Week 5: 3D Printing and Scanning

This week our tasks were:

✔ to understand our Lab's 3D printer settings, varying the settings to see the changes on a printed model;

✔ print something only additive fabrication can do; and,

✔scan an object

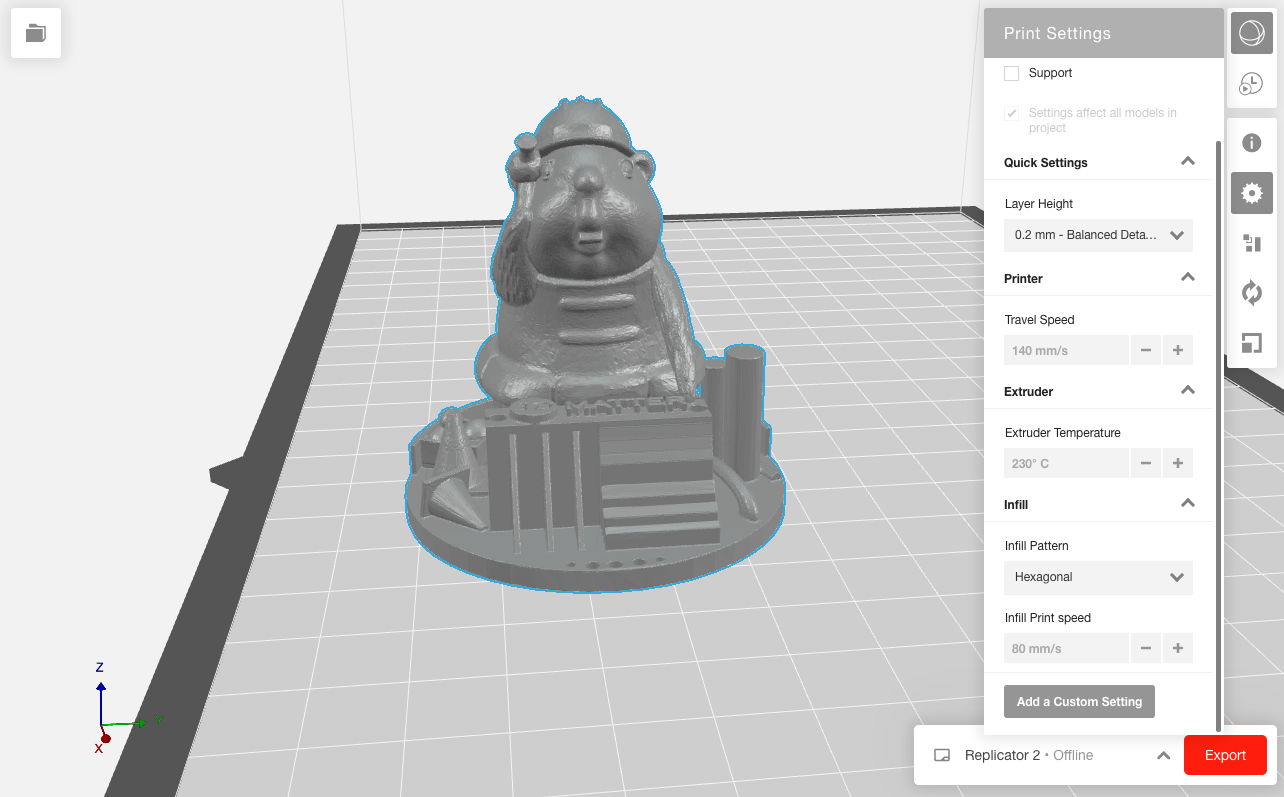

As you can see, the default settings include 230 degrees extrusion temperature, layer height of .2mm, travel speed (of the gantry) of 140mm/s, hexagonal infill pattern, and an infill print speed of 80mm/s.

