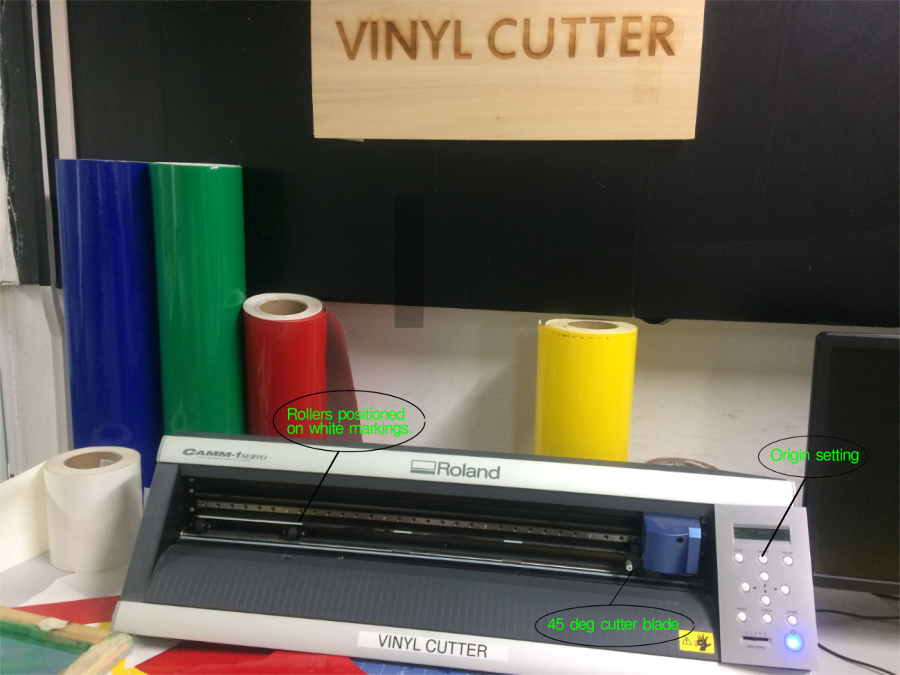

A vinyl cutter is a type of computer-controlled machine. Small vinyl cutters look like computer printers. The computer controls the movement of a sharp blade. This blade is used to cut out shapes and letters from sheets of thin self-adhesive plastic (vinyl). The vinyl cutter uses a small knife to precisely cut the outline of a picture into a sheet or piece of vinyl. The knife moves side to side and turns, while the vinyl is moved beneath the knife. What results from the cut process is an image cut into the material. The material is then 'weeded' where the excess parts of the picture are removed. It is possible to remove the positive parts, which would give a negative sticker, or you could weed the negative parts, giving a positive sticker. Removing the letters would be like removing the positive, giving a negative image of the word, etc.

