Assignment 4

15.2.2017

Topic: Electronics production

- Make an in-circuit programmer by milling the PCB.

- Optionally, try other processes.

Learning outcomes:

- Describe the process of milling, stuffing, de-bugging and

programming.

- Demonstrate correct workflows and identify areas for

improvement if required.

Have you:

- shown how you made and programmed the board,

- explained any problems and how you fixed them,

- included a ‘hero shot’ of your board.

PCB milling

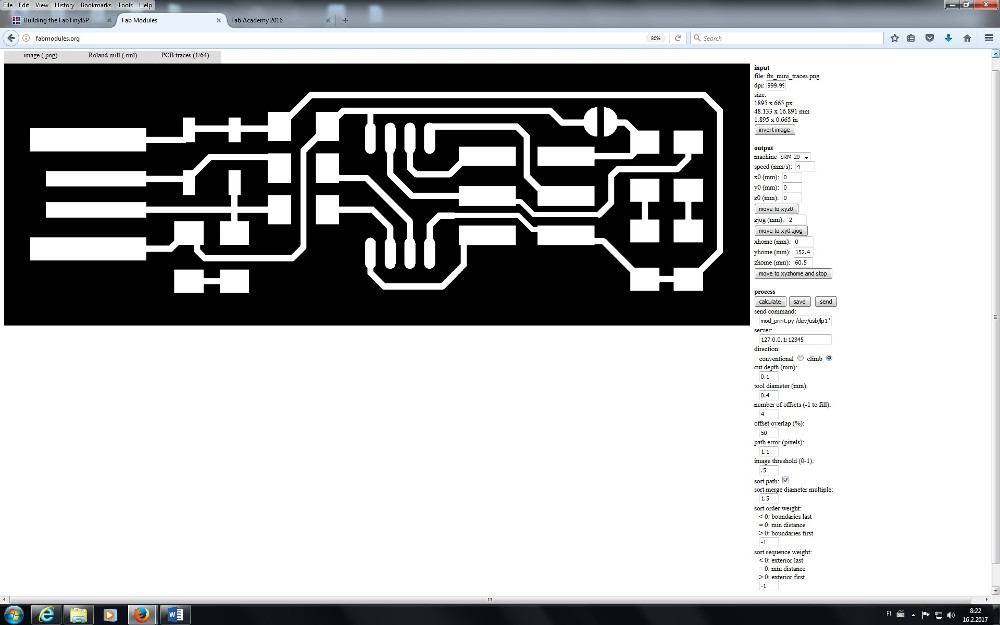

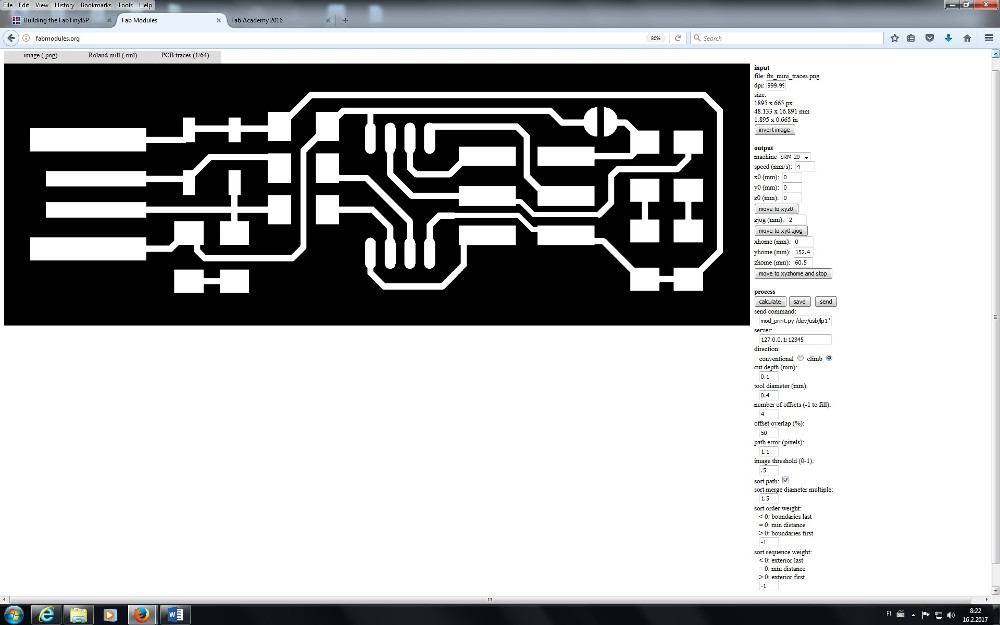

I selected my AVR ISP programmer card as Brian's

work. I impressed the simplicity, no external oscillator or

crystal. I loaded the ready made PNG files for the traces and the

board outline from Brian's page. I used tools on fabmodules.org page to

generate milling files for Roland SRM-20. At first,

I selected input format as image (.png) for traces file, selected

output format as Roland mill (.rml), selected process as PCB

traces (1/64), selected machine as SRM-20, set x0, y0 and z0 as 0,

and checked and set tool diameter as 0.4 mm and cut depth as 0.15

mm. Other parameters were as default. Then, I pressed calculate,

checked traces and saved the file.

I got excellent help from Dorina's

page.Here is the original BNG input file of traces.

