Week 15: COMPOSITES

Assignment

. Read the material safety data sheet (MSDS) and technical data sheet (TDS) for the resins that you're using.

. Design and make a 3D mould and produce a fibre composite part in it.

Preperation

This week i am planning to make a small bowl.

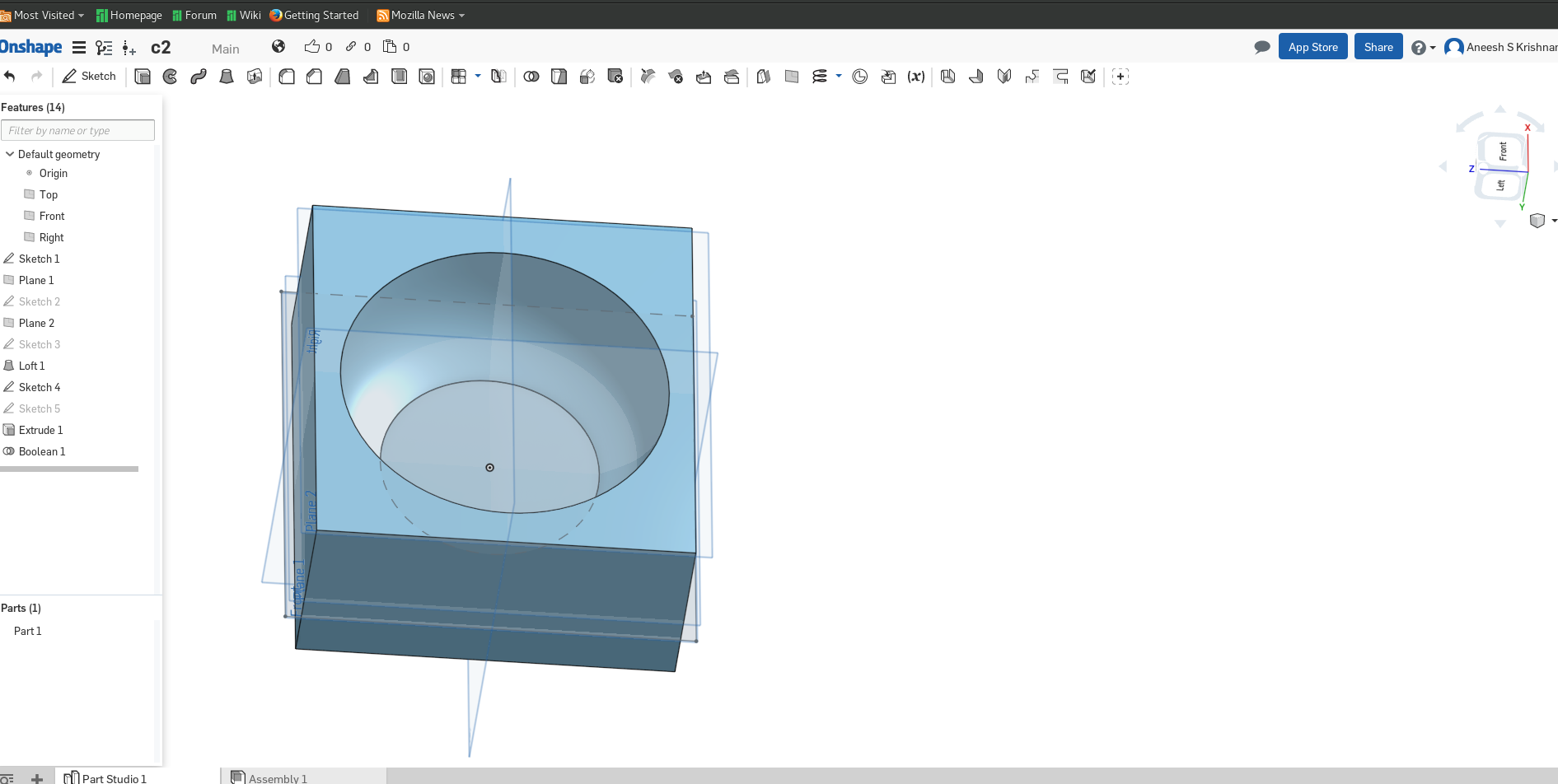

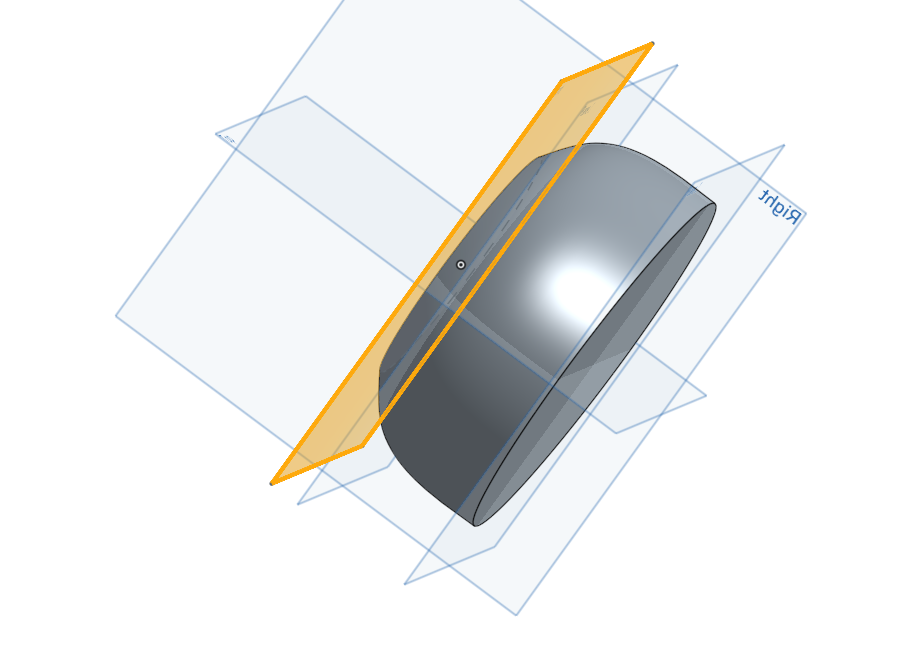

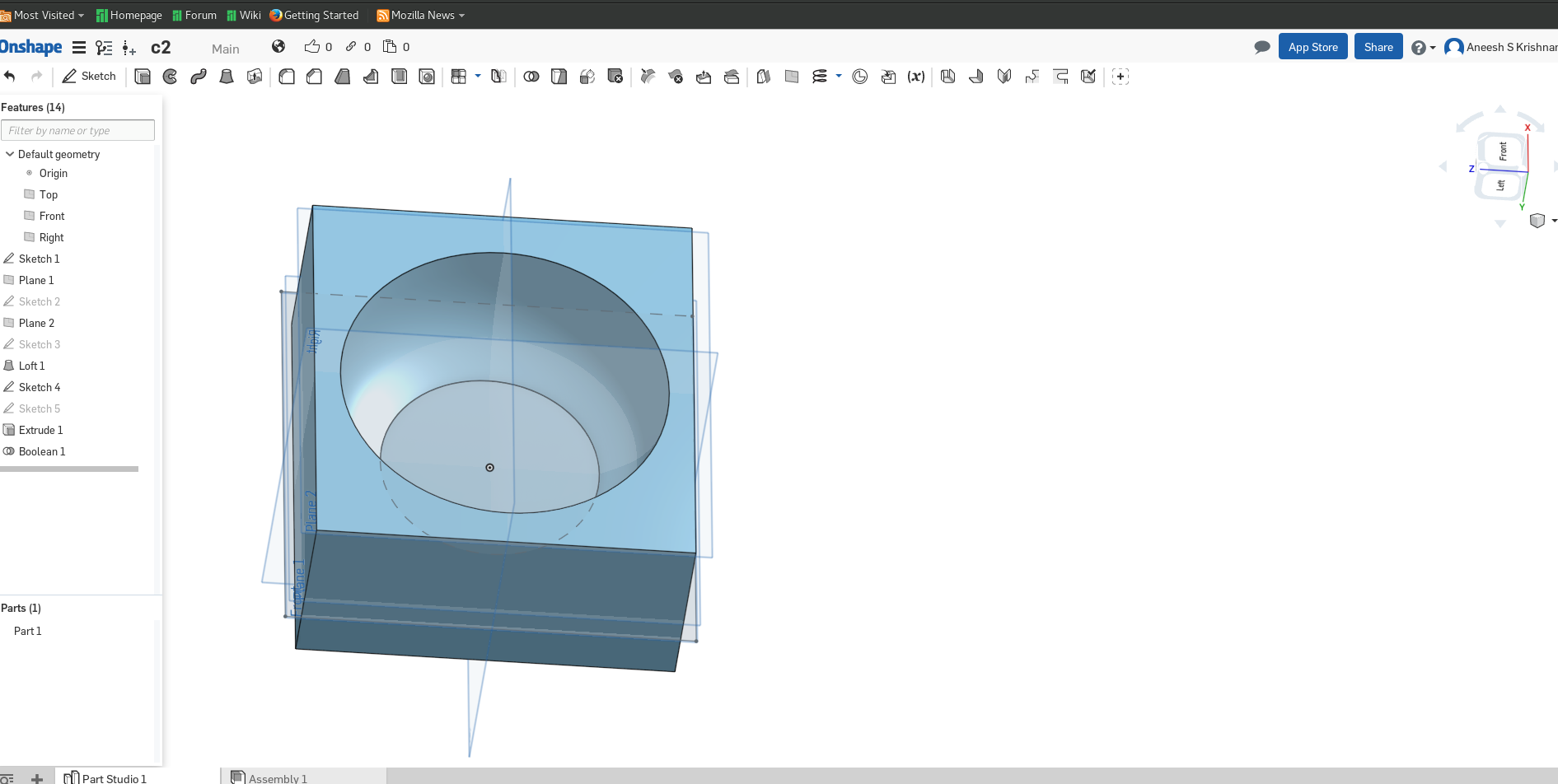

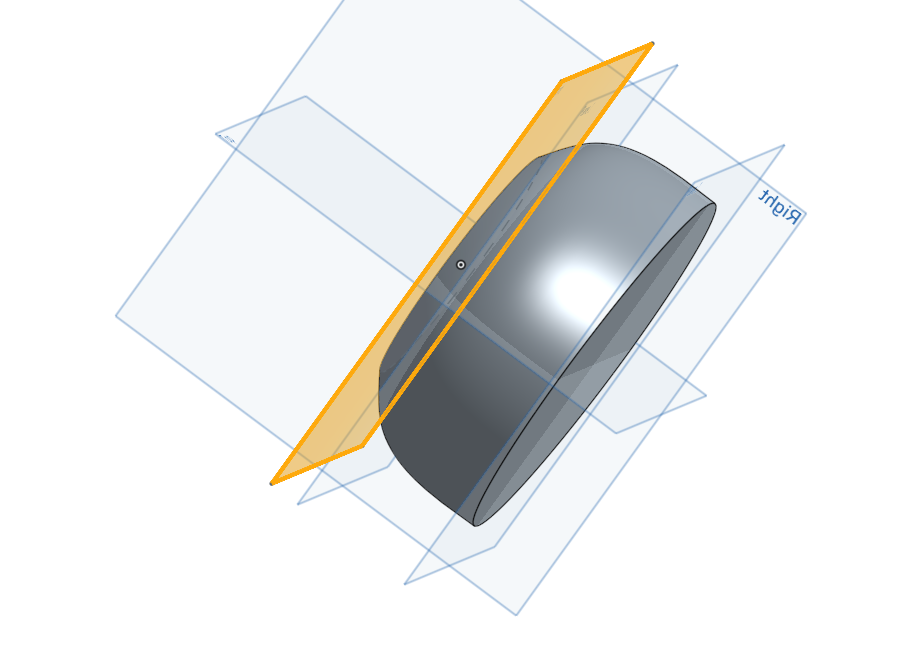

I used Onshape to design.

First I planned to make the positive section.

First I planned to make the positive section.

Then I thought of making the negative mold. I decided to make an outer rectangle as shown below.

This is the design.

Attaching the design here.

