Week 13: MOLDING & CASTING

Assignment

. Design appropriate objects within the limitations of 3 axis machining.

. Demonstrate workflows used in mould design, construction and casting.

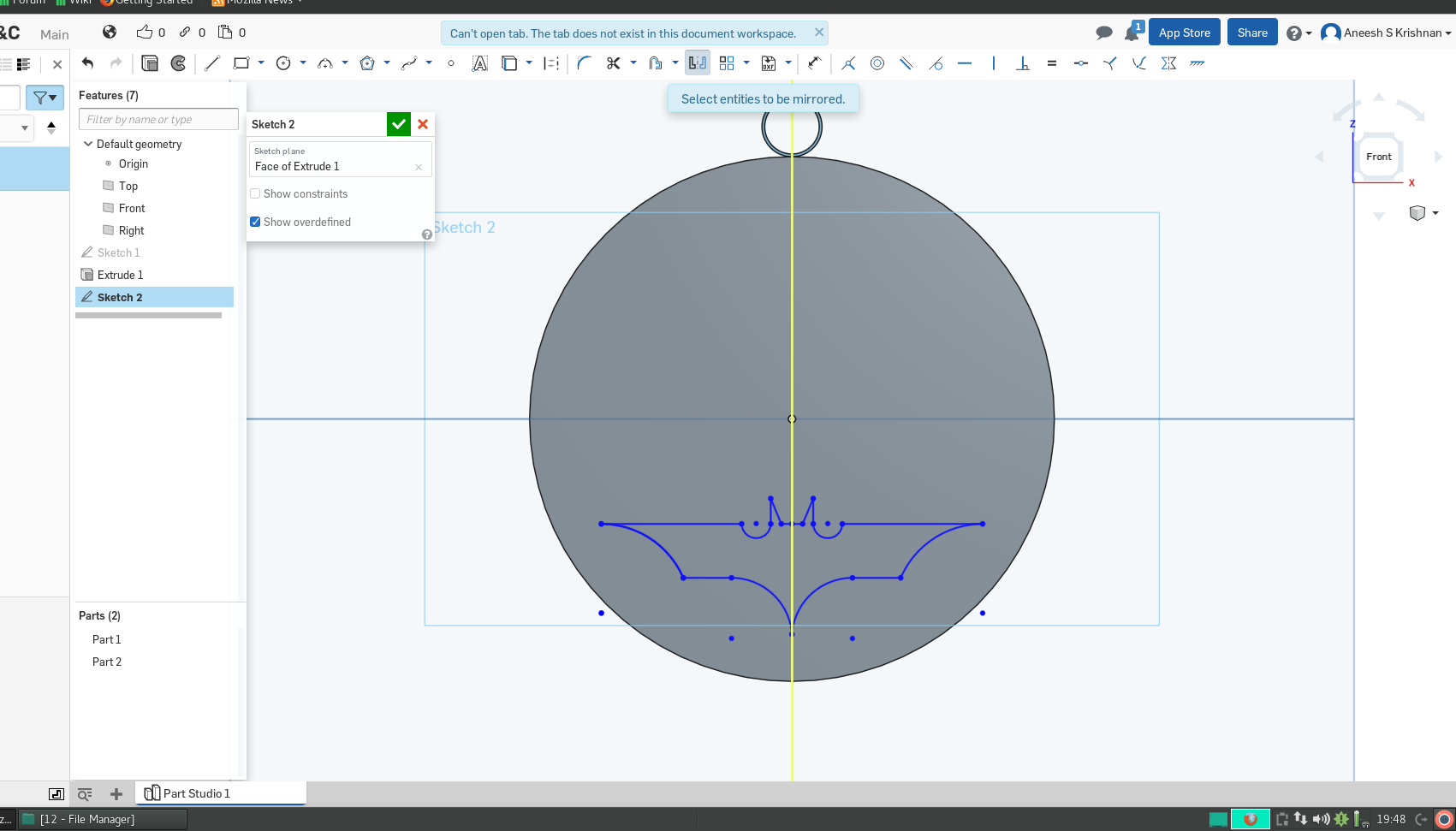

Mold Design

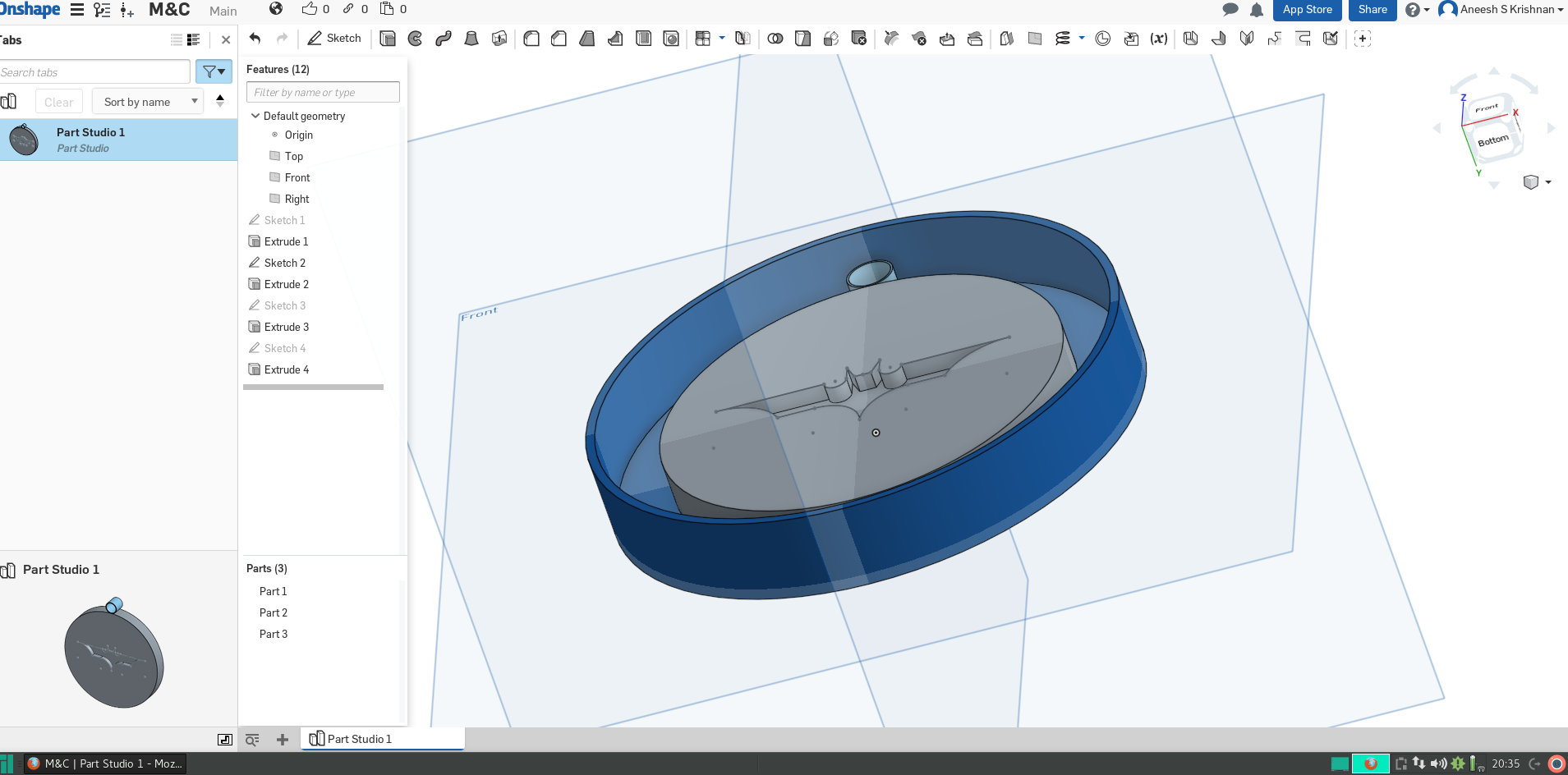

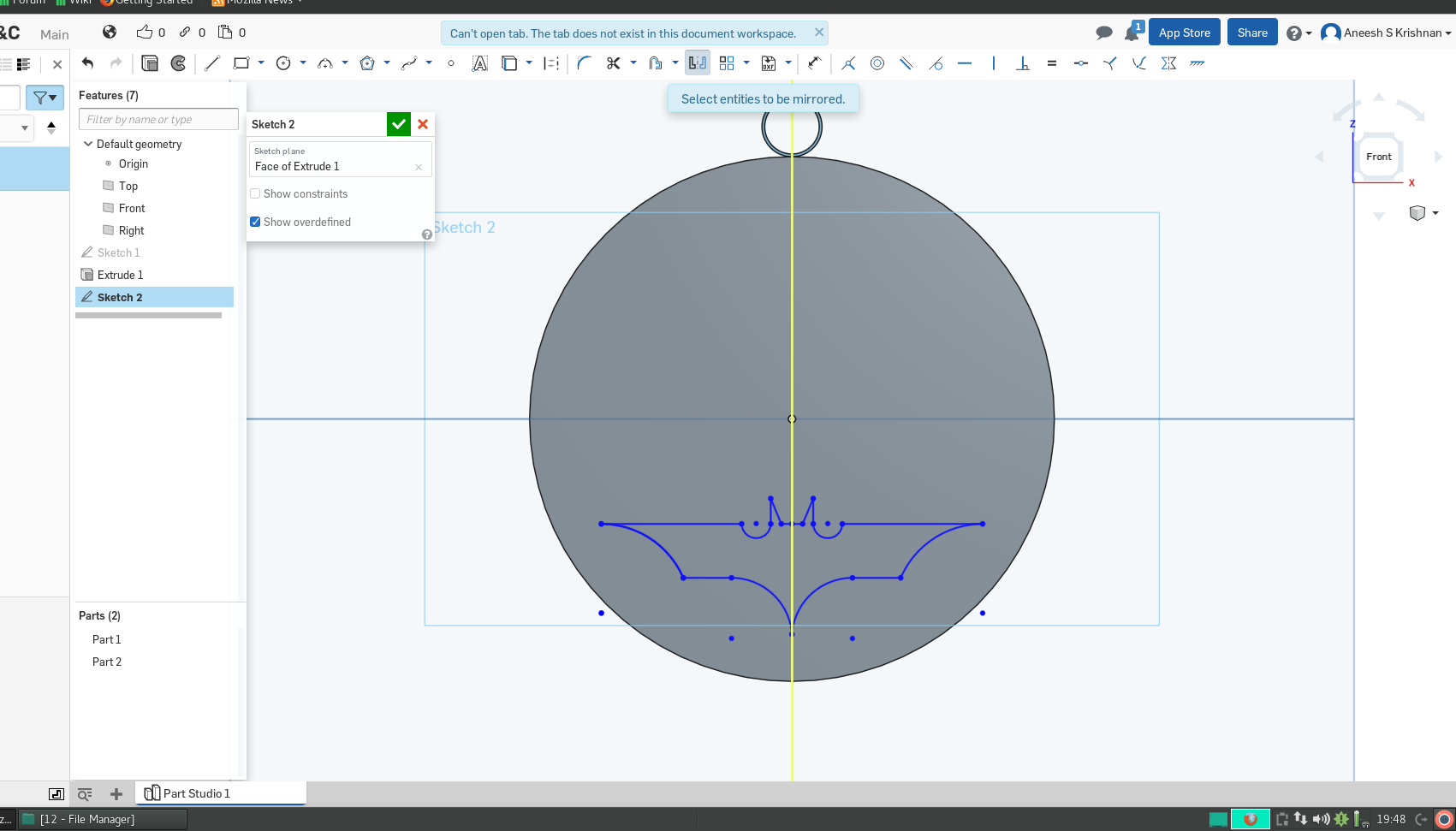

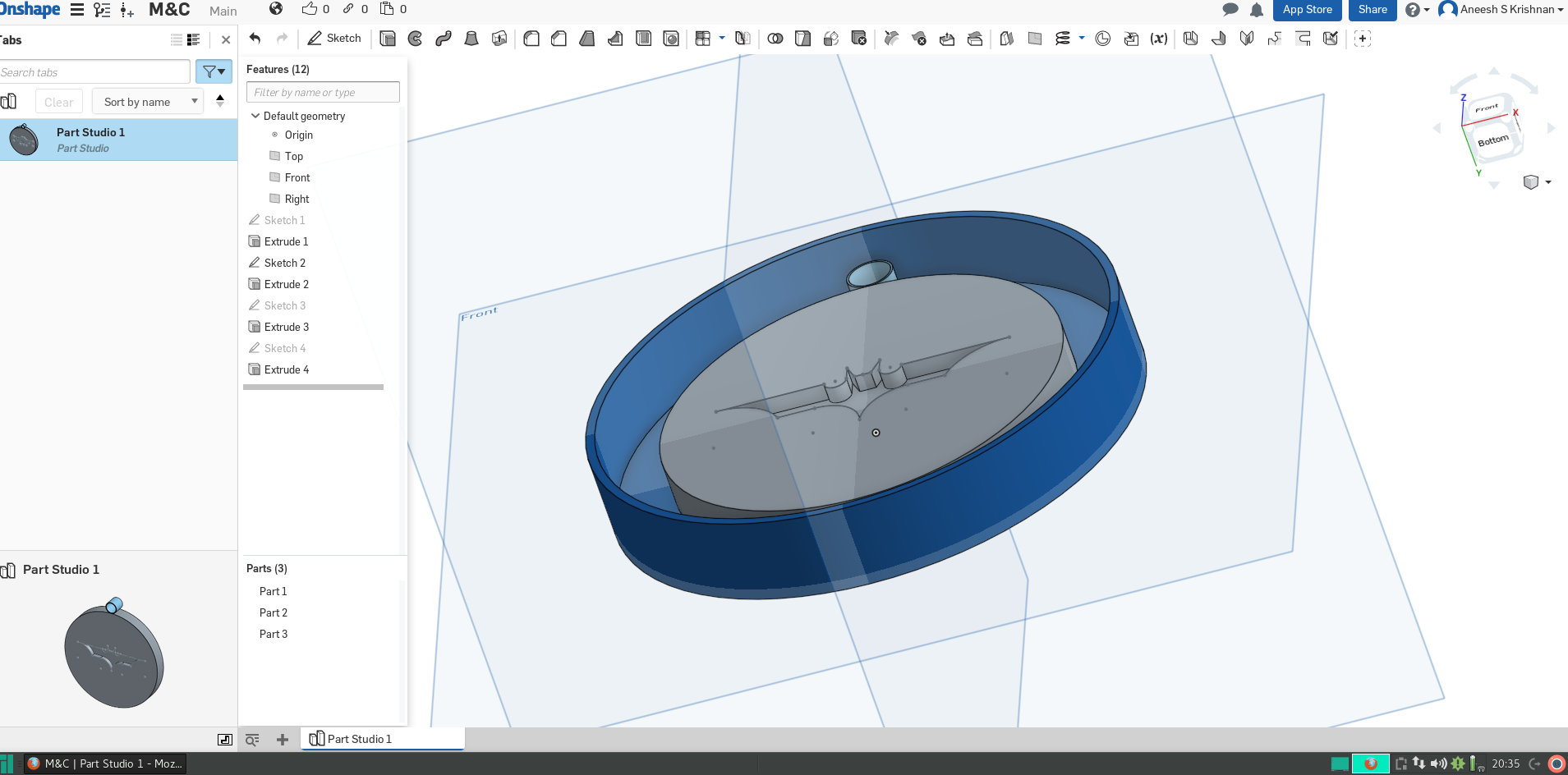

I used Onshape to design.

Initially I thought of making a locket. But in the end it turned out to be a Totem. :D :P

This is the design.

Attaching the design here.

After designing, I milled the wax with modella.

This is the design.

Attaching the design here.

After designing, I milled the wax with modella.