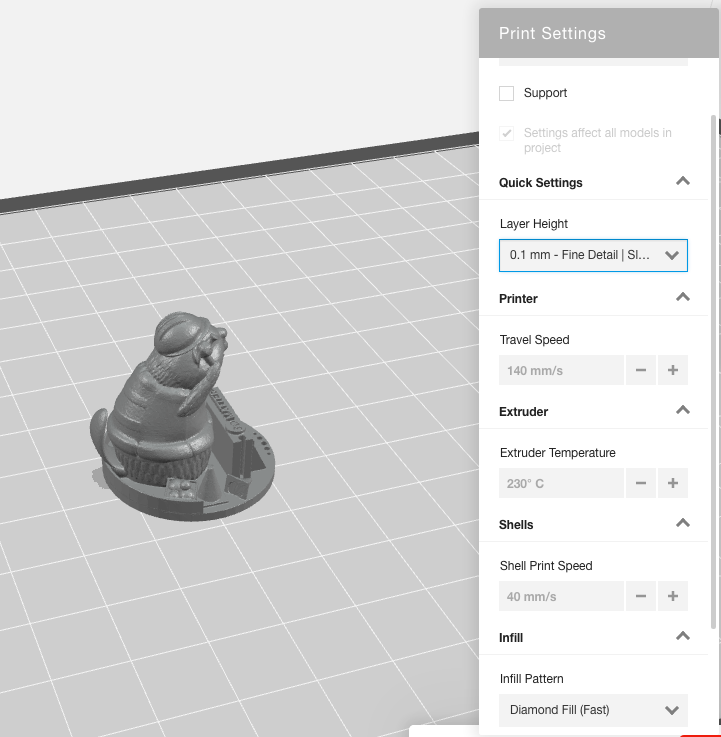

Once the testman was printed, I analyzed the various features of it and decided to change some of the settings so as to optimize the final result. To improve the fineness of the layers, I reduced the layer height to .1mm, and reduced the travel speed and infill speed in order to reduce the amount of 'mess' that was left between the fine structures of the model. I also experimented with a different infill, choosing a diamond pattern that was marked to be a faster option. I thought this would make up (somewhat) for the slower print time caused by the slower settings and attention to detail. The selected settings are shown on the left, below, while the final comparison of the two models is shown on the right. There was improvement on the basis of the changed settings; in particular, the layers were less noticible (smoother), and the finer points of the model came out better. The change of infill pattern did not alter anything obvious on the surface.