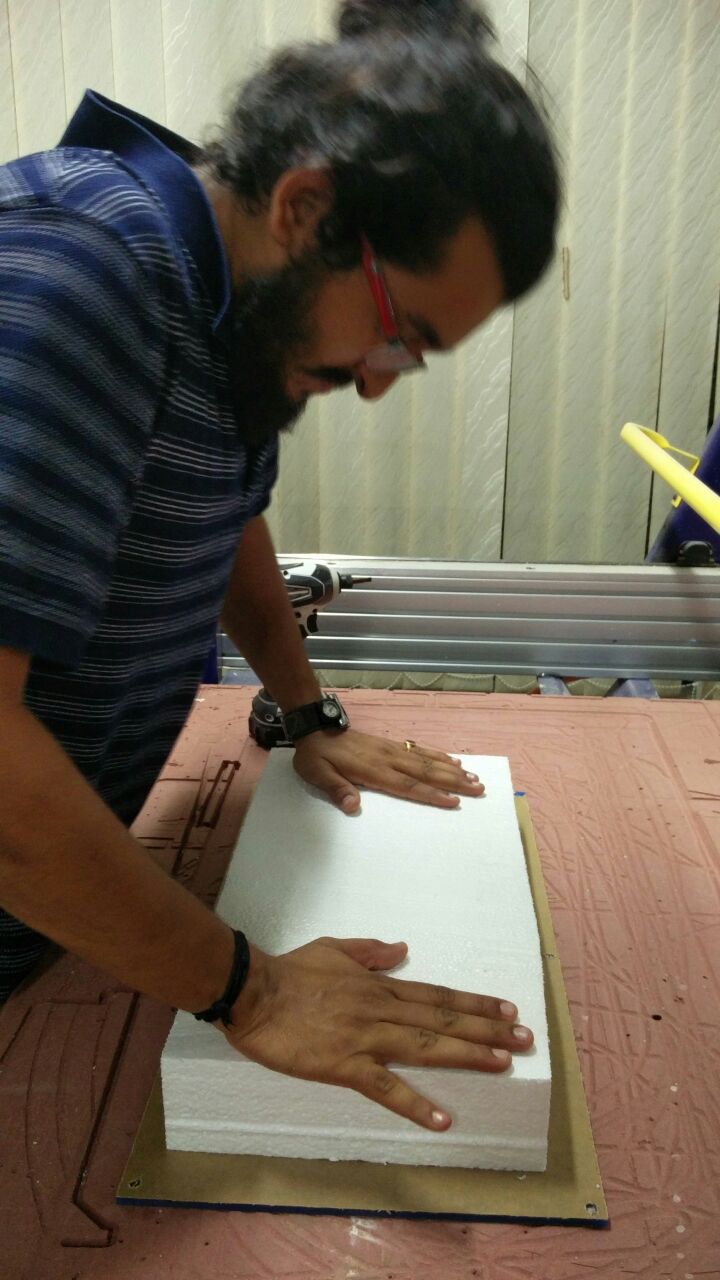

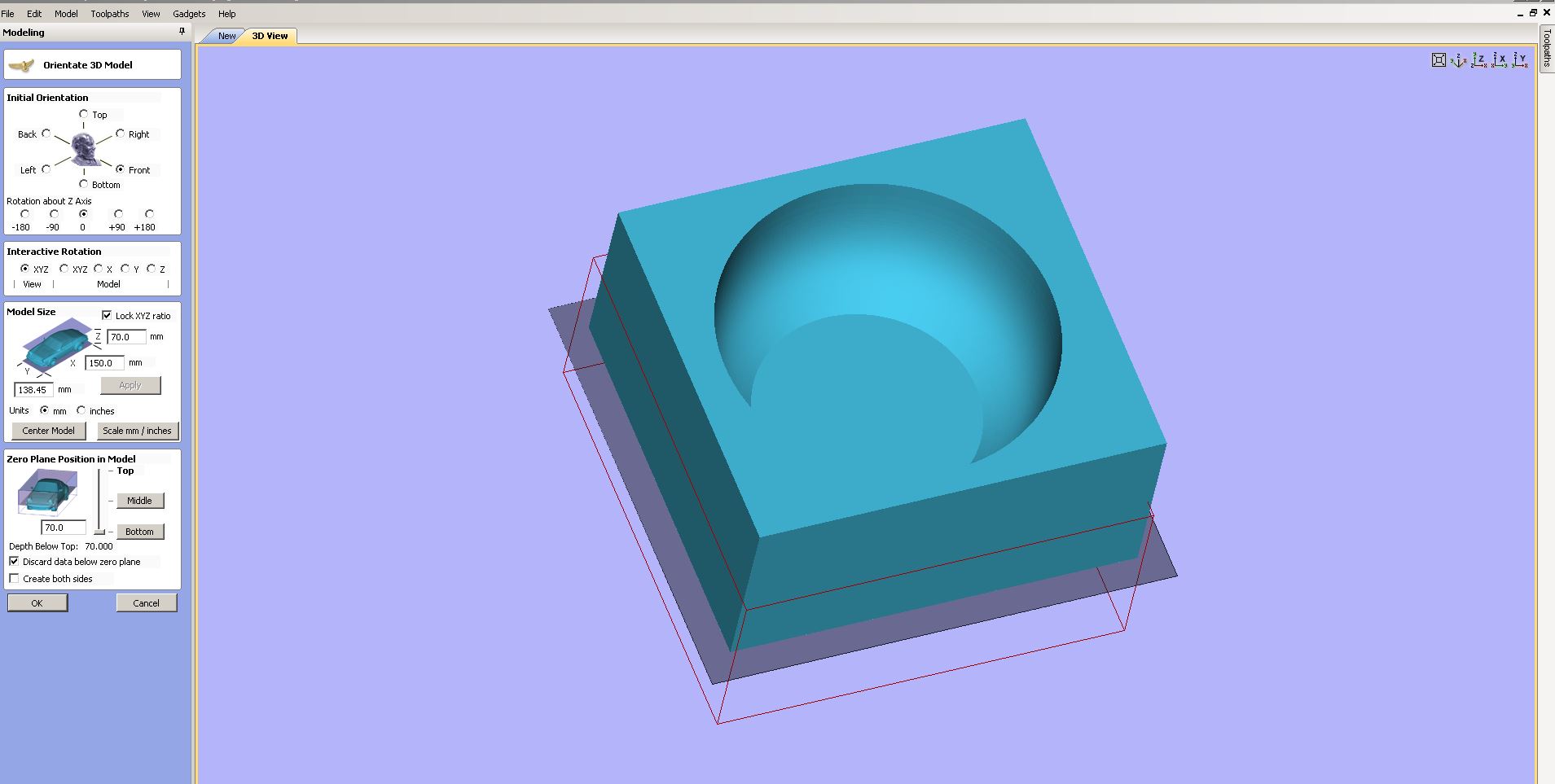

After designing, I decided to use Polystyrene(styrofoam) a.k.a thermocol.

