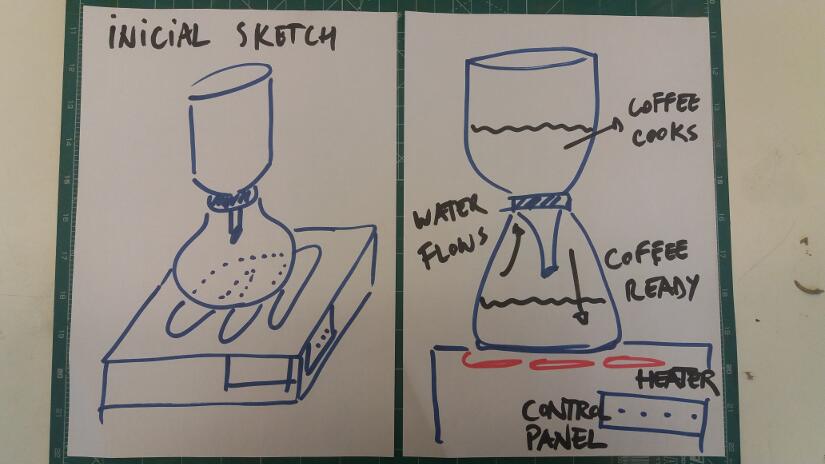

After the first meetig about building the coffee maker, my tutor Kenzo and I came up with an skecth that we thought could be done with the material I had in my disposal at the time. There was the need to improvise the coffee maker body structure to fit the heat actuator I bought (it was really big - more than expected when purchased).