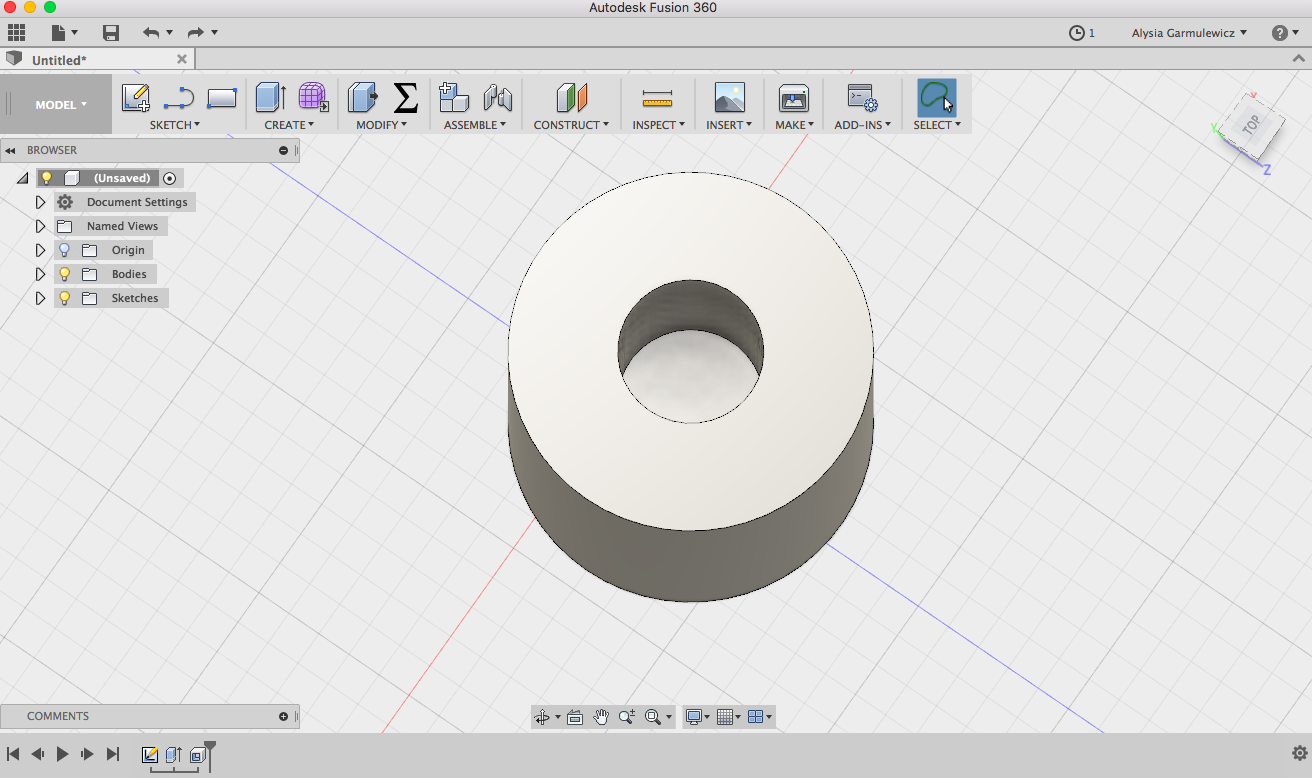

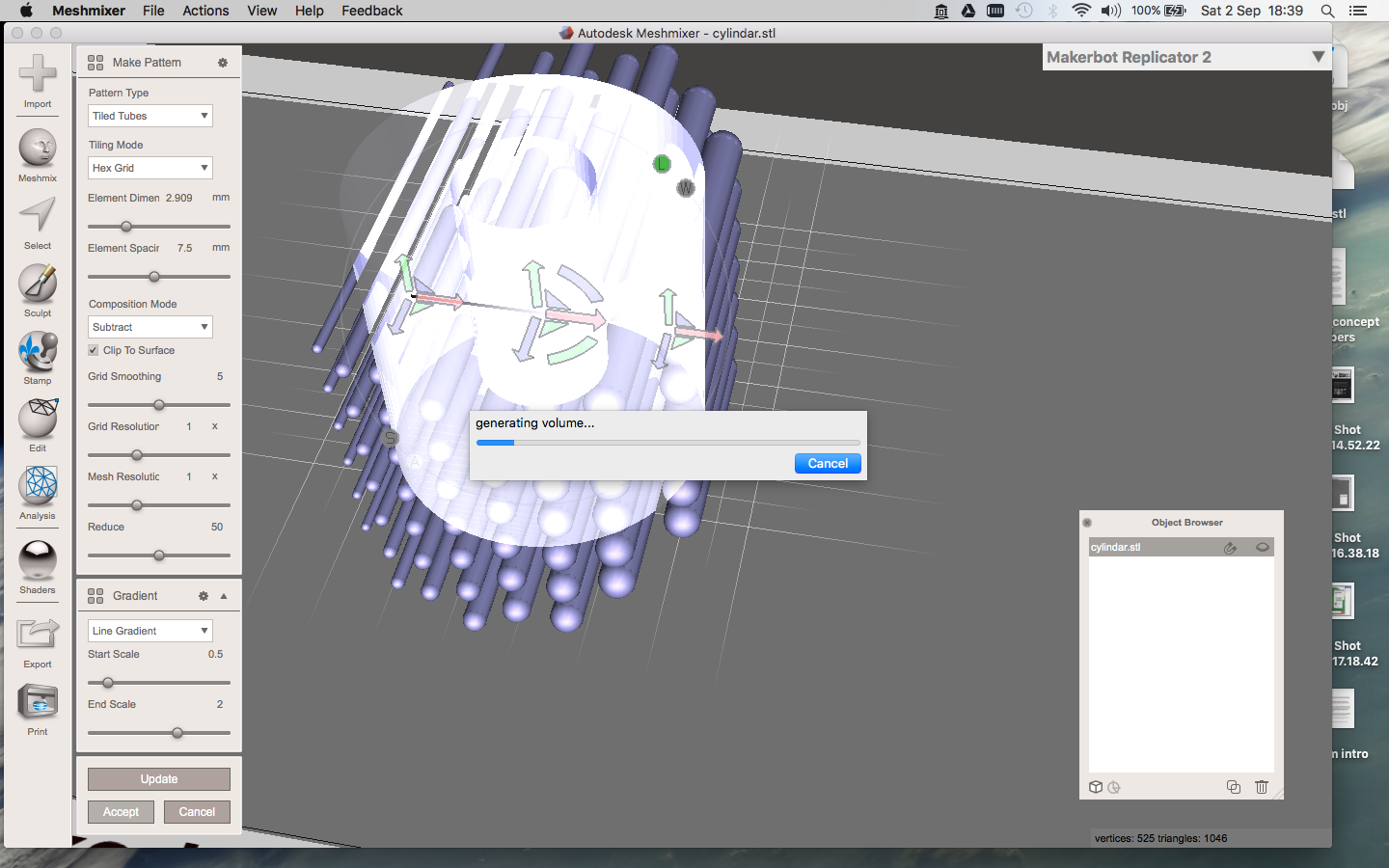

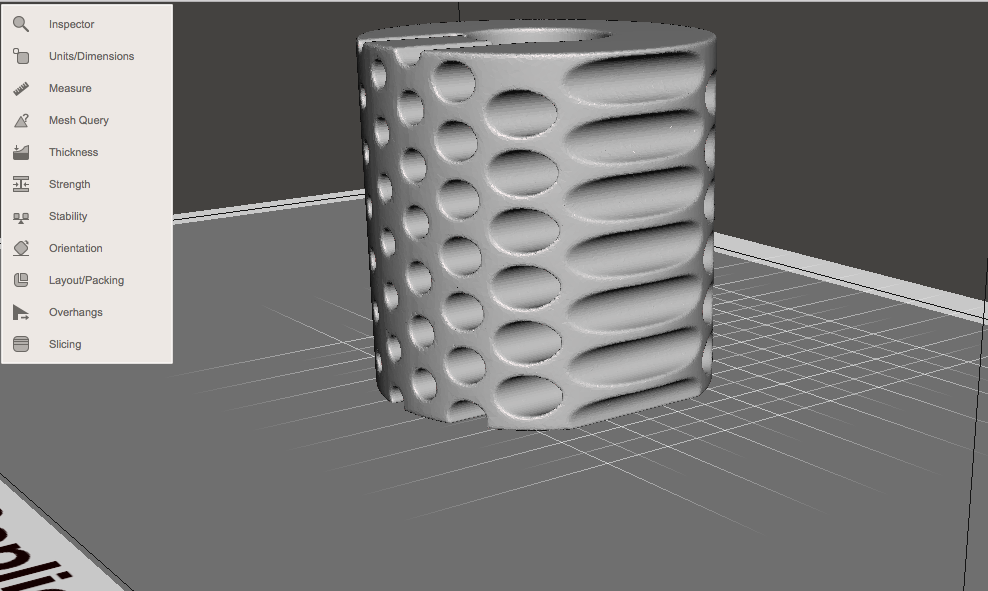

Needing to design a 3D printed structure that could 'not be made any other way', I returned to the exploration of different software, and this time used a combination of Fusion 360 and Meshmixer. I extruded a simple cylindar in Fusion, and then created a hole in the middle.

