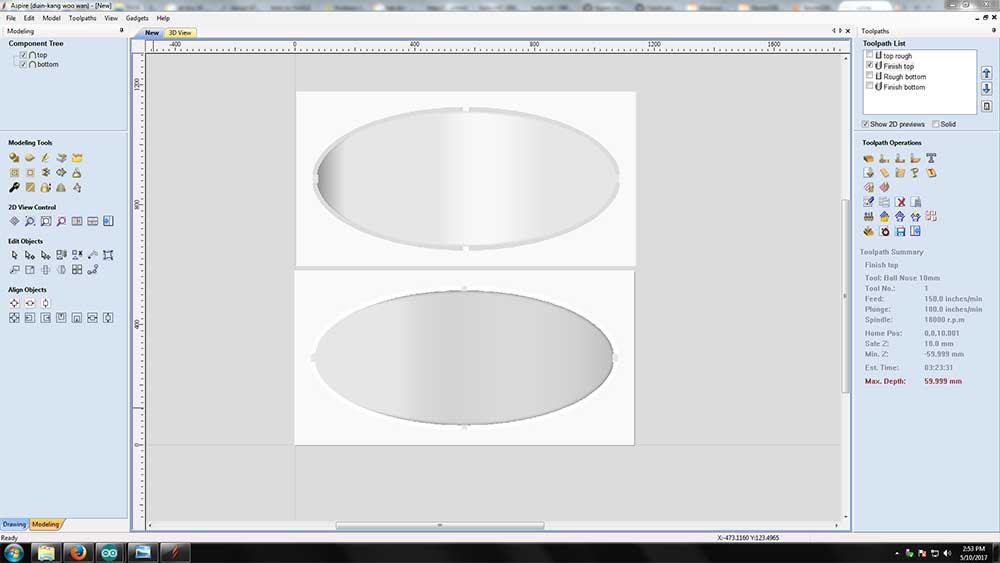

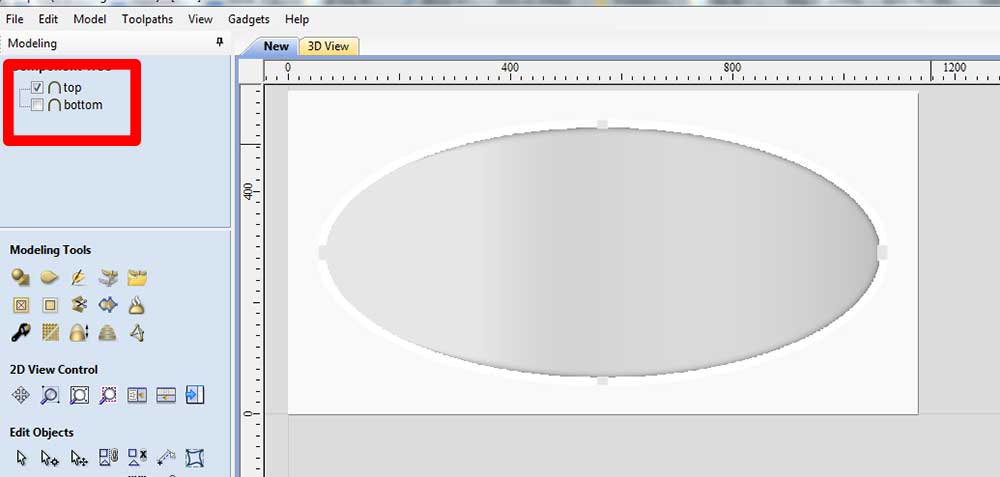

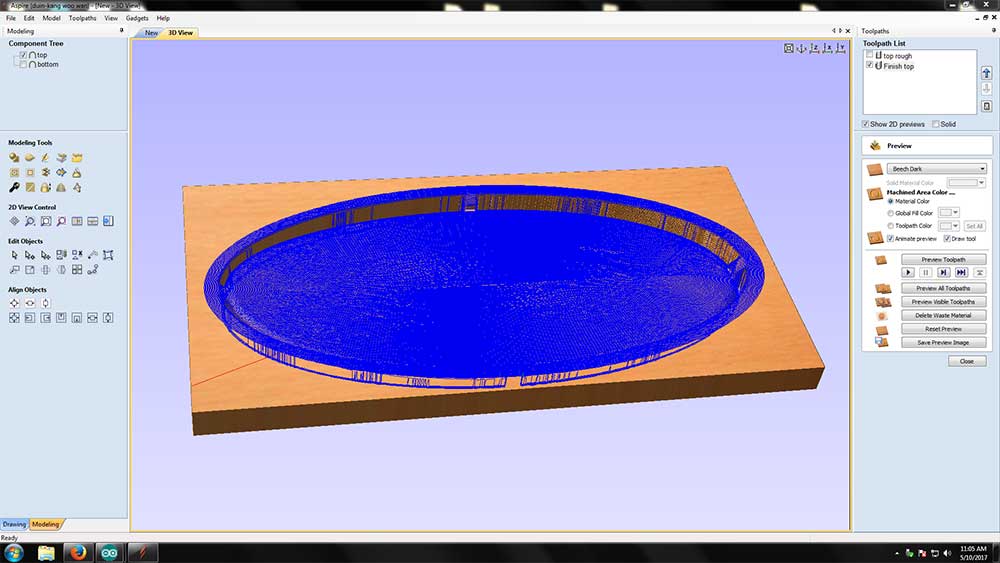

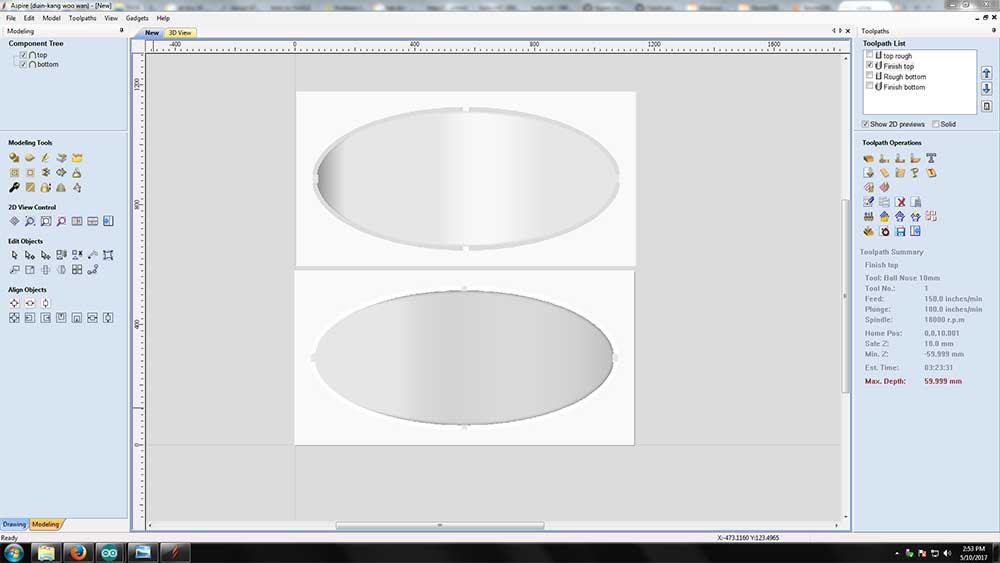