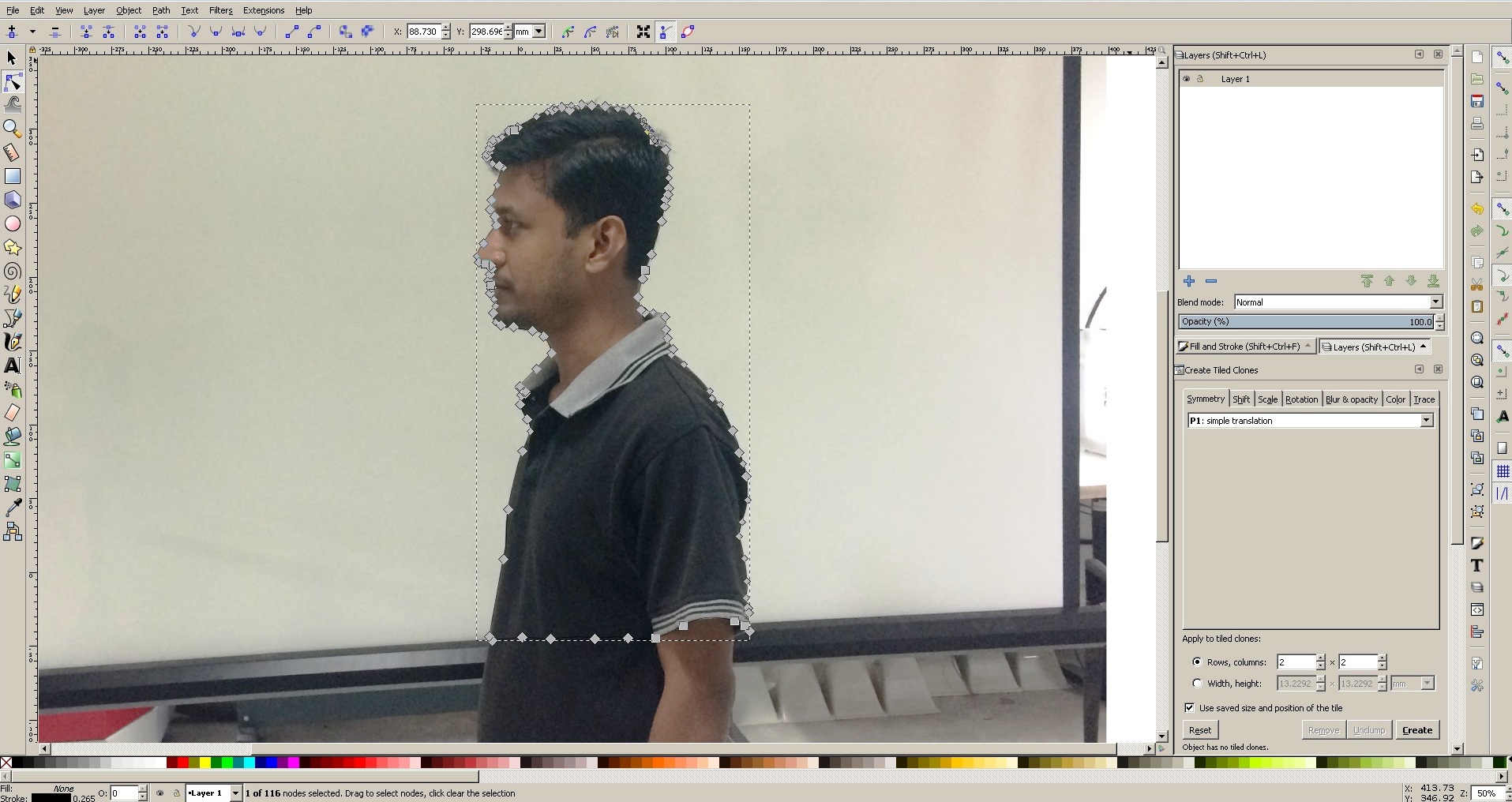

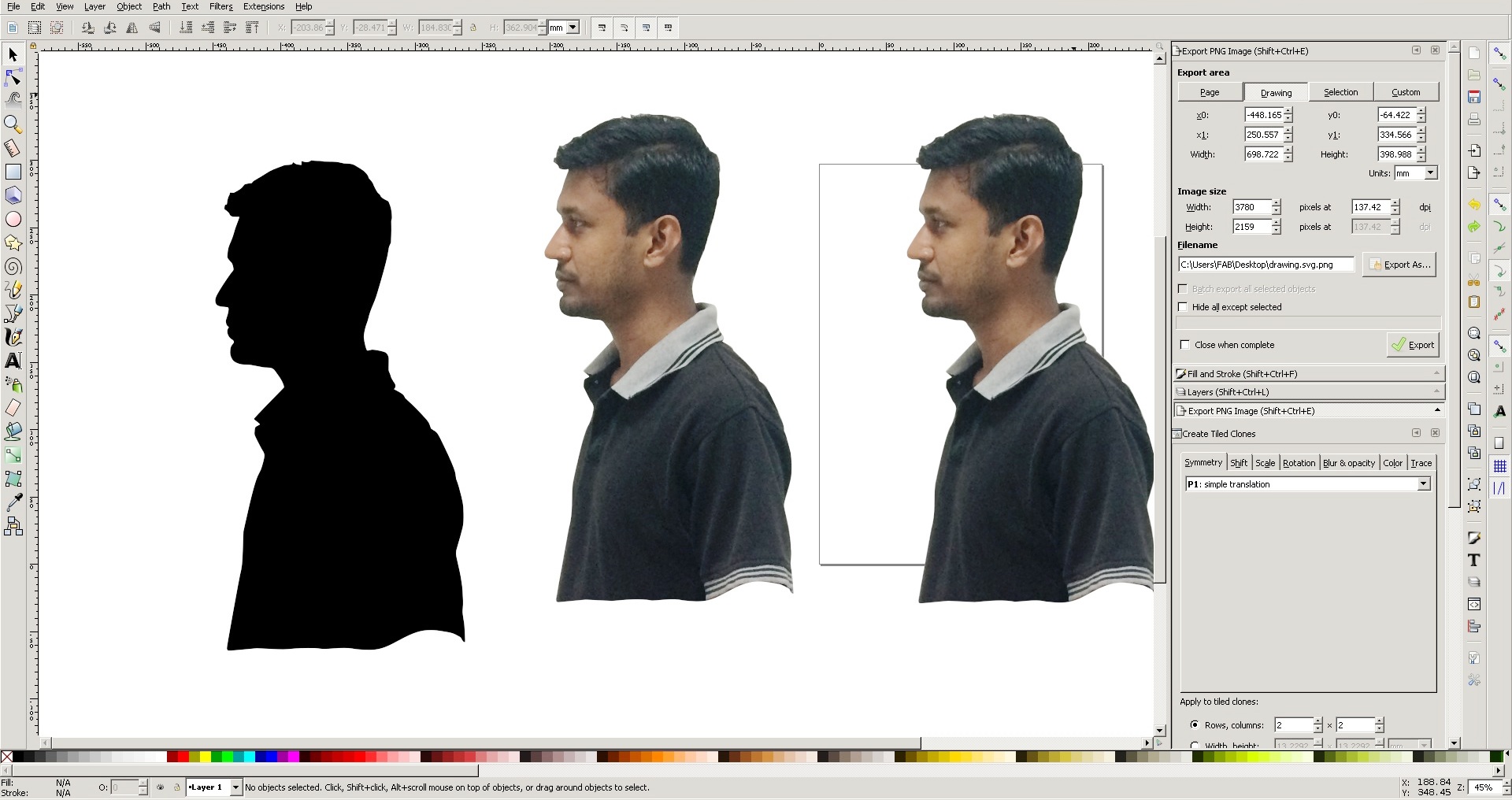

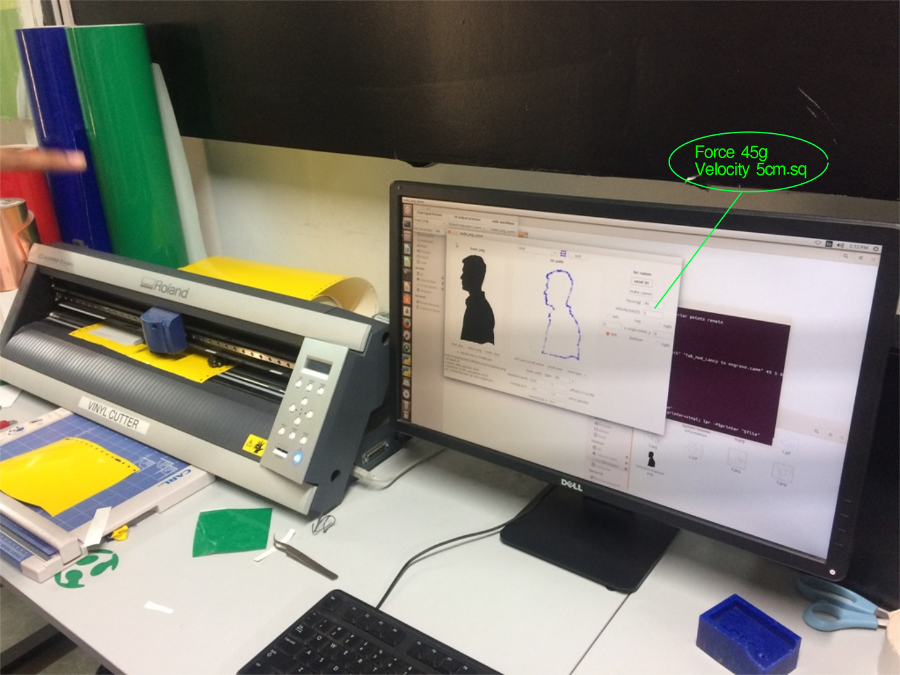

For creating a vector image, I have imported my side view image. The imported file was edited using Inkscape tools like bezier curves, node editing tool. Once the image outline is created, select the images and click, OBJECT>CLICK>SET. This option will crop the required image. Then, select trace bitmap tool and change the fill color. After filling with color, this image can be imported into png file for further operation.