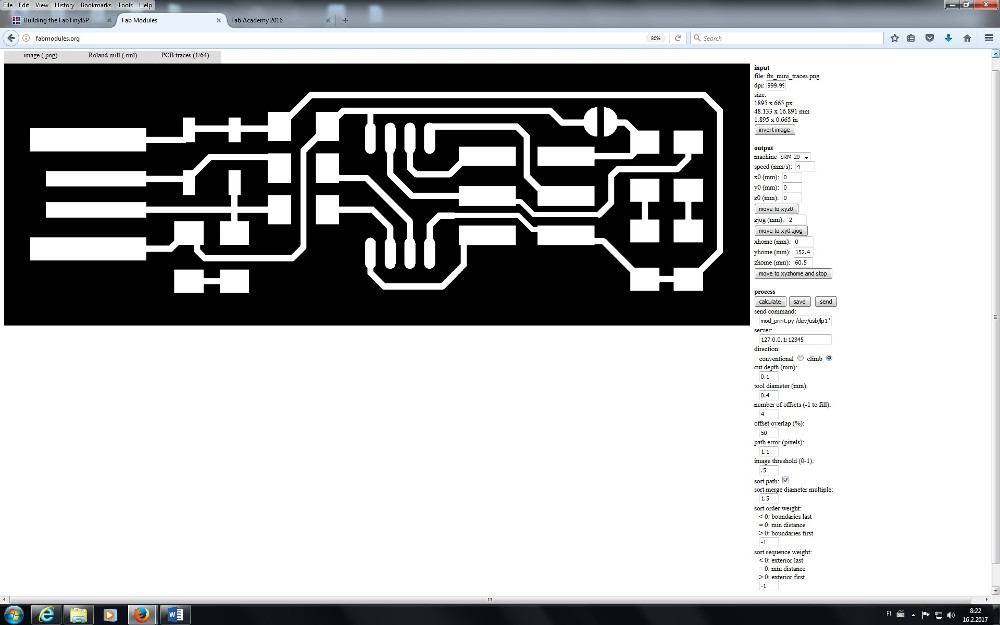

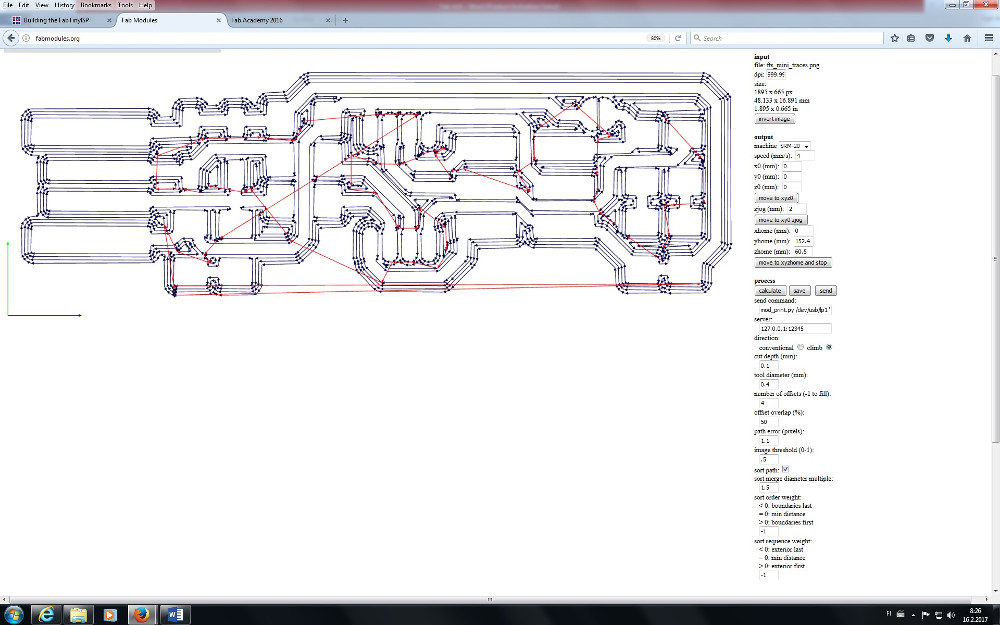

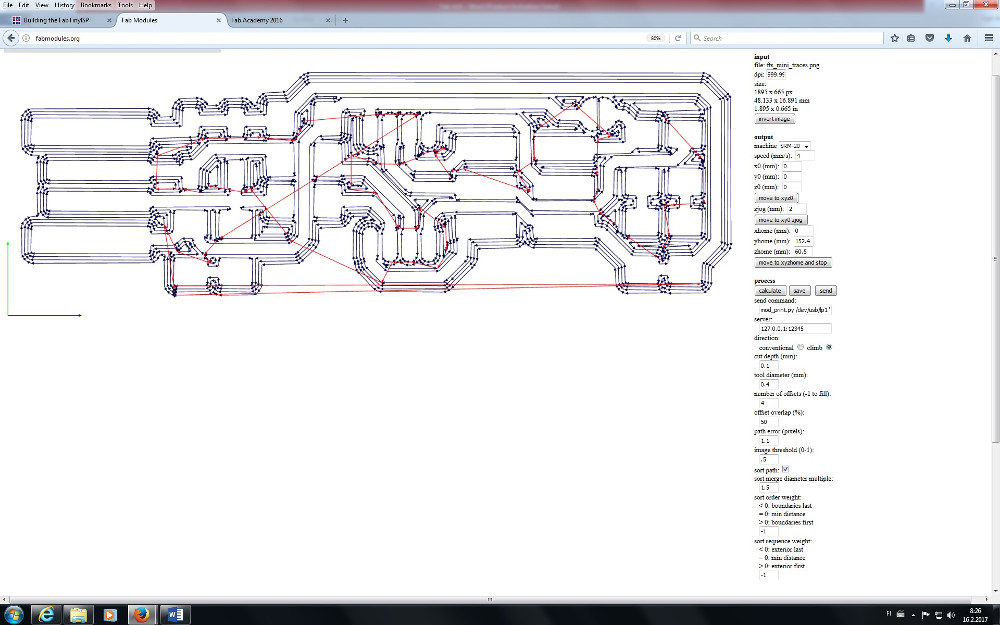

Here is the result the output file. Tool diameter is 0.4 mm

(1/64").

Similarly, I processed outlines file: selected process as

PCB outline(1/32), selected machine as SRM-20, set and checked x0,

y0 and z0 as 0, tool diameter as 0.8 mm and cut depth as 0.6 mm.

Other parameters were as default. Then, I pressed again calculate,

checked outlines and saved the file.

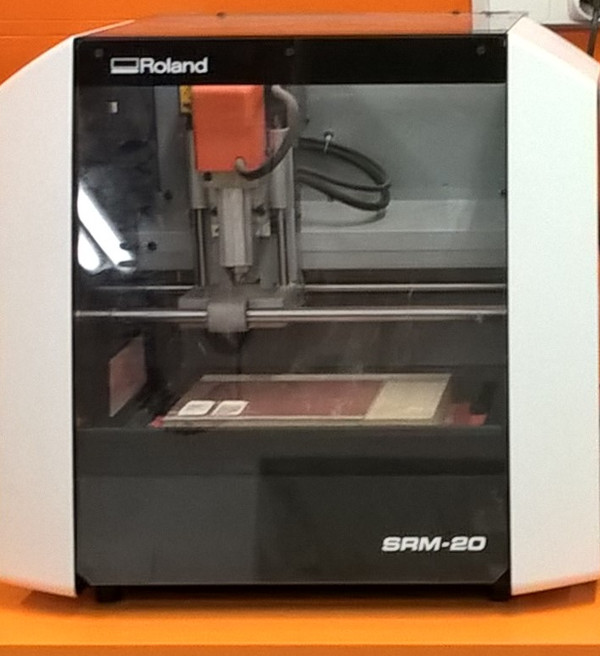

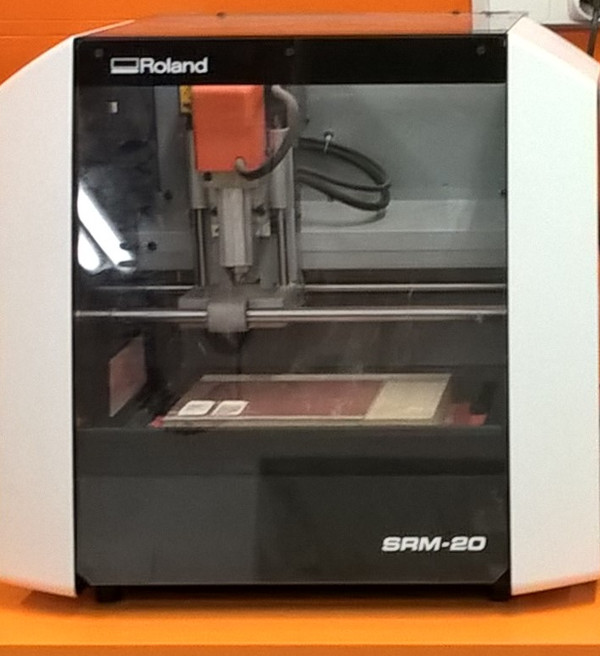

Then, I started the Roland and assembled the 1/64" bit.

Someone else was used the machine before me and there was PCB

board assembled ready in place.The board type was FR4.

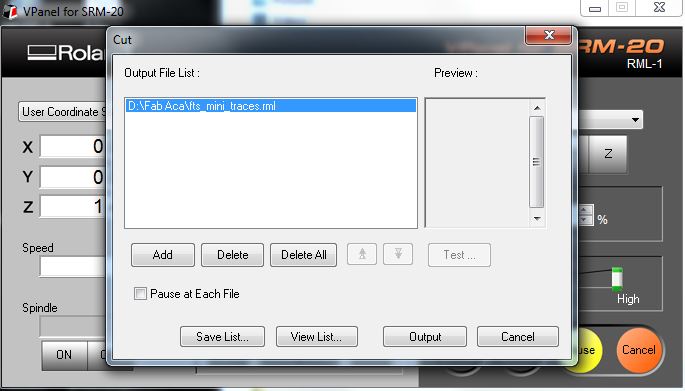

I opened the VPanel program to operate the mil, set the

X/Y and Z origins correct place and pressed the Cut button.