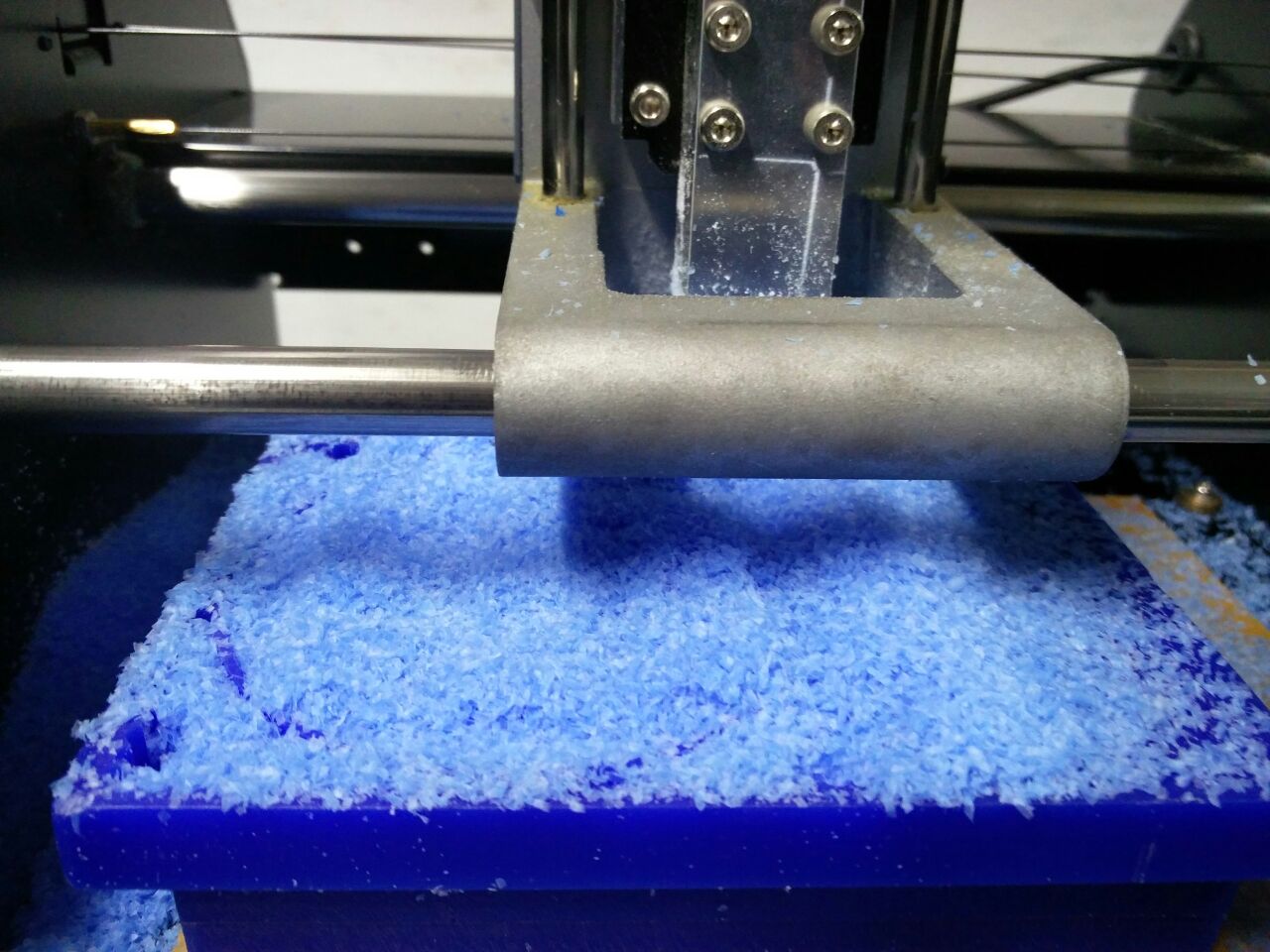

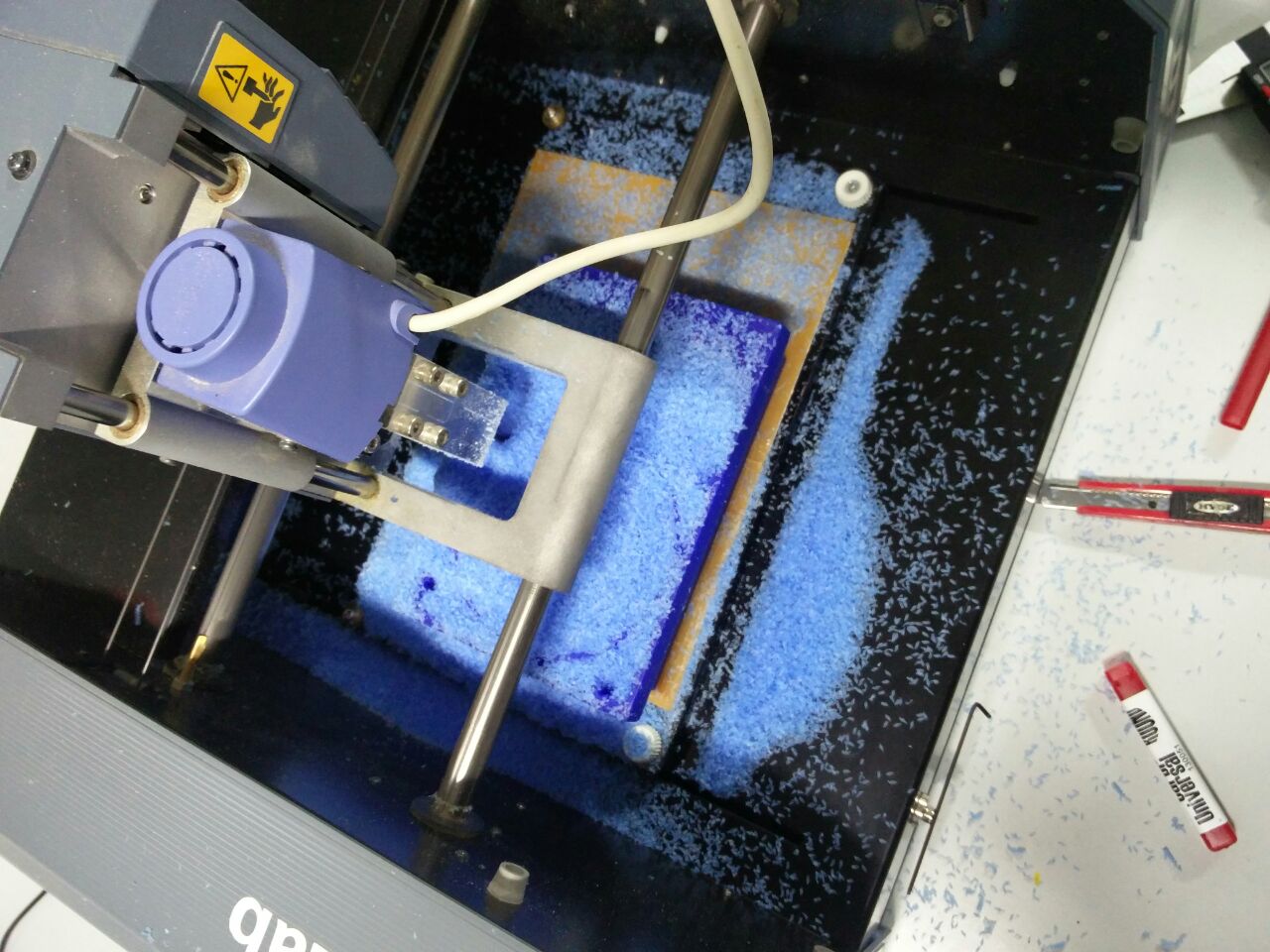

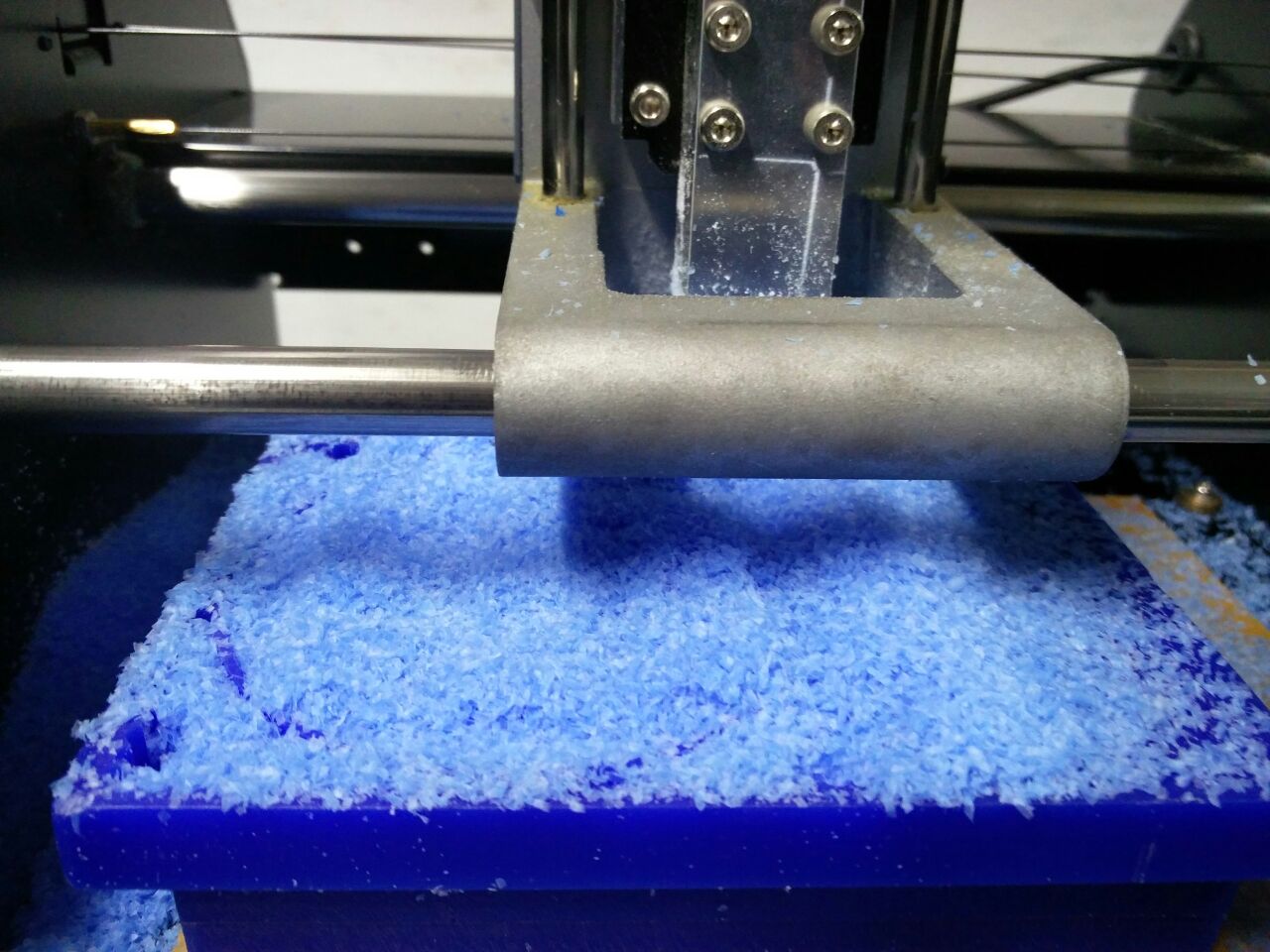

Milling

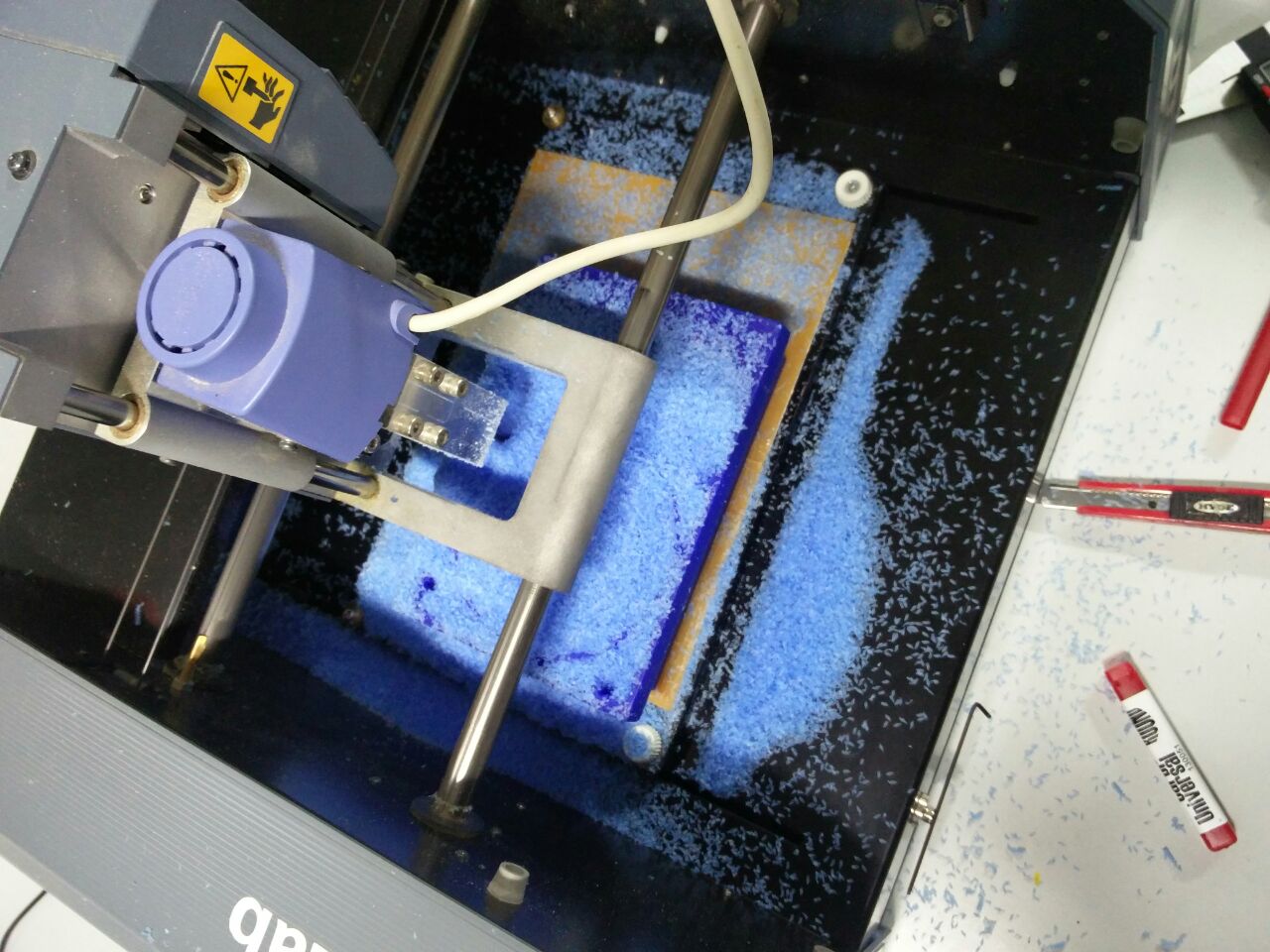

This is me cutting a peice of machinable wax using bandsaw :P

I didn't take a new wax block.

Used an old block! B-)

This is me cutting a peice of machinable wax using bandsaw :P

I didn't take a new wax block.