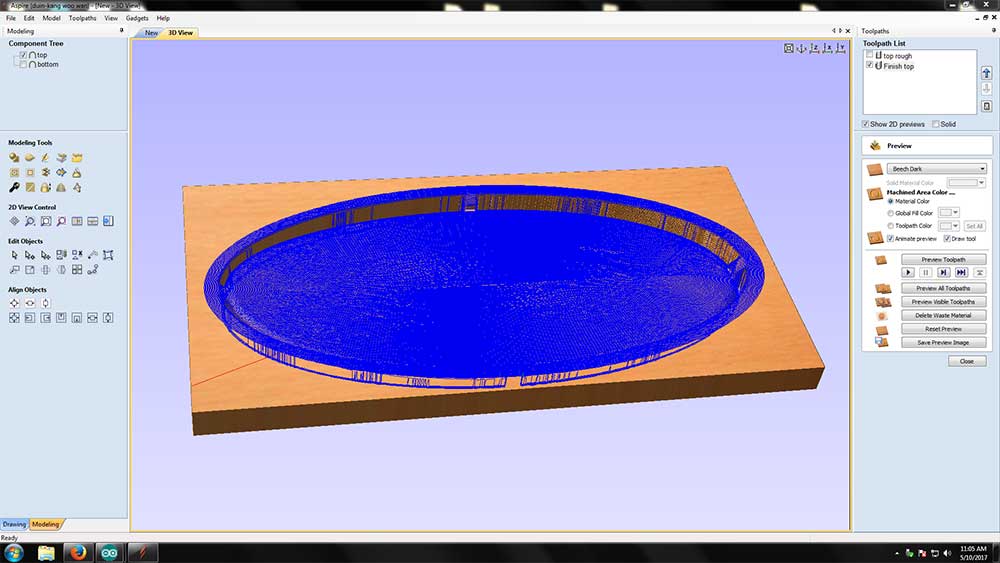

Once I created the correct side I end up with two 2D file that the CNC with interpret as 3D base on the gradation.