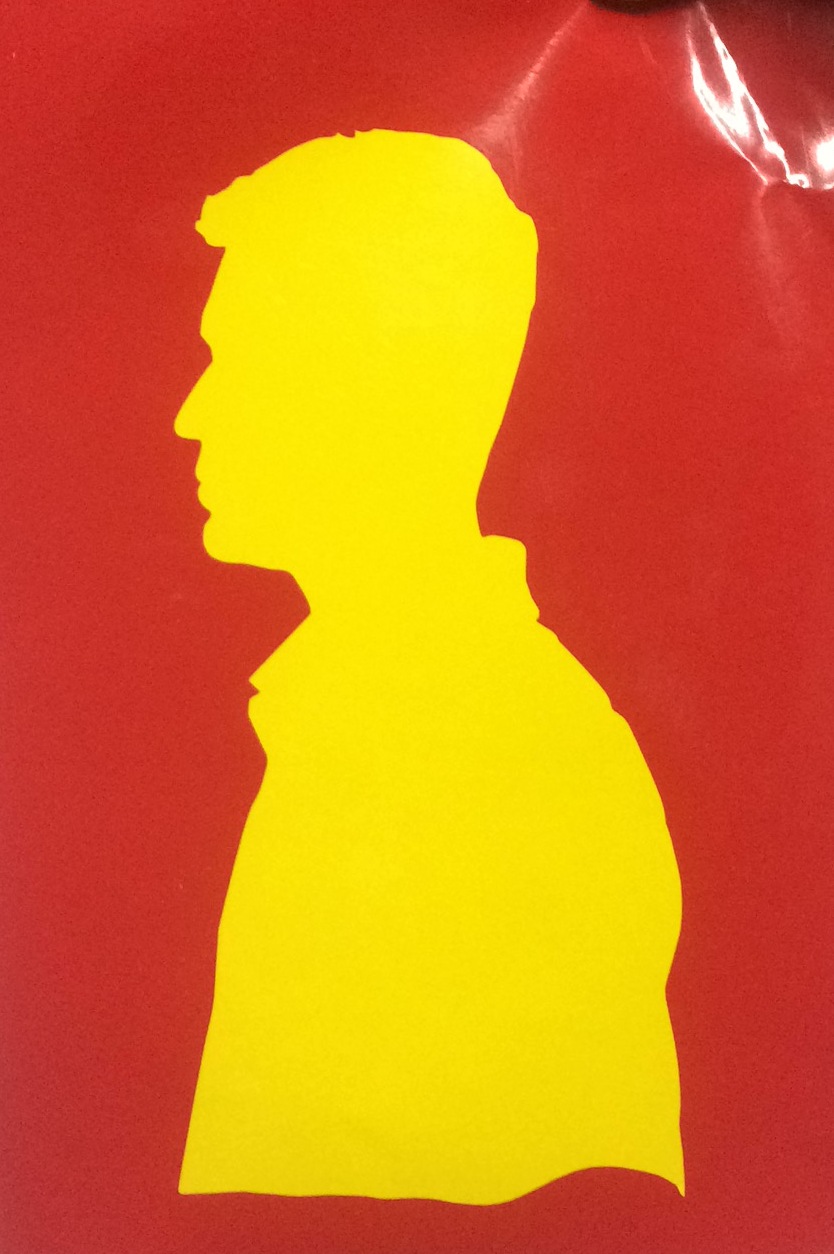

After cutting, remove the vinyl sheet out from the machine using arrow keys. Use forceps to remove unwanted edges from the vinyl sheet. Stick masking tape on the vinly sheet and slowely remove the figure. This figure can be applied to the required surface. Here in my case, i have superimpossed the image over another red vinyl sheet.