Used an old block! B-)

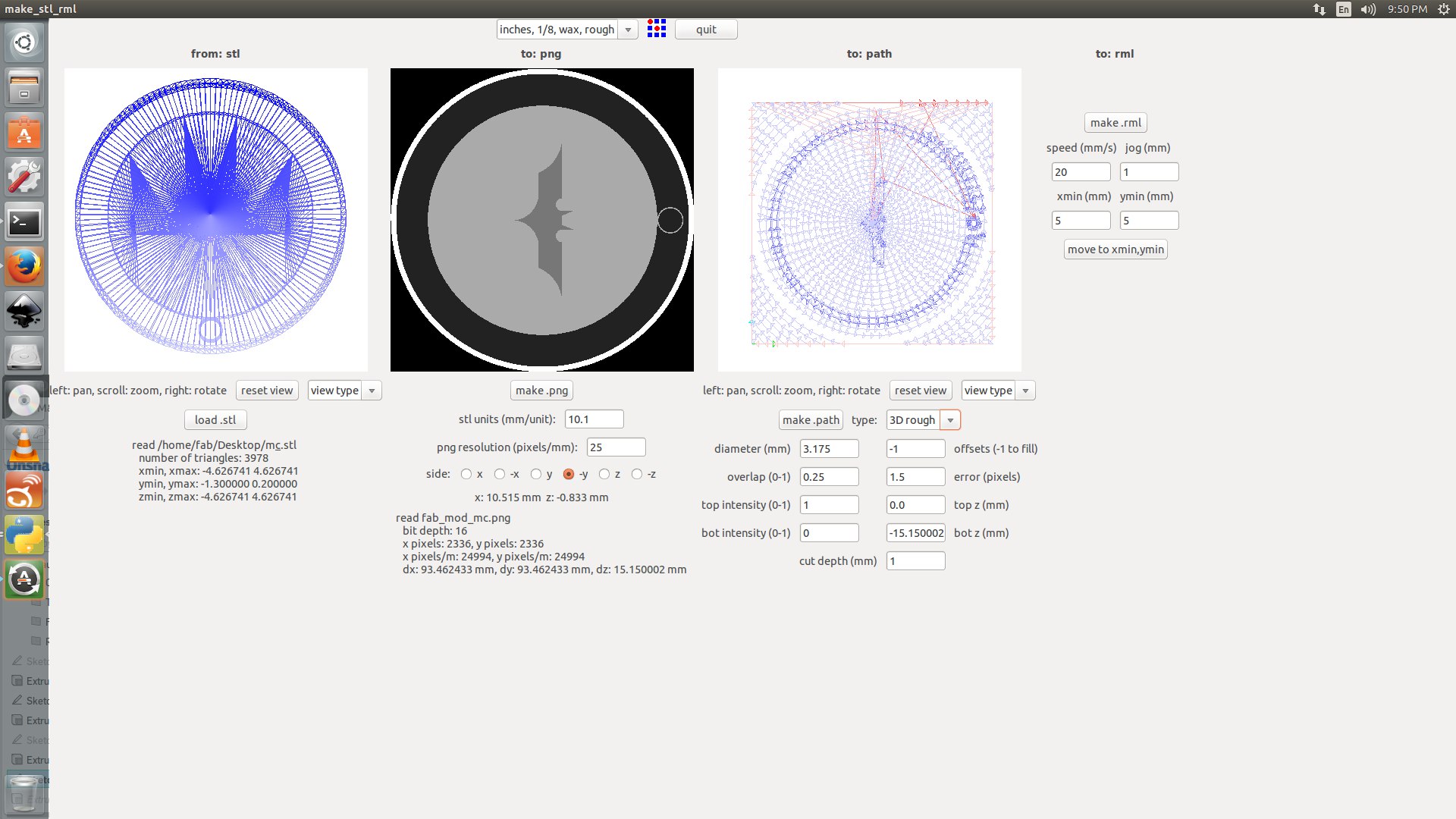

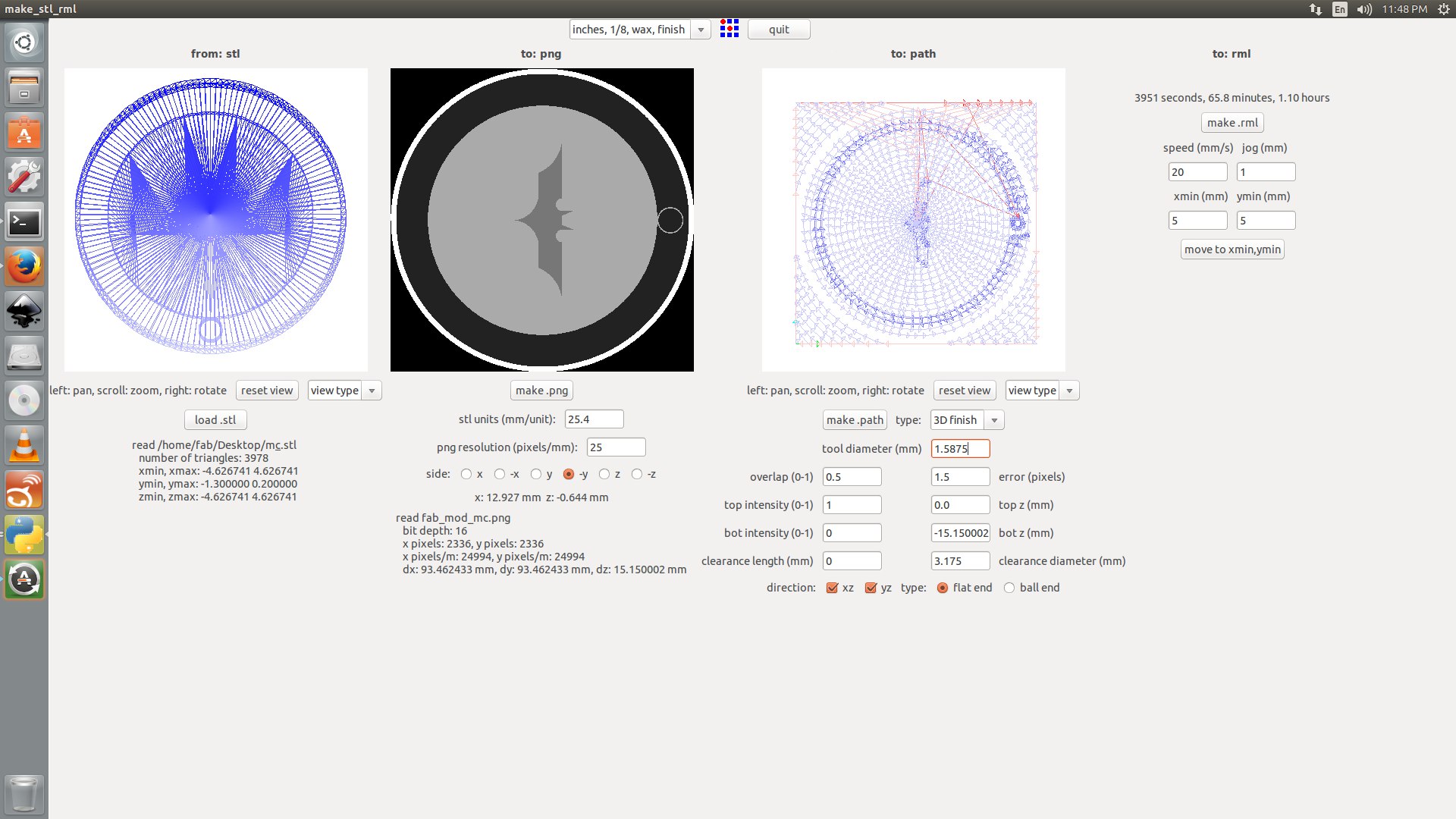

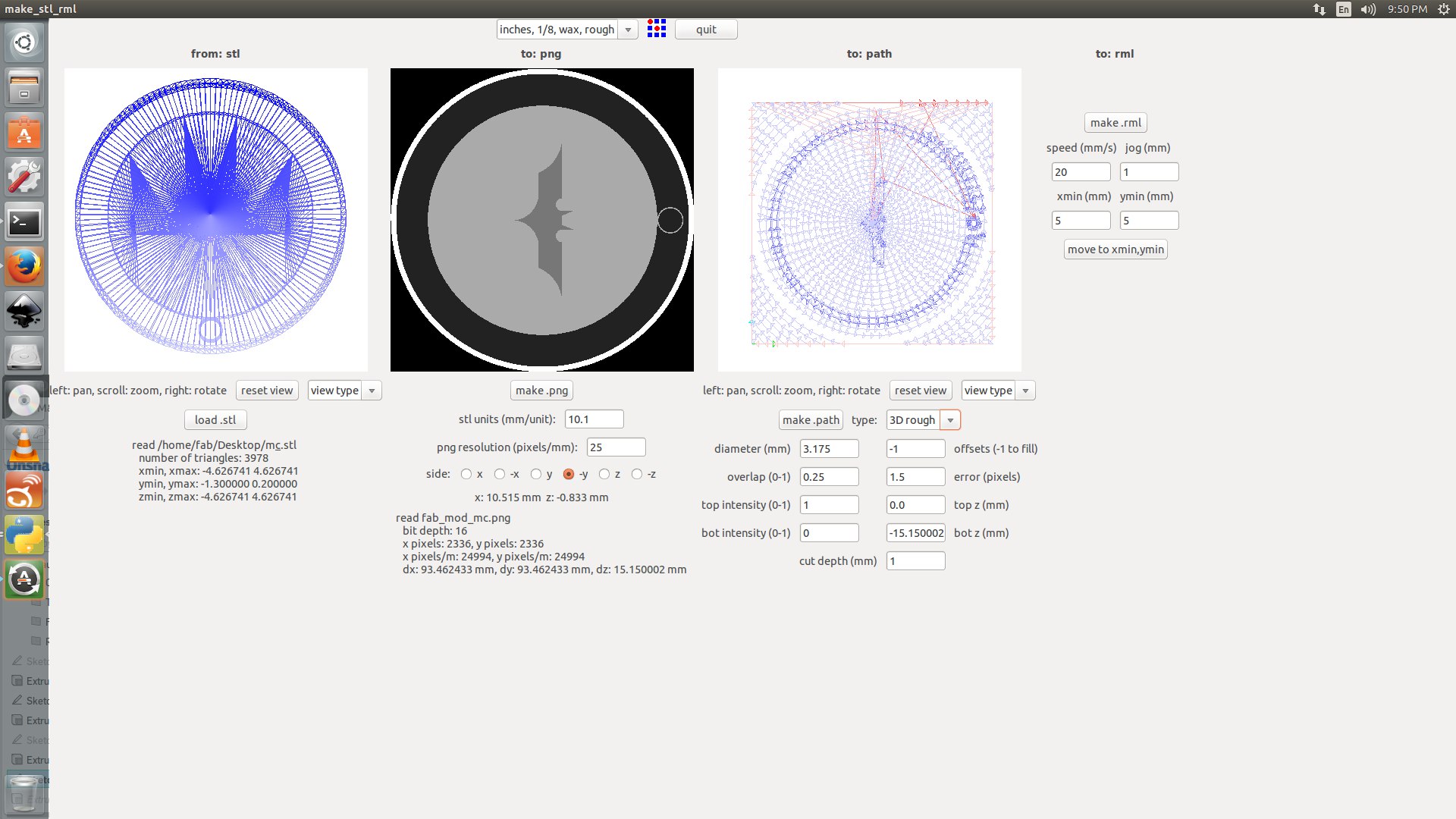

I used two bits for milling process one is 1/8 flat bit for rought cut & 1/16 ball point for finishing.

While using the 1/16 bit, as the 1/16 option is not available, I chose the 1/8 wax finish option and then changed the diameter to half the value.

This is equivalent to 1/16 option.

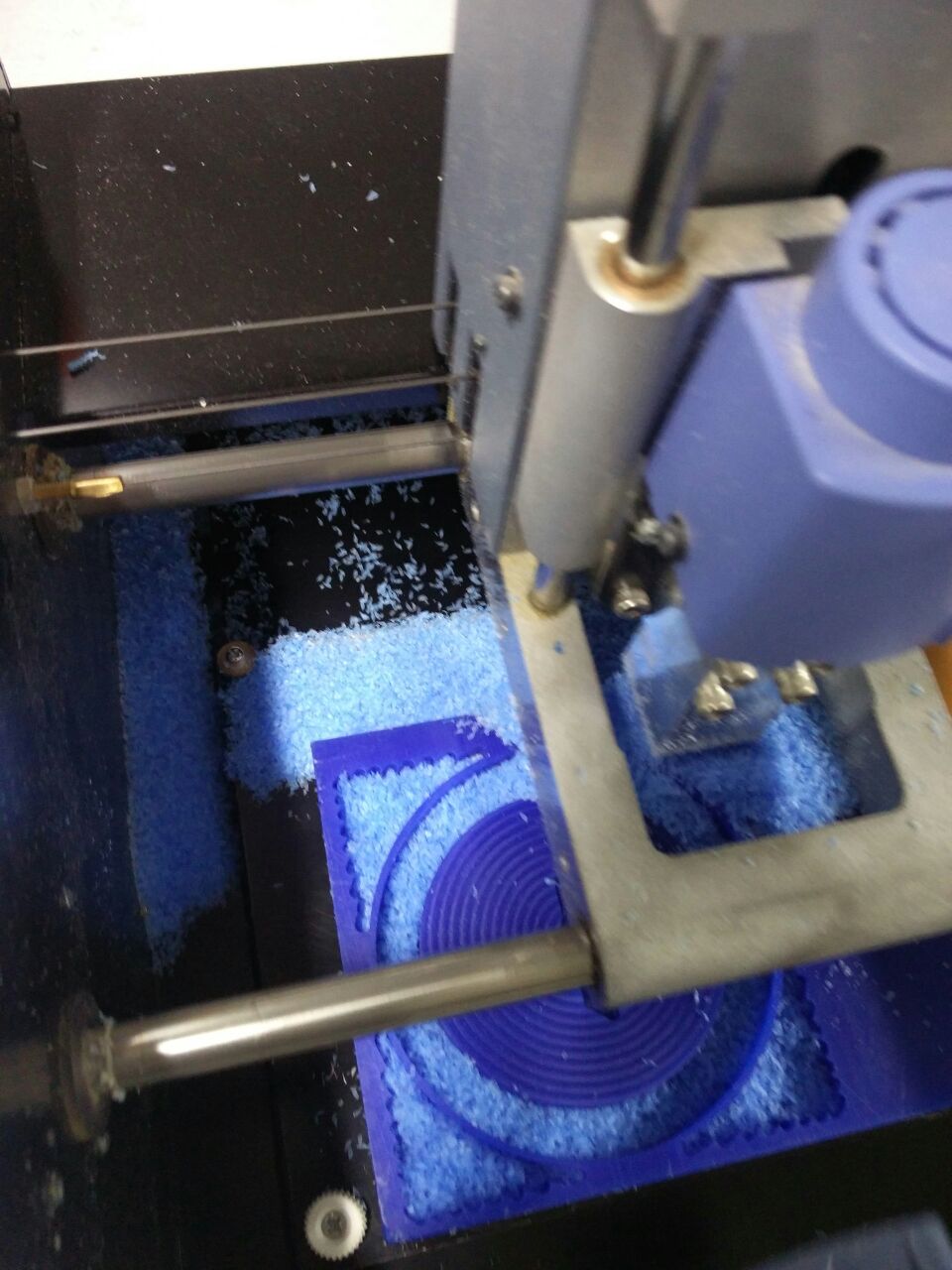

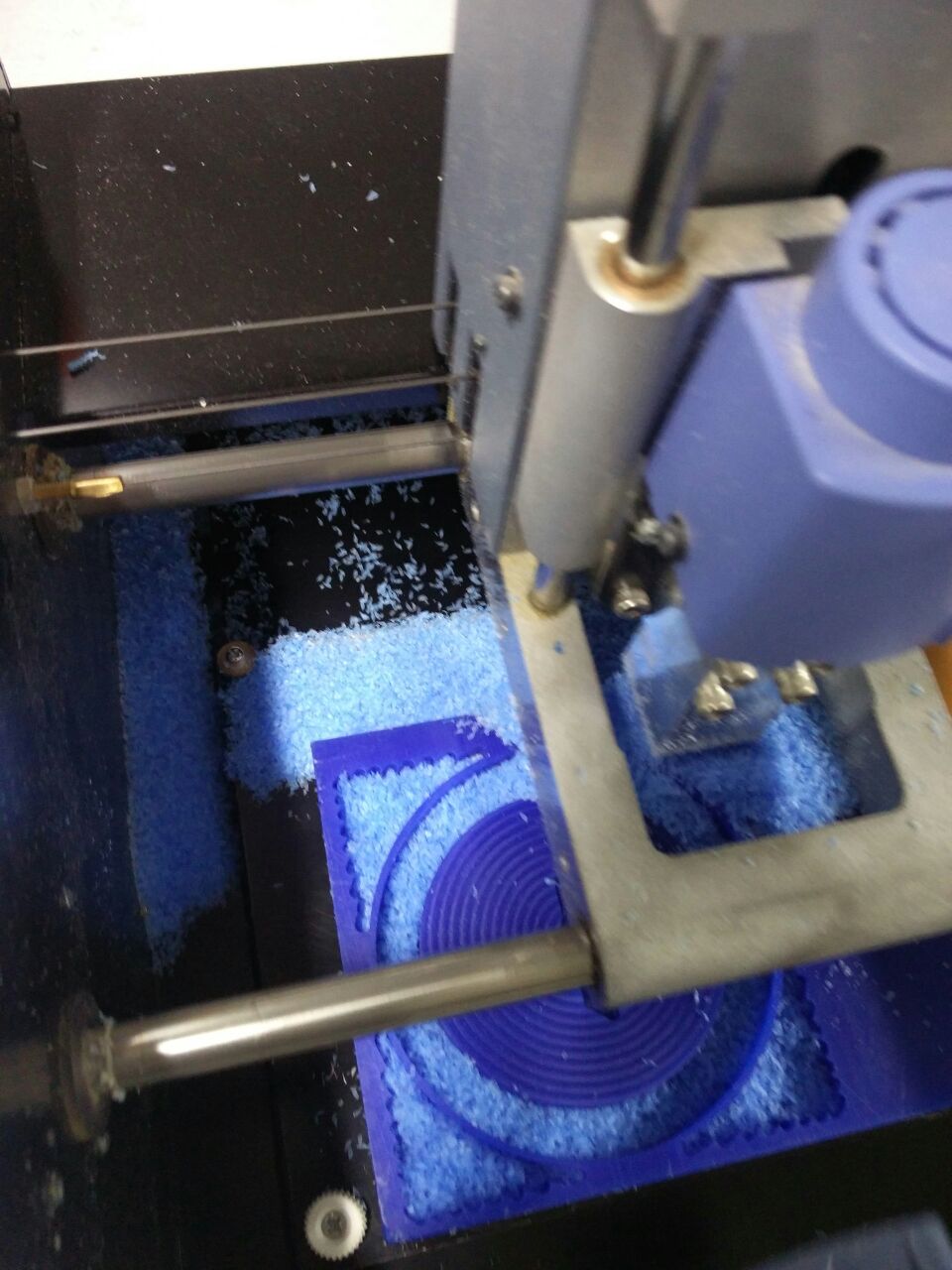

Milled in a wax block using Modella Fab module.

