Final Project

As part of a growing FabLab, who's emphasis in on the social engineering capacity of digital fabrication, we are constantly hosting pop-up labs. Whether these are in a school, a community group or part of a wider festival or event, having a dedicated, portable display mechanism for the presentation of workshops is vital in order to create the correct atmosphere of both learning and excitement.

We utilise flightcases / roadcases to transport the equipment as this guarantees maximum protection, but we lack dedicated pop up furniture that turns a room into a lab.

There are lots of existing flightcase designs, professionally made to suit the entertainment industry in particular, but i do not think that these represent the ethos or indeed the aesthetic of a Fab Lab.

So, as part of the process of addressing this, I have been working on several designs, one of which is a personal study pod ; a small, semi-open isolation square box that will allow visitors to the Lab to achieve a little isolation so as to aid concentration.

So, as part of the process of addressing this, I have been working on several designs, one of which is a personal study pod ; a small, semi-open isolation square box that will allow visitors to the Lab to achieve a little isolation so as to aid concentration.

However, i feel this design has a lot of inherent flexibility in terms of how it is used, and for this final project i intend to design and make a giutar tech station for use on stages.

Idea Outline

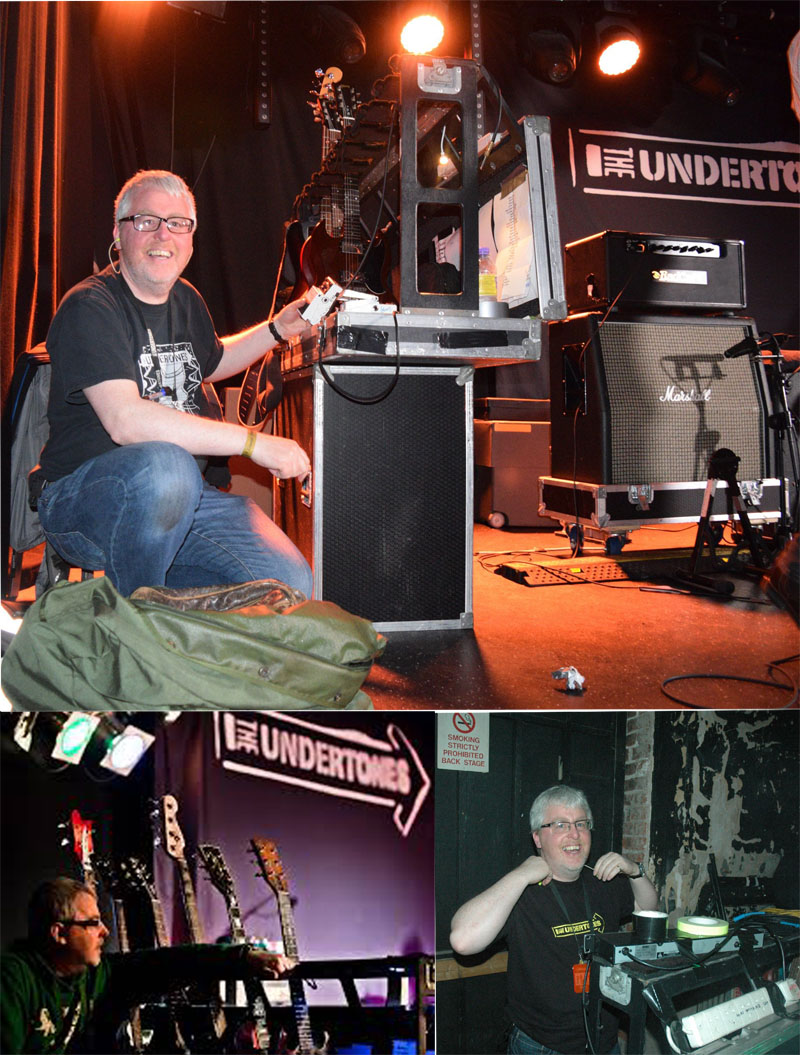

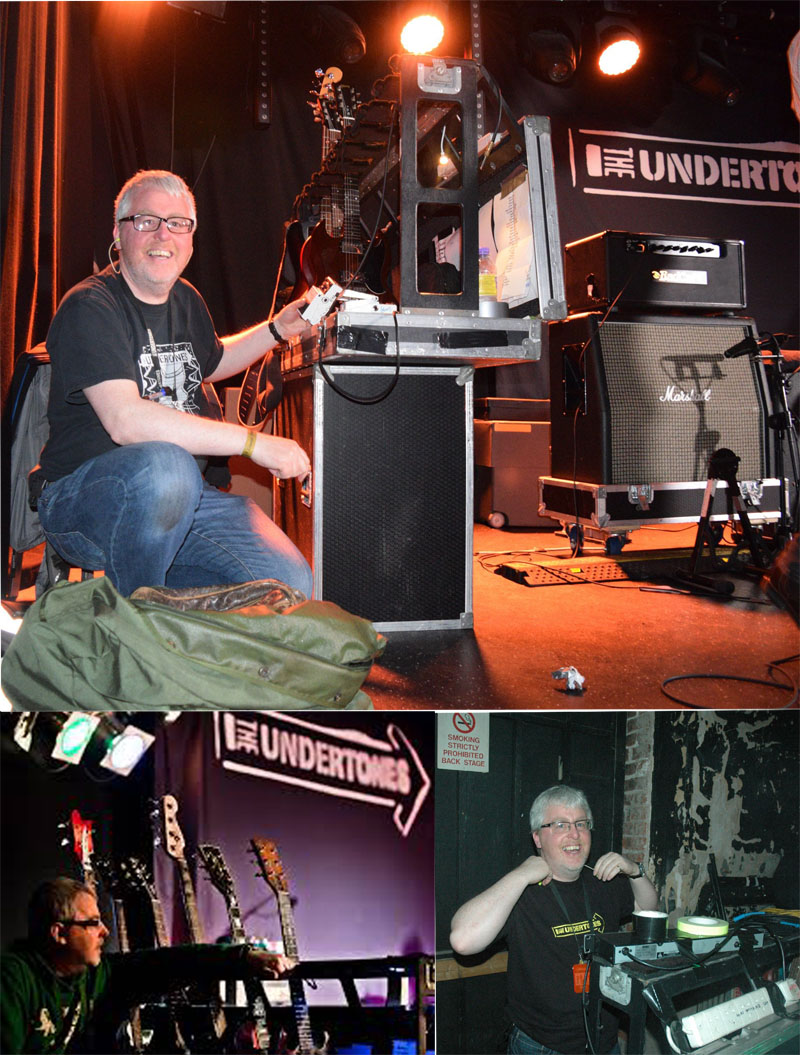

When not working in FabLab I like to indulge in a little guitar tech / stage manager work. This has taken me half way around the world, and it is something that i am very passionate about.

Working on stages, with the band present can be a stressful activity. You are visible to the band, and sometimes to the audience. You need a little privacy to work at certain things, so as not to casuse undue stress with the band members. It is generally dimly lit. It is usually quite hot due to incandescent stage lighting, although this has improved due to the widespread adoption of LED based stage lighting.

Working on stages, with the band present can be a stressful activity. You are visible to the band, and sometimes to the audience. You need a little privacy to work at certain things, so as not to casuse undue stress with the band members. It is generally dimly lit. It is usually quite hot due to incandescent stage lighting, although this has improved due to the widespread adoption of LED based stage lighting.

So, in order to address these issues, i am proposing building a guitar tech station that offers a little isolation, whilst providing adequate light to work, and cooloing for the tech as needed.