Then, I selected file I want to drive by Add button and

pressed the Output button.

Milling started well, but I noticed it didn't mill firmly. I paused

milling and looked what was wrong. The PCB board was bent upward

from the middle. Therefore, I took it out taped again very carefully

with new tape. Then, I started milling again. And, all went well. I

milled traces, changed bit as 1/32", set Z origin again and

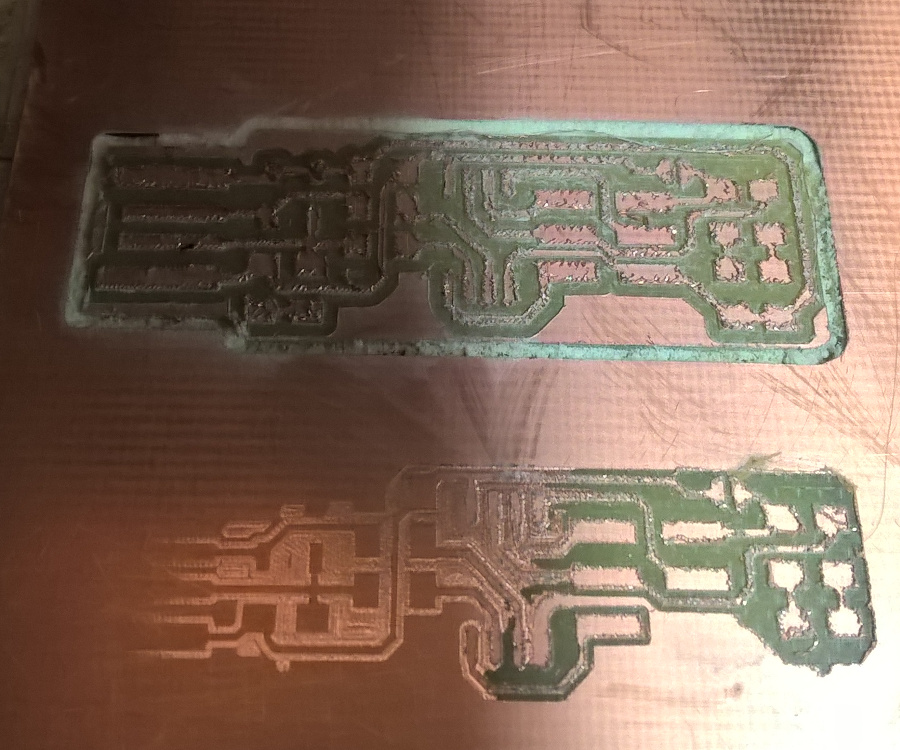

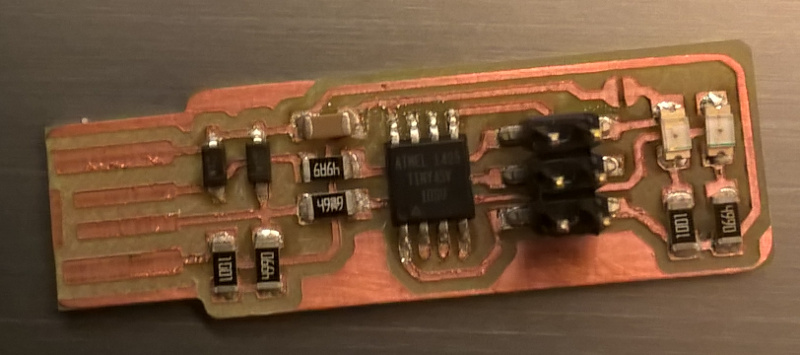

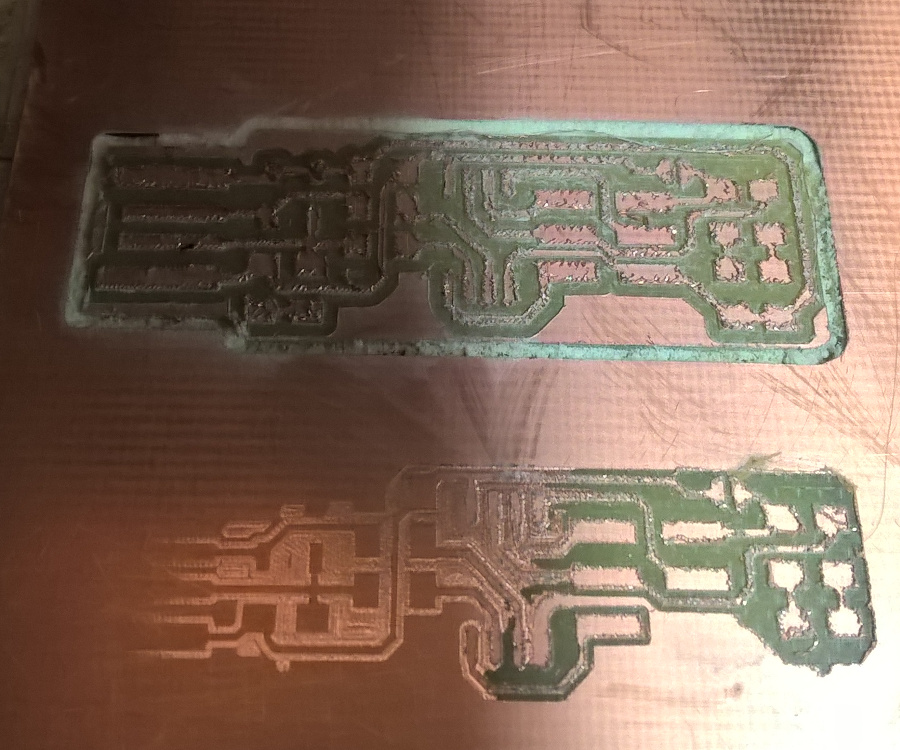

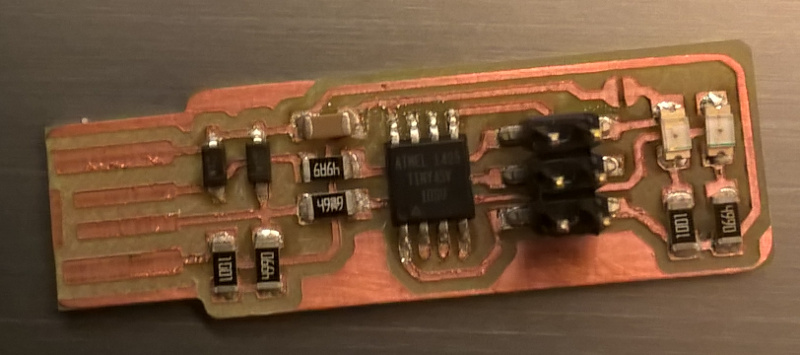

milled outlines also. Following picture shows the first trial below

and the final milling above.

I removed the copper edge with a knife from the USB connector

side. I sandblasted firmly the board, checked it under microscope

and accepted it for further processes.

Assembling the PCB

Next step was the soldering of components. I needed following ones:

- ATtiny45 microcontroller, my version is ATtiny45V

- 1 kΩ resistors x2

- 499 Ω resistors x2

- 49 Ω resistors x2

- 3.3 V Zener diodes x2

- red and green LEDs, optional

- 100 nF capacitor, I selected 0.1 uF

- 2x3 pin header, I made it from 2x5 pin header.