I selected from fromat model(.stl) to process Roland Modela(.rml). then with program make stl rml.

Milled in a wax block using Modella Fab module.

I selected from fromat model(.stl) to process Roland Modela(.rml). then with program make stl rml.

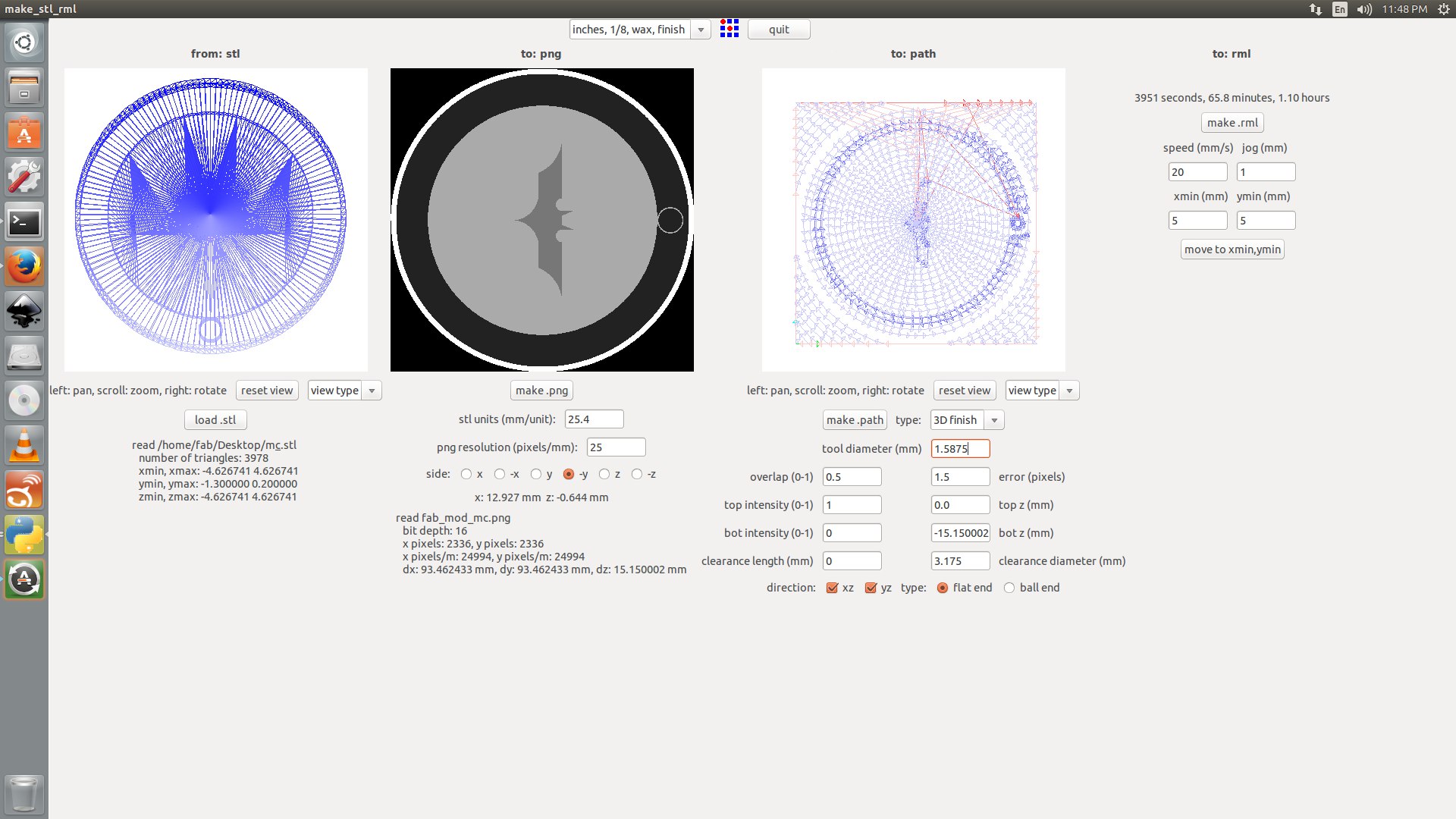

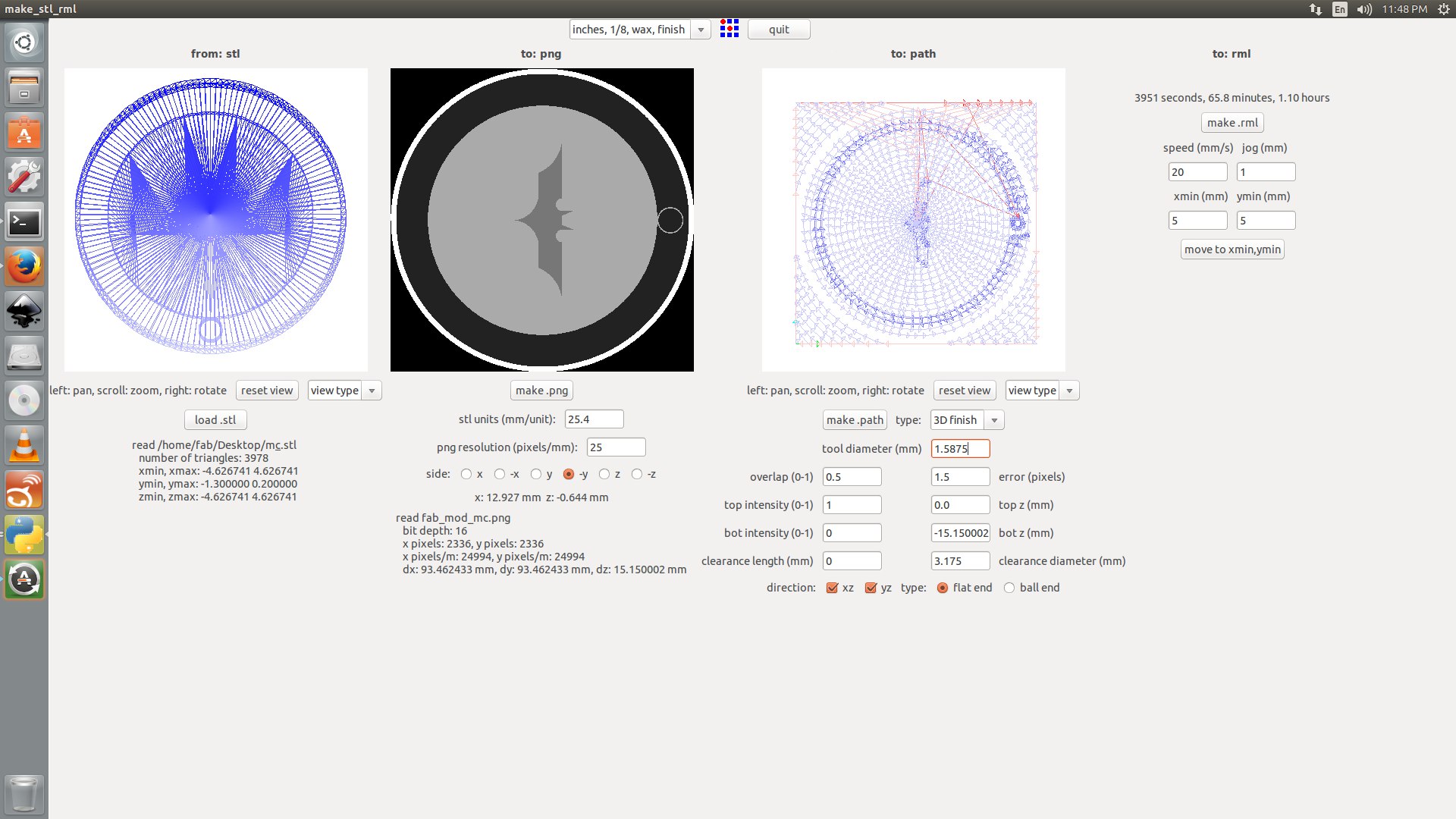

For finishing I used 1/16" bit! The diameter change can be seen in the below screenshot.

For finishing I used 1/16" bit! The diameter change can be seen in the below screenshot.