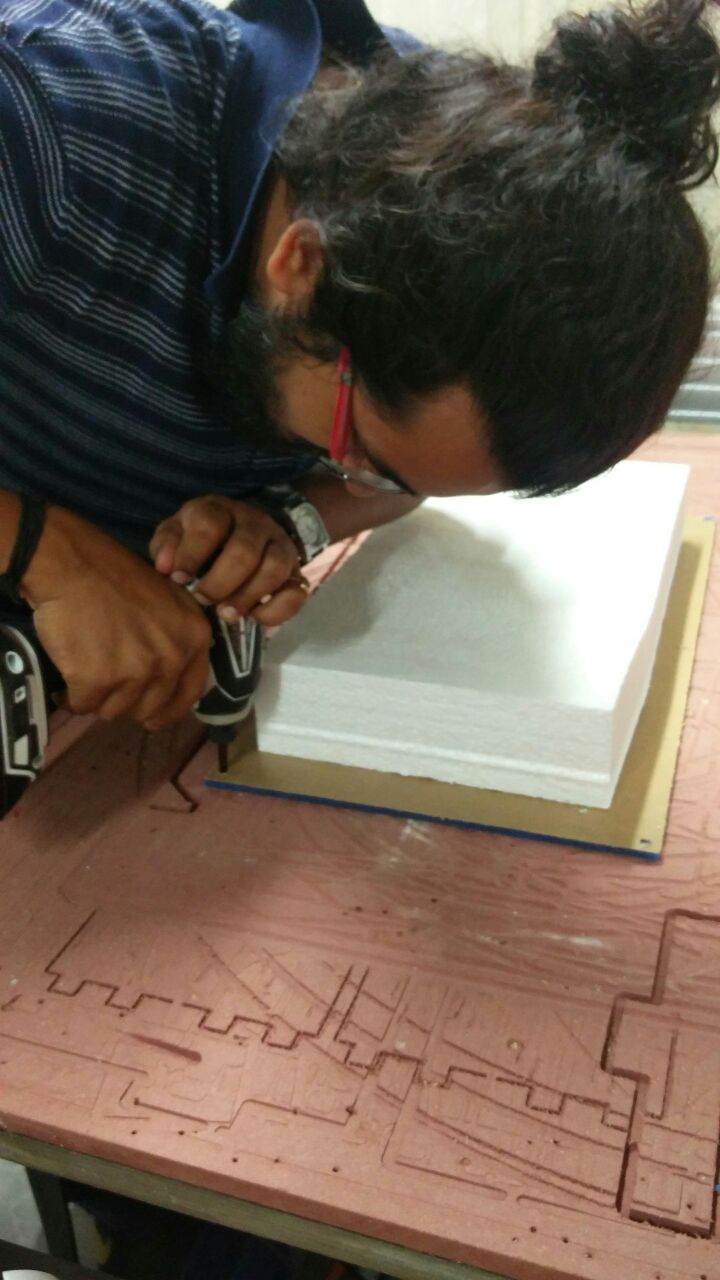

I used shopbot to cut the thermocol.

