Week 14: Composites

This week our task was to make a composite material using a mold we make, and prepare by reading the data sheet for the material ingredients

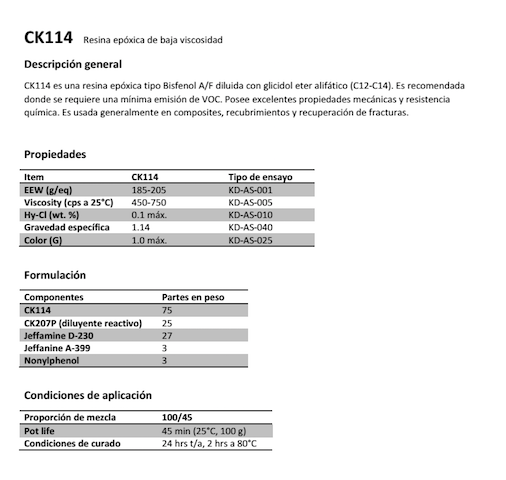

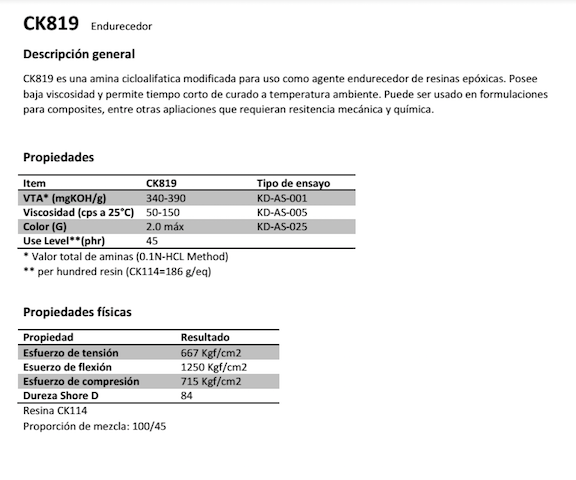

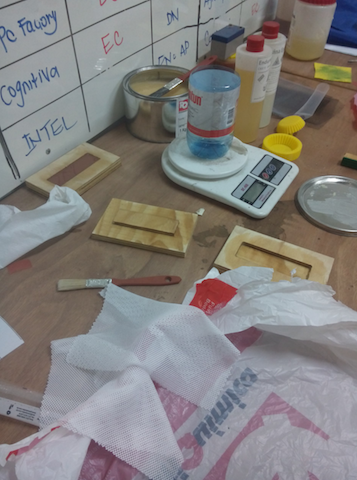

For this assignment I used an epoxy made by Fibratec This included an epoxy and a hardener

The data sheets listed material properties, and estimated curing times. A short list of instructions and safety precautions were listed on the bottles, in addition to the proportions for mixing (100:75, epoxy:hardener)

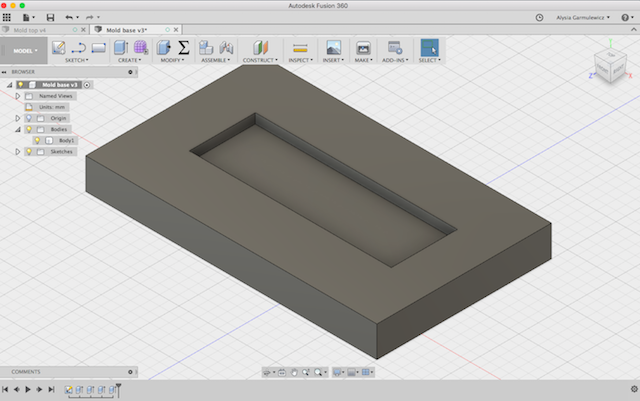

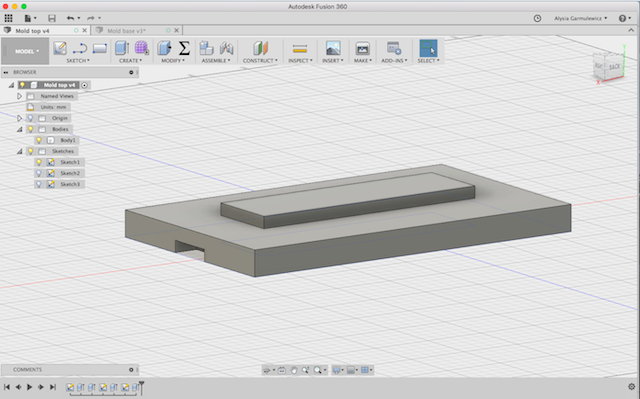

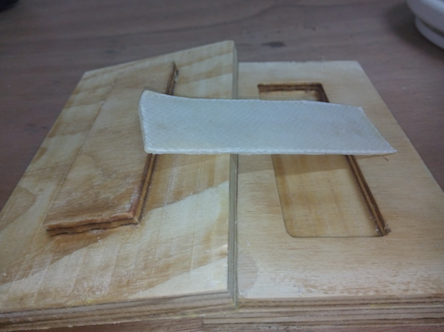

I decided to design a mold that would allow me to create sample bars of new materials for testing with my final project machine. I designed it with a shallow 5mm deep rectangle, with a top to that inserted for pressing the composite.

I used the CNC machine to make it, and finished the raw molds with sanding.

I then waxed the mold to allow so that the composite would not stick.

I prepared the composite, using 4 layers of porous net material, and mixing the composite with the hardener (using the scale to measure the correct proportions). Using a paint brush I brushed each layer of netting with the epoxy mixture

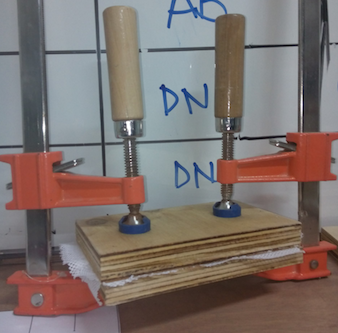

I then pushed the wet material net/epoxy into the mold and pressed down the top of the mold. I then clamped the mold and set it to dry

After drying I extracted the composite from the mold. It created a very thin, strong yet flexible bar of material

Here are the files from this week:

Mold base for composite Mold top for composite