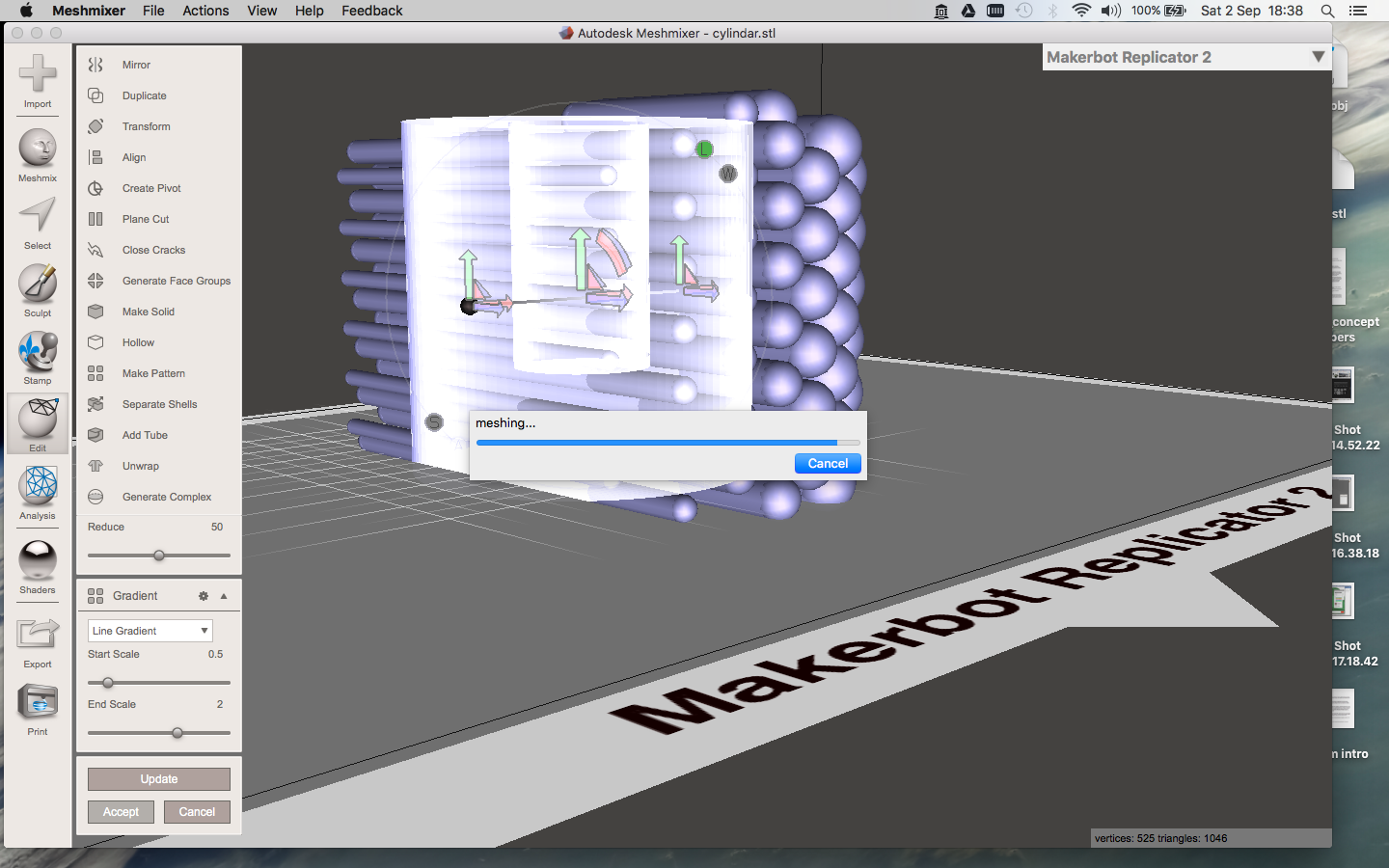

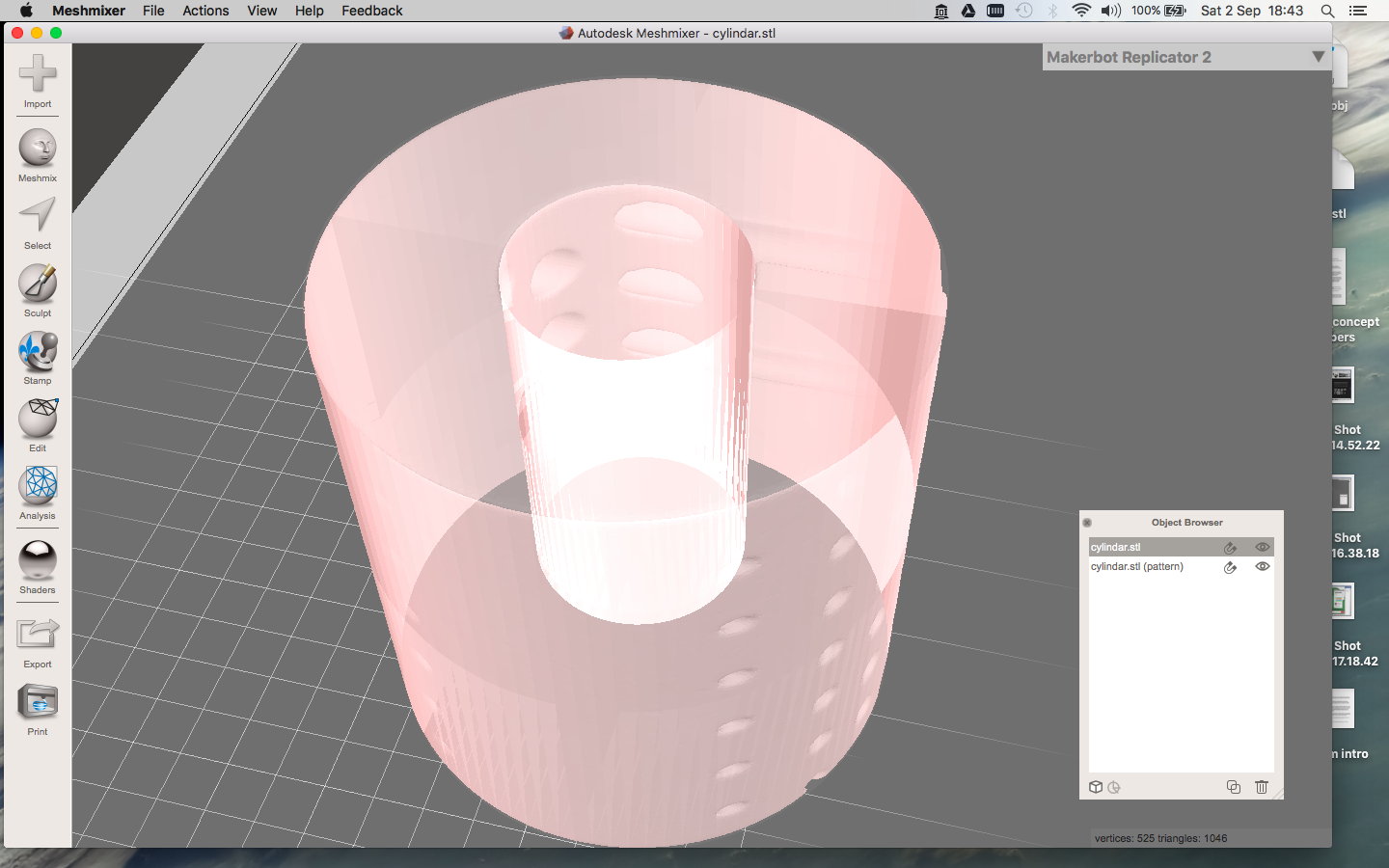

I then exported it to Meshmixer, and had a lot of fun playing with creating internal patterns in the mesh. The idea was to create internal patterns that vary in density, which are particularly perfect for 3D printing as a fabrication method. Indeed, this type of design demonstrates the freedom of geometric design that can be achieved with additive fabrication techniques.