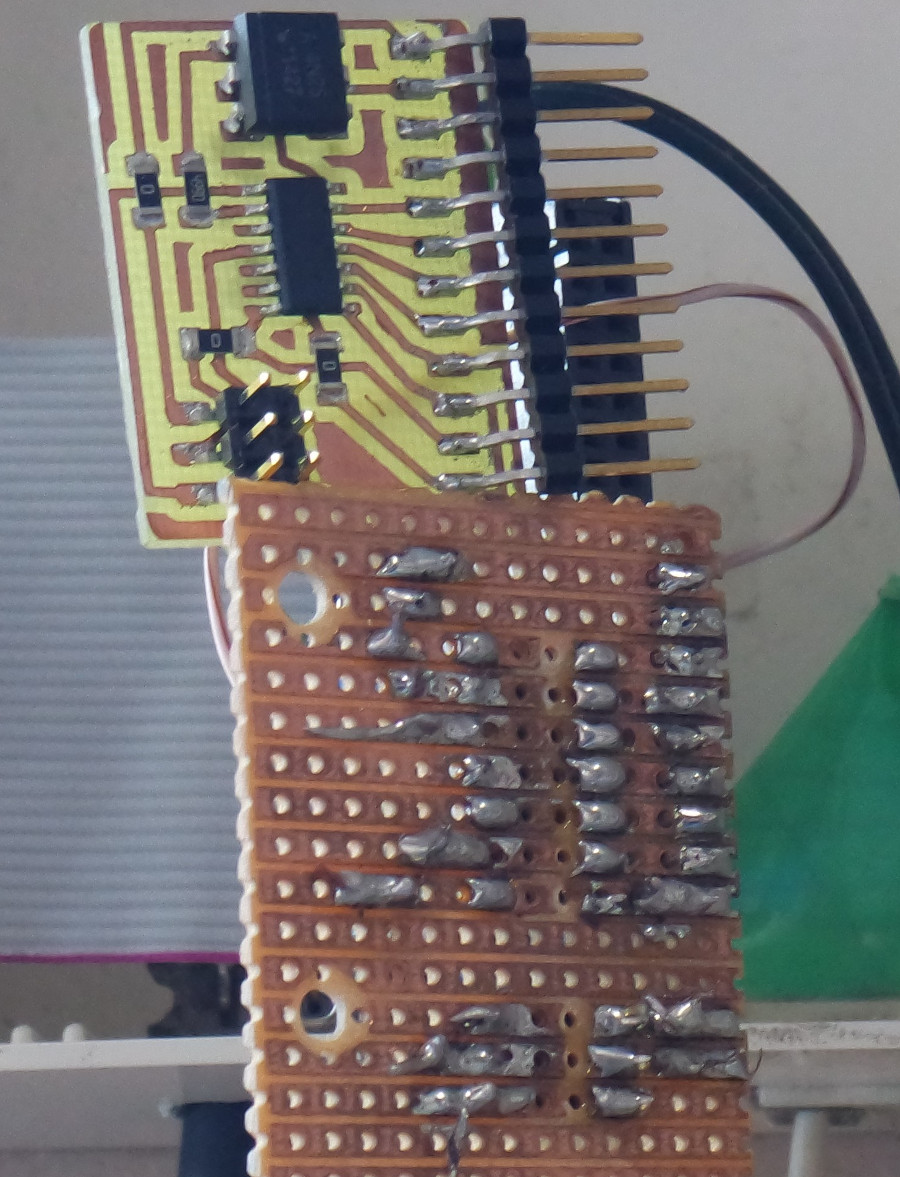

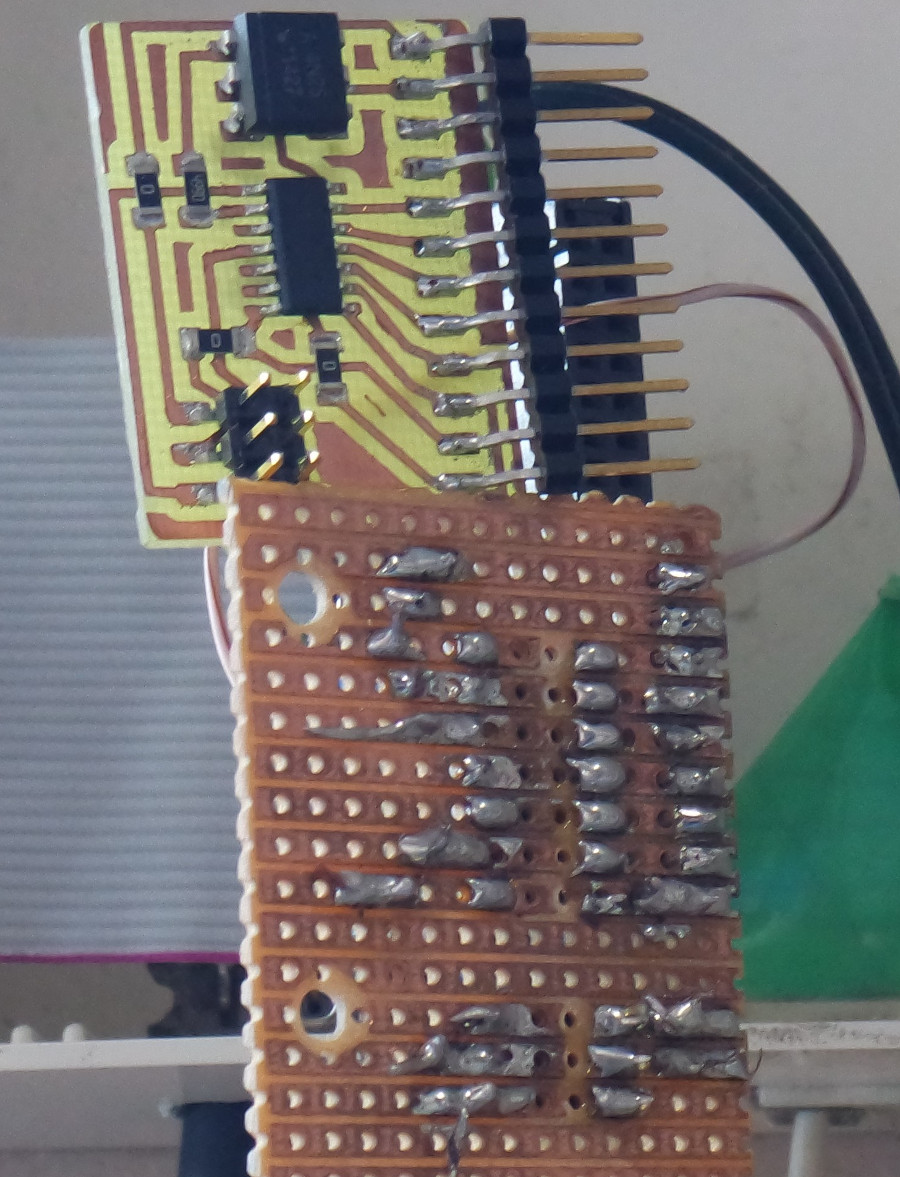

I have soldered earlier many times by hand. My fist PCB milling and

soldering of surface mount components project was my garage door

opener last year.