Design Elements

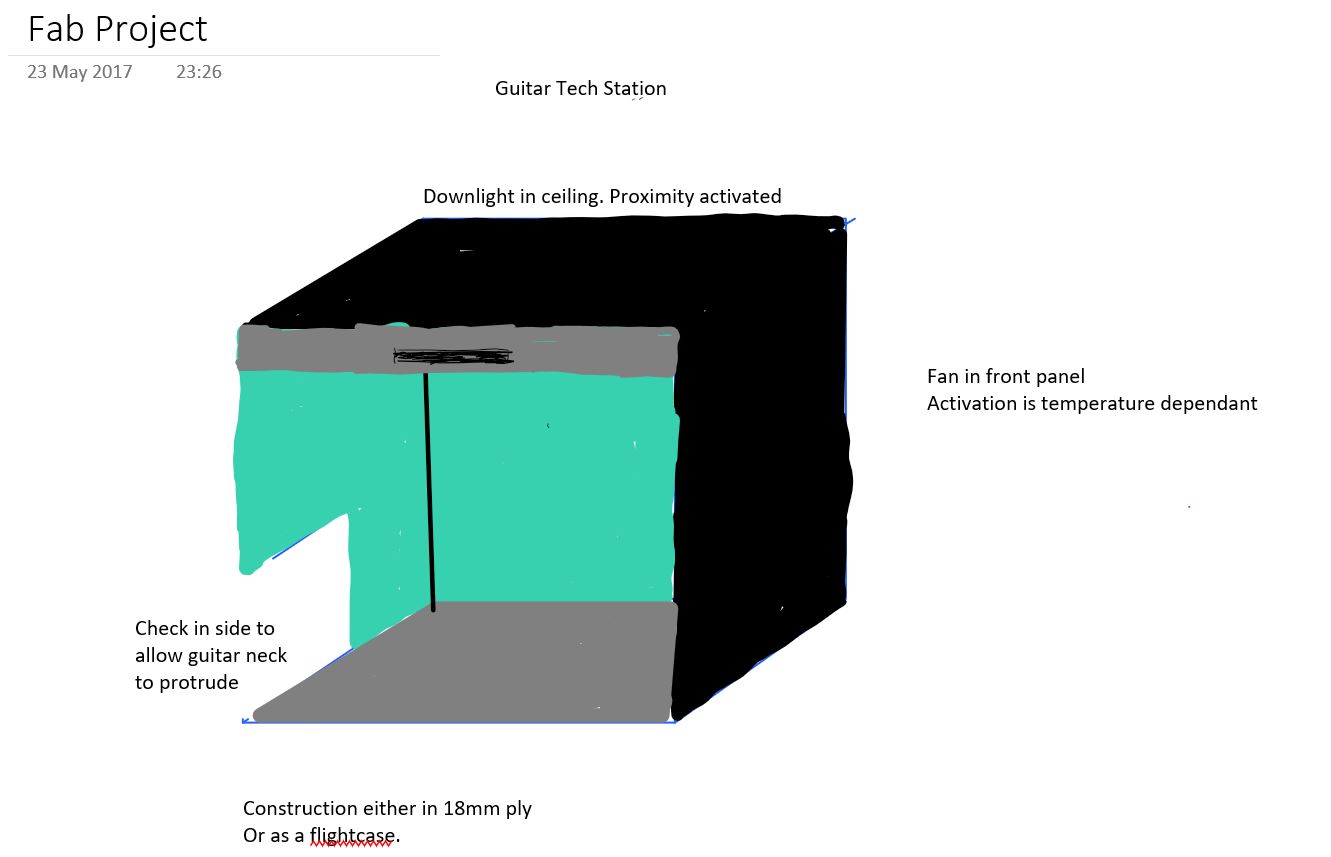

Box: The unit itself will be constructed either in 18mm ply for permanent applications, but can also be made utilising flightcase marerials, and a mechanism for folding introduced if it is to be taken on ther road. As part of the work involves rapidly changing / replacing strings and tuning of guitars, a part of the left wall will; need to be removed in order for the guitar neck to stick out during work. As the work pod will generally sit on top of empty flightcases there is no need for legs.

The unit will contain a shelf at the rear that will hold both guitar tuner, tools and also a number of receptacles for putting spare parts in. This aspect of the design can me made of a composite material, or 3d printed.