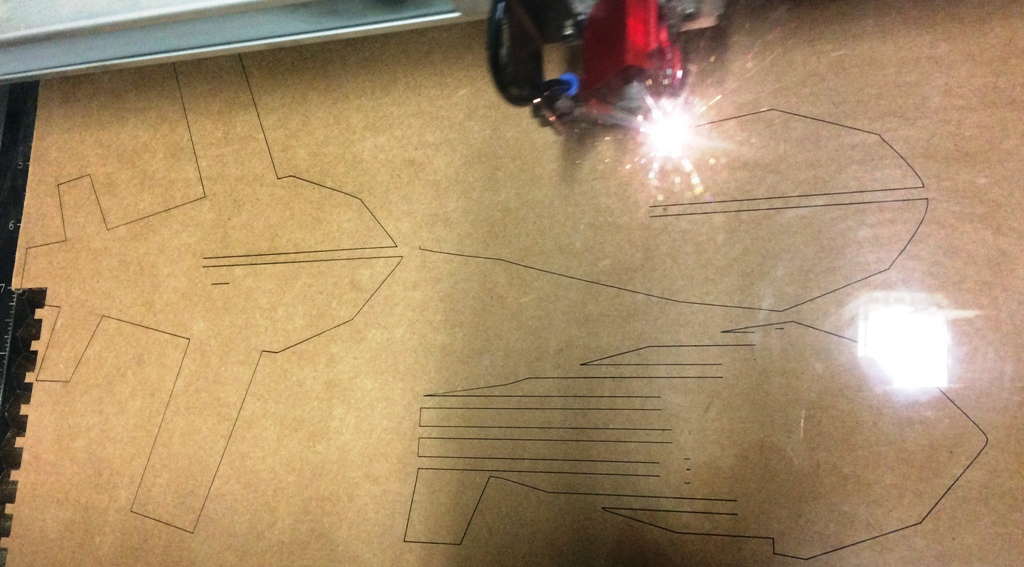

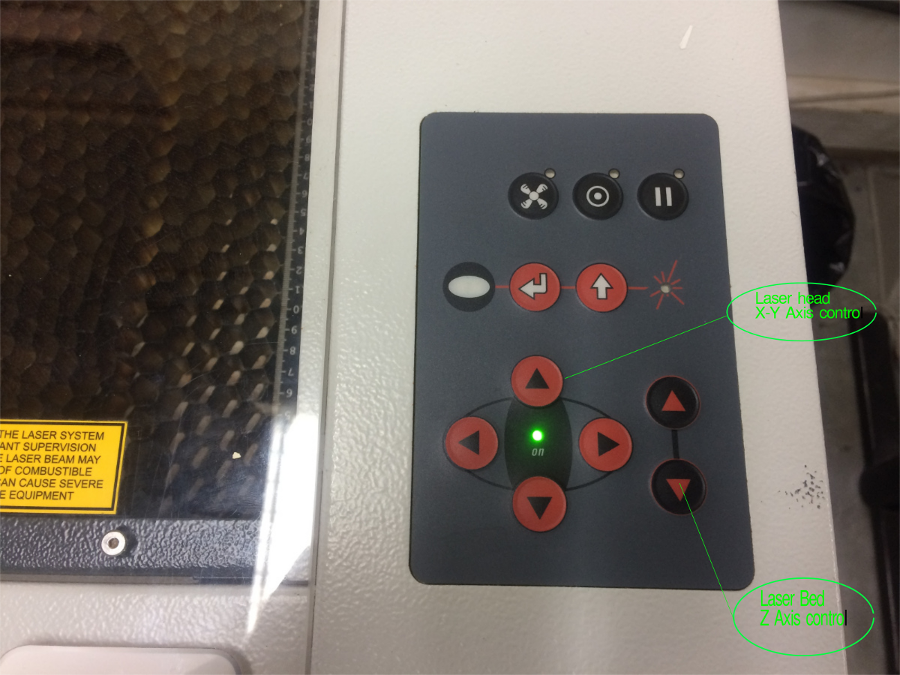

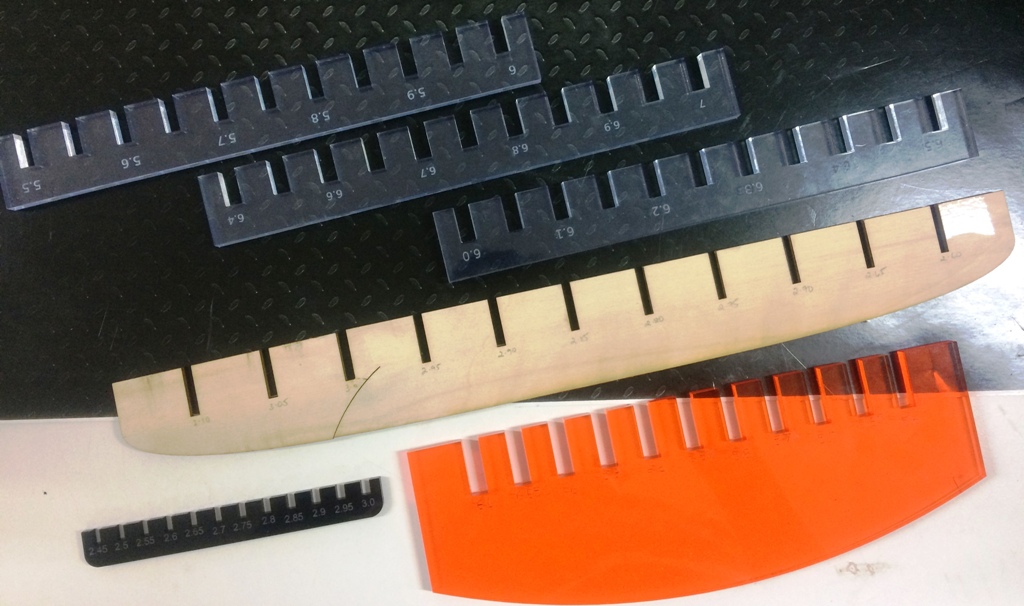

Trotech Trotec Speedy 100), which is a entry level CO2 laser cutter. It got 60W power max for its cutting/engraving operation. The general idea of this CO2 laser system is that a beam is directed down to a part for cutting. The part sits on a stationaly platform which laser beam move around the piece. Cutting is acheived by passing the beam through a focusing lens (Zinc Selenide lens). A focused beam exits through the bottom of a cutting head nozzle. Gas/air is fed into the side of the chamber below the focusing lens by means of a fan. This gas exits the nozzle along with the beam and the laser beam combination serves to vaporize the material for cutting. The head of the laser needs to be focused depending upon thickness of the material used. Focus tool is used for the same. This tool is held the close to the laser head slit, and the bed is moved closer to the head using arrow keys (Z axis) on laser cutter till the tool touches the material in the bed and tip over. The current position is said to be the optimal focus position for that material in the bed and the user can proceed with cutting. The machine cuts and engraves based on its speed to power ratio. Generally cutting can be performed by setting high power and slow speed and engraving can be performed by setting low power and high speed.