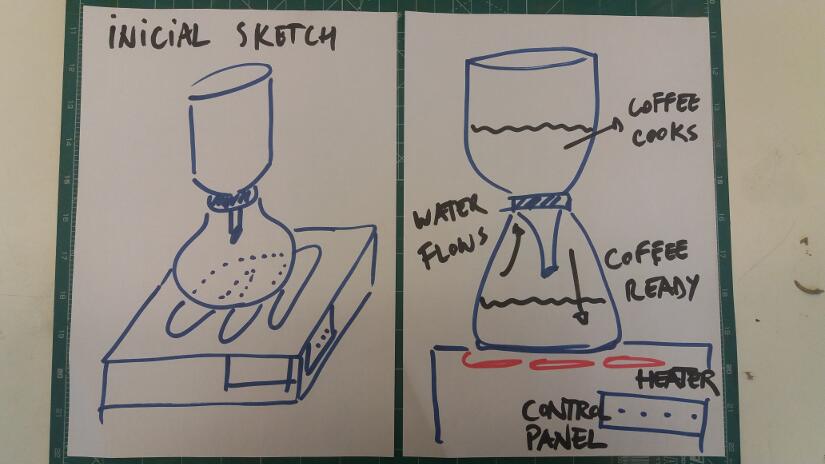

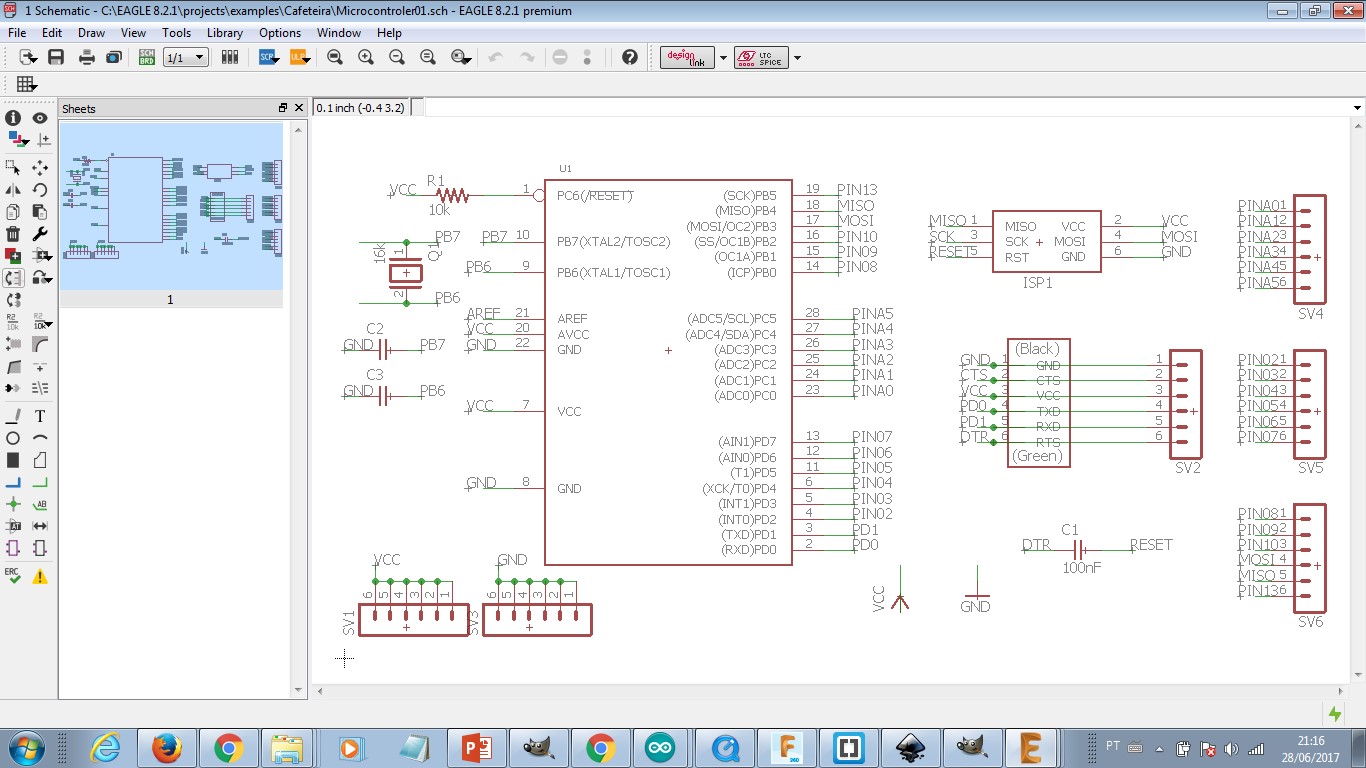

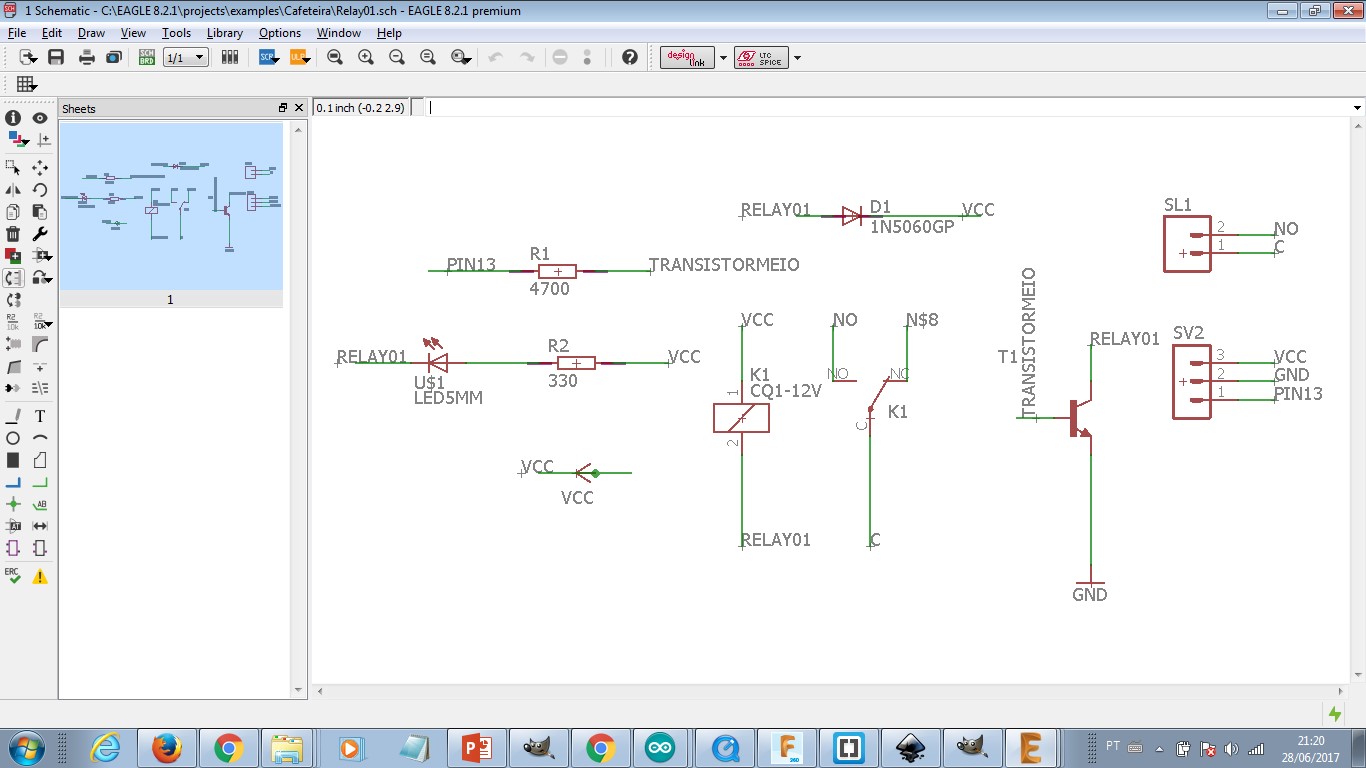

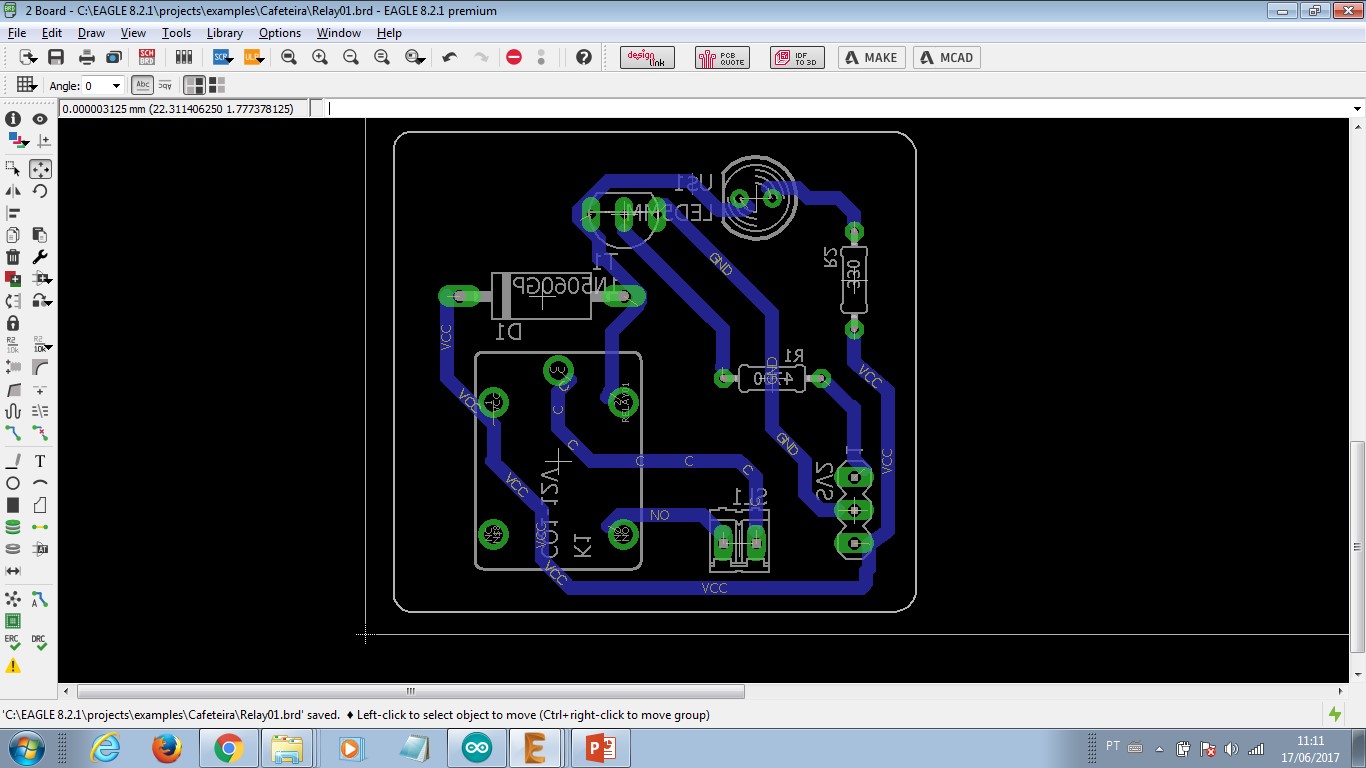

My final project is a coffee maker. What I did achieve is a heat actuator controled by relay integrated with an user interface with keyboard and LCD display. All of that has a self design microcontroler AtMega328 board.

