2 Computer Aided Design

The task for this assignment was to use computer aided design (CAD) tools to draw in 2D and 3D, a representation of the students's final project. During the class lecture on this topic various CAD tools were listed with a distinction made between raster and vector drawing tools and between open source/free tools and commercially licensed tools. Through the Fab Academy the students were able to get a temporary license (1year) for Solidworks and Autodesk. At the class lecture it was emphasized we try as many of the CAD tools as possible in order to find tools that we could work with and that were best suited to the design.

In reality I was unable to test drive a lot of the CAD tools mentioned. I spent most of this week's time trying to figure out the dimesnsions and geometry of my final project design,- Stirling Engine Stove Fan- so that I could draw it. In the end I opted to use an exsiting engine design as the basis for my CAD drawing project.

However, from talking to other students and my instructor useful CAD tools that meet the requirements of ease of use and price are listed as

- Rhino

- Inkscape

- CorelDRAW

- FreeCAD

- TinkerCAD

- Solidworks

Over the course of the Fab Academy I intend to gain some experience of the above tools and will be able to update this page with the results

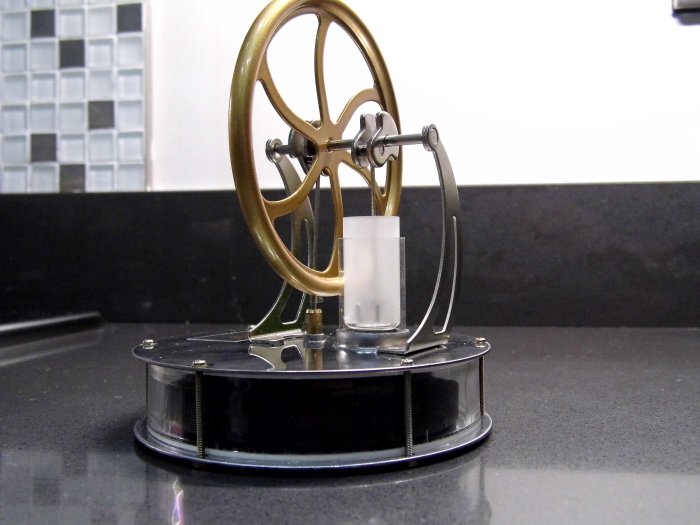

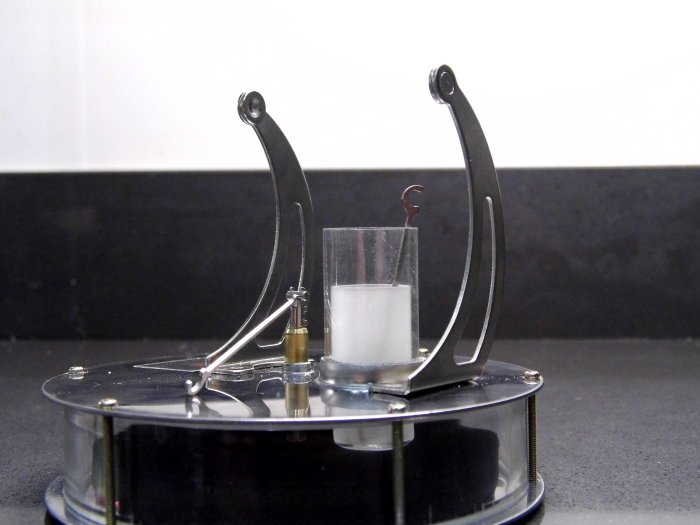

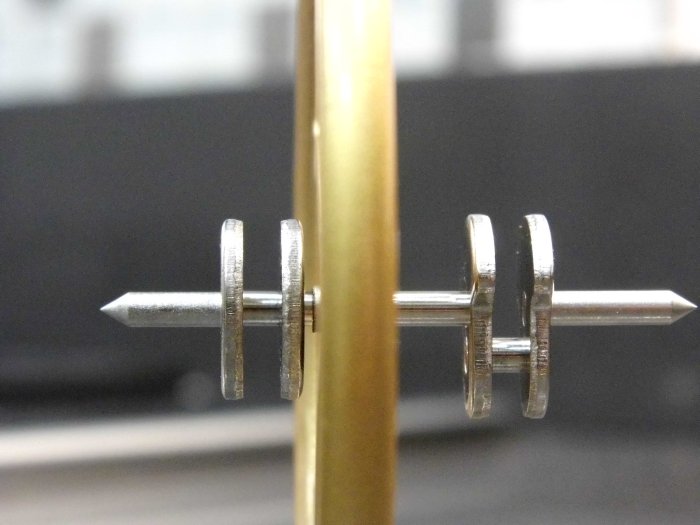

Existing Engine