Lighting: Good lighting is necessary to achieve quite a lot of stage-side repairs. But this is rarely incorporated into stage located tech stations. In larger productions the tech world is often located either under, or offstage, and this enabled full lighting to be used. But the pod I am designing is to be used onstage. Having the enclosed box gives the freedom to light the unit from within, bith providing a better working environment whilst not causing light pollution within the stage porduction. In order to keep light use to only necessary times, I will use a proximity sensor to switch the lighting on and off. Essentially, if the operator is standing in front of the pod, the lights will come on. At all other times, the lighting will remain off.

Ventilation: In order to aid in keeping the technician cool when operating on a very hot stage environment, I am proposing to mount a small, quiet fan on the front face of the guitar pod. This can either be controlled by temperature dependant switching, or simply under operator control through the use of a switch.

Project Outline

What will it do?

The guitar station is one iteration of a privacy cube. Essentially, it will provide a place to host all of the facilities required to operate as a guitar technician on small to medium sized (circa 1000 capacity) music events. The essential elements are

1. Privacy

2. Workbench with relevant storage areas for tools / spare parts

3. Adequate lighting

4. Cooling

The unit is being constructed as a custom response to my personal needs when working as a stage technician, and will be located permanently within the Nerve Centre music venue. http://www.nervecentre.org/facilities/nerve-centre-main-venue#.WStiIOvyupo

Who's done what beforehand?

To my knowledge, no one in fab academy has attempted to complete a similar project. However, there are a few bespoke items available from custom road trunk manufacturers. These units are designed to fold away into a unit roughly the size of a guitar case, but provide no facility for lighting, cooling, storage etc.

Also, the unit in question is being custom fabricated for location within a single music venue, to my particular specification.

What materials and components will be required?

Main Structure; 12mm OSB or birch ply. Wood glue. Screws.

Storage shelf; 18mm ply frame with composite shelf

Lighting; Led array - Controlled by ultrasonic distance measurement sensor. Sensor housing to be 3d printed or laser cut

Operator cooling fan; operated by either switch or temperature measurement sensor. Fan grille to be laser cut. Housing for sensor to be 3d printed

Neutrik powercon socket to be chasis mounted for incoming mains electricity supply

Mains distribution unit

Where will they come from?

Apart from powercon and distribution unit, all other materials are in stock at FabLab Nerve Centre.

How much will it cost?

1x sheet osb £15

distance sensor £1

Temperature sensor£1

LED £3

Fan £3

Powercon £5

Power distro £4

What parts and systems will be made?

Chasis

Lighting control

Temperature control

What processes will be used?

Large scale machining

Laser cutting

Composites

3d printing

Electronics design, production, programming

What tasks need to be completed?

Design and construction of main chasis using shopbot

Fabrication of bespoke shelf/housing for tools to be achieved through the use of resin based composite.

Housings for sensors to be 3d printed

Boards for control of electronics to be milled and soldered and programmed.

What questions need to be answered?

What is the schedule?

How will it be evaluated?

So, as part of the process of addressing this, I have been working on several designs, one of which is a personal study pod ; a small, semi-open isolation square box that will allow visitors to the Lab to achieve a little isolation so as to aid concentration.

So, as part of the process of addressing this, I have been working on several designs, one of which is a personal study pod ; a small, semi-open isolation square box that will allow visitors to the Lab to achieve a little isolation so as to aid concentration.

Working on stages, with the band present can be a stressful activity. You are visible to the band, and sometimes to the audience. You need a little privacy to work at certain things, so as not to casuse undue stress with the band members. It is generally dimly lit. It is usually quite hot due to incandescent stage lighting, although this has improved due to the widespread adoption of LED based stage lighting.

Working on stages, with the band present can be a stressful activity. You are visible to the band, and sometimes to the audience. You need a little privacy to work at certain things, so as not to casuse undue stress with the band members. It is generally dimly lit. It is usually quite hot due to incandescent stage lighting, although this has improved due to the widespread adoption of LED based stage lighting.