Week 9: Mechanical Design

Assignment

Aim: design a machine (mechanism+automation), including the end effector build the passive parts and operate it manually document the group project and your individual contribution

This week our task was to make a machine that operates manually. As a team, Norella and I are making a circular knitting machine from Instructables

The design of this machine had to be adapted significantly so it could be functional here in Chile. See below and Assignment 11 .

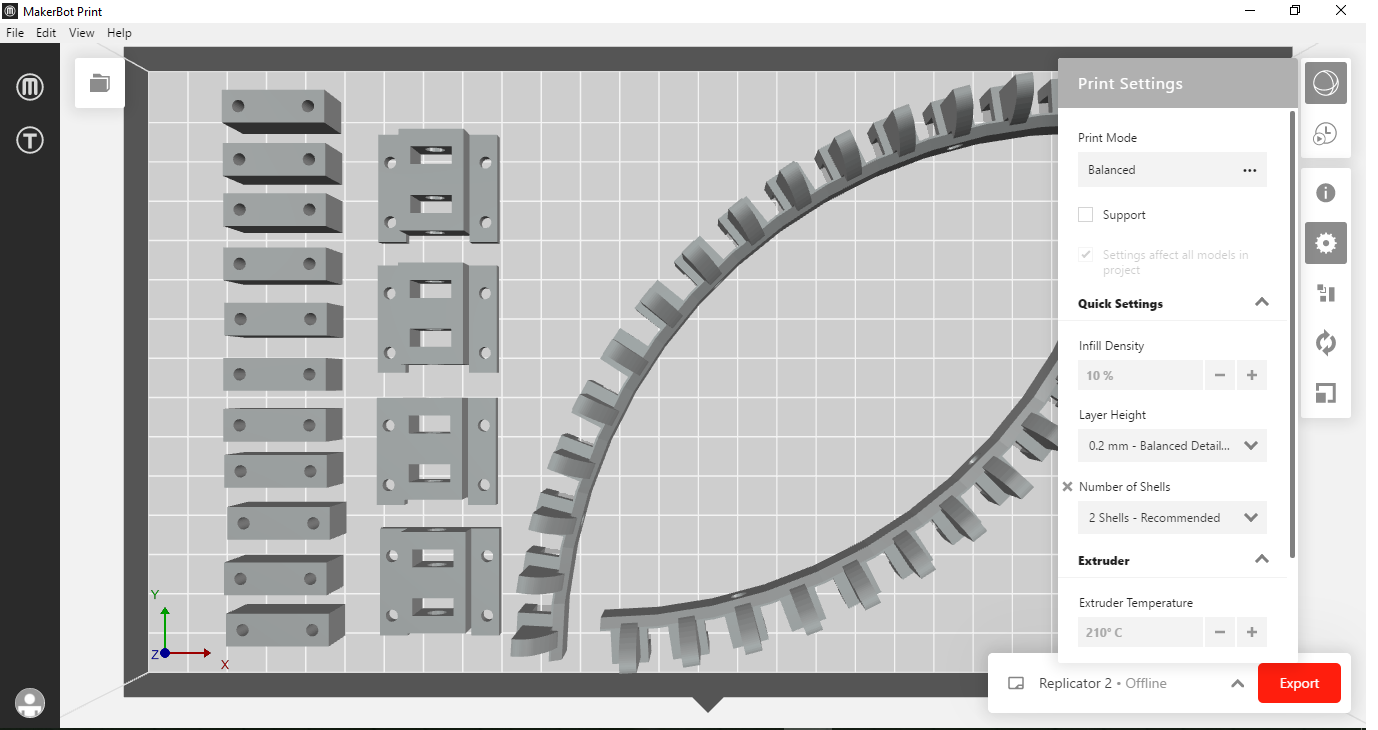