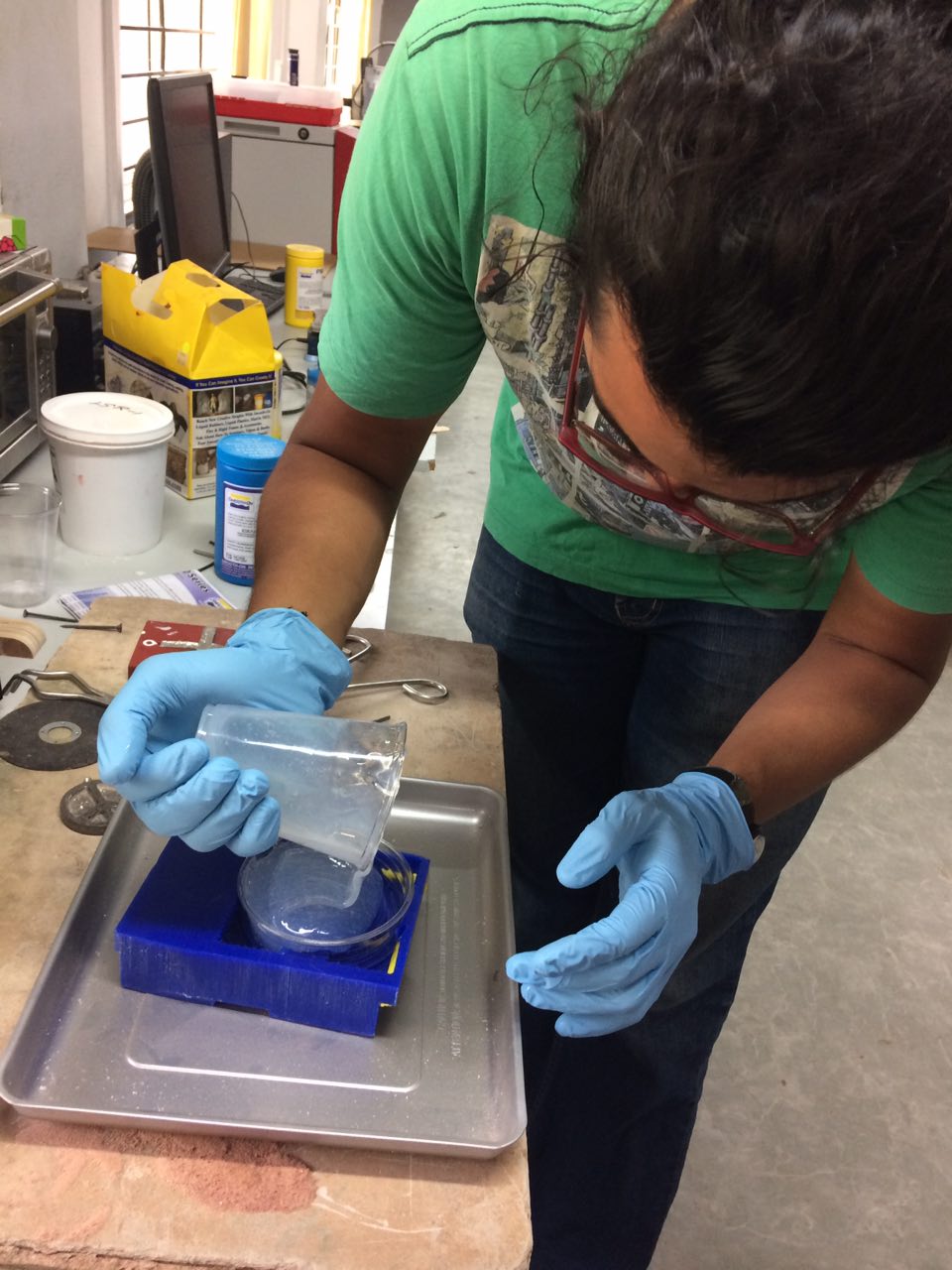

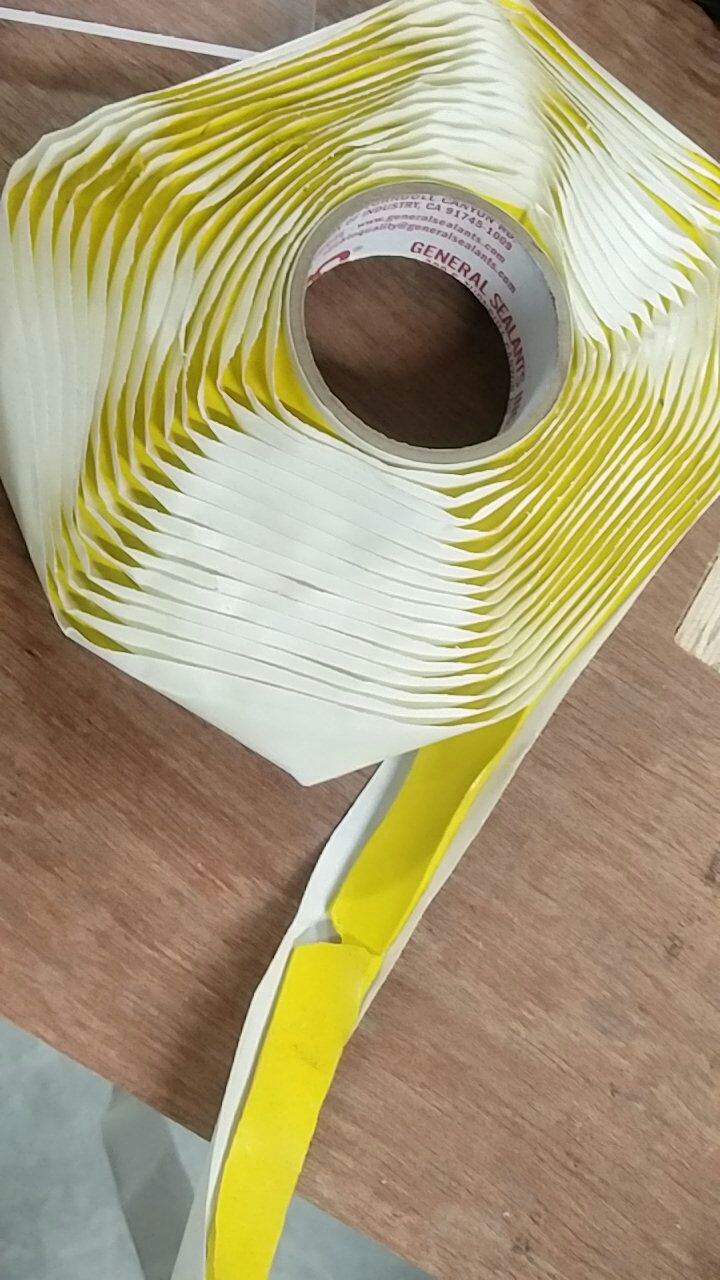

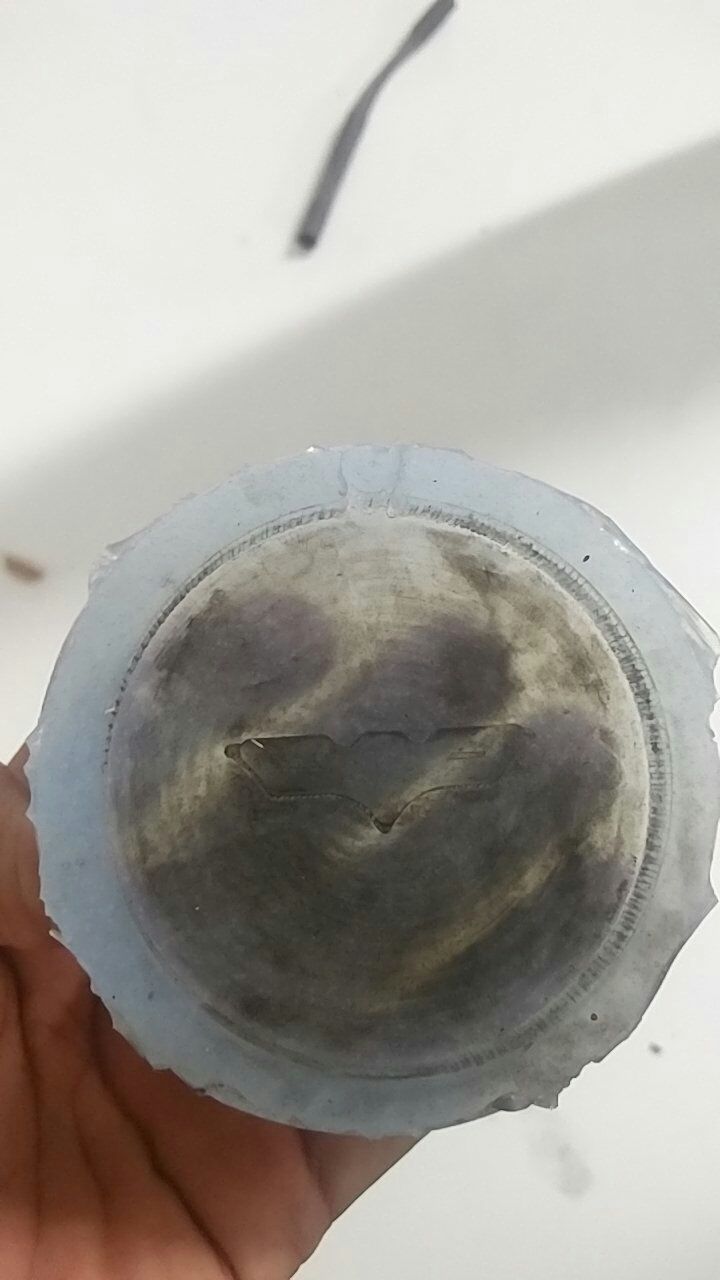

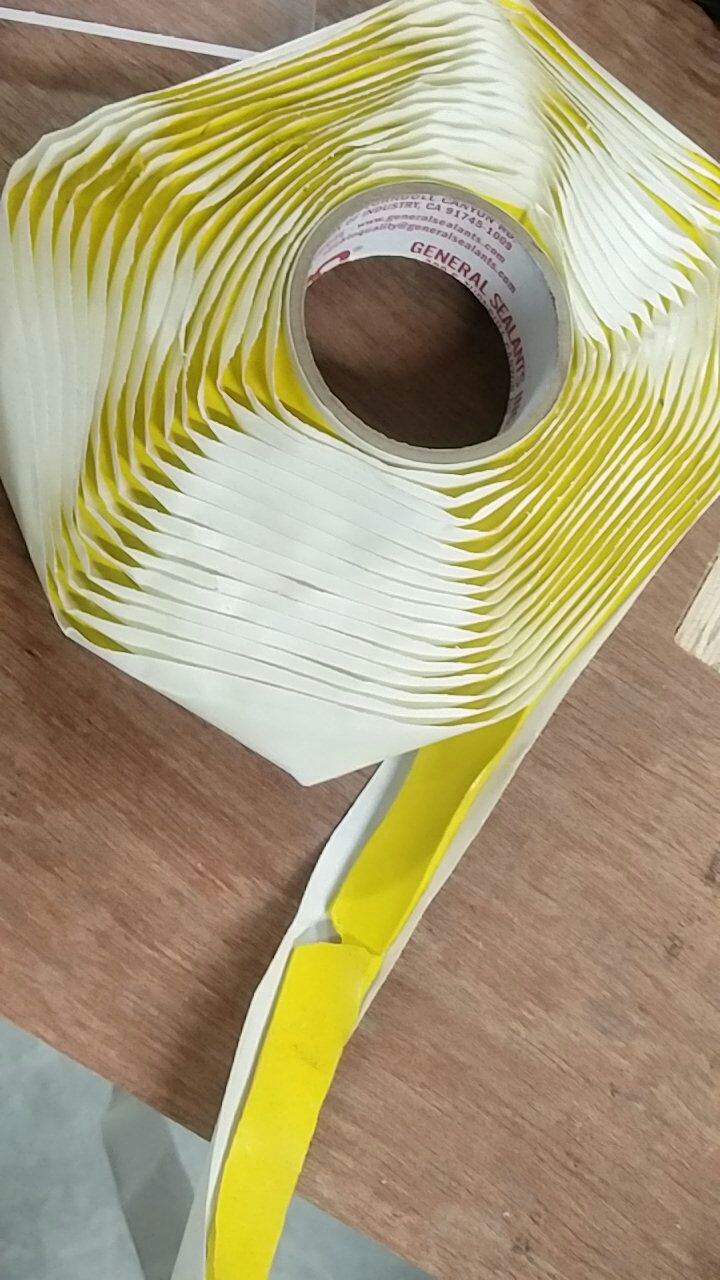

After the milling I found that the walls at some parts were broken.

I was worried for sometime. Then it struck me that I can fix it.

I used sealant tape and a plastic cups lip to cover the broken region!