The overall block size is 0.6mx0.25mx0.18m

Milling

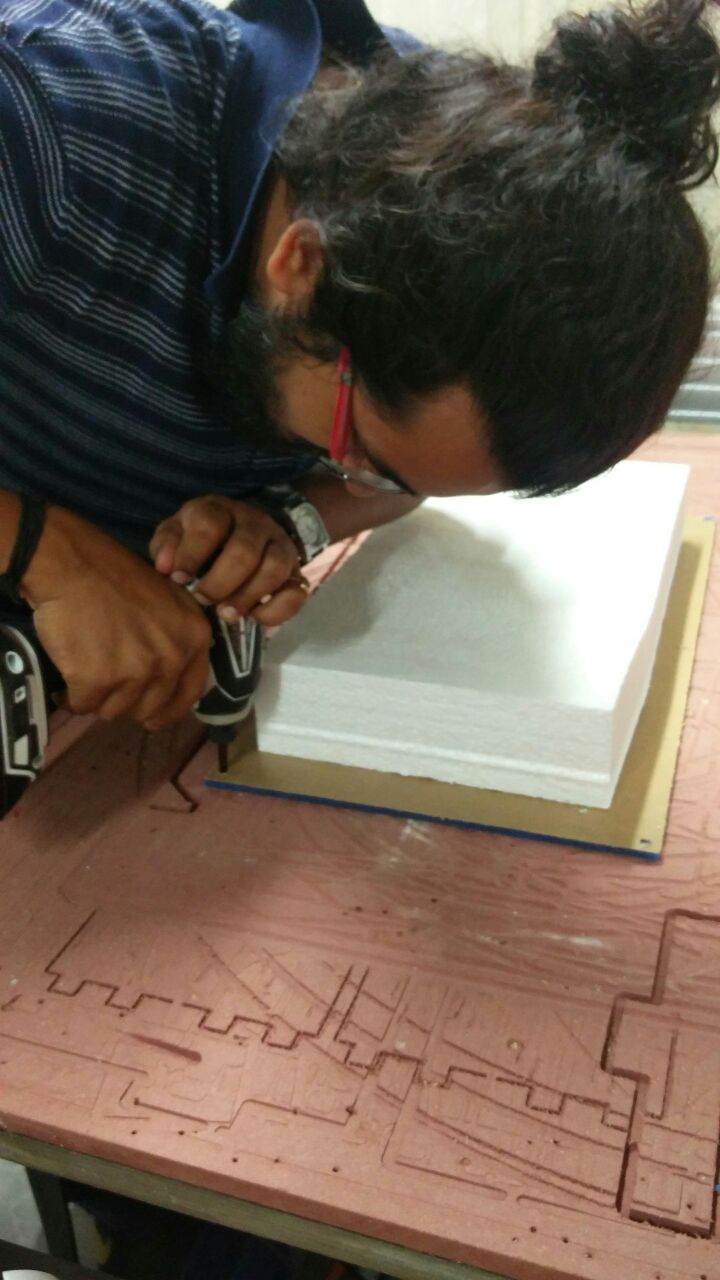

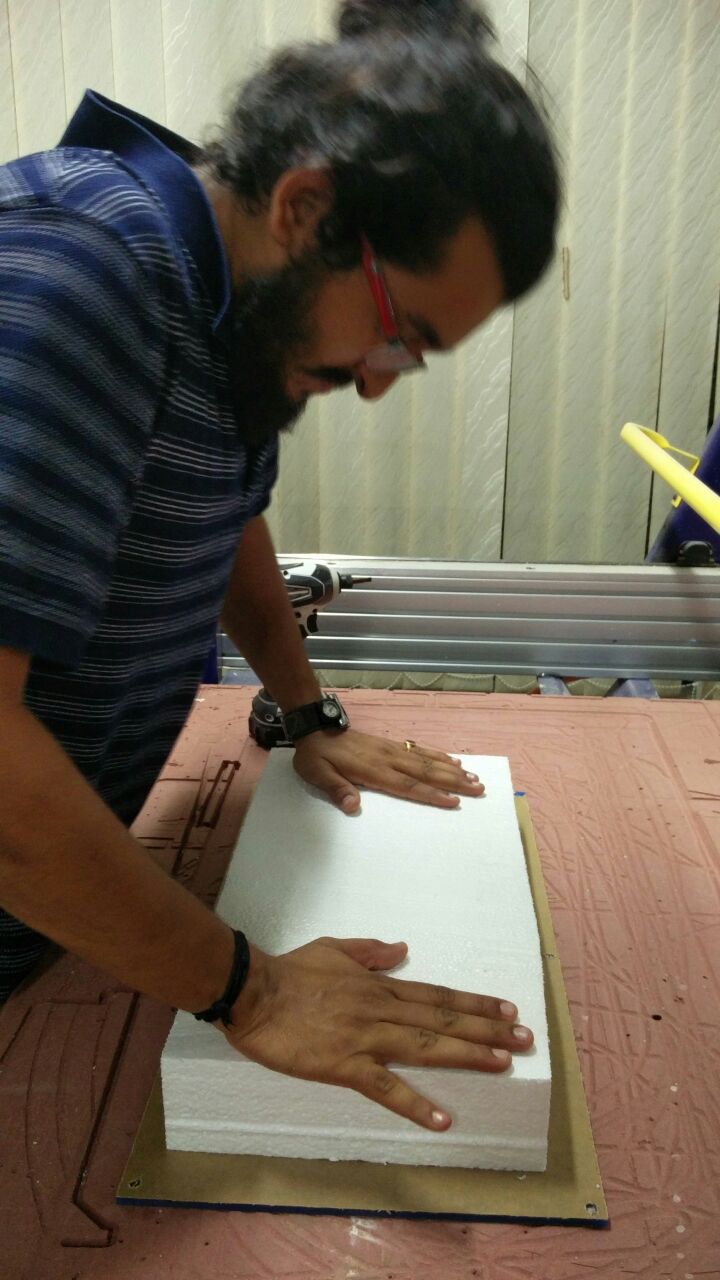

I took an acrylic sheet and stuck the thermocol on top of that using a double sided tape as the tape will not stick to wood/sacrificial layer properly

Then I drilled holes on the 4 edges and also the middle portion of the longer sides for fixing the acryilic board using screws.