Once I created the correct side I end up with two 2D file that the CNC with interpret as 3D base on the gradation.

One important thing to accomplish this is that your material needs to be the same size as the project you create in the shopbot to be able to flip it over and cut the back/front part.

One important thing to accomplish this is that your material needs to be the same size as the project you create in the shopbot to be able to flip it over and cut the back/front part.

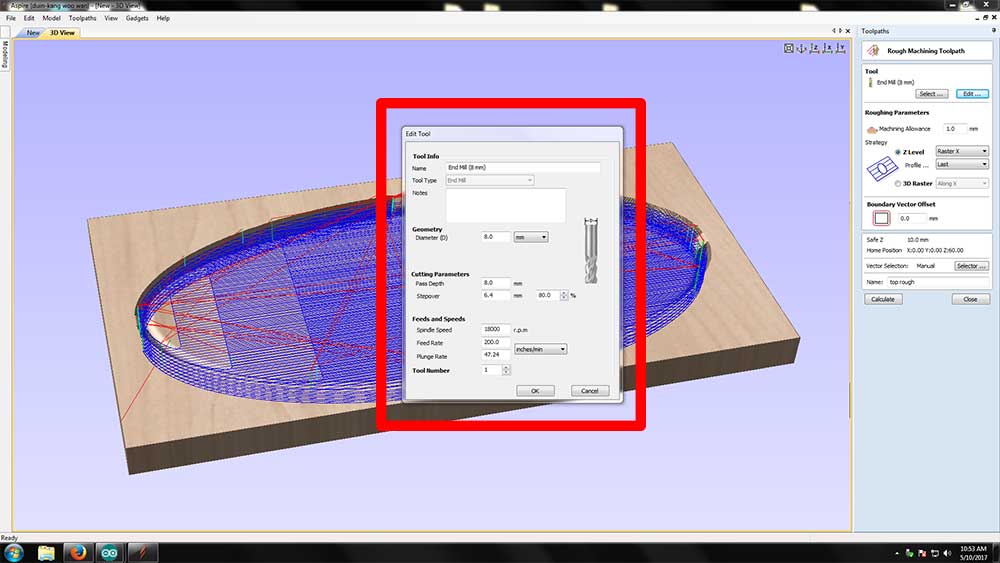

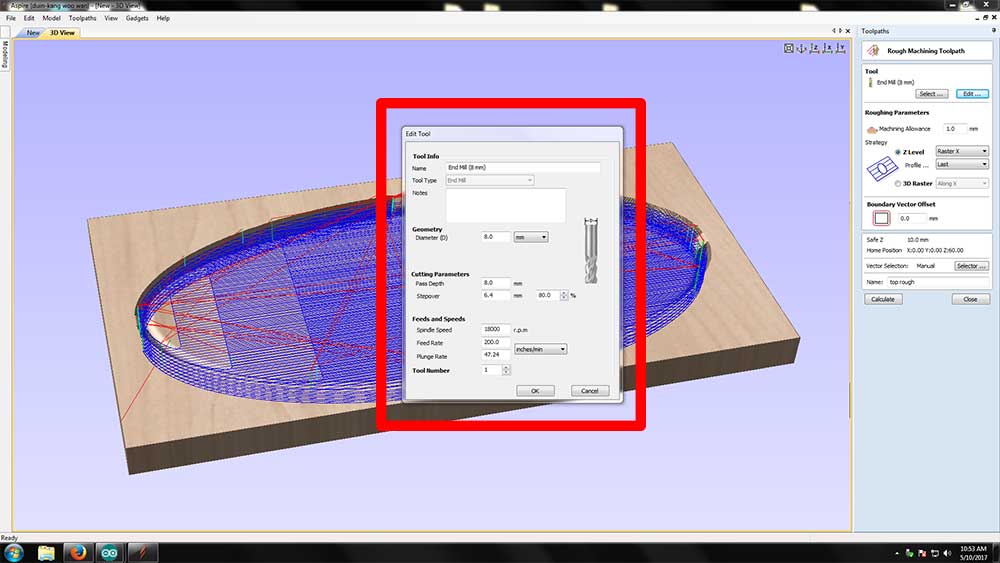

I used an 8.0mm flat endmill for the rough cut 80% stepover 15,000Rpm and 200 feed rate.