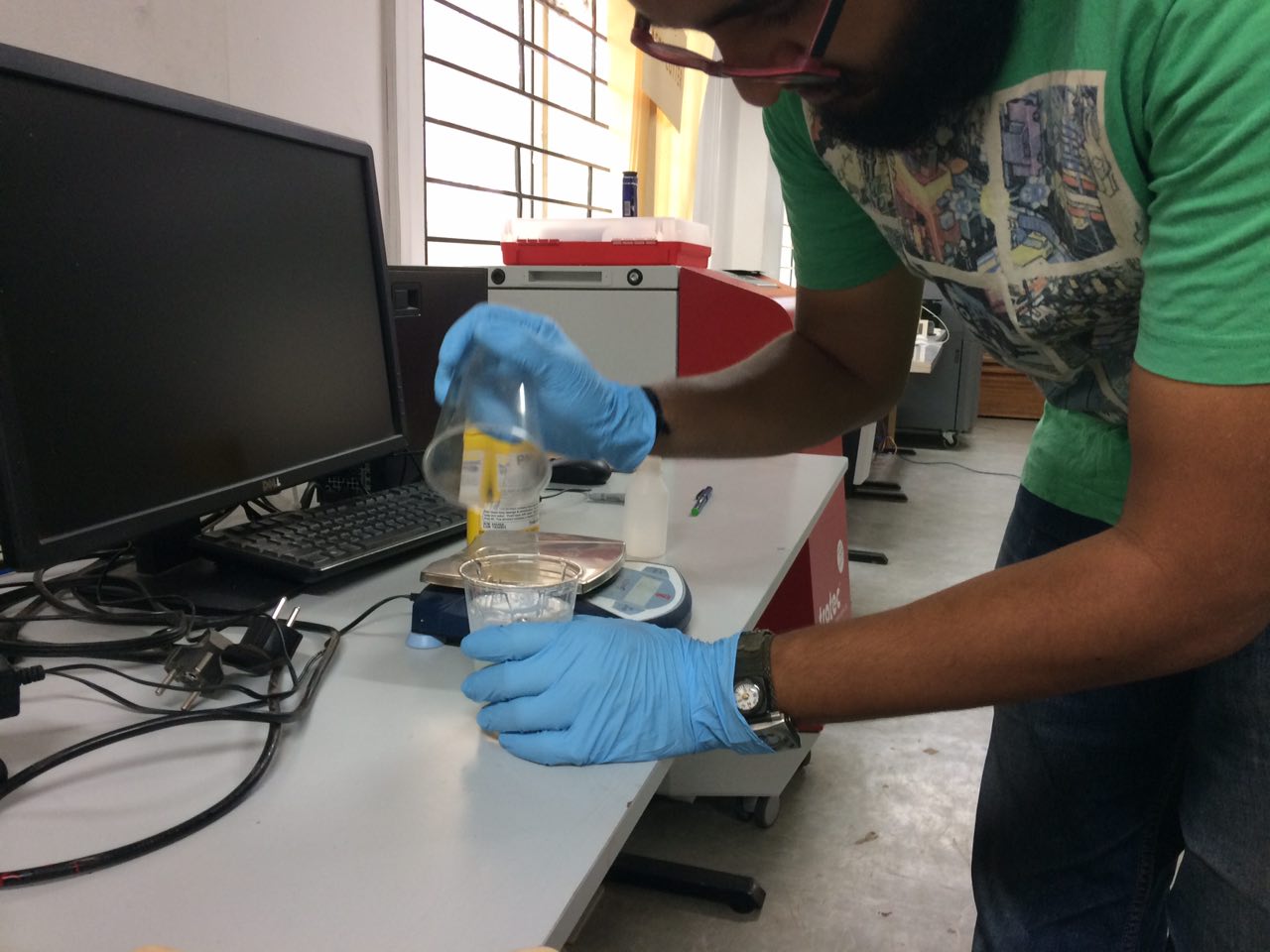

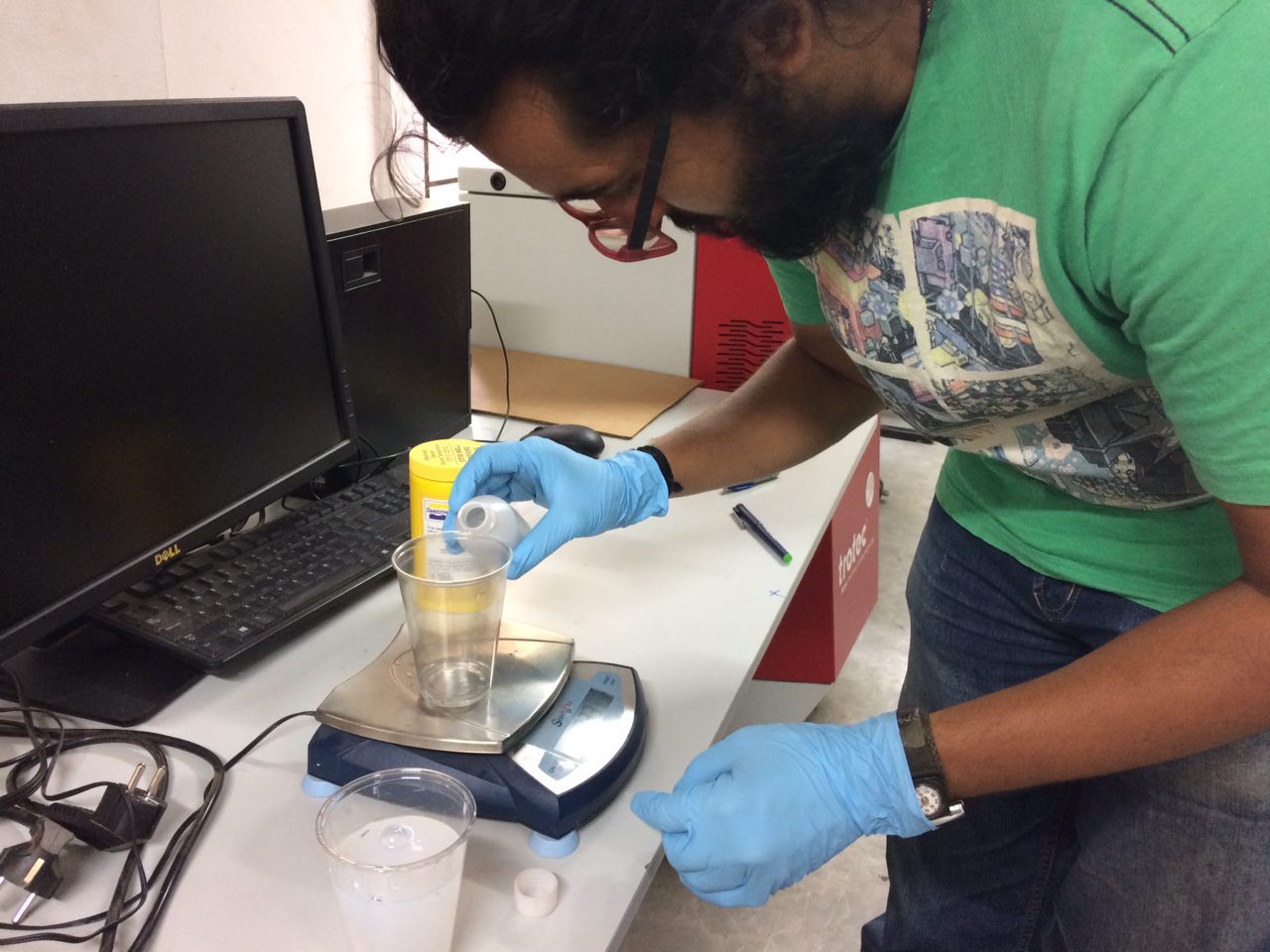

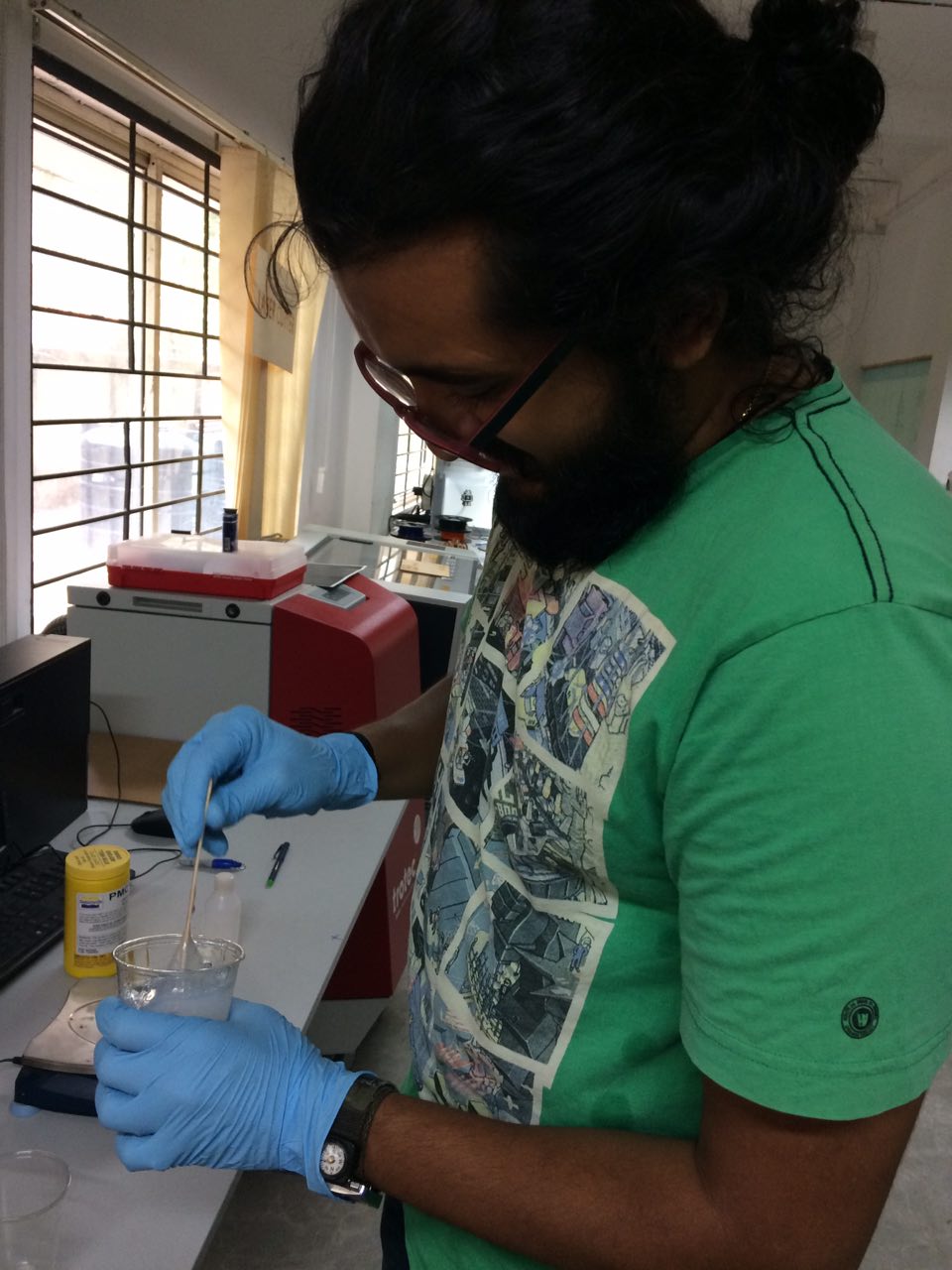

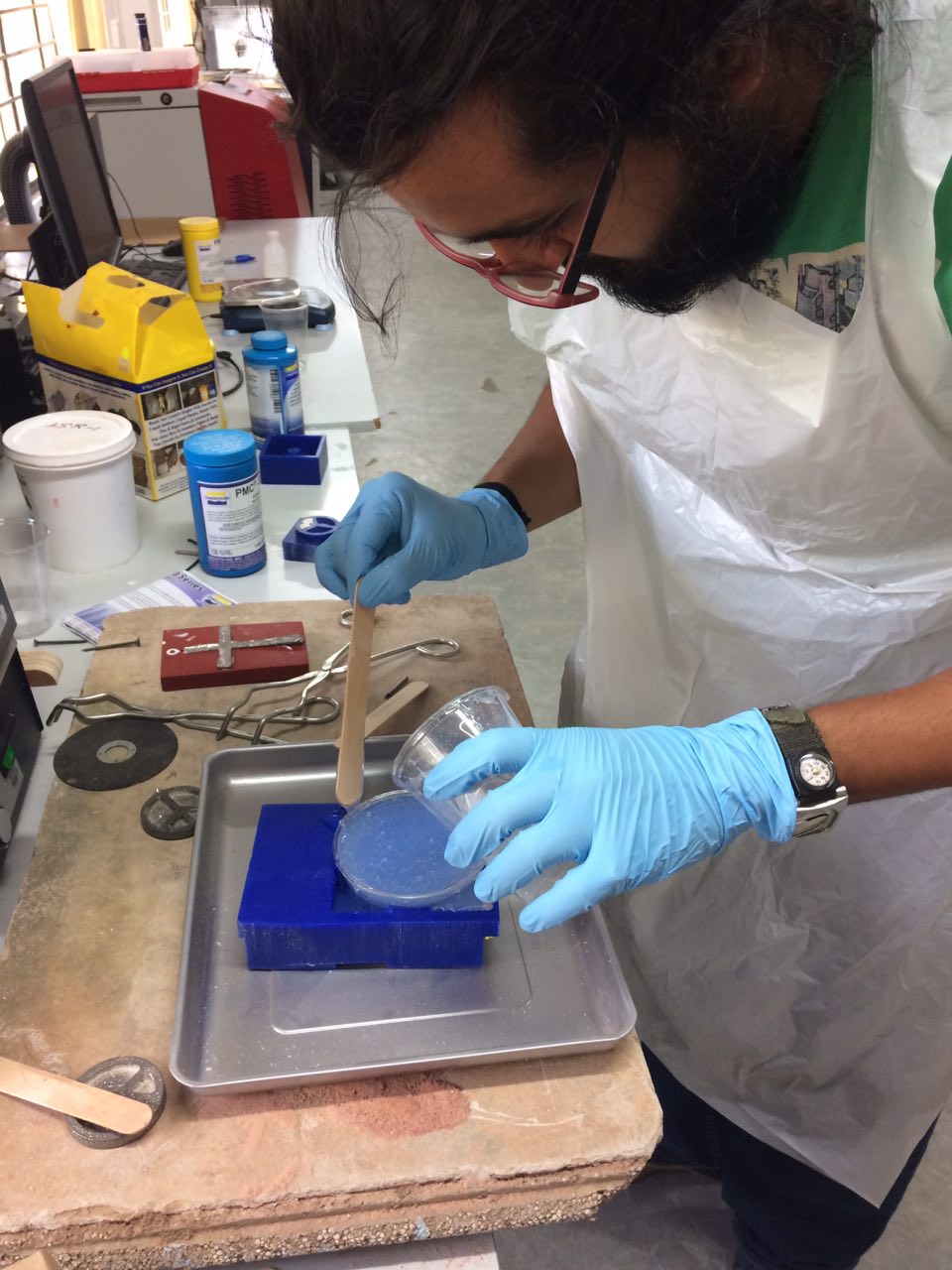

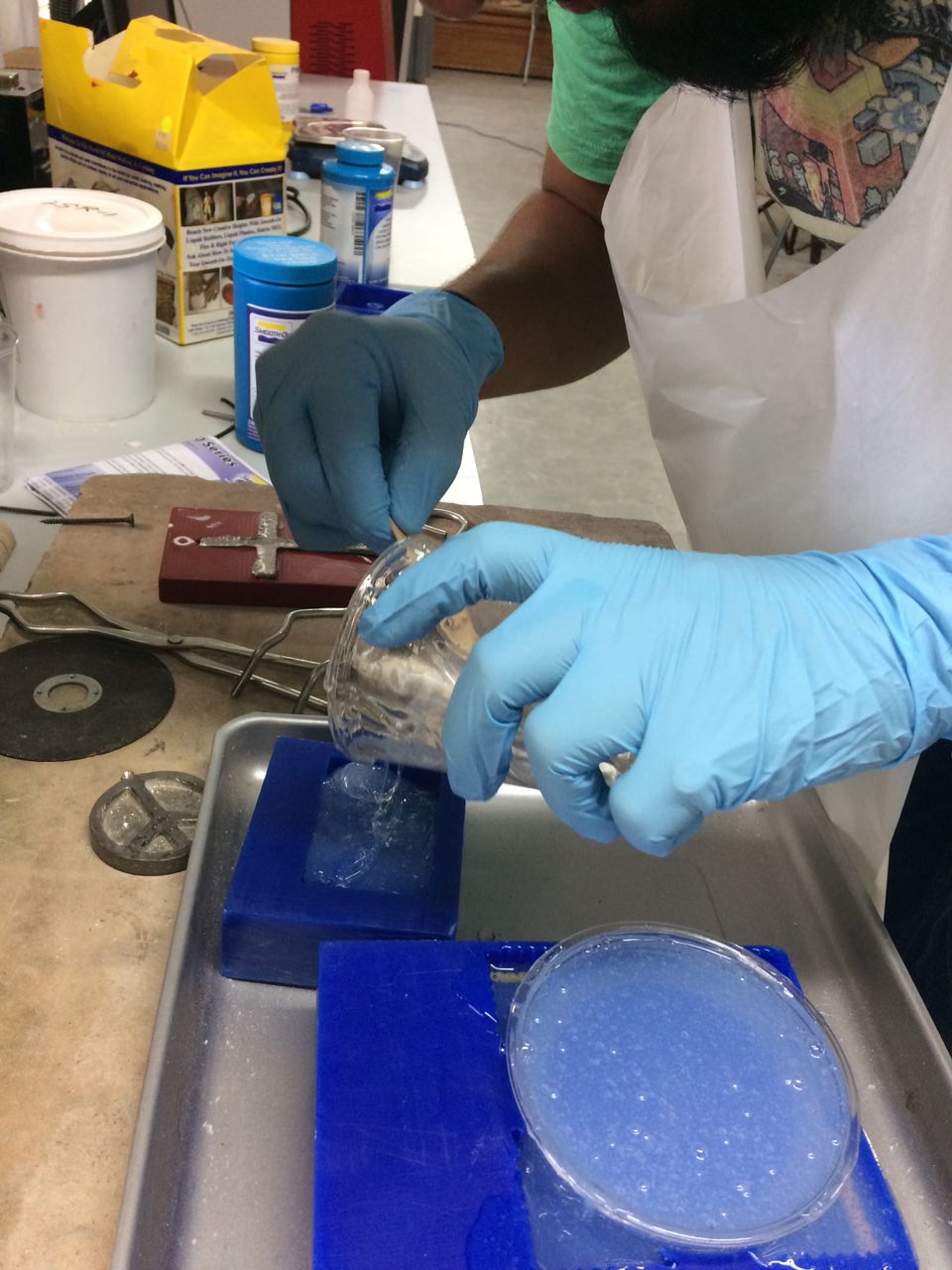

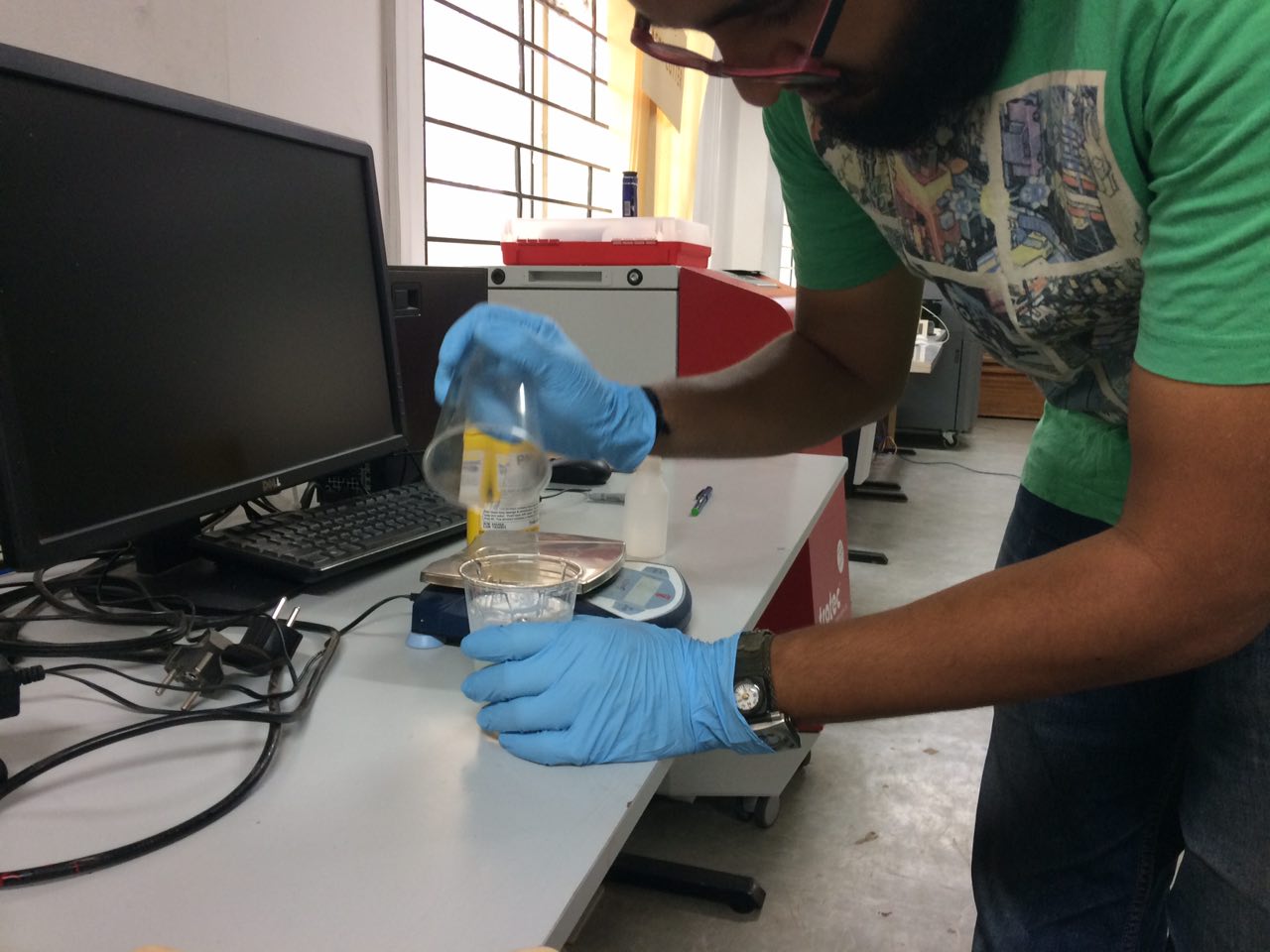

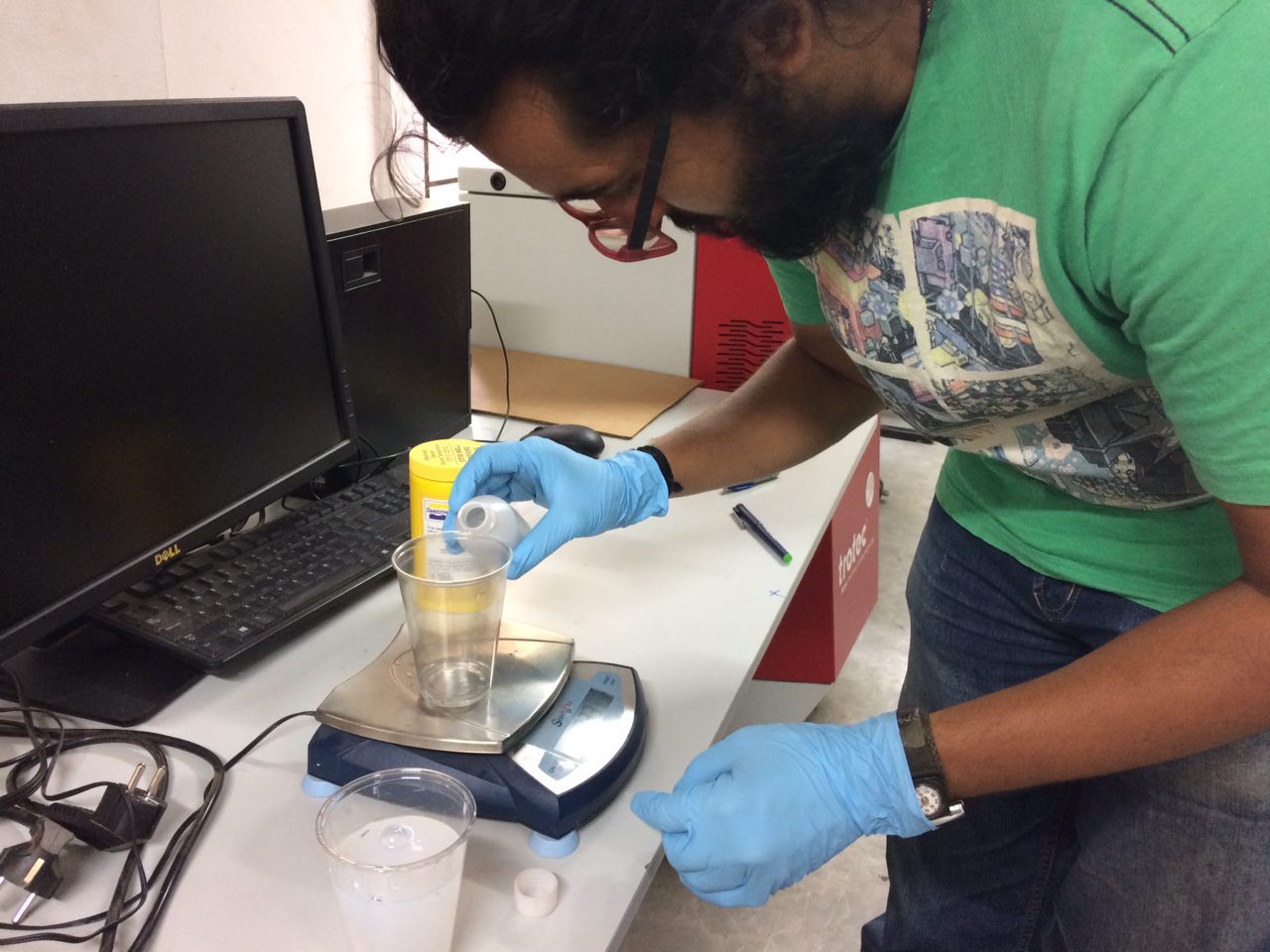

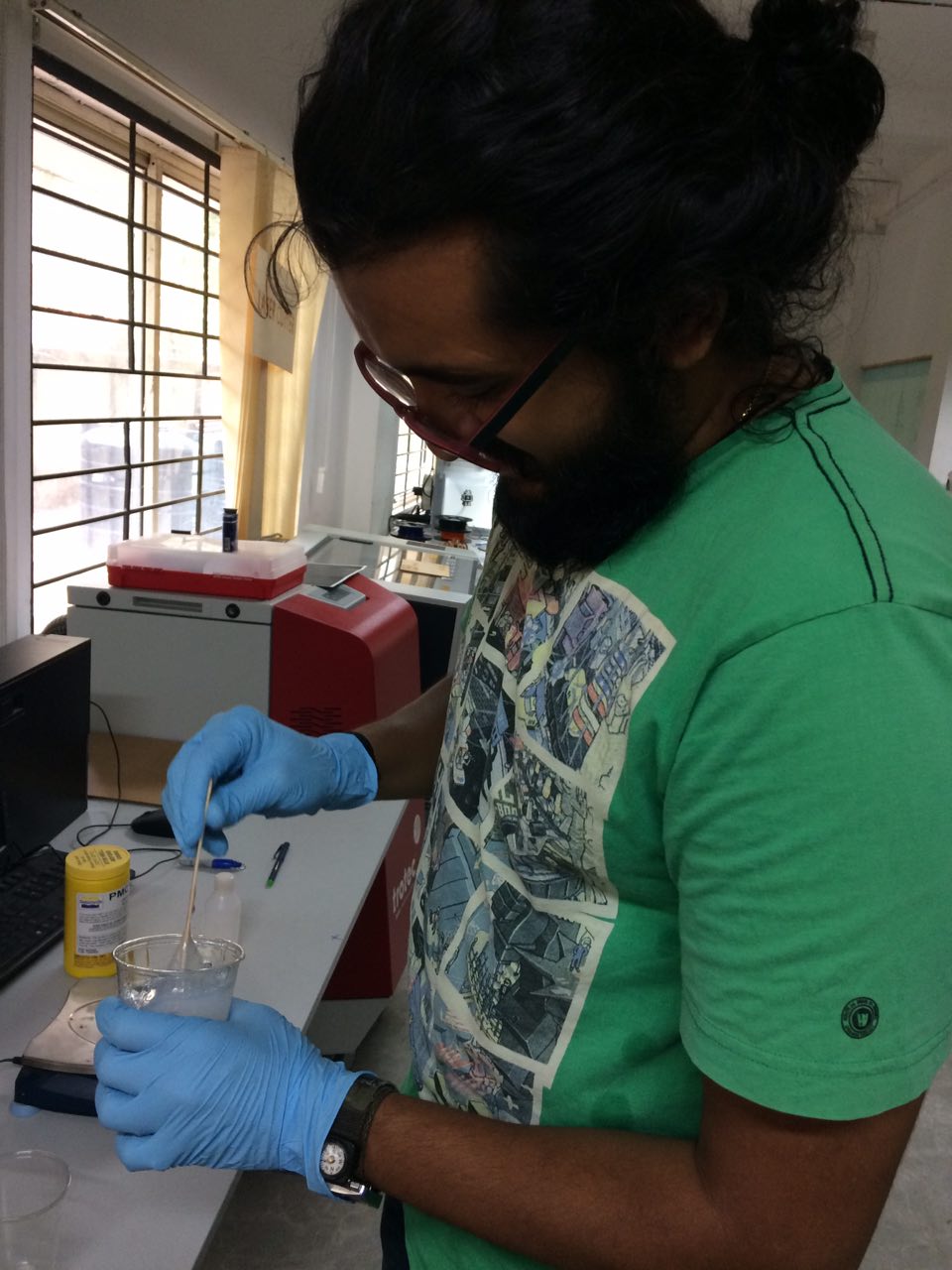

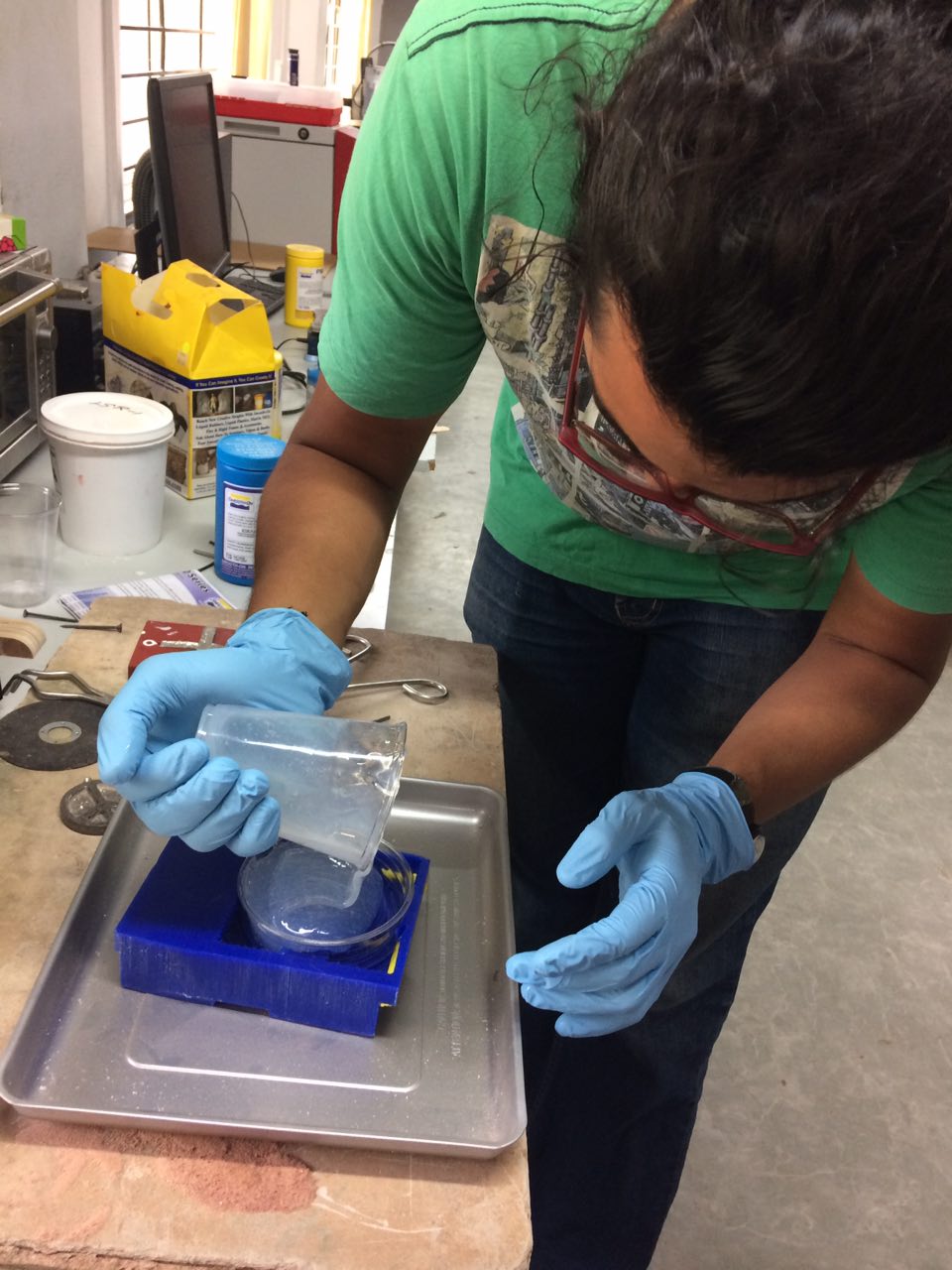