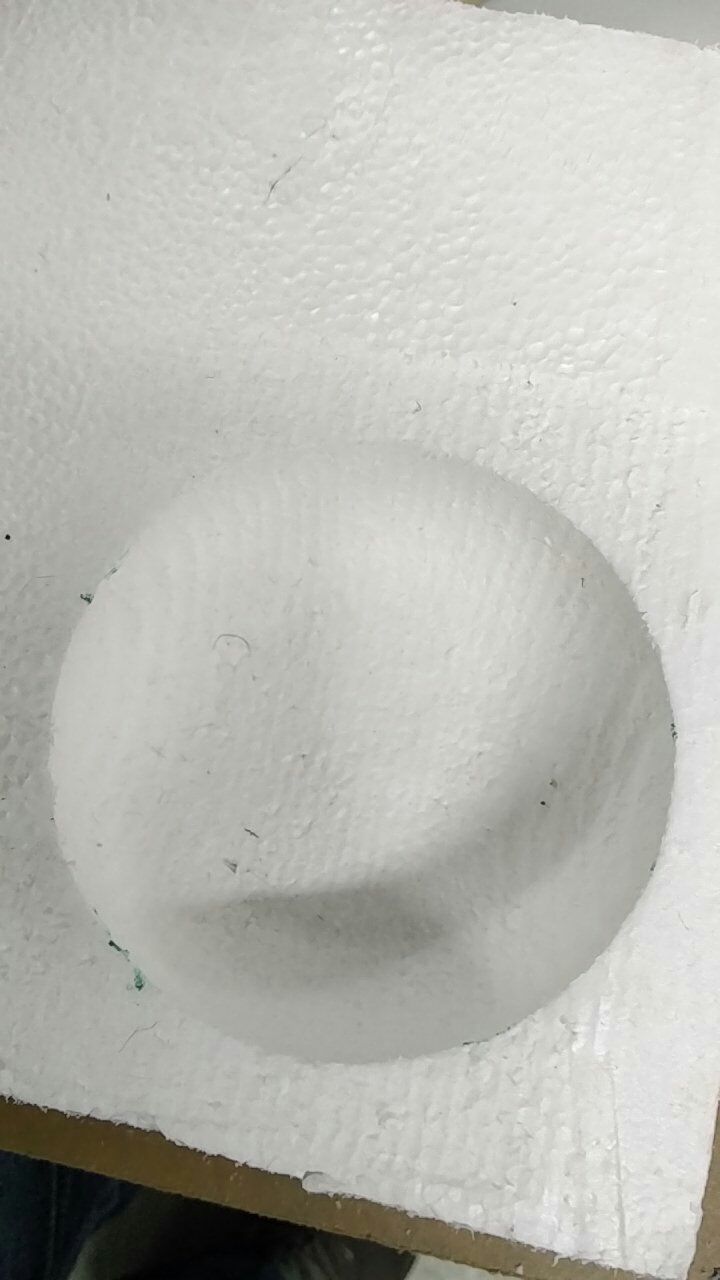

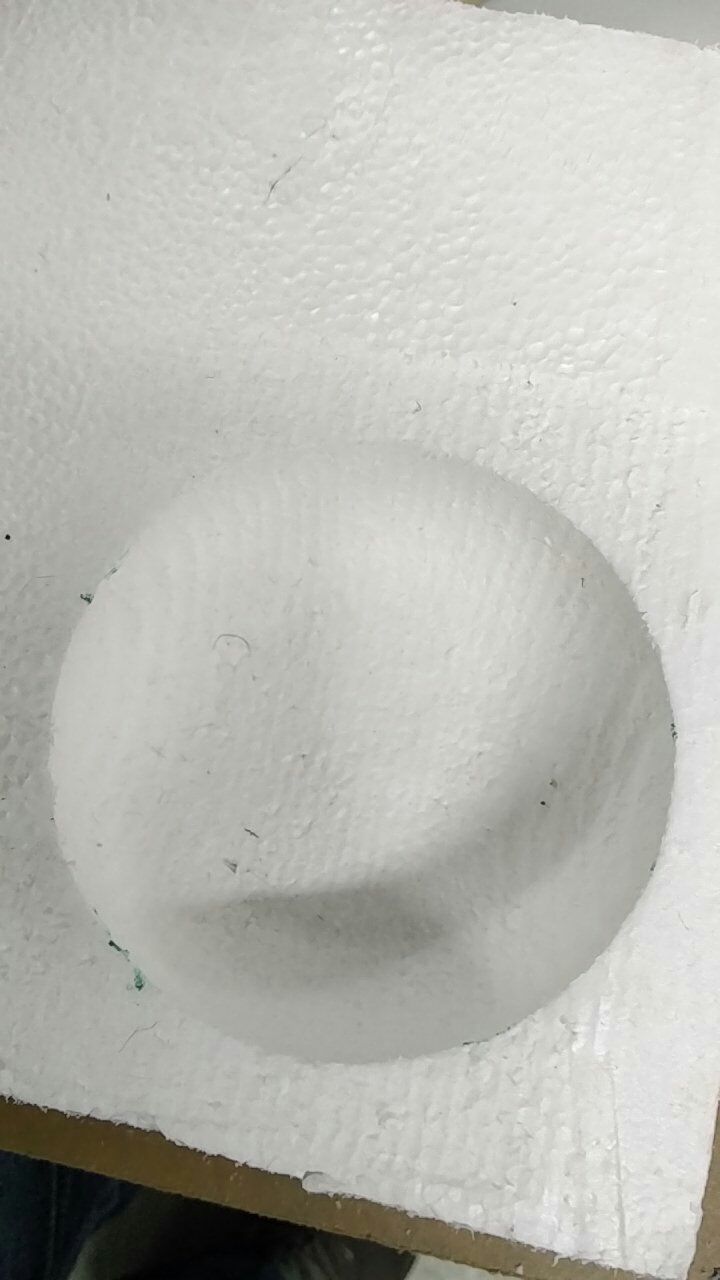

This is the final mold after rough and fine cuts.

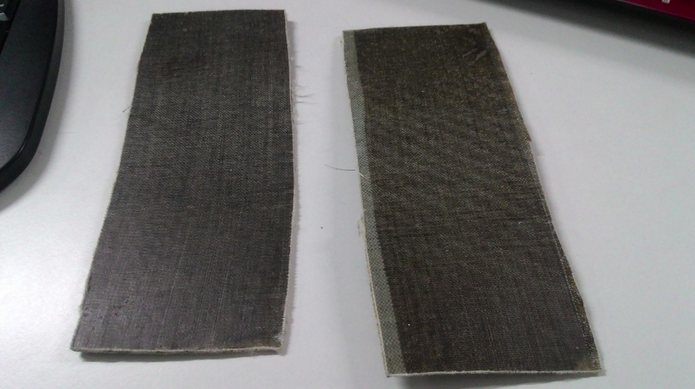

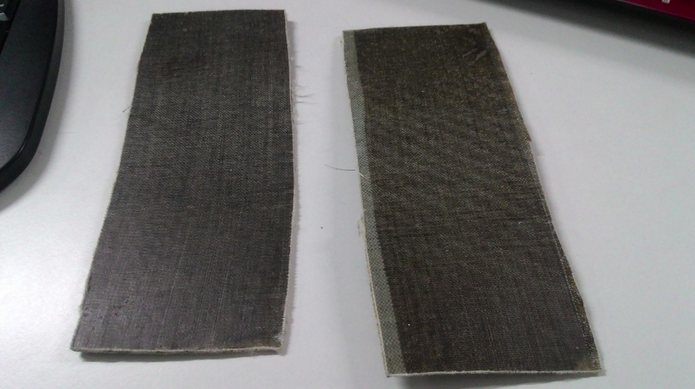

Next is preparing the filler materials for making the composite I took from our lab - some linen clothes , burlap / jute fabric / Swab Cotton-Low Lint cloth and cut into the required shape as shown below.

Testing of the Resin

We had two types of resins here in the lab.

We decided to test both of them by adding the mixtures in defined quantities.

(The first resin was mixed in the ratio 1:0.6 ; the second one - Aditya - was mixed in the ratio 2:1).

Once the epoxy was mixed in the ratio 2:1, it was applied over the burlap and cotton fabric layers.

3 layered composite(linen-burlap-linen) with enough resin in each layer was placed between two wax pieces and compressed using two clamps.

Composite

Placing the perforated film

Placing the breather material sheet.

We used Shopbot's Shop-vac vaccum cleaner as the vaccum pump is in our lab isn't working efficiently.

Using the transformers as a weight bag.

:D

Removing the thermocol from the sides of the bowl. I used sandpaper and sharp plastic object in the lab to remove thermocol.

As the bowl was bit flexible, we decided to keep it in the oven for sometime.

The design file can be found here.

First I planned to make the positive section.

First I planned to make the positive section.