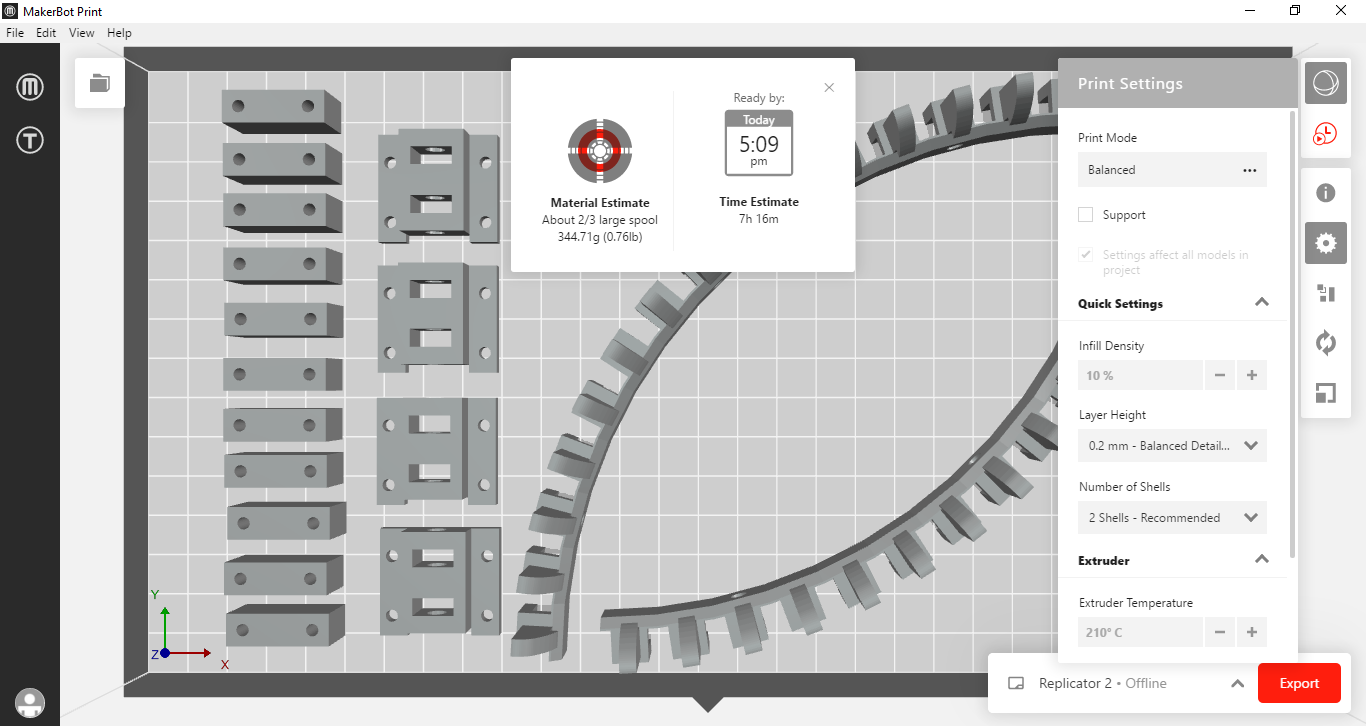

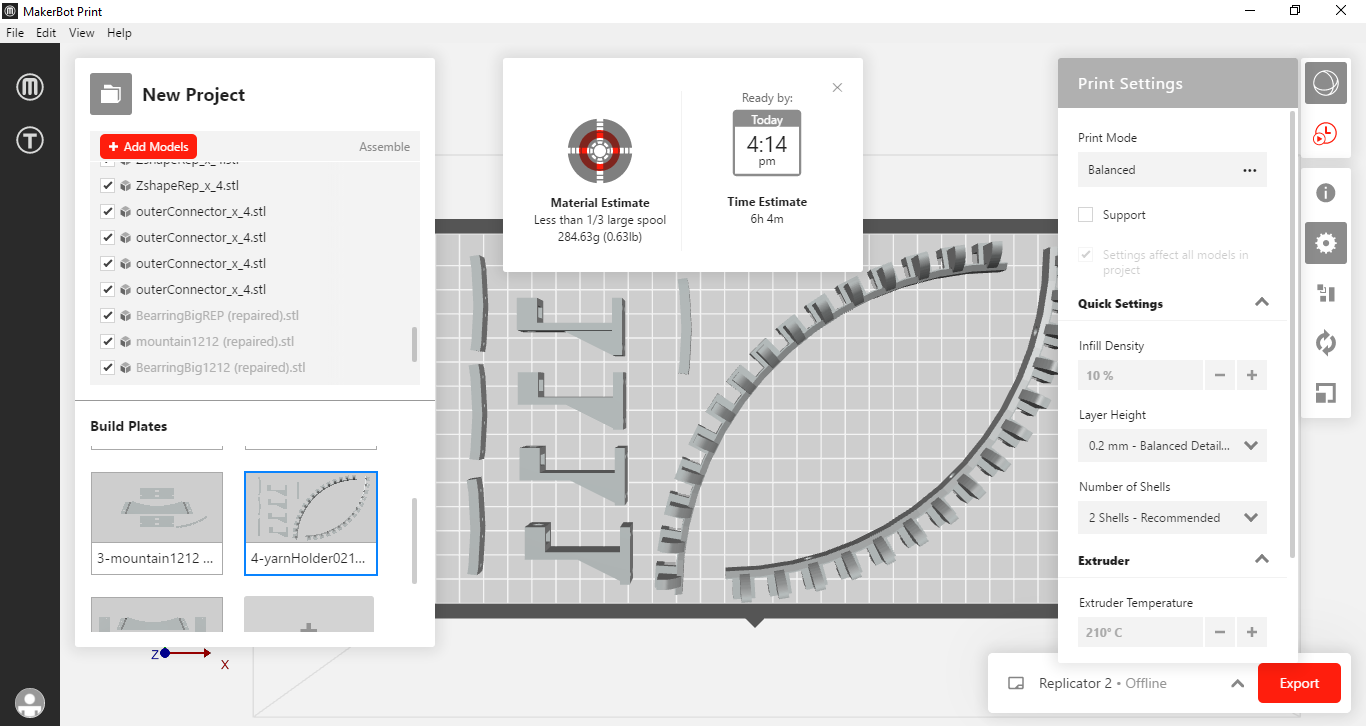

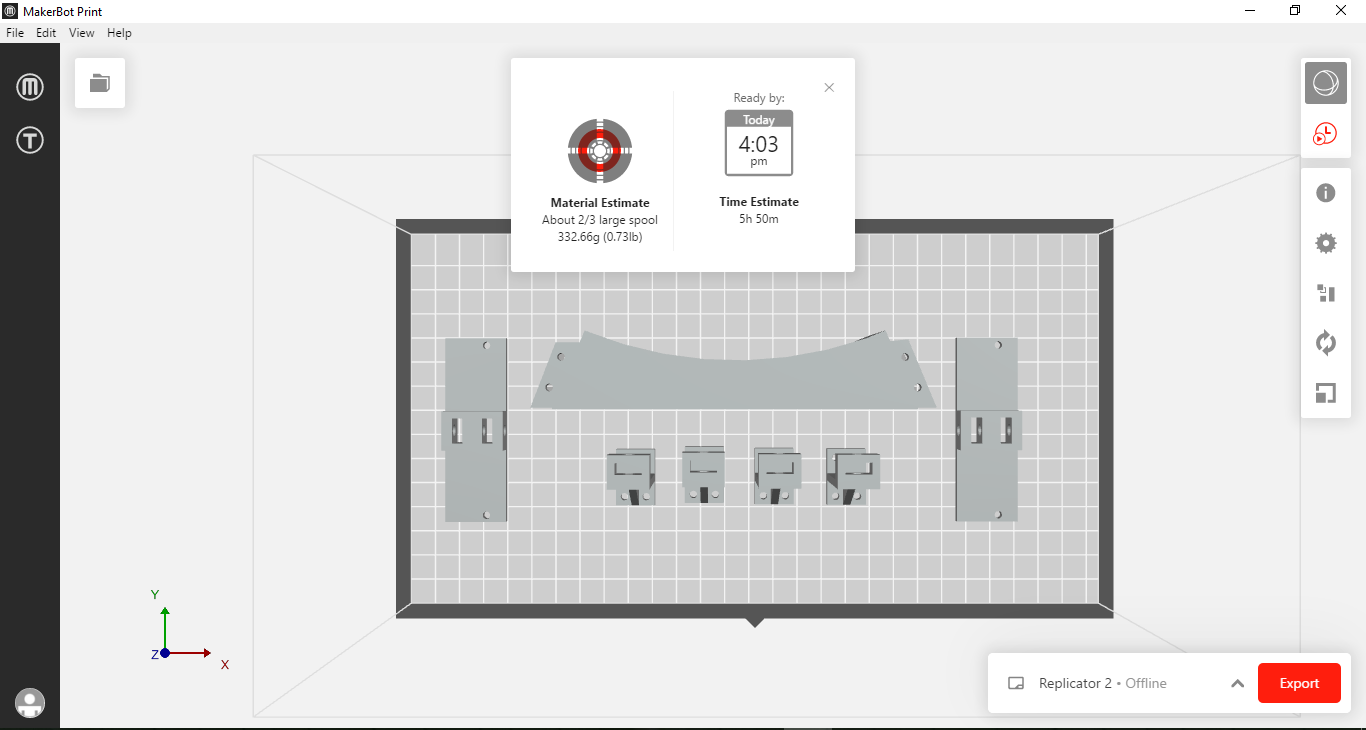

Step 1: download the .stl files from Gitub: Circular Knitic. The name of a file tells also the quantity and how many of them you will need. Print in high quality max. 0.1mm layer height! In the images above you can see can see how the process was done.

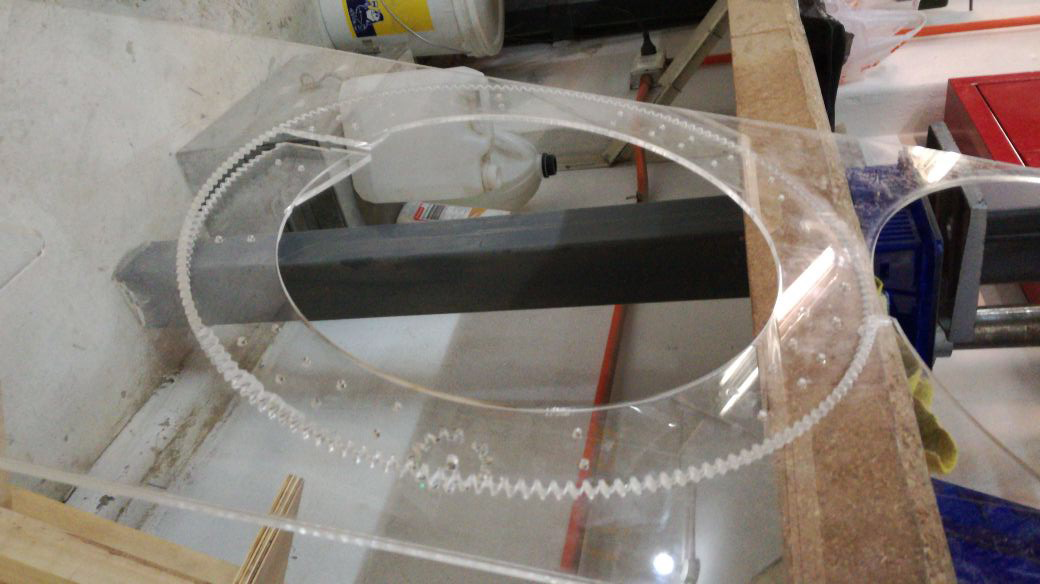

Step 2: Laser Cut Parts, you will need 5mm - 6mm plexi. Files in Circular Knitic. Again file name will tell which plexi is needed.

Step 3: Cut Wood, Use 28x28mm wood if possible. The wood is needed for building a table or a frame for the circular knitting machine. Hence, the dimensions of a table are 60x40cm. Cut the 28x28mm wood into following parts:

- 4x800mm

- 3x600mm

- 2x540mm

- 4x344mm

- 3x180mm

- 1x80mm

- 28 x L-Shape

- Some screws

Files in Circular Knitic.

Step 4: Get Materials, in Chile they didn't sell some of the parts, so he have to order them form US (took almost 1 month to arrive and some parts didn't arrive, so we had to modify the design of the machine):

- 60 x needles

- Stepper motor nema23

- Big Easy stepper motor Driver

- Arduino Uno

- Ventilator 12v 40mm x 40mm

- Power supply 12v

- Cabling

- Carbon fiber tensor 2mm (55cm)

- 14 x bearings (bore 5mm x 10mm x 4mm)

- Screws and nuts

- Shaft of motor

- Switch

- 60 x paper clips 50mm

- 2 x makerbeam 150mm

- 2 x makerbeam 60mm

- Makerbeam 40mm

- Makerbeam screws

- 6 x makerbeam Lshape

- 4 x claw weight (this we didn't buy)