I used an 8.0mm flat endmill for the rough cut 80% stepover 15,000Rpm and 200 feed rate.

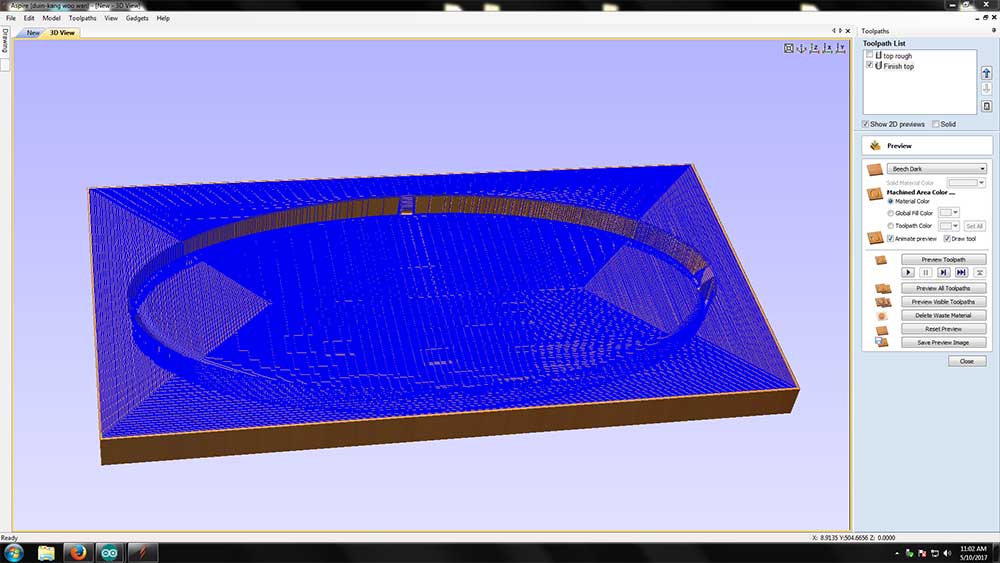

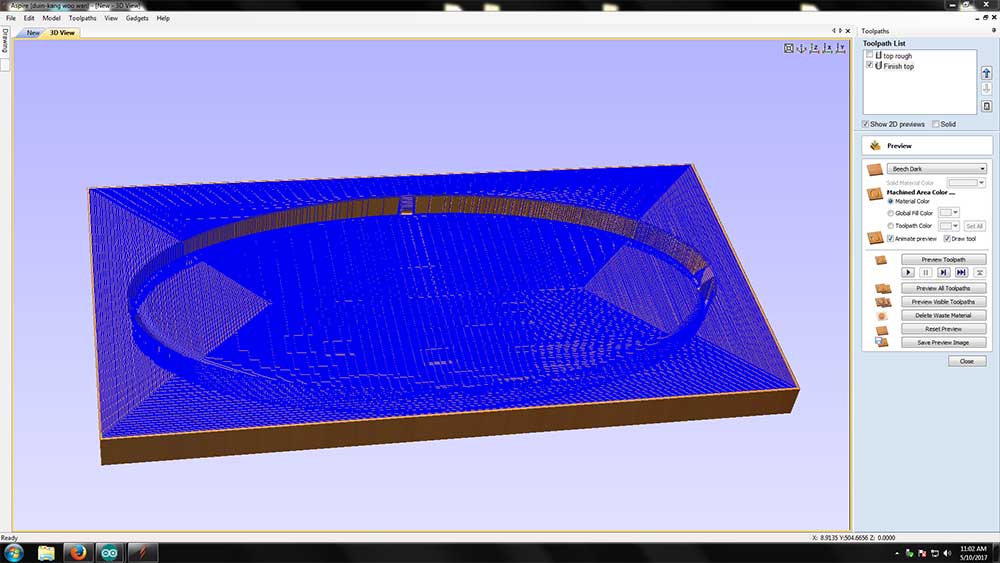

As you can see in the picture on the right the tool path was in the whole surface and that increased the time of the cut.