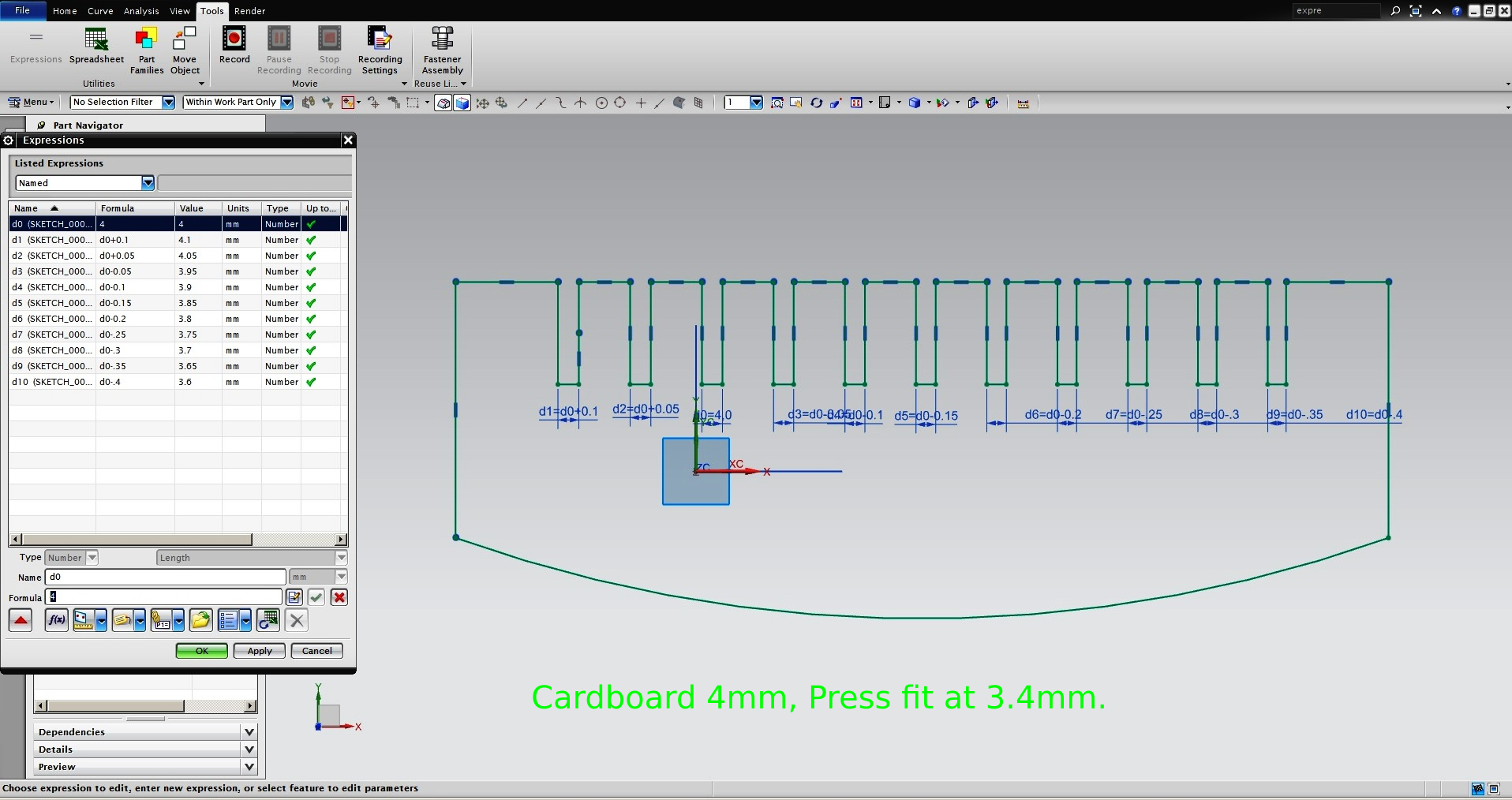

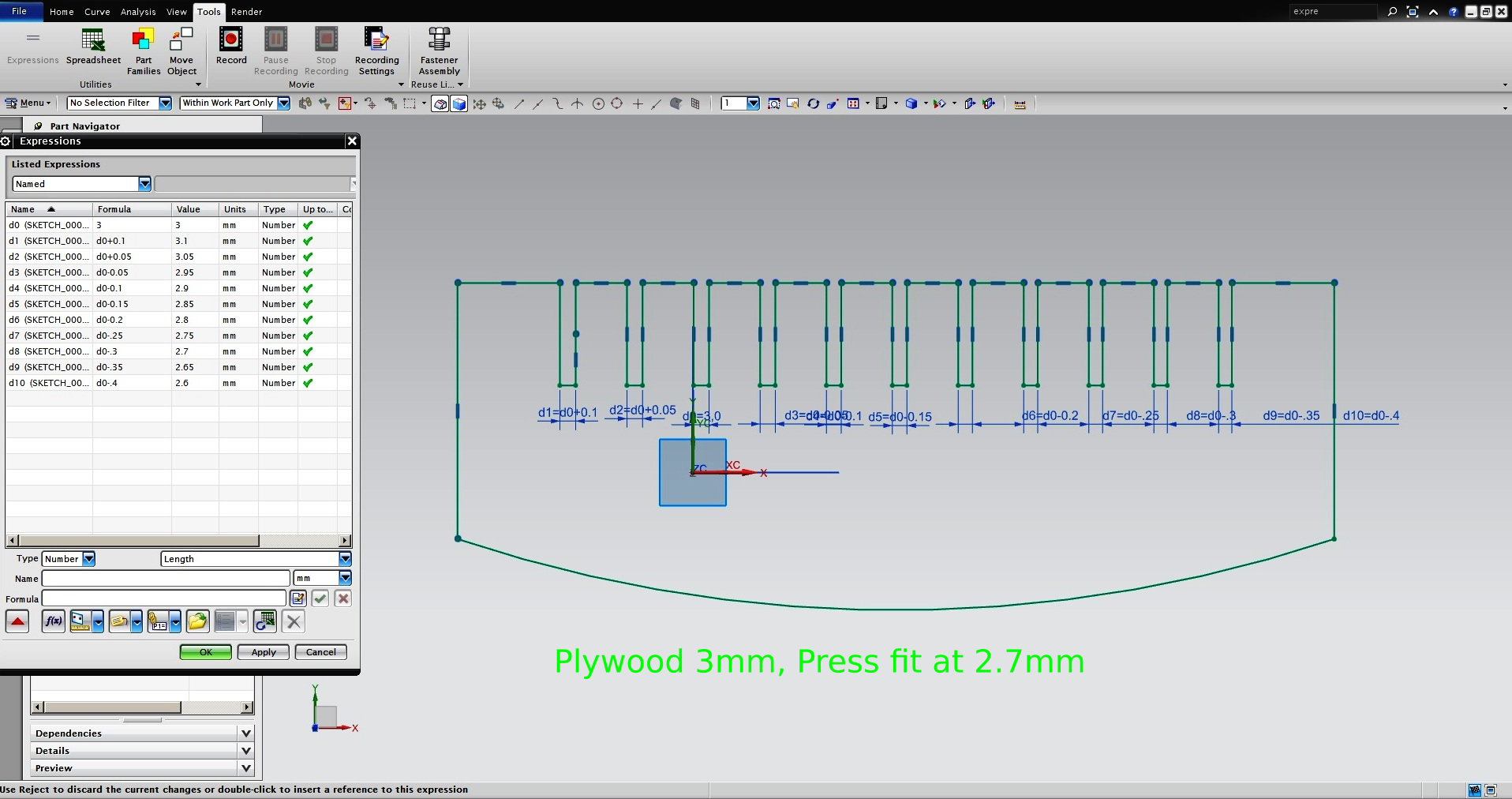

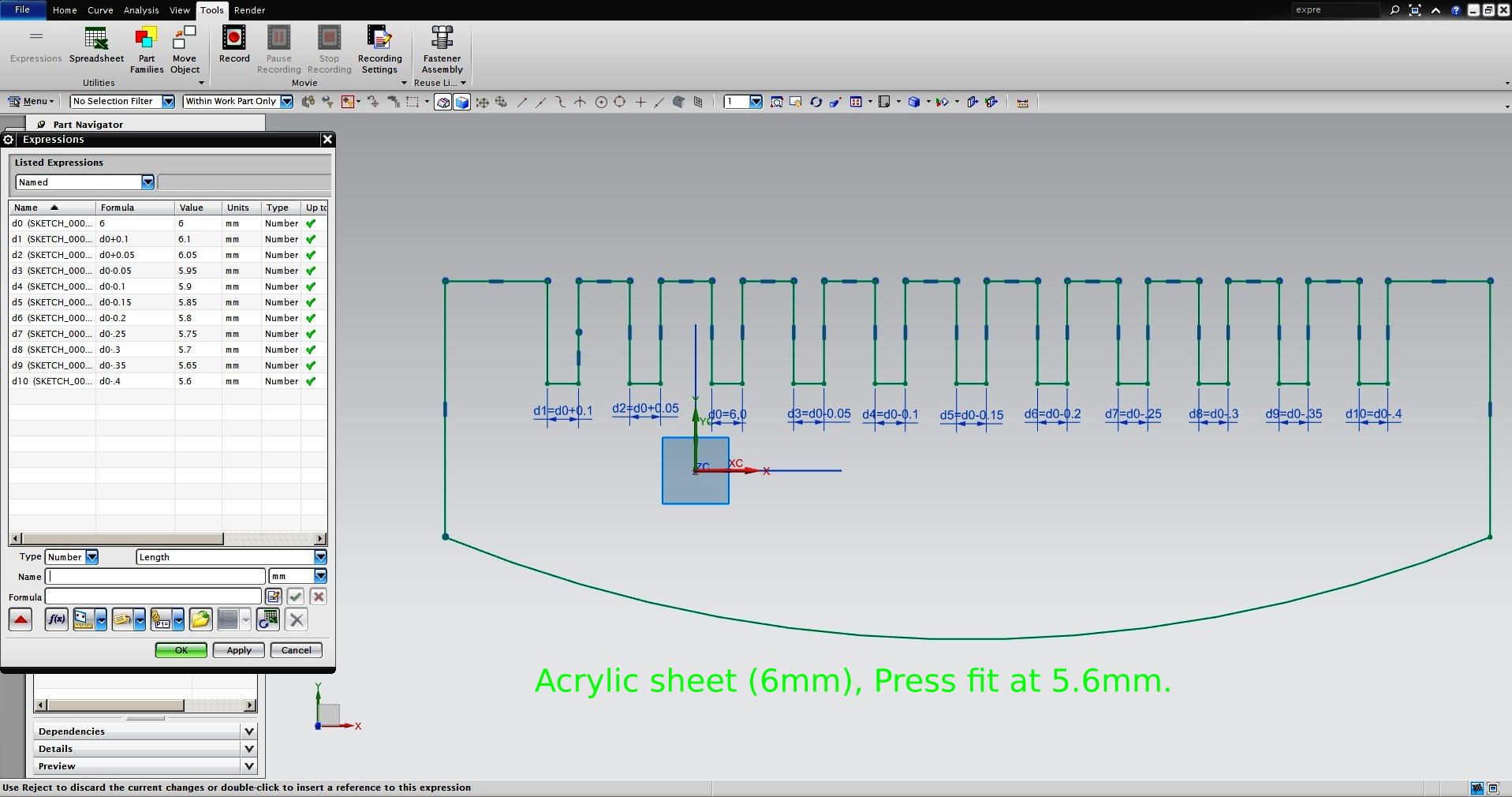

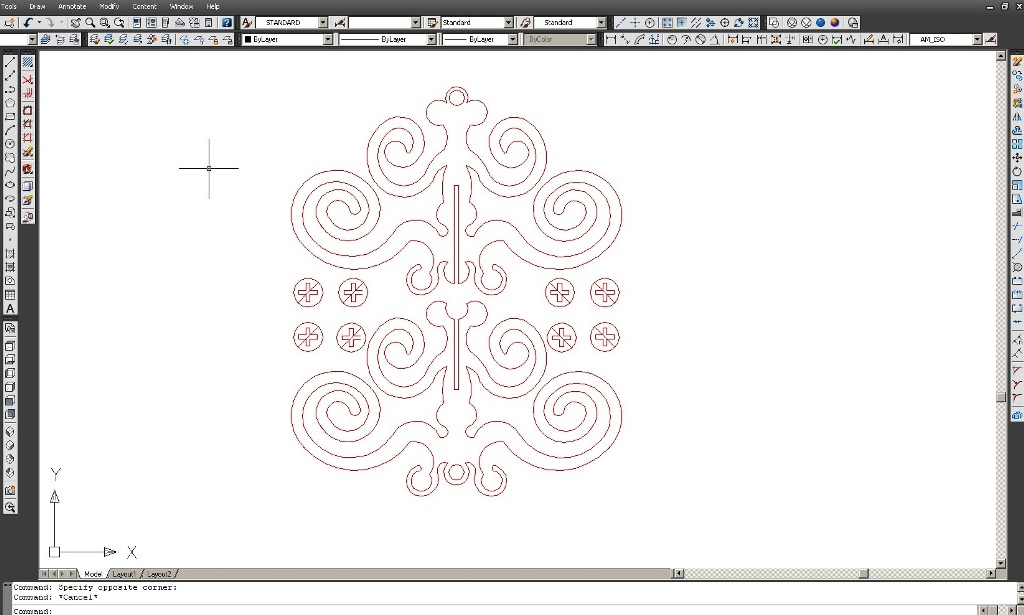

The precision levels and edge quality achieved with laser cutting machines are better than traditional cutting methods, as the laser beam will not wear during the laser cutting process. Laser cutting technology also enables us to cut complex shapes without the need for tooling and at a similar or faster speed than other cutting methods. The fact that laser cutting technology offers reduced contamination of the workpiece presents certain advantages over traditional mechanical cutting techniques. Laser cutting also allows us to cut small diameter holes with complex detail and good edge quality in either sheet, plate, tube or box section. I have designed Chandelier using Autocad and carved out from cardboard of 4mm thickness using lasercutter.