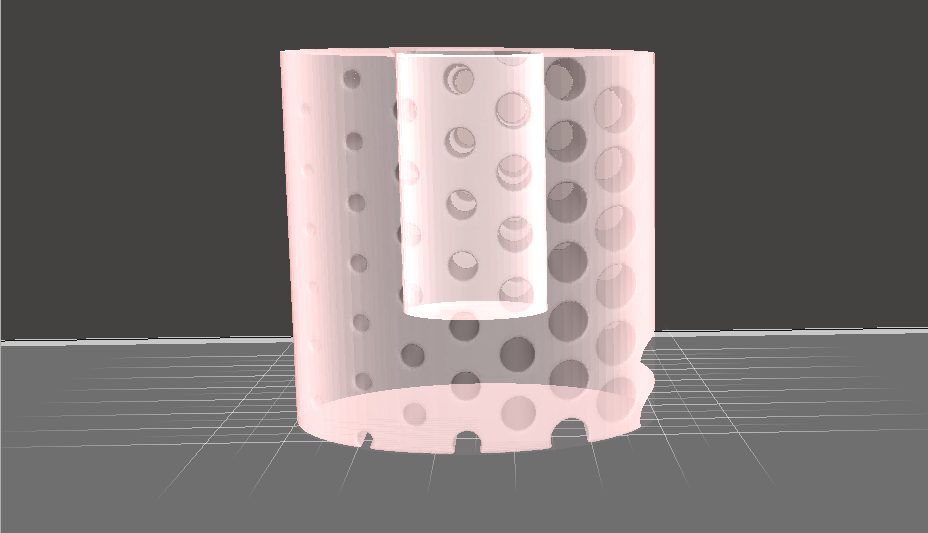

After playing around with various pattern types and modes, I found a pattern I liked (below, left) that created a really interesting internal pattern (below, right).

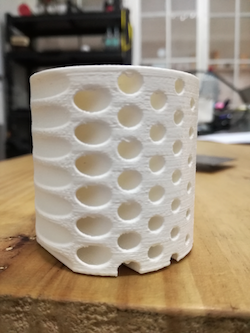

This pattern of 'tiles tubes' created a very interesting honeycomb-like internal pattern to the cylindar, and I added a density gradient to make it even more interesting. You can see the results in the mesh below.