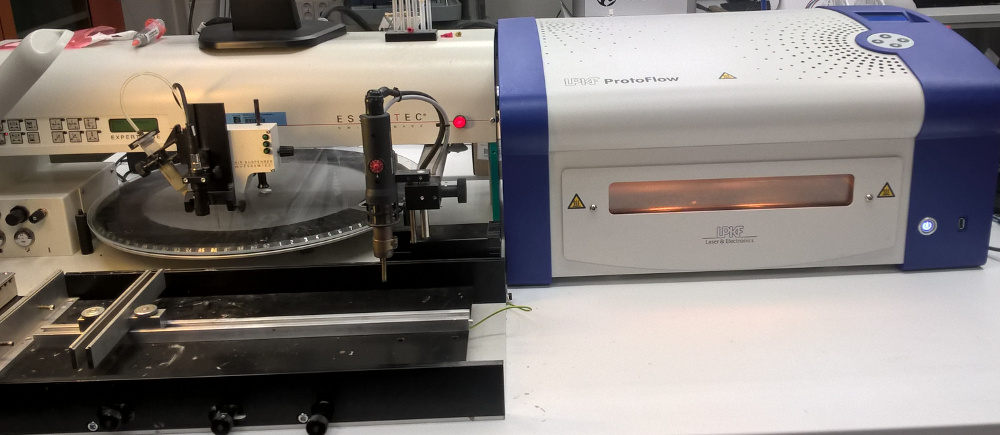

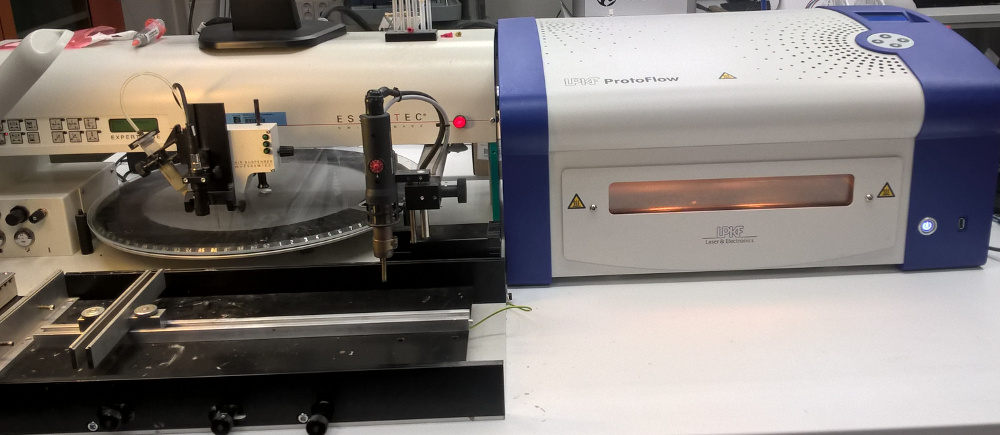

Therefore, I decided to use pick and place machine and reflow oven

again. Simply, those components are too small to my old eyes and

fingers. Results are so beautiful. And, I need still practicing.

I must use 10x magnifying loupe to place the paste and

recognize, orient and place the components. I studied cathode sides

of diodes and leds, as well as orientations to the board many times.

However, slow and careful work succeeded. The card was ready for

oven.

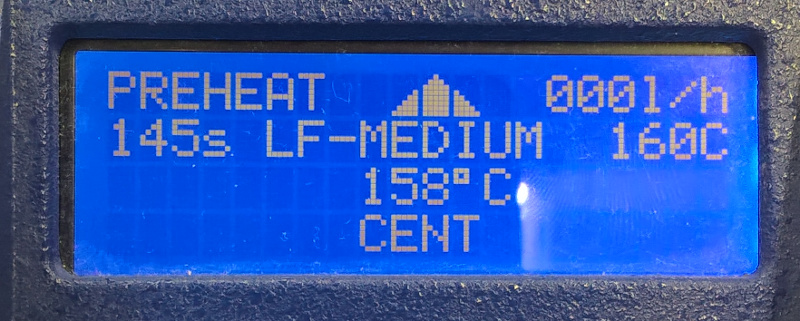

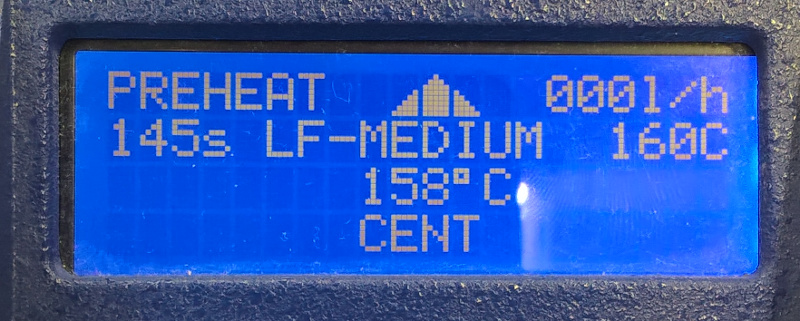

Oven was very easy to use. I opened it, prepared card place ready,

closed and selected the ramp as LF-MEDIUM.

After some minutes oven opened. I put the card on tray and closed

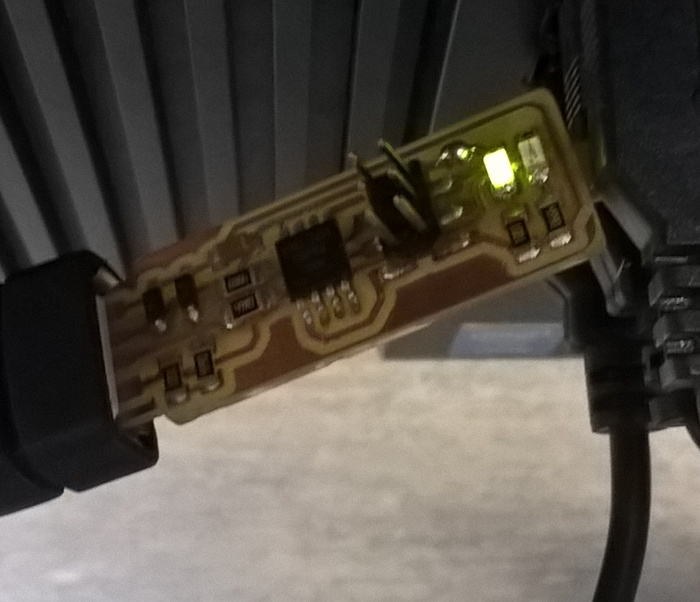

the oven. And, the final result is here. Yet, I must solder jumper

J1 by hand.

I checked connections visually by loupe and measured them by

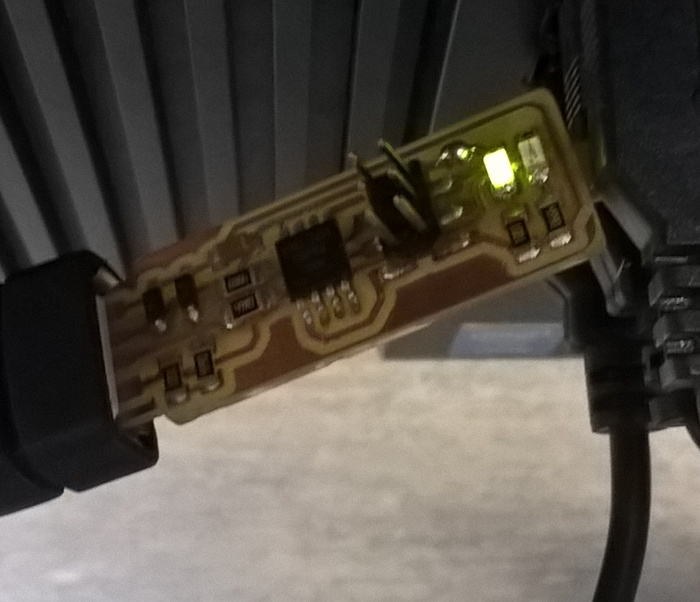

multimeter. I have got good results. I connected the card to the USB

extension cable. It was loose there, but I used wood stick to fix

the connection. Then, I plugged it to the USB port. And, HEUREKA,

it works. Only minor damage existed. LEDs were placed in wrong

order. The green led lighted up instead of red.

