COMPOSITES

- Demonstrate workflows used in mould design and construction

- Select and apply suitable materials and processes to create a composite part.

this is the best option of testing reaction of resin on HD Styrofoam in order to approve if i will use it as reinforcemnt on my drone. I have been looking forward to this week for a long time, getting to work with composites. This week is also all about 3D milling on the ShopBot which I find very exciting. So even though our resins have still not arrived I had a excellent week learning to 3D mill, that helps me to make fuselage of my drone with higly precision on HD styrofoarm.

Mould Design and mashining the mold

with the mould design i used a wing I designed during my week 2 "computer aided design "but i reduce the scale, I learn other skills on computer controlled mashining. the way I can used OUR ShopBot. to do that you have to import 3d model(*.stl,*.obj) in v Vcarve. because I was using the hard tool bit and soft material (HD styrofoam) I used smooth finishing tool instead of using rought tool

.jpg)

.jpg)

.jpg)

.jpg)

TIME FOR COMPOSITE

before doing any thing ready carefull resin safety data sheetDownload it here

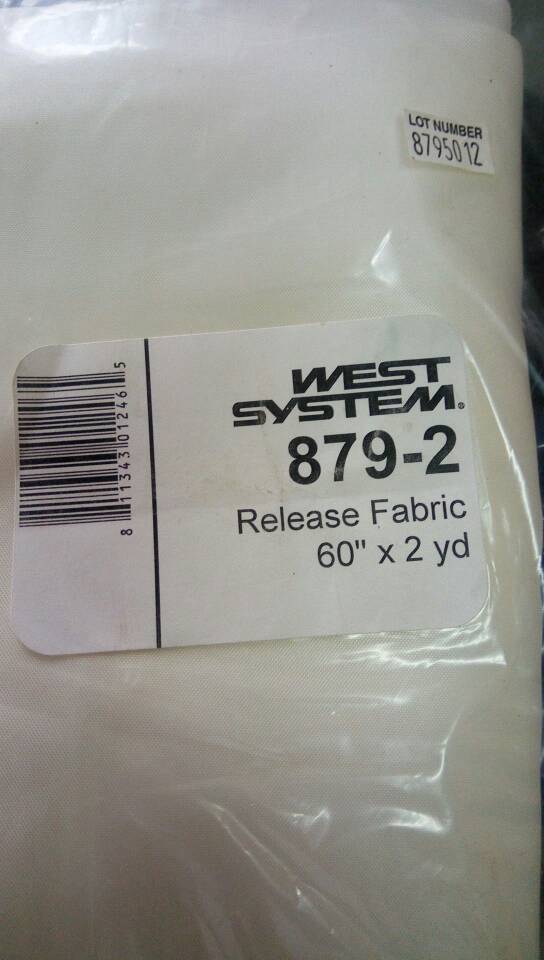

For composite i used

after putting every thing together its time for preparing work space. I covered all table insulating film with my collegues Serge and Denis

after putting every thing together its time for preparing work space. I covered all table insulating film with my collegues Serge and Denis

after preparing work space and material needed it time for start composite. as my resing datasheet says i have to mixe 2/1 as ration of part A (ONE Epoxy) and part B (ONF Hardener).

FINAL

This is the result I got after after making test i used the same procedures for making my fuselage of my drone

but at this time our vaccum clean was not working so to do that i used a small hand operated vaccum pump by this i spend more that 20 min or vaccuming the vaccum bag

after making test i used the same procedures for making my fuselage of my drone

but at this time our vaccum clean was not working so to do that i used a small hand operated vaccum pump by this i spend more that 20 min or vaccuming the vaccum bag