Week 7

Computer-Controlled Machining

In this week i planned to make a workshop chair out of MDF sheet.I designed the chair using Onshape and converted into Machine understanding format by using Art CAM.

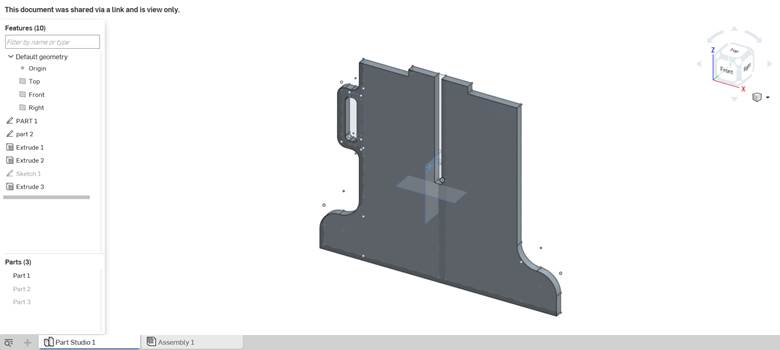

Creating the design

For designing i used Onshape website.

Onshape is a web based designing application which can be used even in our mobile phone. I liked the simplicity and user friendly and easiness of it.creating the parts,Assembling of parts are easy.

I Created a new design and named as Chair.

Designing of the supporting structures with the as shown below.

Created two parts with cut.(18mm-Thickness of MDF) so that they can lock it well.Cuts of two parts are done in a way that One with cut at top part and other in bottom part .Saved both as different parts.

Extruding the parts are done so that i can view how my actual part looks like.

Then i mated the two parts and checked how they will cross fits.

Then i designed the top part of the chair and made the cut so that the structure get inserted well. The width of cut is taken as 18 mm(thickness of the MDF chosen).

Top part is mated with these base and checked the assembly and verified that it fit well.

After assembling . I converted the parts in to DXF format by converting this to 2D for CNC machine.

Exporting to DXF format is done in Onshape.So that i can import in Art CAM software.

My design file in On shape is here

Importing the design for CNC

Imported the dxf formatted parts into Art CAM and placed them as shown below so that wastage of material can be avoided.

For cutting , i choosed the 3 mm endmill in toolpath profiling.

The problem in this model will be the correct fitting of the interlock mechanism.

To avoid that i checked with a sample cut with different allowance while profiling in toolpath.

Finally i found -0.15 is the best fit .

My design process in Onshape and importing of file into Art CAM is included in the following video. youtube link

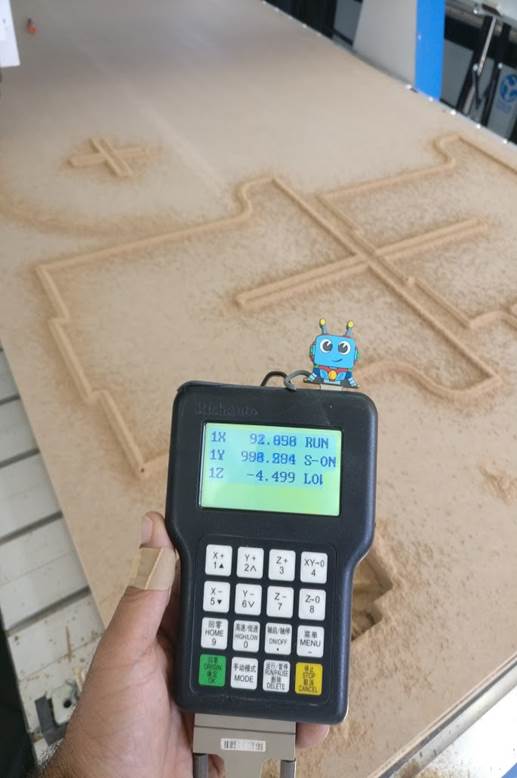

I converted my design in to CNC machine compatible format of .plt format and loaded into machine and started cutting.

|

|

|

Assembling the parts and

final result.

I assembled the parts and filed the parts little and the assembly fitted well.

Files:

Onshape design file: here

Dxf files after downloading as parts from onshape.

Top: Top part

Side1: side part1

Side2: side part2

CNC machine understanding file (.plt file after artcam processing): plt file