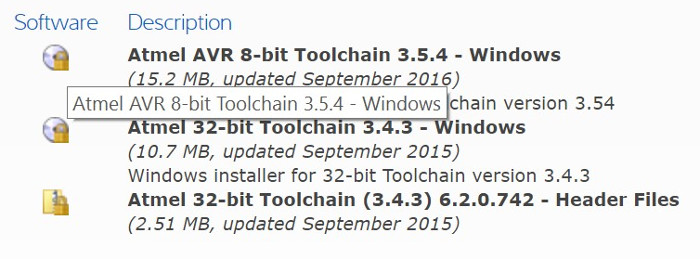

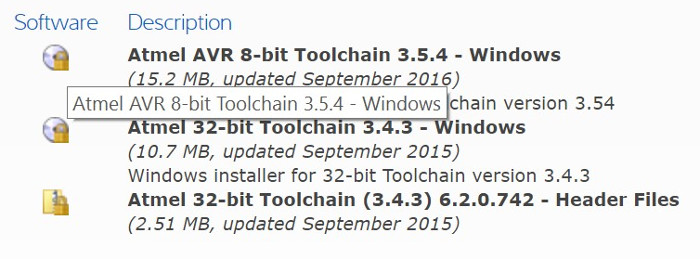

Software installation

Again, I used Brian's

instructions for software installation. I checked my computers

and I found some old GNU AVR and Make installations on my desktop

computer. I tried to install new ones without success. I didn't have

privileges to install them. Therefore, I talked with others. They

recommended installing of Linux to a USB stick and further, Linux

versions of software installations.

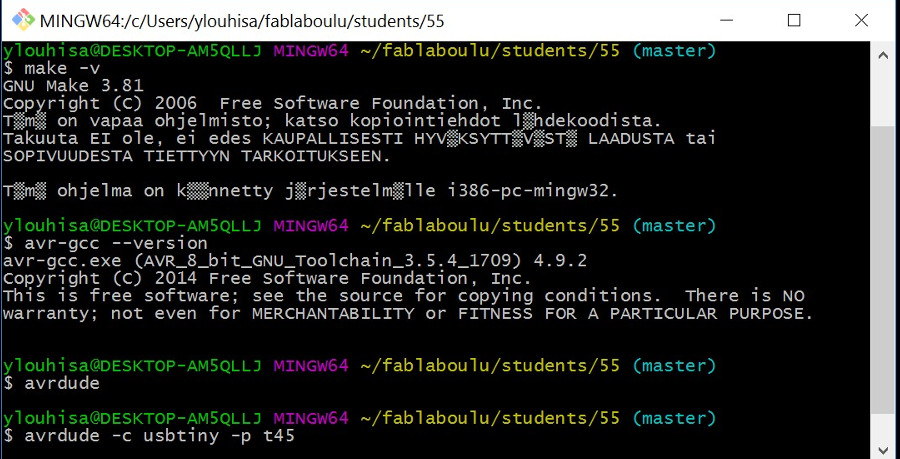

However, I decided to install required software to my laptop. It is

Windows 10 computer and Brian had good instructions for it. I

installed the Atmel GNU Toolchain (8-bit version), GNU Make,

avrdude, updated my PATH, installed drivers and made Sanity

Check as instructed.

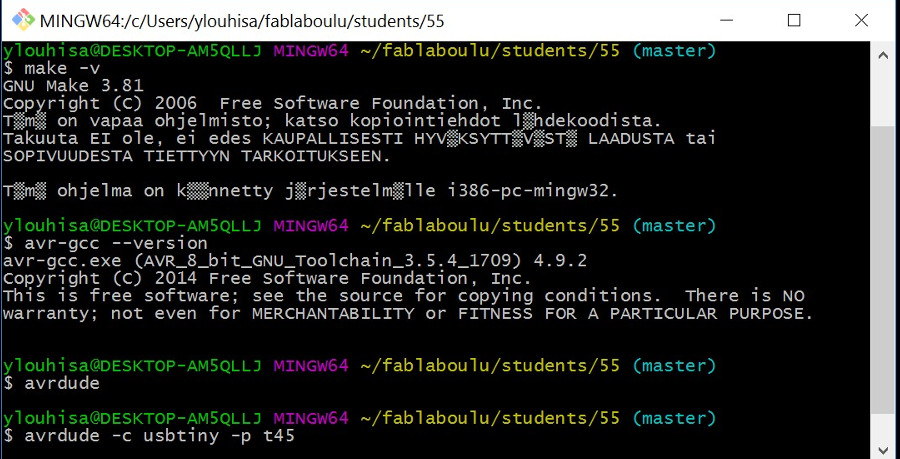

All installed well, except avrdude not. I used Atmel ICE ISP

programmer in my check and it didn't got response as proposed.

I downloaded firmware source from Brian's page and made Make successfully.

Therefore, I got the fts_firmware.hex file ready.

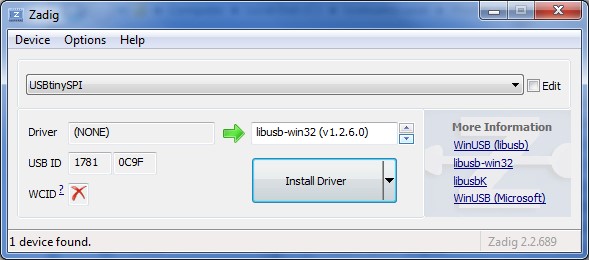

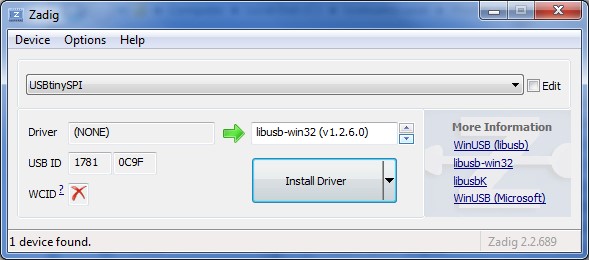

I installed Zadig and updated drivers, but without help.

Therefore, I decided to install Atmel Studio 7. It is big software.

Installing went well, but I couldn't use it. There exists ongoing

Atmel Tools driver problem with Windows 10.

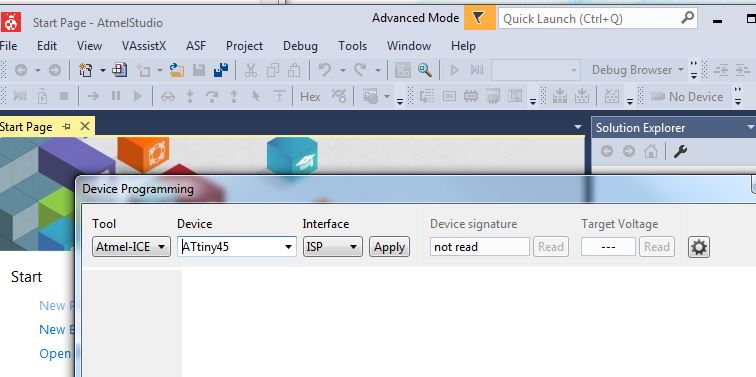

Therefore, I used one ready installed Atmel Studio 7 in our lab's

computer to program my FAB TinyISP programmer working as a

programmer. I plugged the Atmel ICE programmer into the USB port,

plugged ISP cable from programmer to my TinyISP card and then it to

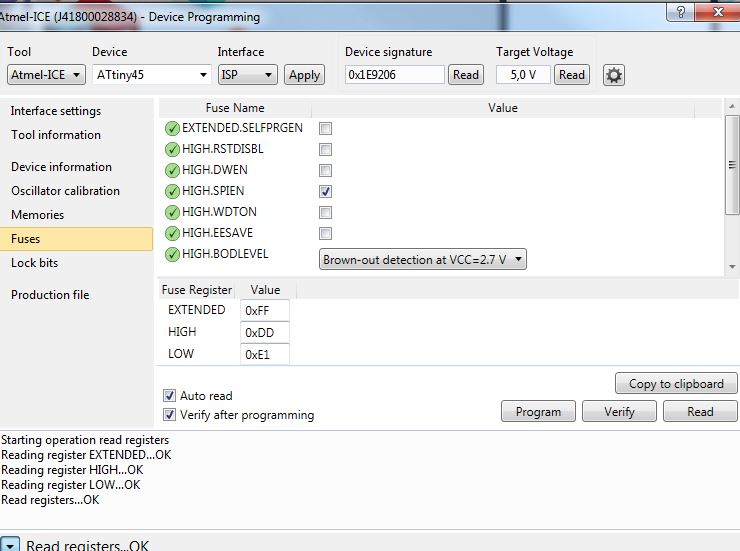

the USB port. I started Atmel Studio 7 and selected Tools >

Device Programming. I found Atmel ICE there, selected ATtiny45 as

device and ISP as interface.