Some images of a Stirling Engine used for educational purposes are shown below. Scroll through them to see the various engine parts such as the flywheel, crankshaft and pistons.

Inkscape

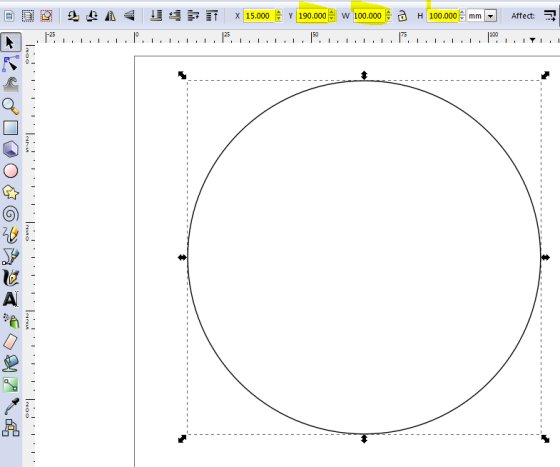

First thing I did in Inskscape was to go to File->Document Properties and set the page size to A3, Orientation to Landscape and the Default Units to mm.

The screenshot below shows the initial drawing of the engine flywheel: it's a circle with diameter 100mm. To do this with Inkscape draw the circle and in the W

and H fields (highlighted) change the dimensions to the value needed - in this case 100. The other parameter fields higlighted X

and Y are the X and Y co-ordinates of the drawn object. These coordinates are useful when an object needs moved to

an exact position.

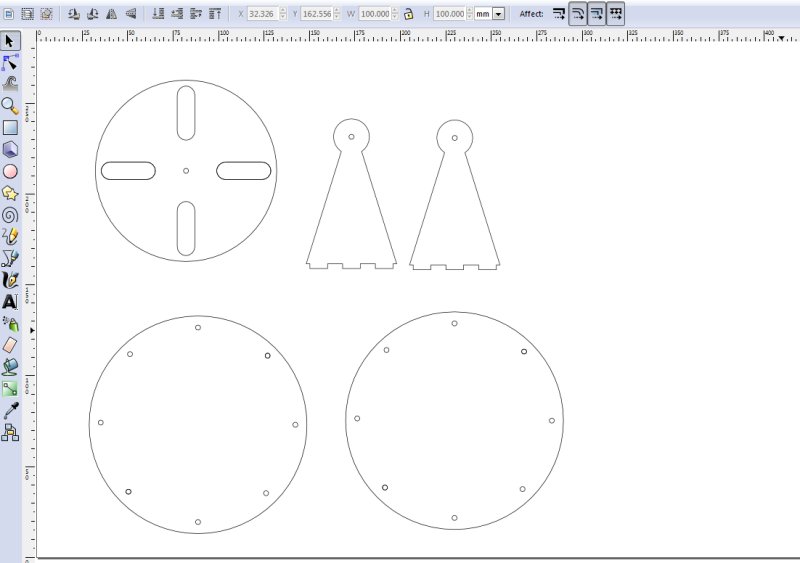

After drawing the flywheel circle I added a few slots and a centre hole for the crankshaft. The slots were drawn by intially drawing one slot and then cloning it using the ALT D short cut. This means that if the original parent is changed then all cloned offspring will change. This is a useful feature and allows dimensions to be easily changed if required. The Align and Distribute tool was used to place the slots equally around the flywheel circle.

I added some more engine parts to the design

- crankshaft support brackets

- top and bottom displacement cylinder plates

Further engine parts will be added to this drawing before attempting to cut them out using the laser cutter.