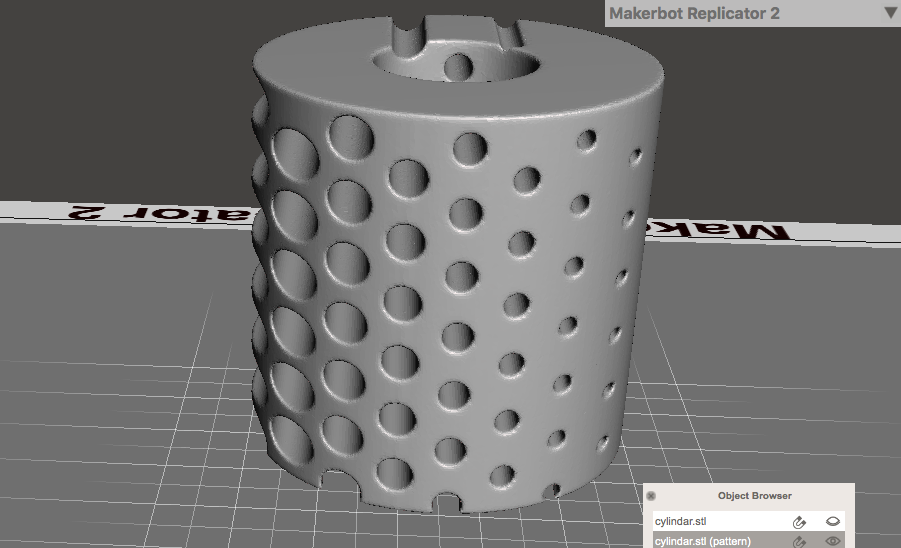

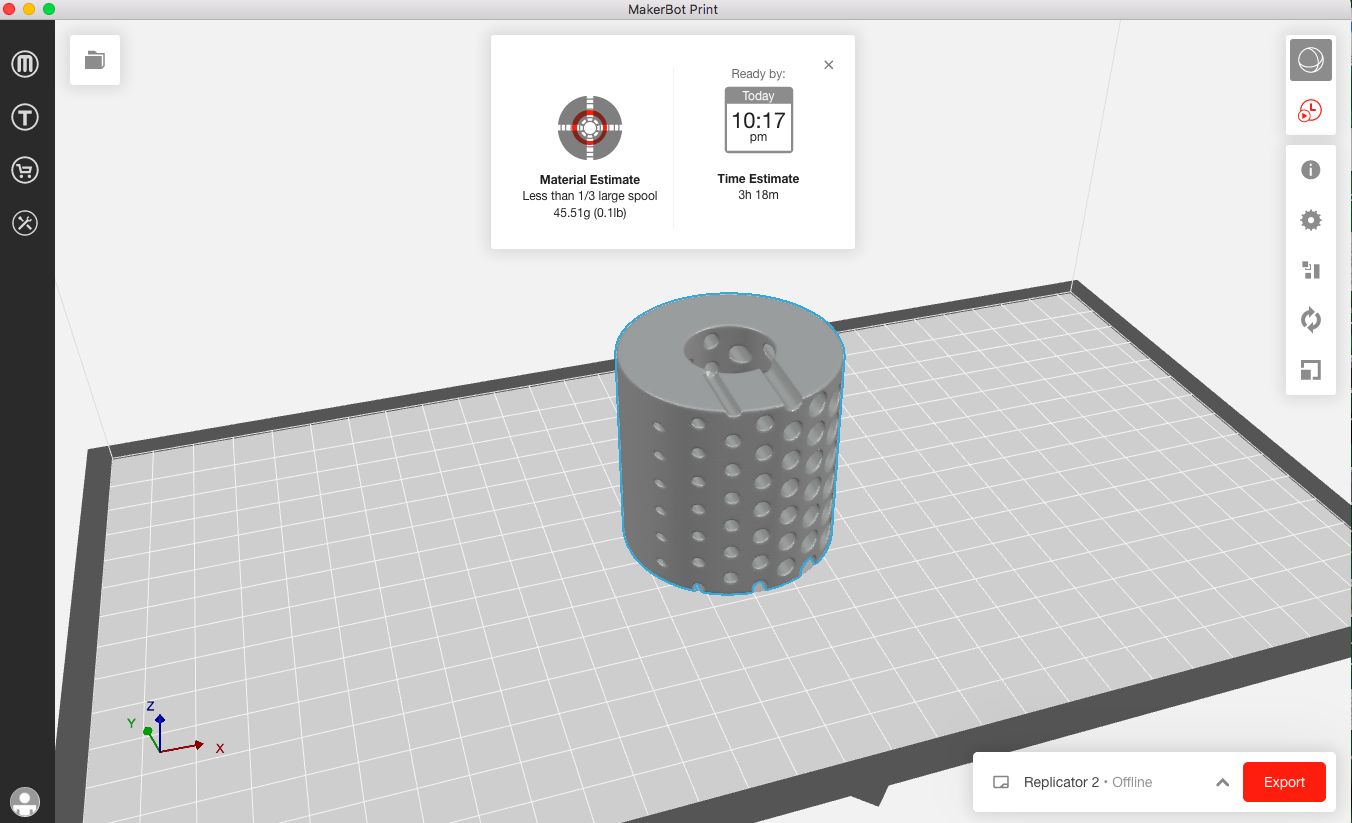

I then exported it for printing (below, left), and it came out beautifully! See below for a couple of angles showcasing the inside, as well as the gradients.

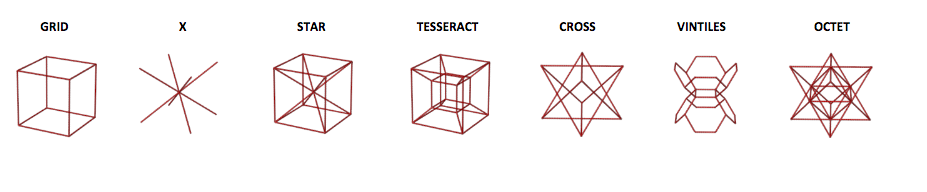

I then began to explore the design of an object that could only be 3D printed. First I explored the use of Grasshopper as a plugin for Rhino, with an additional plugin called Intralattice

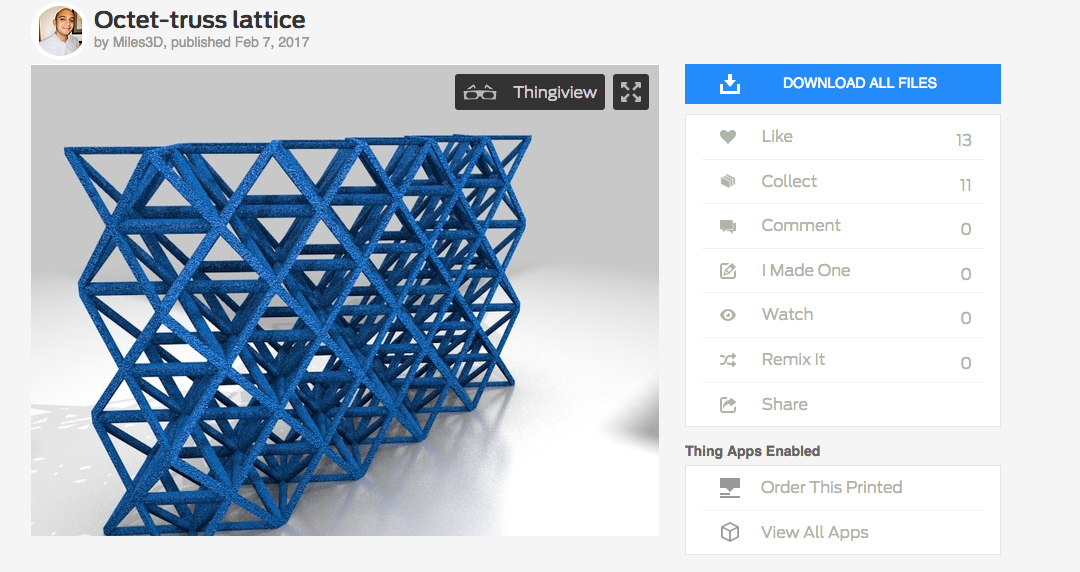

Intralattice is a plugin that allows easy modelling of lattice structures by switching between unit cells pictured above. Below are some of my favorite lattices I explored: octet, honeycomb, diamond, tesseract, and vintiles. With the Rhino workflow, you can easily switch between lattice structures