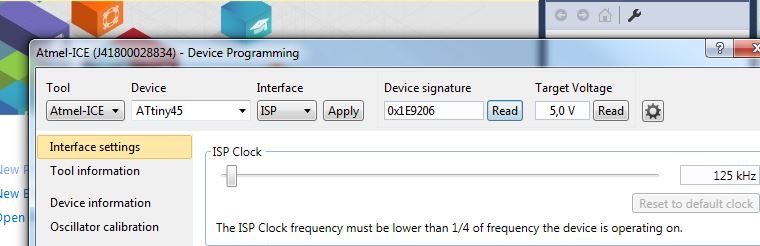

Then, I checked the target voltage and the device signature. ISP

clock setting was default 125 kHz.

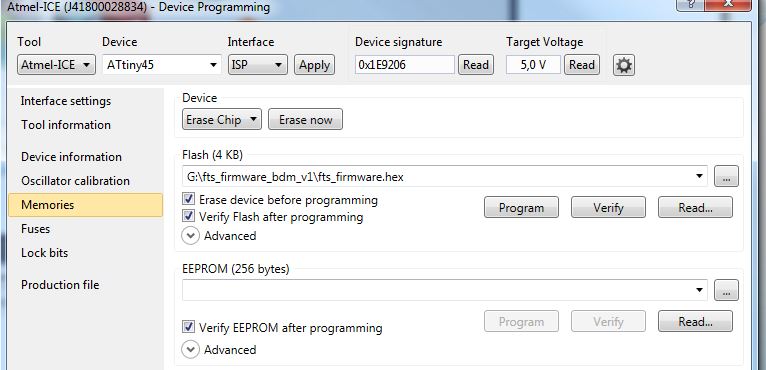

Further, I erased the chip, loaded my fts_firmware.hex

file and programmed it.

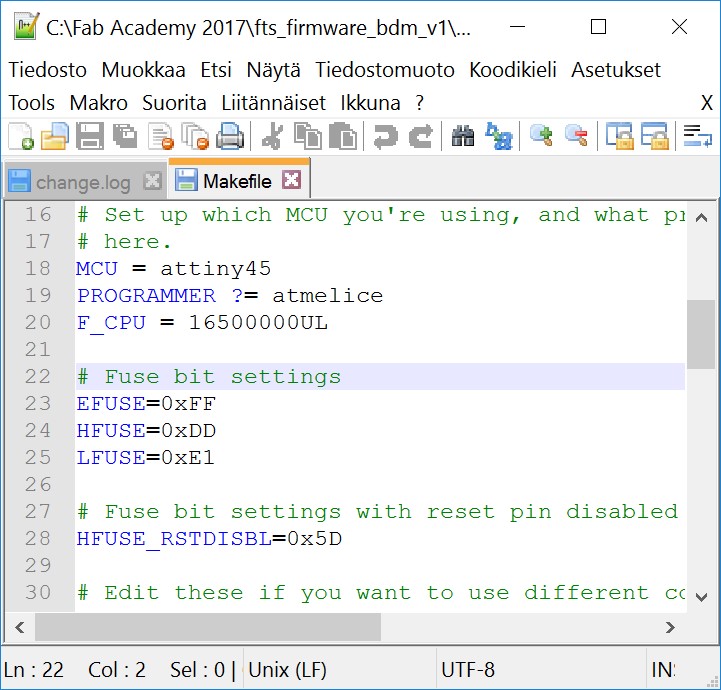

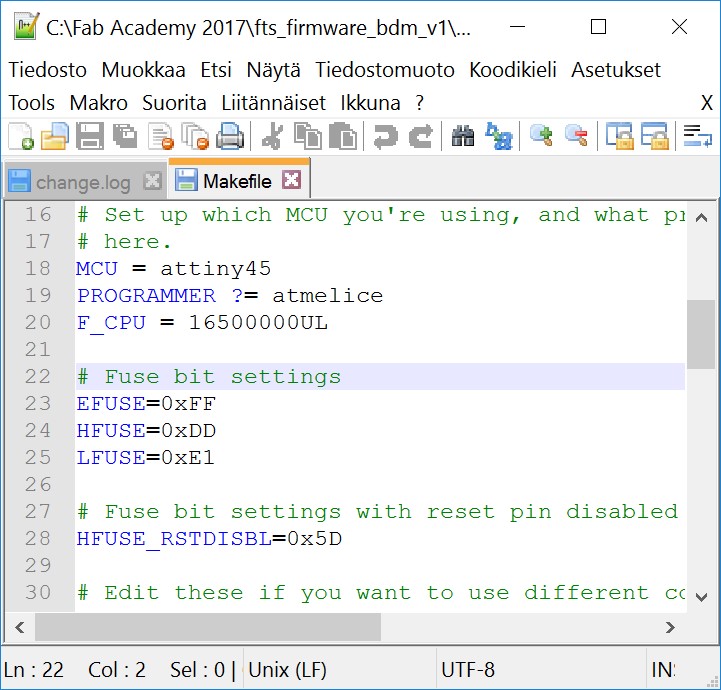

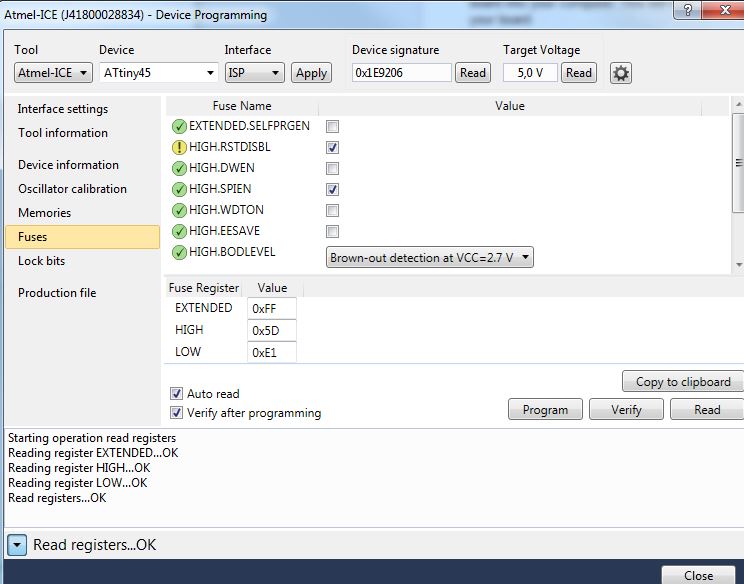

Next step was the fuses. I read the correct values from makefile

and set them to the fuse register.