I fixed that by adding and offset/vector to the edge of the board to tell the Aspire the limit of the cut.

I fixed that by adding and offset/vector to the edge of the board to tell the Aspire the limit of the cut.

After that I glue my material.

Put some heavy on it and wait for 24 hours.

Put some heavy on it and wait for 24 hours.

Finish Cut and the stair like rough cut.

Finish Cut and the stair like rough cut.

Made the first finish and flip it over and it was done!! it took around two rough cuts equivalents to 4 hours each and to finishing cuts equivalent to 5 hours each.

Made the first finish and flip it over and it was done!! it took around two rough cuts equivalents to 4 hours each and to finishing cuts equivalent to 5 hours each.

Let's suit up for a little sanding!

I was so exited to see the model being born!

I was so exited to see the model being born!

After a little sanding and was ready to lay down!

After a little sanding and was ready to lay down!

I was so happy that I even if I had no help from my instrutor, I tried to do it by myself and I TOTALLY failed!!!!! HAHAHAH (crying inside)

I was so happy that I even if I had no help from my instrutor, I tried to do it by myself and I TOTALLY failed!!!!! HAHAHAH (crying inside)

Problem!! the epoxy specification were 30 minute to cure no enough time for the proper laydown.

Problem!! the epoxy specification were 30 minute to cure no enough time for the proper laydown.

since it was not 100% correct it made bubbles that would make the board failed when riding it! So, I could fixit but it wouldn't have the compressor technic that is required for this week assigment.

Starting all over again (almost)

