Week 5

3d scanning and printing

In this week, the two assignment i done are 3D scanning of an object, designed a 3 dimensional object which i can print using a 3D printer.

3D Printing

For 3 D printing, I designed a ball in a cage and called as impossible. I used onshape for designing.

I export my this impossible named design to STL format.

3D printer and

filament

The 3 D printer used here is the Weistek’s Speed 3D printer. It prints very fast.

I loaded green filament into the machine and checked that filament extrudes well after proper heating of nozzle.The temperature of the nozzle is set to 2100 C.which is fine for the PLA type filament.

Weistek Speed 3D Printer with PLA filament

Slicing software and converting into the machine code:

The software used for converting the STL file into machine code is Real vision.

In this Software,the STL file is converted into the machine code as F-Code.

There are many tools and options in the application.We can scale the object,rotate it,flip,duplicate etc.

Temperature of the plate and the nozzle can be varied as well. After adjusting required options and settings, i converted into F code and exported into the USB drive.

After loading this converted file into the printer, I started print and finally i got my design printed completely.

3D Printed output

My 3D files,

Onshape design file here

my .stl file after onshape design is STL file

Result:

As per the design of mine, I got the 3D printed output.

The best part of 3D printing is we can see our 3D concept into reality.

3D scanning

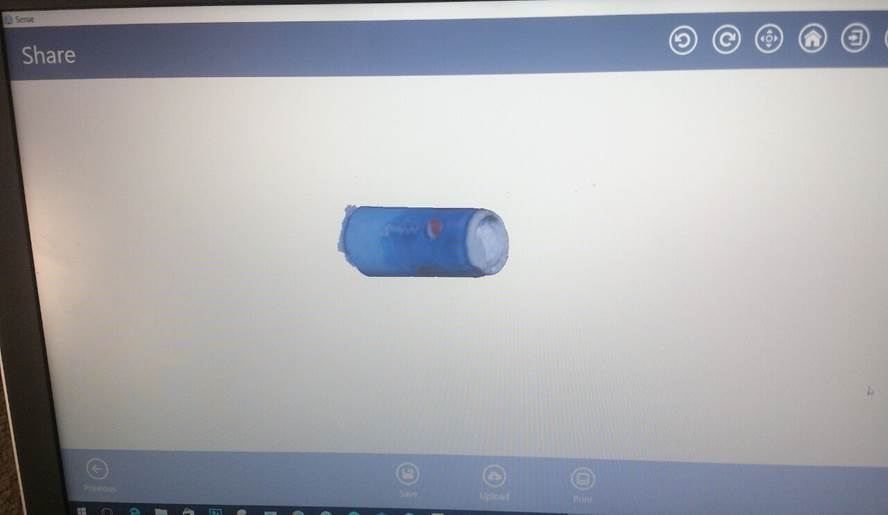

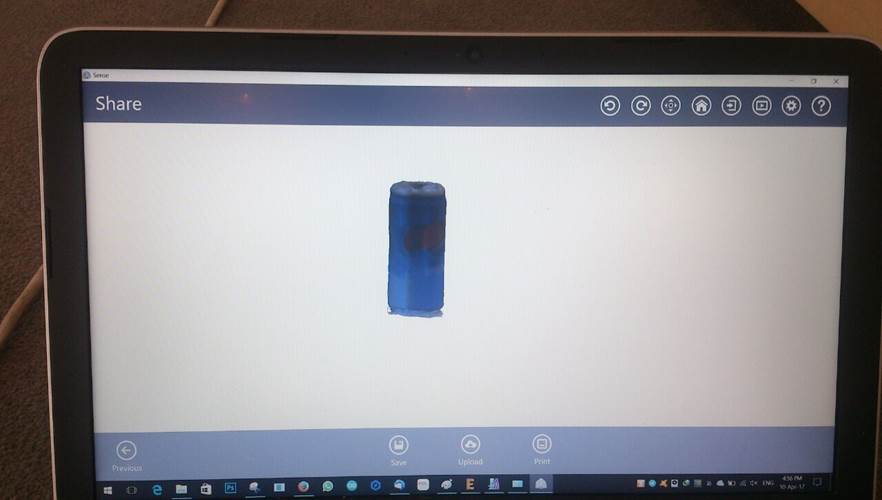

For 3D scanning,i used sense first generation device.

Application

application used for scanning is sense.website

After connecting the scanner to PC, we have to choose the options. Object or the person. I want to scan a pepsi can. So i choosed the object.