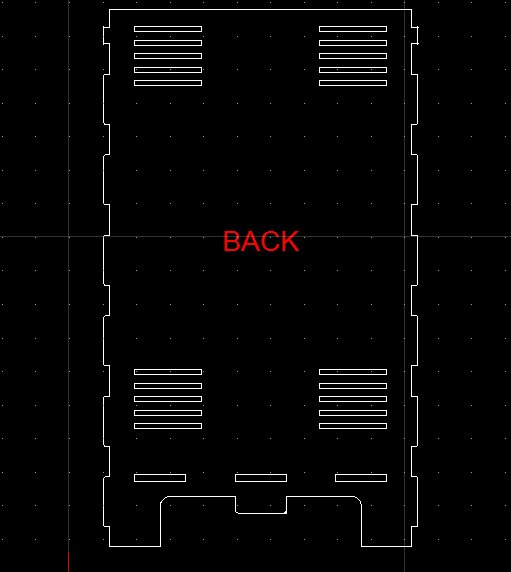

Solid Works

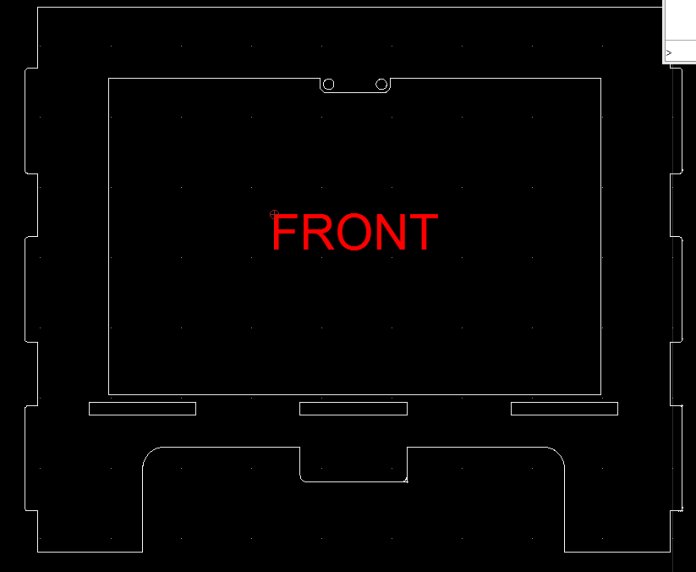

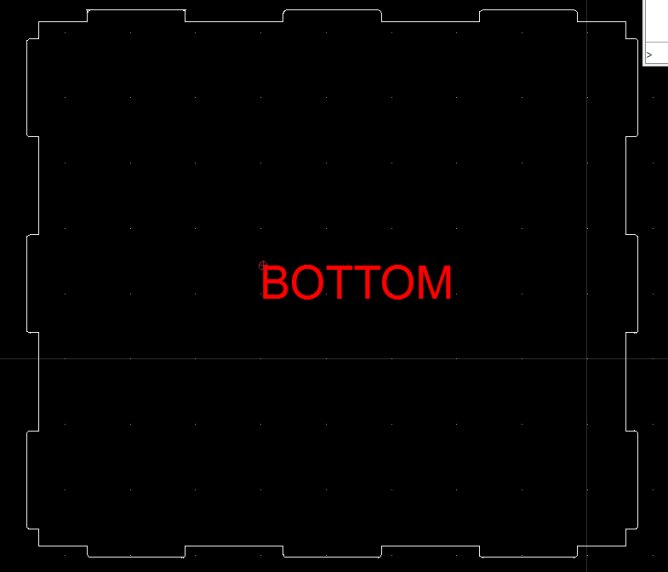

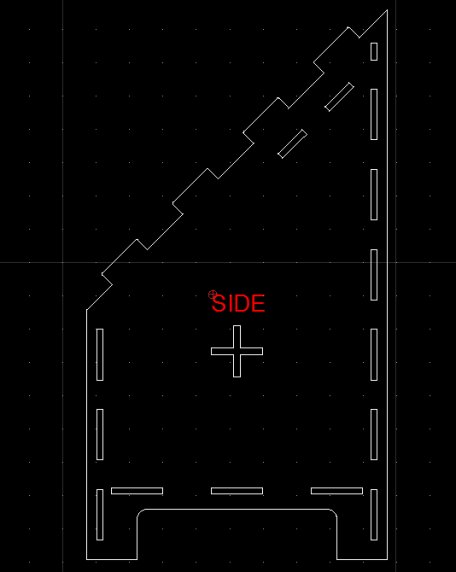

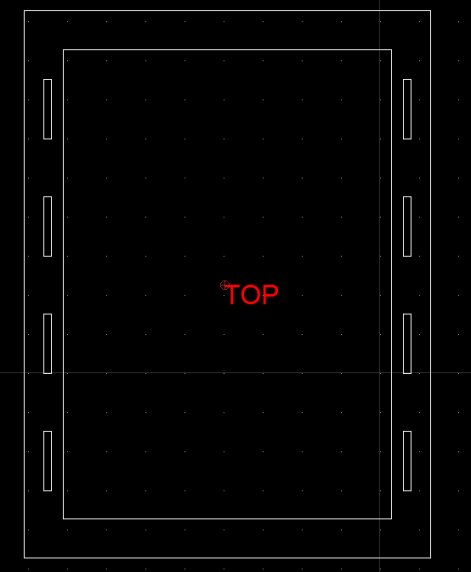

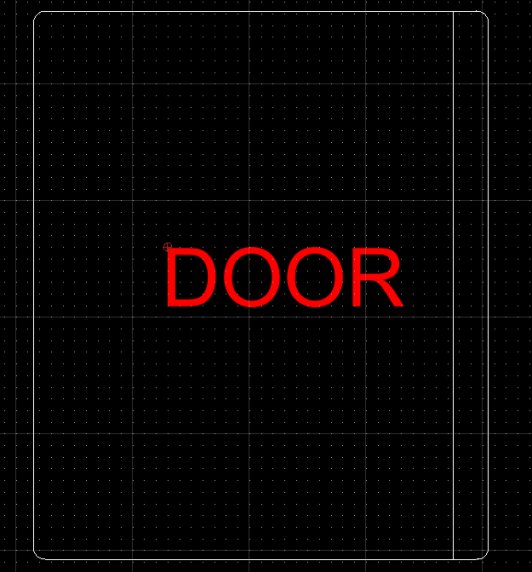

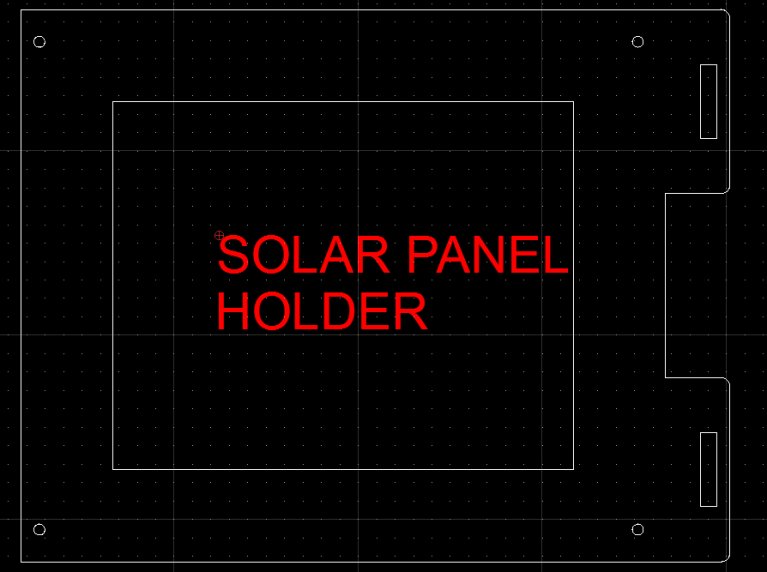

After I changed my project from a stove fan to solar kiln I did the solar kiln drawings in Solid works. The design for this can be found on my final project page along with the design files which are linked below.

The screen shots below also show the various drawings of the Solar Kiln