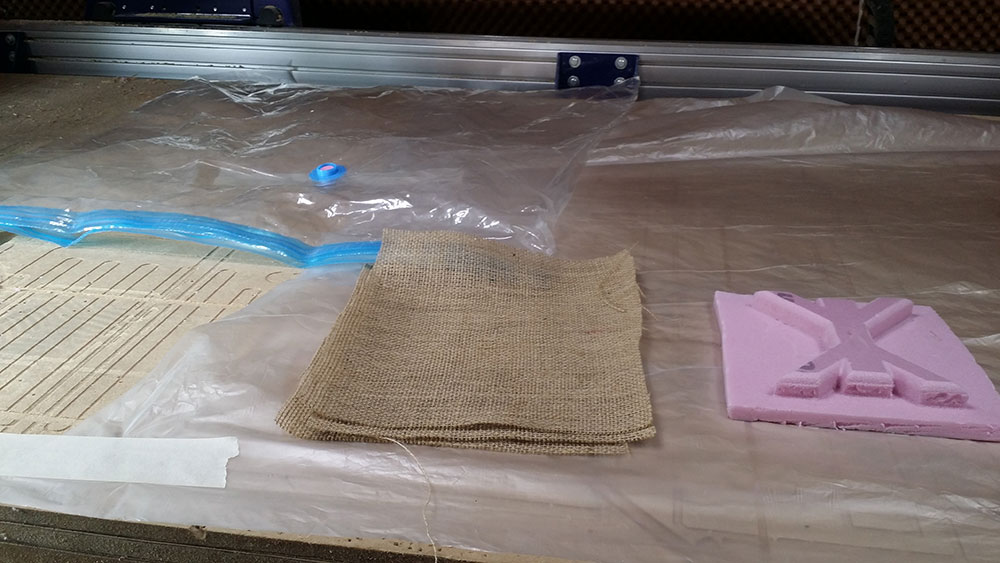

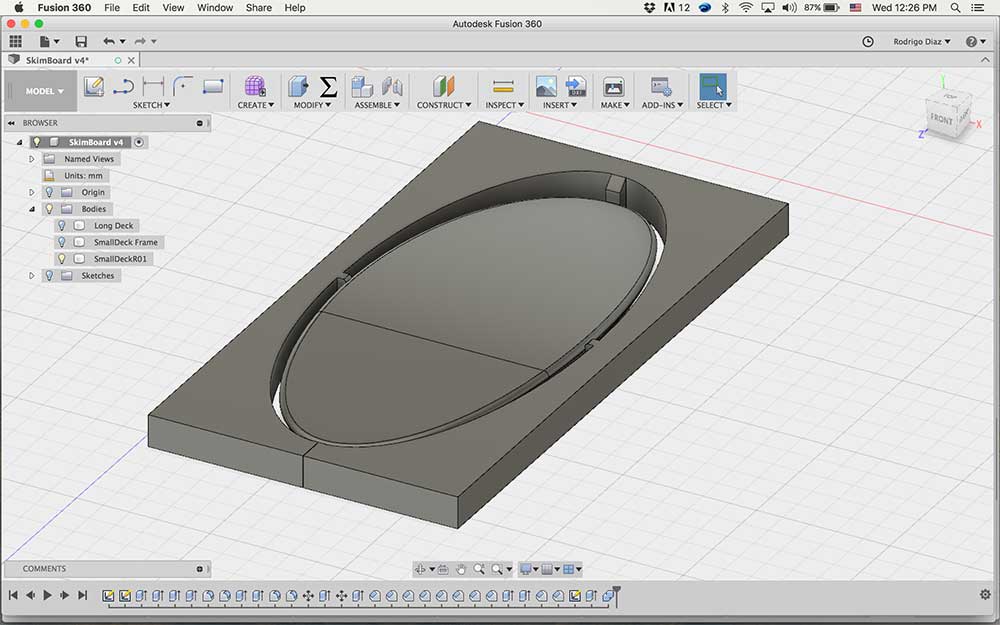

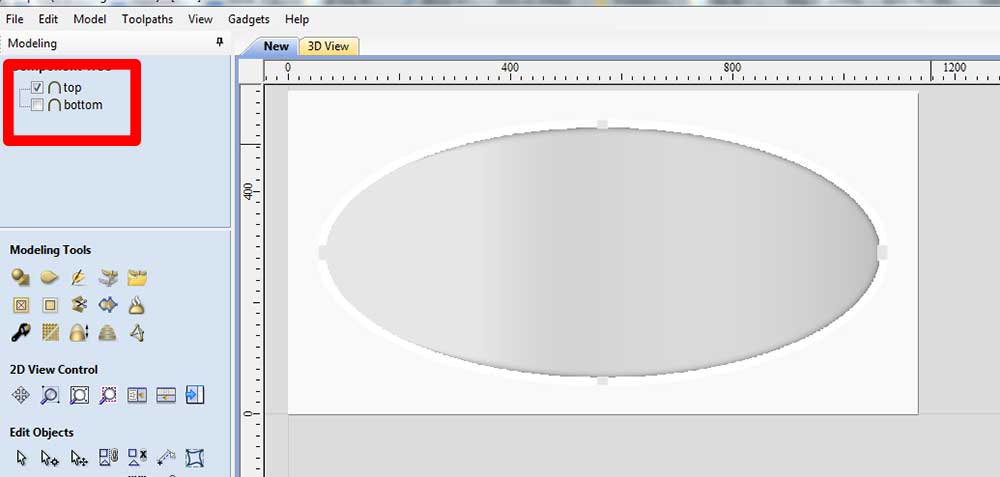

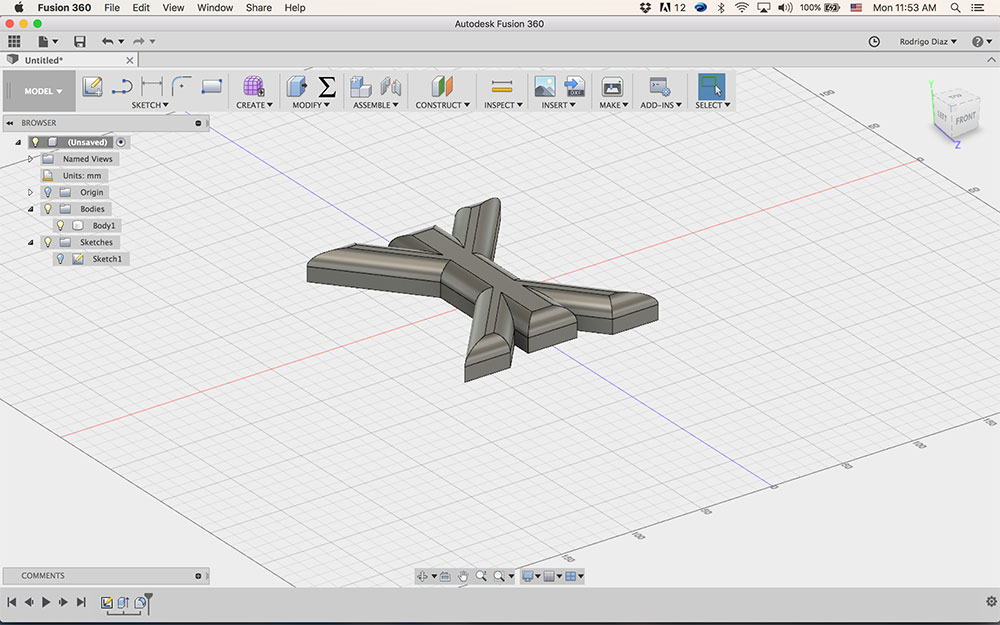

Since I learnt how to make big/double side molds I decide to go for an smaller and easier mold!

Since I learnt how to make big/double side molds I decide to go for an smaller and easier mold!

A drone frame to test how would look!

A drone frame to test how would look!

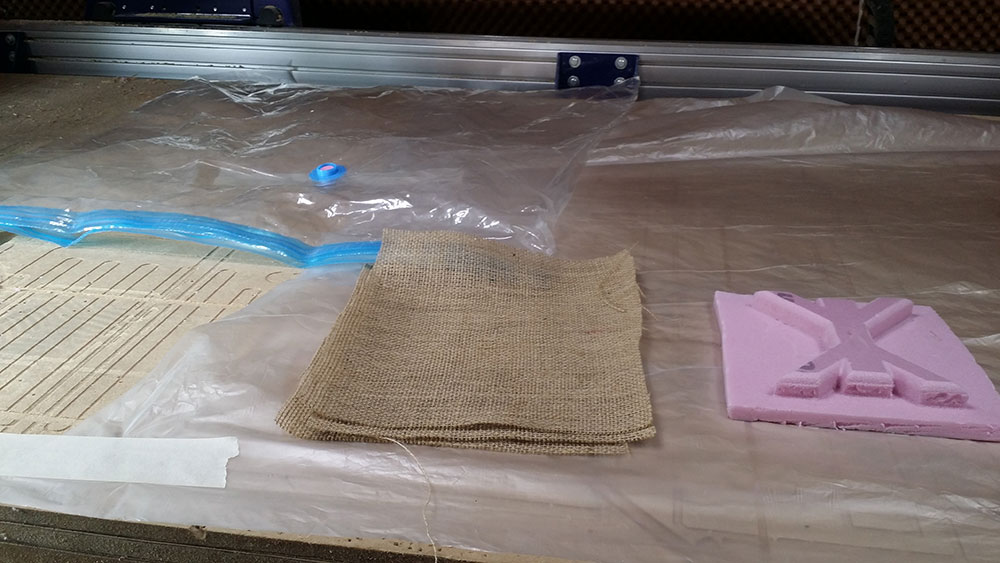

MSDS for Polyester Fiber and Resin.

This time I prepared in advance! Since I was the one student doing this task (after final presentation) there's was no breather left, So I used the same material "burlap" just by adding an extra layer of it!, The resin I used is the one we buy in bulk (super cheap very) has about 40 minute to cure time (plenty of time, lesson learnt) and from 24 hours to a week to fully harden. For safety I used gloves and a respirator (safety first). after that have a vendor that takes care of the dispossal.

Mix 2:1 activator:resin and pure very slowly to dont make a mess!!

Mix 2:1 activator:resin and pure very slowly to dont make a mess!!