- Spring

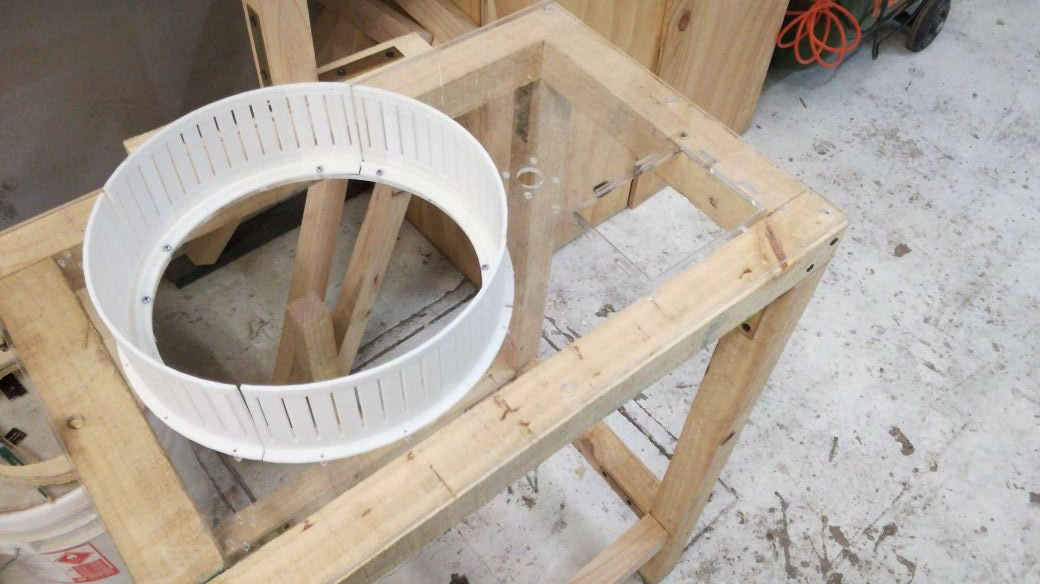

Step 5: Wood Structure, using wood, 90degree-angles, and screws mount the wood structure for Circular Knitic.

Step 6: Circular Knitic Base, fix base of Circular Knitic to the wood structure using washers and screws.