Then i selected small object since it is a small.

Scanning

I placed the can on a table and rotated the scanner.

After that i got a 3D object. I solidified the object by solidify option and removed unwanted things got after scanning.Cropped the object and saved the final output as STL format. There is .obj format as well.

I prefered .STL format,which can be printed after converting the file in to f code format after slicing with the REAL vision software.

scanned output file for 3D scanner is : Pepsi can

The problems faced during the 3D scanning using sense is the rotation.For to get a complete shape,rotating around the object need to be very slowly to avoid the lose of tracking.

For what i learned or experienced in this week, i can say

that the 3D scanning and printing limitations:

3D Scanning limitations:

1- Can not scan

hidden designs and scans only surfaces.

2- Low accuracy

with the available low cost 3D scanners.

3- Cannot

determine the material that been scanned.

4- Hard to scan

transparent and reflective objects .

3D printing limitations:

1- Rough

surface with FDM printers and needs acetone steam bath

2- Sometime its

hard to remove the support especially if its inside the object and there is not

way to reach it

3- Low speed

4- Limited print materials, although SLA have many types of materials.

Also I understood

there are different types of materials used in 3D printing technology. Some of

them and their characteristics are.

1-

ABS(Acrylonitrile butadiene

styrene)

The product made of ABS is durable and impact resistant. It can be used

for functional Parts.

strength - Medium.

Density - 1010 kg/m³.

Flexibility- Medium

Durability –High

Difficulty to print- Medium

Print temperature (in degree Celcius) -210 - 250

Bed temperature(in degree Celcius) -50 - 100

2-

PLA(polylactic acid):

It is easy to print and bio degradable. It can be used for Consumer

Products.

strength - Medium.

Density - 1240 kg/m³.

Flexibility- low

Durability –Medium

Difficulty to print- low

Print temperature (in degree Celcius) -180 - 230

Bed

temperature(in degree Celcius) - No heated bed needed

3-

HIPS (high-impact

polystyrene)

This is dissolvable and biodegradable.Used as Support structures when

using ABS on a dual extrusion printer.

strength - Low.

Density - 1040 kg/m3

Flexibility- Medium

Durability – High

Difficulty to print- Medium

Print temperature (in degree Celcius) - 210 - 250

Bed temperature(in degree Celcius) - 50 – 100

4-

PVA(Polyvinyl alcohol)

This material is dissolvable, water Soluble, biodegradable and oil resistant.This

is used as support structures when using PLA or ABS on a dual extrusion

printer.This is hygroscopic and we need to keep sealed when not in use.

strength - High.

Flexibility- Low

Durability – Medium

Difficulty to print- Low

Print temperature (in degree Celcius) - 180 - 230

Bed temperature(in degree Celcius) - No heated bed needed.

5-

Nylon is a generic

designation for a family of synthetic polymers.

This is strong, flexible and durable. So can be used for all uses.

strength - High.

Flexibility- High

Durability – High

Difficulty to print- Medium

Print temperature (in degree Celcius) - 220 - 260

Bed temperature(in degree Celcius) - 50 - 100

6-

Wood

This is having its property as name gives.that is wood like finish. So this can be used for home

décor.

strength - Medium.

Flexibility- Medium

Durability – Medium

Difficulty to print- Medium

Print temperature (in degree Celcius) - 195 - 220

Bed temperature(in degree Celcius) - No heated bed needed.

7-

PET/(Polyethylene

terephthalate )

This is very strong,flexible,durable and recyclable. So this can

be used for all uses.

strength - High.

Flexibility- High

Durability – High

Difficulty to print- Medium

Print temperature (in degree Celcius) - 220 - 250

Bed temperature(in degree Celcius) - No heated bed needed.

8-

Polycarbonate (PC)

This is very strong,flexible,durable,transparent and heat resistant. So this can

be used for functional parts.

strength - High.

Density - 1.18 – 1.20 g/cm³

Flexibility- High

Durability – High

Difficulty to print- Medium

Print temperature (in degree Celcius) - 270 - 310

Bed temperature(in degree Celcius) - 90 - 105

9-

TPE(thermoplastic

elastomers )

This is plastics with rubber-like qualities.This is extremely flexible,rubber

like material.So it can be used in elastic parts and wearables.

strength - Low.

Flexibility- High

Durability – Medium

Difficulty to print- High

Print temperature (in degree Celcius) - 225 – 235

Bed

temperature(in degree Celcius) - 40