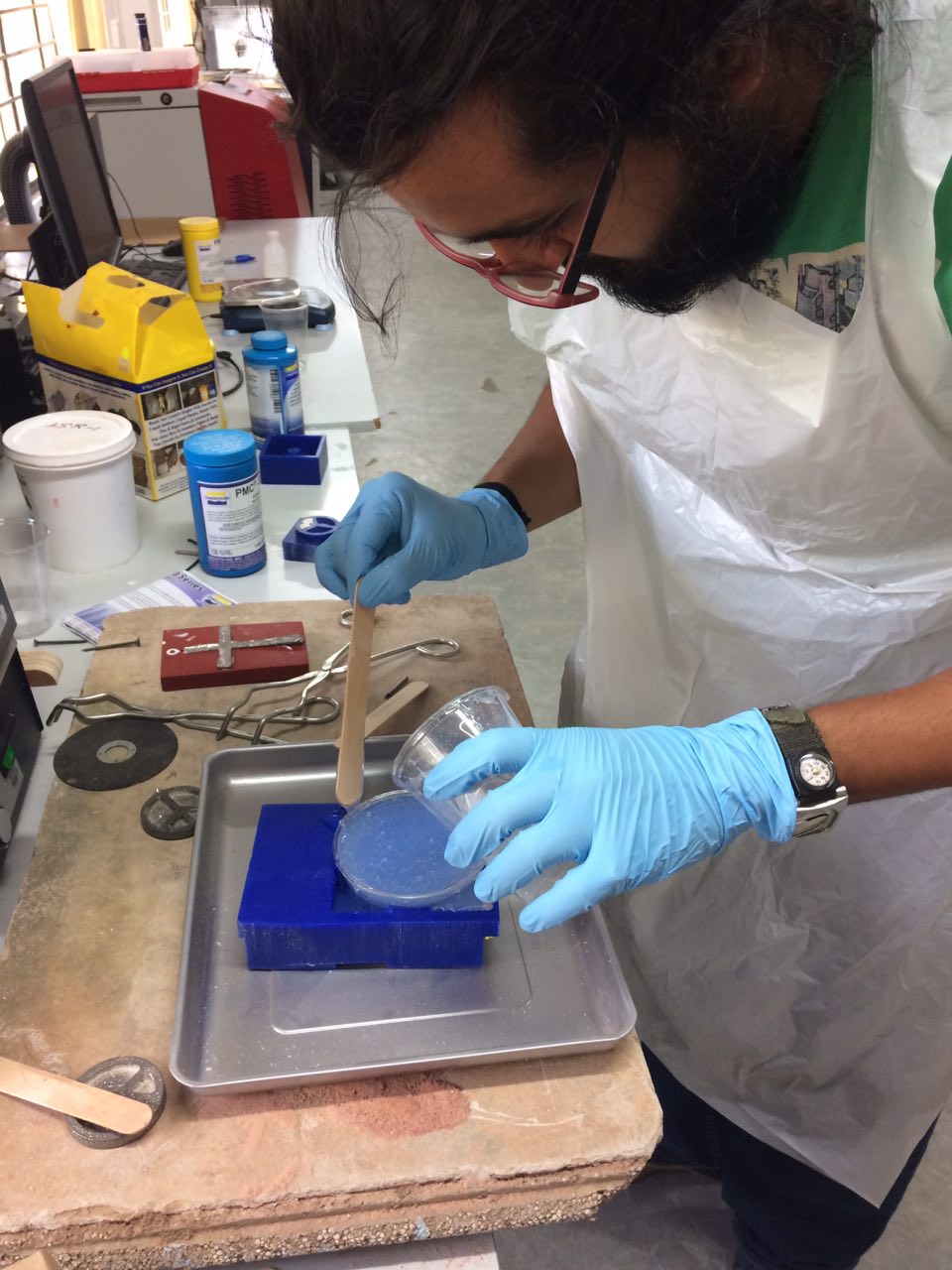

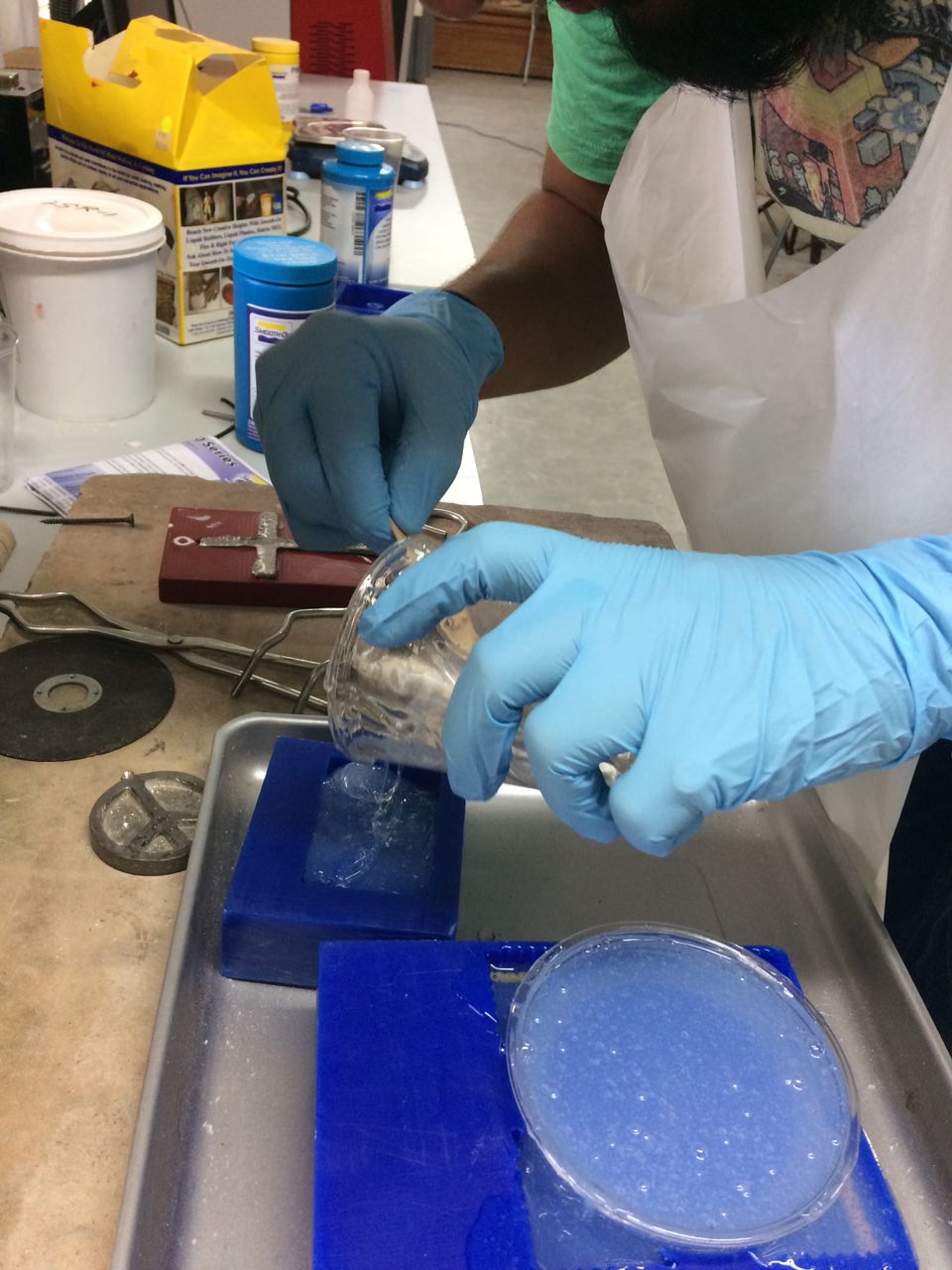

After that I made the mould using liquid silicon rubber by mixing its part A & B in the ratio 1:10.

After that I made the mould using liquid silicon rubber by mixing its part A & B in the ratio 1:10.

The setting time of this mixture is 24 hours - at 25 deg.

So I kept the mold for setting for a day.

