Fabacademy 2017

Nineteenth Week. Project development

Index

What is the deadline? How much time do I have left?

I will present next week on the Friday the 16th. From there until the 28th is twelve days in which I will be documenting the final project page and going through my local review to complete tasks from my previous assignments.

What tasks have been completed, and what tasks remain?

Completed:

- Finalizing parametric design for the window structure

- Cutting the structure

- Finalizing DC Motor controlling board and sensor board

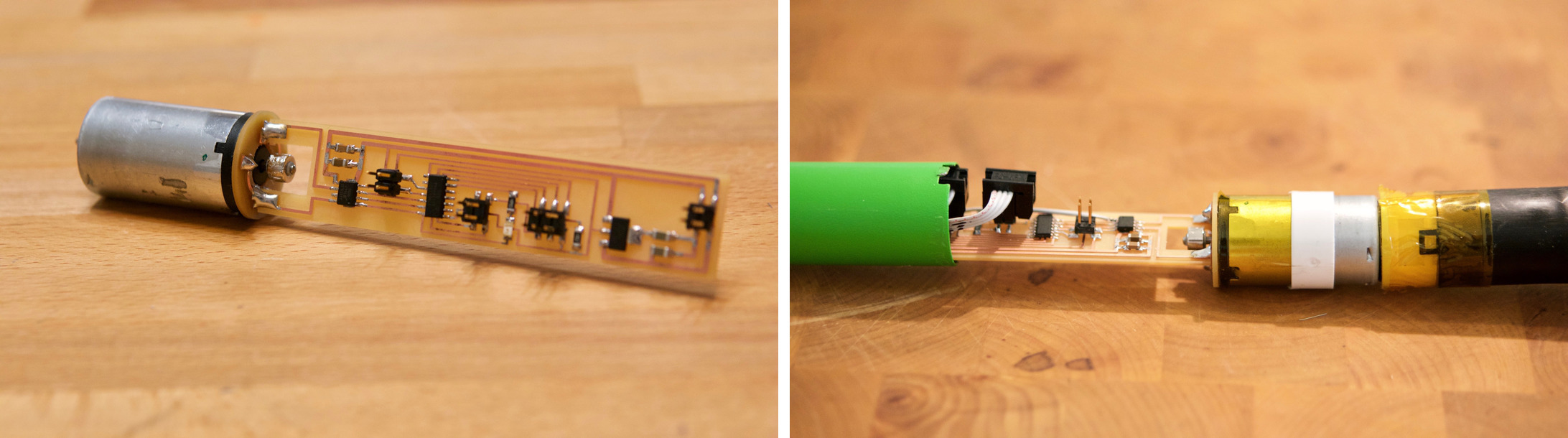

- Milling board and soldering components

Remaining:

- Assembling the structure

- Finalizing microcontroller programming

- Testing and documentation

- Installing window glazing and gasket seals. Budget restrictions on this one

How will I complete the remaining tasks in time?

My schedule for the next week:

- Assembling the structure. One day

- Asembly dc motor, roller blind and electronics. One day

- Finalizing microcontroller programming. Two days

- Testing, documentation and video. Three days

What has worked? what hasn't?

DC motor board has worked very well. The two component designs allows to solder the dc motors pins directly to the boards creating a very clean assembly. I am also very pleased with the quality of the structure, if feels very solid and precise up to my initial requirements for this project.

For budget restriction issues –I was not allowed to use more than one single sheet of ply for this prototype and my initial dimensions would have required two– I have to do a reduced version of the window 1000mm by 1200mm instead of 1200mm by 1600mm so I wont be able to install the window in my own house. This will limit a lot the testing process of this prototype, I intend to do a second prototype with the proper dimensions during the summer.

I still need to figure out a complete waterproof solution for the light sensor.

What questions need to be resolved?

- Can the DC motor controller and battery be safely integrated within the roller tube? I realized that in order to achieve this I will need to develop a charging circuit within my controller board so the built-in battery can be charged using small solar panels embedded on the frame. Dont think I will be able to do it on this iteration though.

- Does the design comply Eurocode standards? I wont be able to test the window in a real work scenario due to budget issues so It will be harder to test sound proof and weatherproof capabilities.

What have you learned?

This has been the first that I've done entirely using parametric CAD software. As explained on Week 2 I've used many other CAD softwares before but moving to a fully parametric solution was a great decision. It makes design for fabrication much quicker so design can iterate many more times. On the down side, sometimes it feels too linearly driven though. In the next iteration I will try to explore conditional statements so the design could get more sophisticated and adaptable.

Studying in great detail how a window works and is constructed has been very insightful too. From an architectural point of view I plan to continue this analytical approach for other basic building elements.

Designing, fabricating and programming your own boards from scratch is very empowering. It is great to learn how the microcontroller works at a low-level although leaning C and bit-wise operations has been challenging for me. I plan to continue my learning about all this by adding new sensors and actuators to the design.