Then, I unplugged programmer and my TinyISP card. And, plugged my

card alone to the USB port. My computer recognized it, but driver

was missing. I used Zadig program and installed libusb-win32 driver

for it.

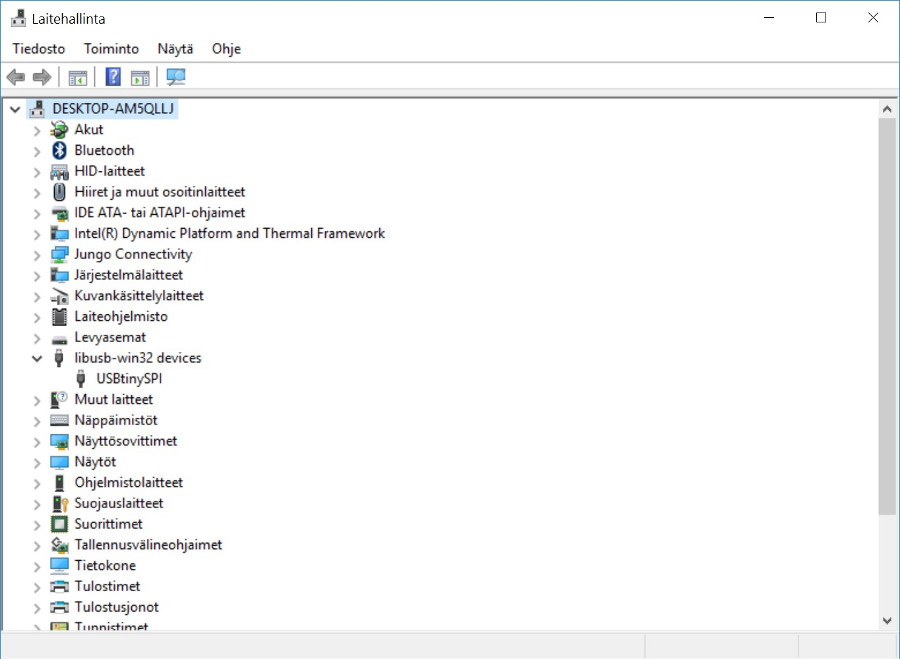

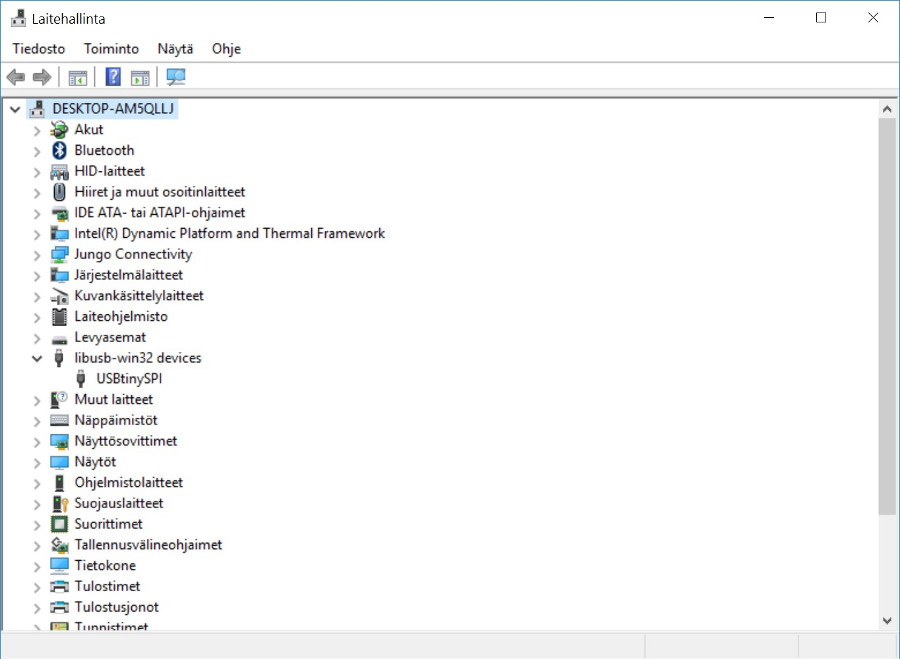

Device manager of my laptop shows my programmer as USBtinySPI under

libusb-win32 devices now. I have still problems with Atmel ICE. It

should exist under Atmel devices, when I use Atmel Studio 7.

However, AVR Dragon exists under Jungo devices as supposed.

Final work was the reset-pin setting as fuse and de-soldering

of J1 jumper.

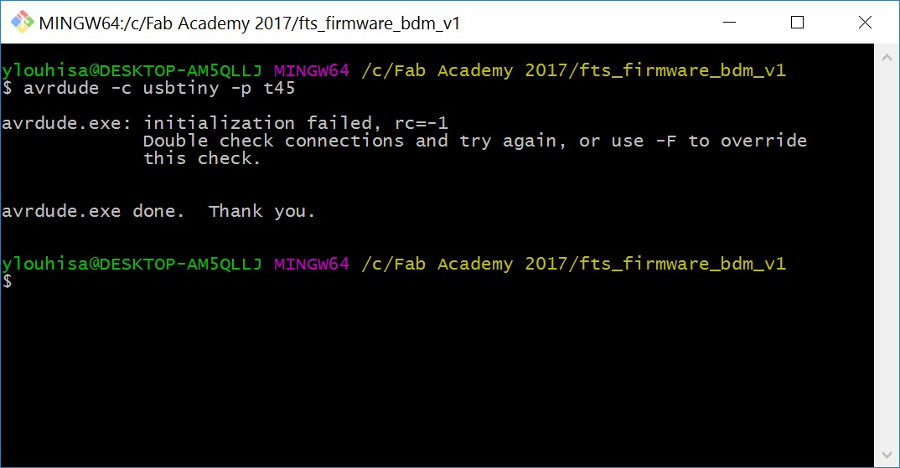

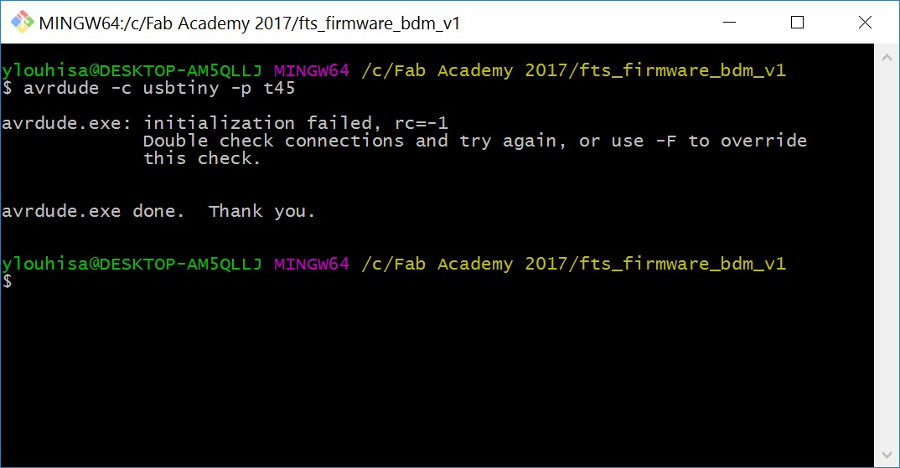

Also, averdude works now with my FAB TinyISP.

My FAB TinyISP is working now. Only minor damage existed. I placed

LEDs in wrong order. Jani predicted me that the red LED in wrong

place may damage later, because they use different dropping

resistors, red 1kΩ and green 499Ω. Red LED has 2.0 V forward voltage

and green has 3.2 V. However, I tested them and they are still

working.

Original milling files are here: fts_mini_traces.rml

and fts_mini_cut.rml .