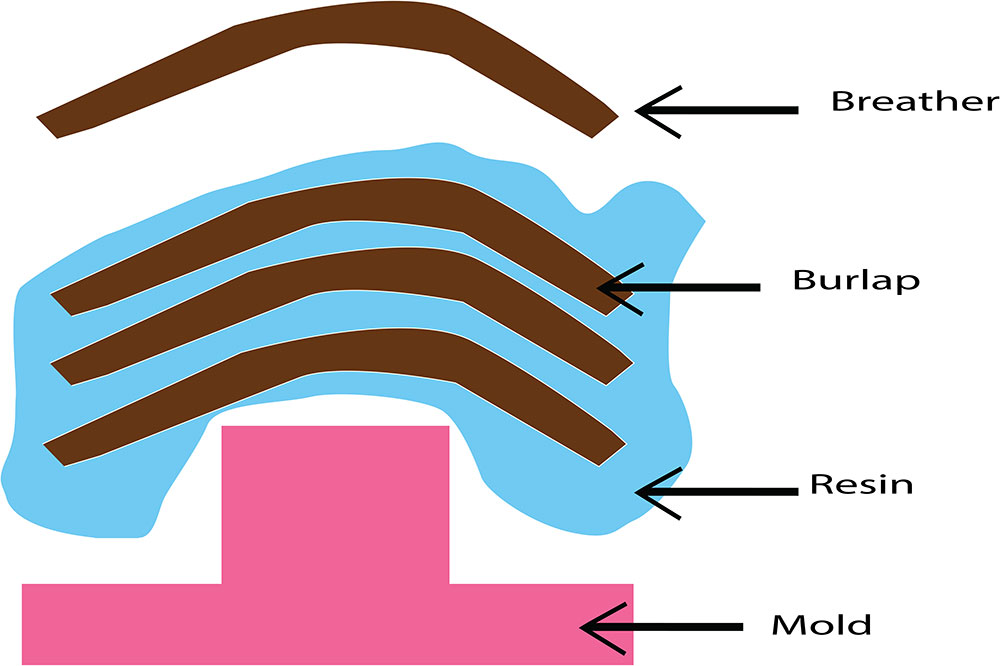

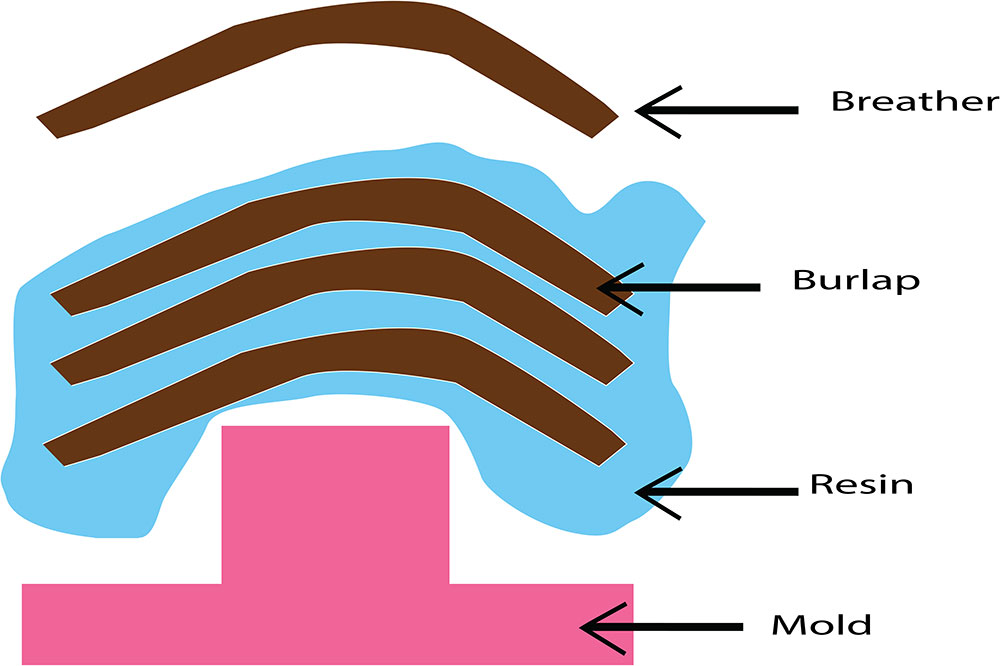

This is the order on layingdown the burlap and the last on top to make an space between the piece and the plastic vacum bag!

This is the order on layingdown the burlap and the last on top to make an space between the piece and the plastic vacum bag!

Even though the vacum cleaner was broken I was lucky enough we have the dust cleaner from the CNC and does the same job!

Even though the vacum cleaner was broken I was lucky enough we have the dust cleaner from the CNC and does the same job!

I did only one layer of realease agent on the mold and that caused the mold to stick to the composite. (next time two or thicker layers.)

the sound of a successful composite week!

Lessons Learnt

What I failed this week!!:

- not Use Carbon Fiber!!

- I fail so bad in my surf board, but was good learning for double side mode

- Fail to take out the composite cleanly from the mold, (due to the lack of realease agent or too much epoxy.

What I did but need to get better at:

- Learn Spire for 3D cut in the Shopbot

- Get better at Fusion

- do two kind of composites techniques even I failed the first one!

- make my own Skimboard!

| Week13 | Week15 |