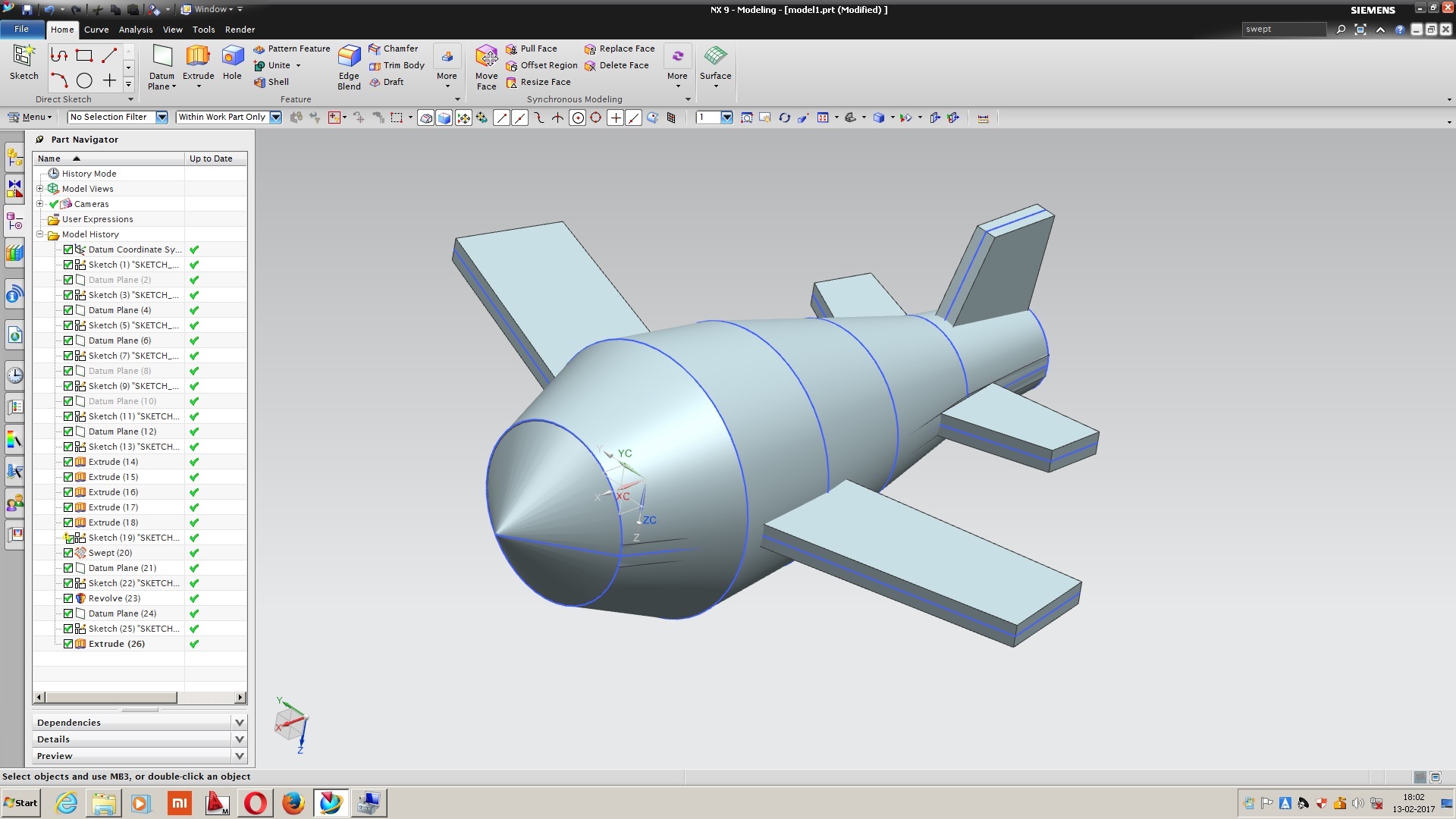

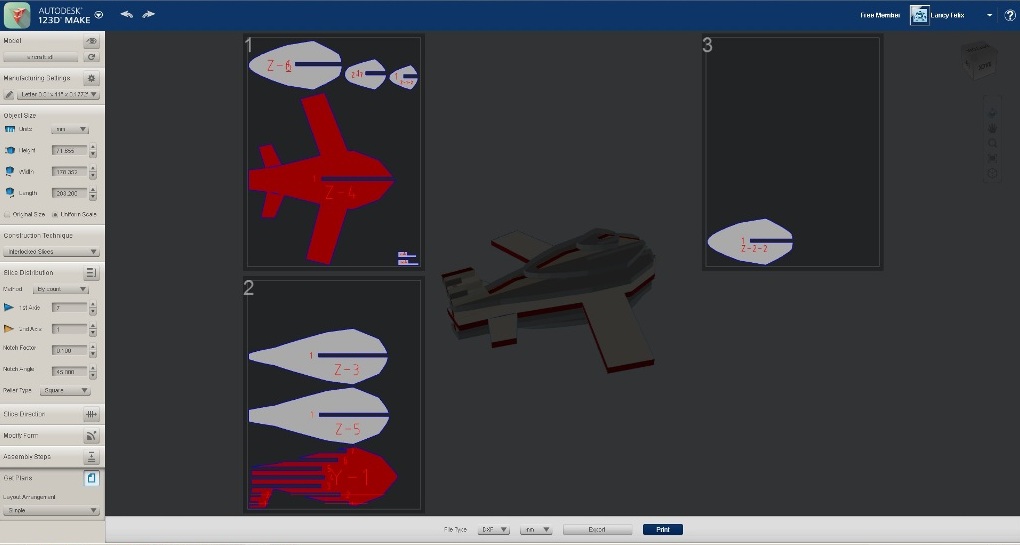

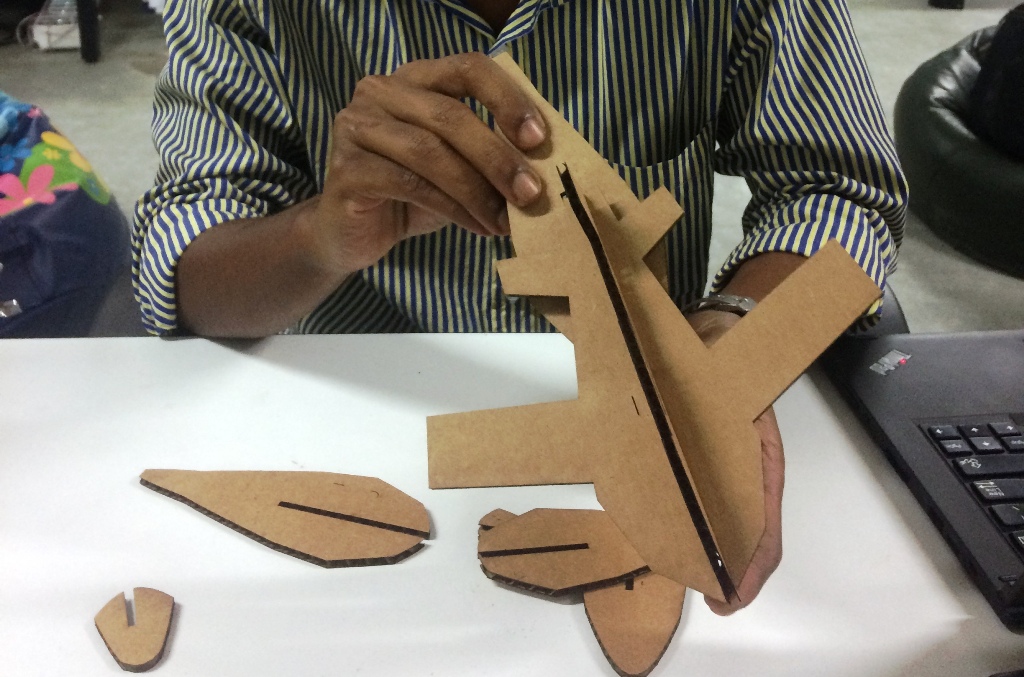

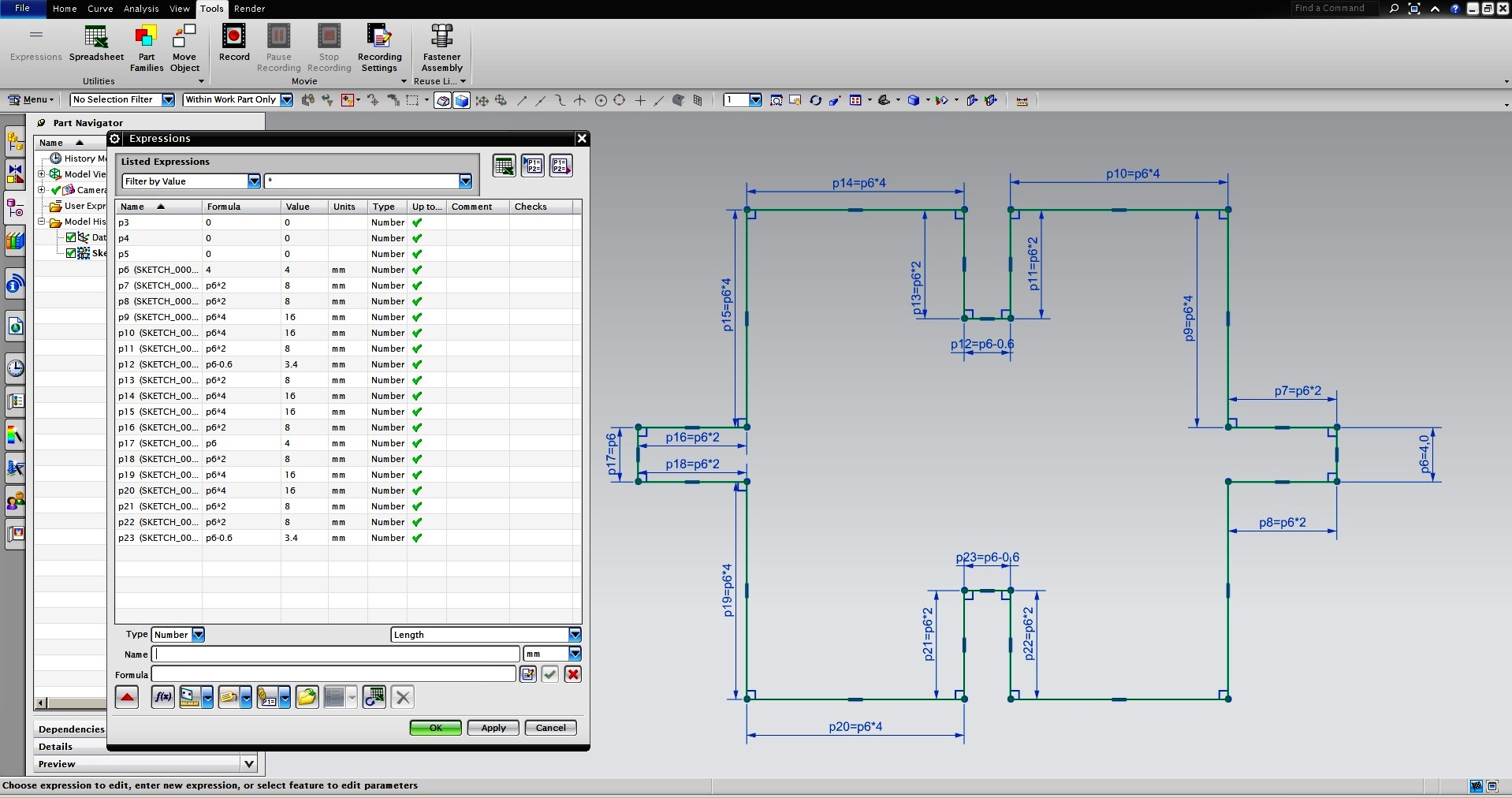

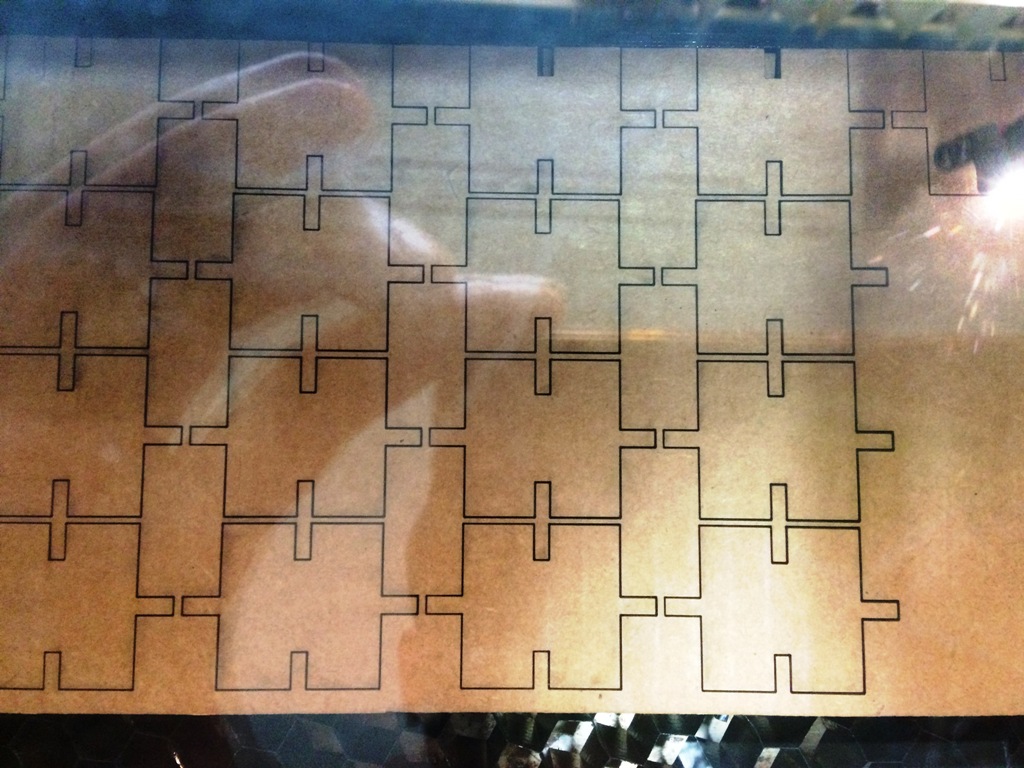

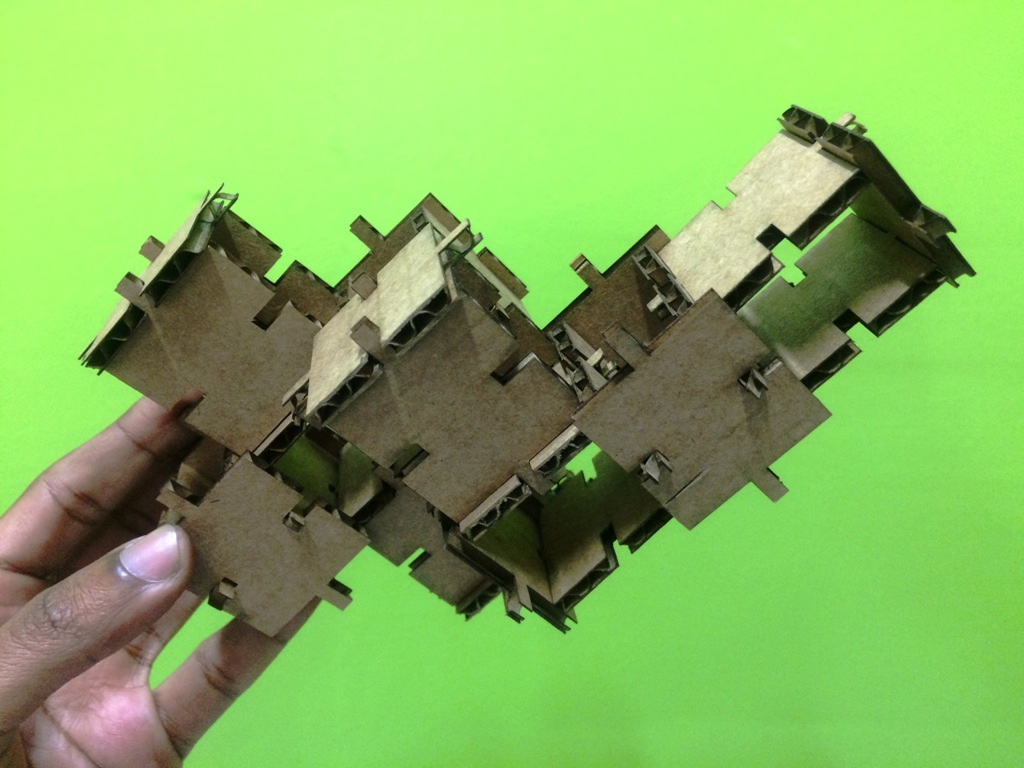

Apart from the above designs, I am interested in making a 3 model using laser cutting machine. Since 3D model cannot be replicated, but its skeleton structure can be created and jointed together to form 3D model.