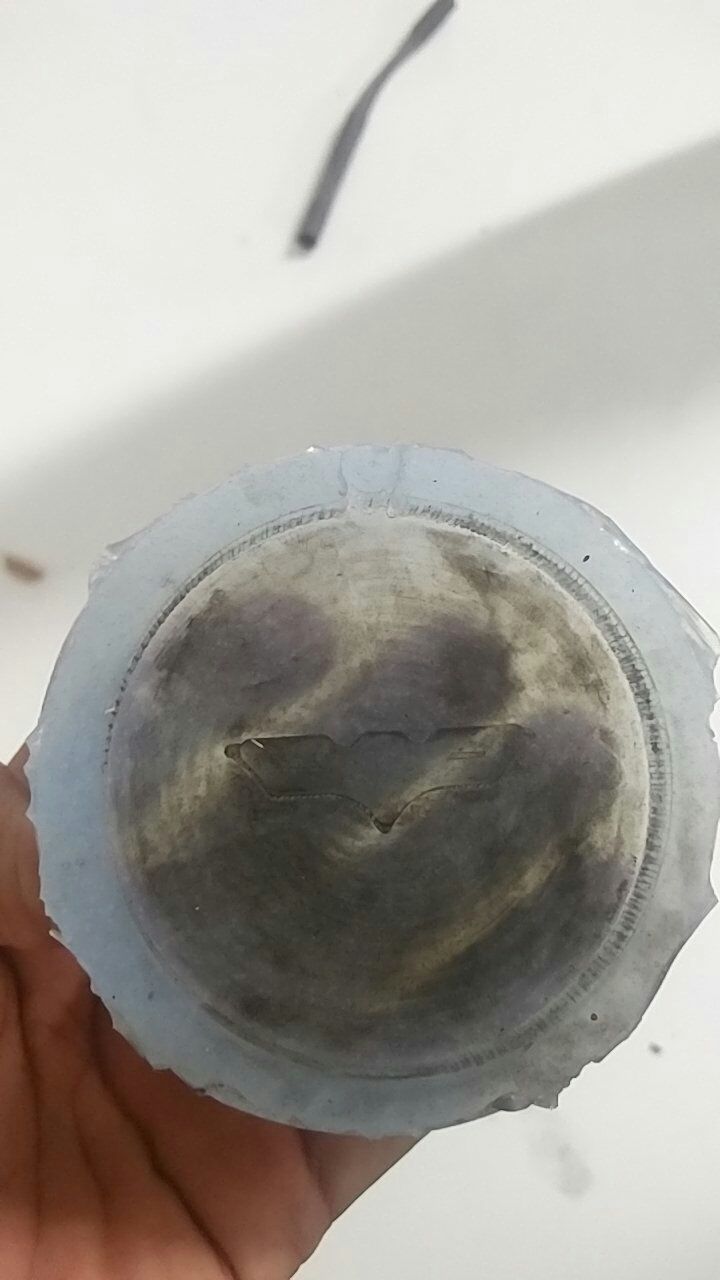

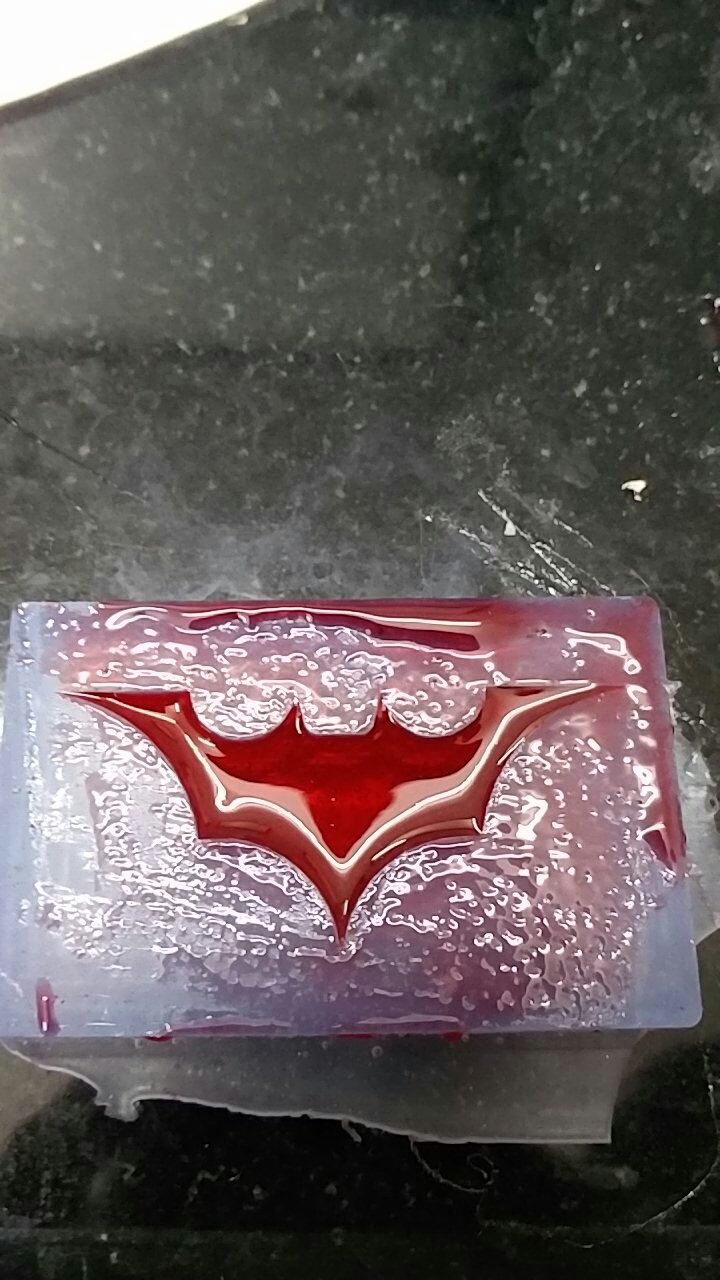

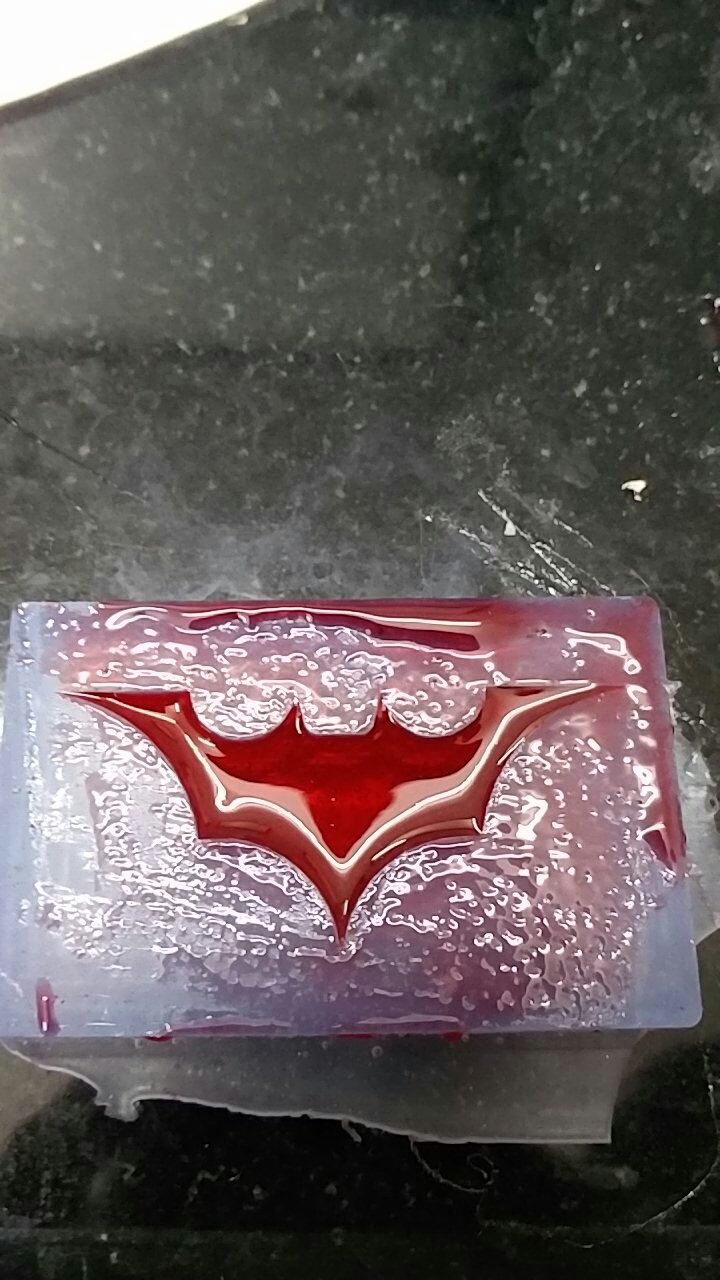

Here is the mould I created.

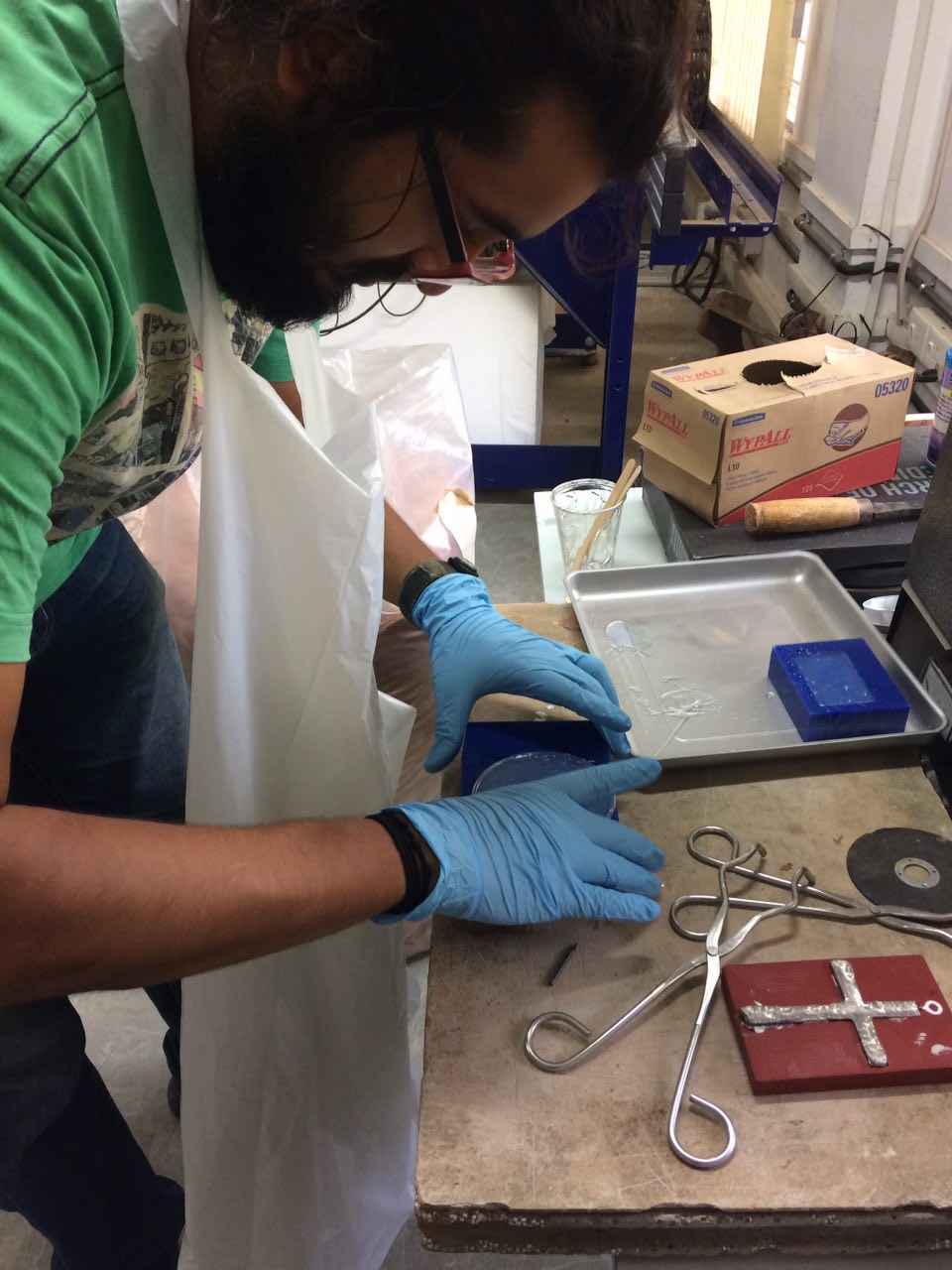

For getting a smooth surface - as per my instructor sibu's instruction I showed the mold on to a flame.

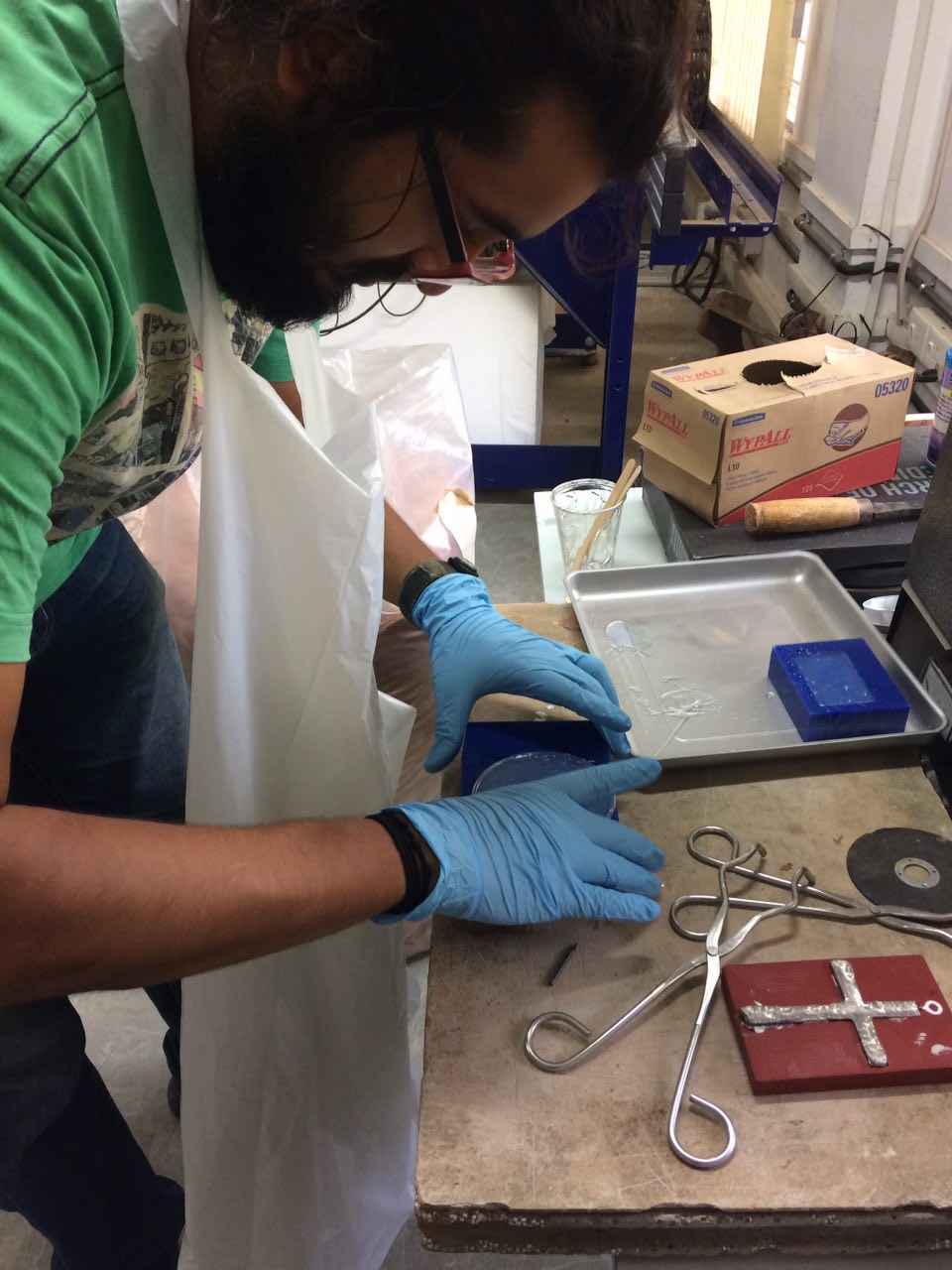

After this I melted the babbit metal(Bismuth alloy) to about 400 degree celsius in the furnace, and poured it into the mold.

To the second mold I made I poured plastic.

For Plastic casting : I Used high glossy epoxy resin which was bought locally.

It is also a two part system with a mixing ratio of 100:60, having agel time of 10min and setting time of 30minutes.

Final Result

Major Takeaways

This week gave me an opportunity to do casting of which I had always thought of doing someday.

Importantance of Material Data safety sheet was informative.

While casting we must shake the material and should try our best to push out the air bubbles inside the mold.

Design file can be found here.

This is the design.

Attaching the design here.

After designing, I milled the wax with modella.

This is the design.

Attaching the design here.

After designing, I milled the wax with modella.

This is me cutting a peice of machinable wax using bandsaw :P

I didn't take a new wax block.

Used an old block! B-)

This is me cutting a peice of machinable wax using bandsaw :P

I didn't take a new wax block.

Used an old block! B-)

Milled in a wax block using Modella Fab module.

I selected from fromat model(.stl) to process Roland Modela(.rml). then with program make stl rml.

Milled in a wax block using Modella Fab module.

I selected from fromat model(.stl) to process Roland Modela(.rml). then with program make stl rml.

After that I made the mould using liquid silicon rubber by mixing its part A & B in the ratio 1:10.

After that I made the mould using liquid silicon rubber by mixing its part A & B in the ratio 1:10.