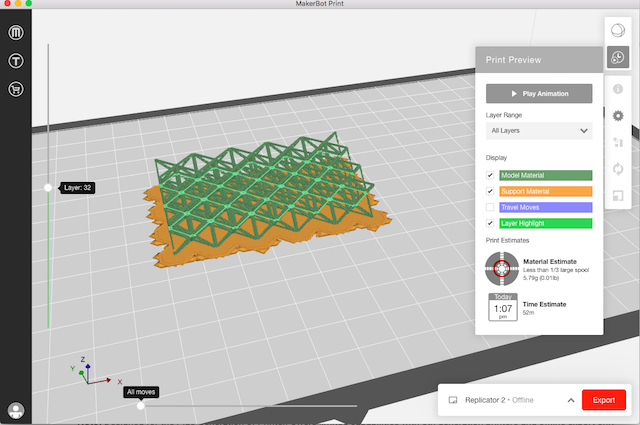

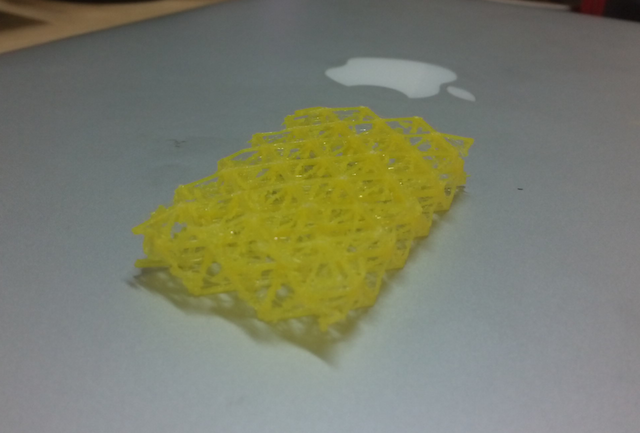

I also tried printing a lattice with 2 different materials using a model on Thingiverse.

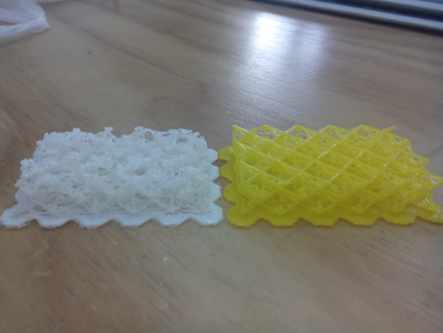

I chose to test out Ninjaflex just to see what would happen. I then printed a regular PLA from Makerbot. As you can see below, the results are radically different. This demonstrates the importance of print settings (such as speed and nozzle temperature) for different types of materials.

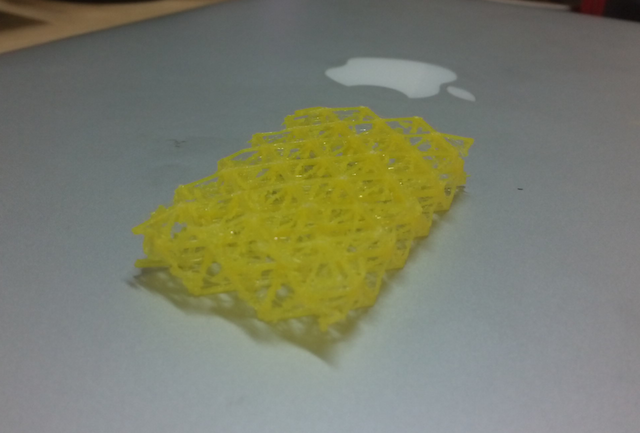

I then tried scanning the printed octet mesh, to see if I the software could replicate the structure digitally. I used Autodesk Remake, which uses photos to reconstruct a 3D object. As you can see below, the octet lattice didn't scan very well. It was an interesting experiment. I then tried a more conventional object, which has more variation from side to side - a little figurine I have on my desk. As it happens, I bought this figurine as a momento from Fab10 in Barcelona. The scan turned out very well as you can see below. In Remake you can look at the mesh view as well as the object view, showing what the computer sees when slicing it for 3D printing.

Here are the files from this week:

Test model

Testman model for print settings

Patterned Cylindar

stl model

Makerbot model

Meshmixer model

Lattice models

Intralattice mesh

Octet Lattice file from Thingiverse

Scan files

Mesh scan, or see .mtl file and obj file

Bookman sculpture scan