Issues and Improvements

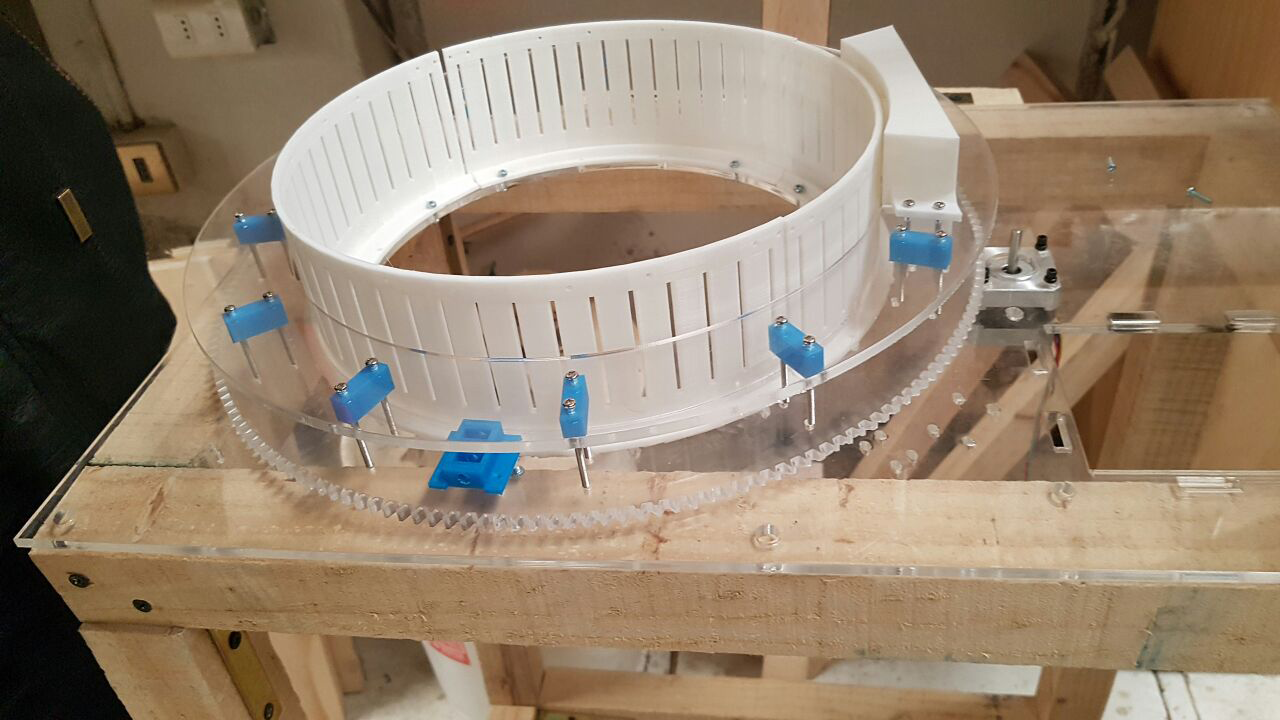

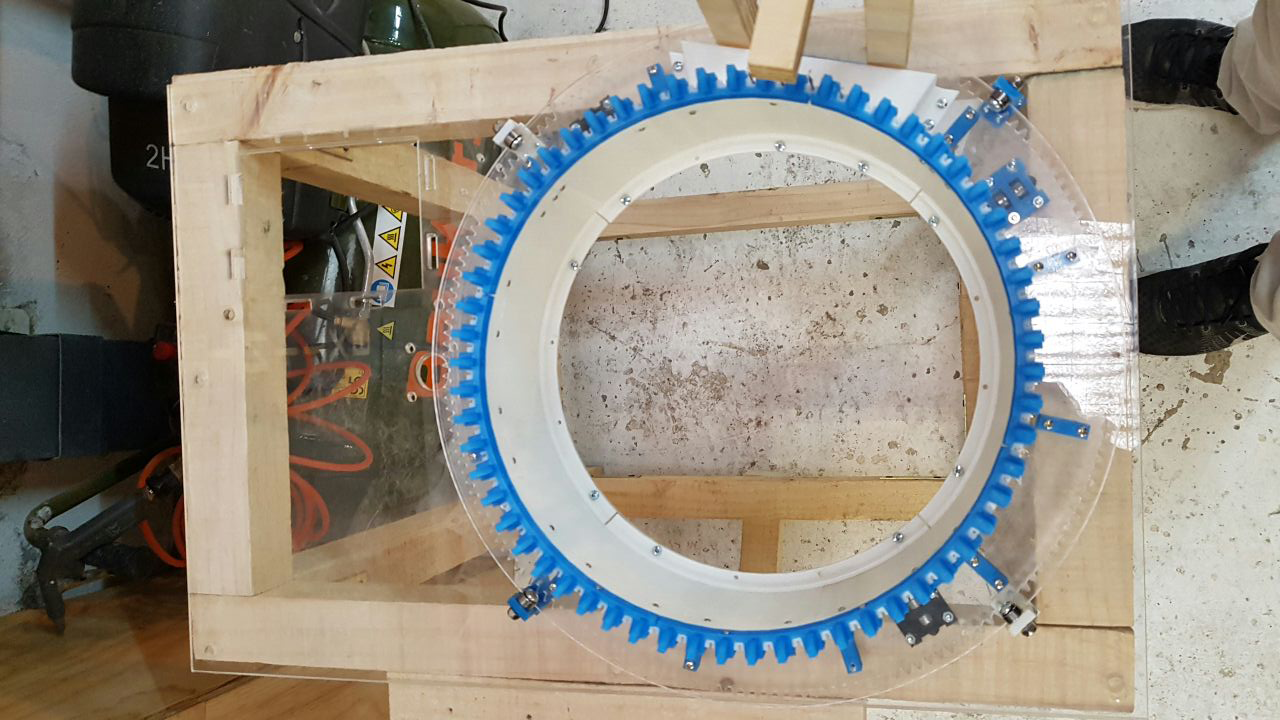

We had to redesign and improve key parts of the machine in order to customize it to our locally available resources (some parts like the right screws simply did not come). The following parts needed modification and design:

- 3D Printed Bearing Holders: we had to adapt to non-standard bearings

- Needles: we could not source the correct needle size

- 3D printed 'inners' which hold the needles: these had to be narrowed to account for the different needles

- 'Mountain yarn feeder': we had to make this from scratch because makerbeam parts were not available

- 3D printed connectors where screws are mounted: these had to be altered to account for larger screw size

Each of these adaptations to the design are documented in full in the second part of this assignment.

Download Files here:

Circular Knitic Instructable