I assembled a grill - heat actuator - over a bed - very smooth rock milled and shaped - in a way I could control how much time the heat is turned ON and OFF so that the coffee would be as the user whished.

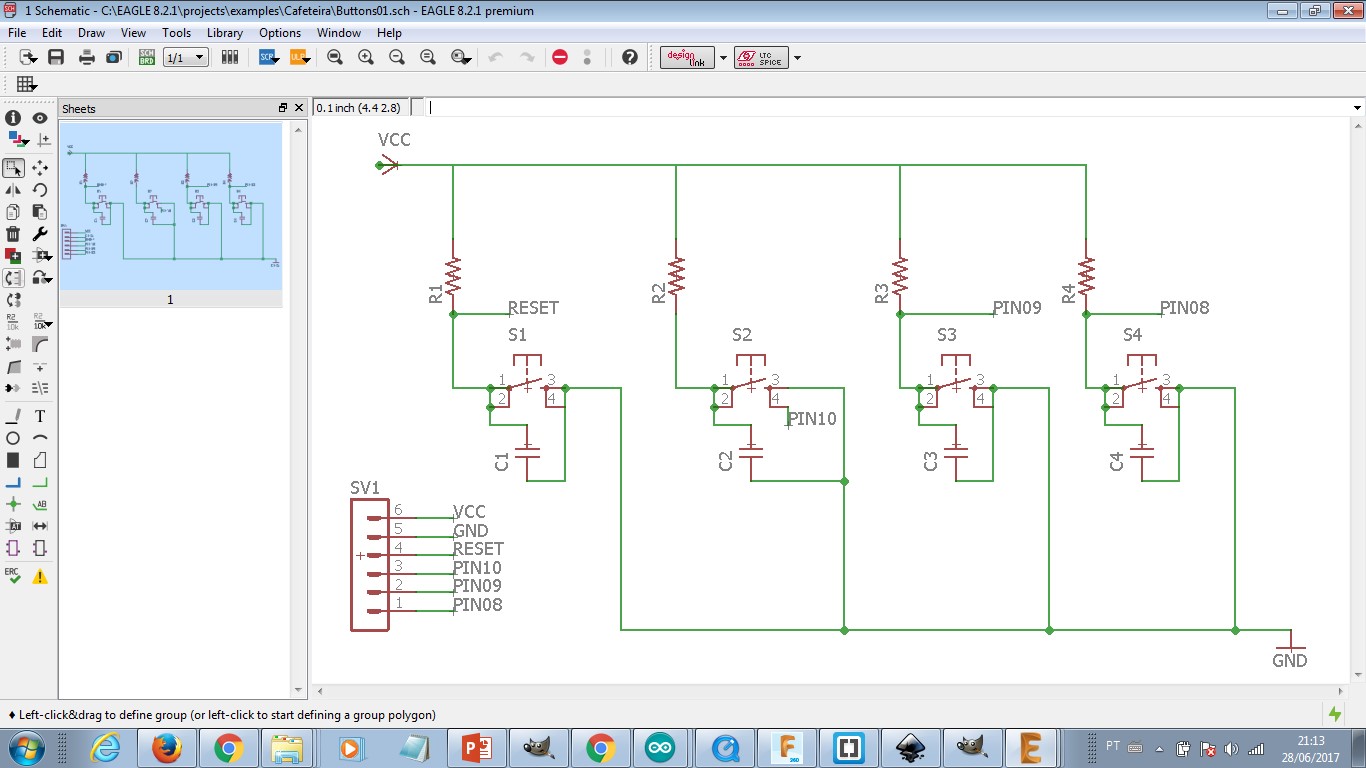

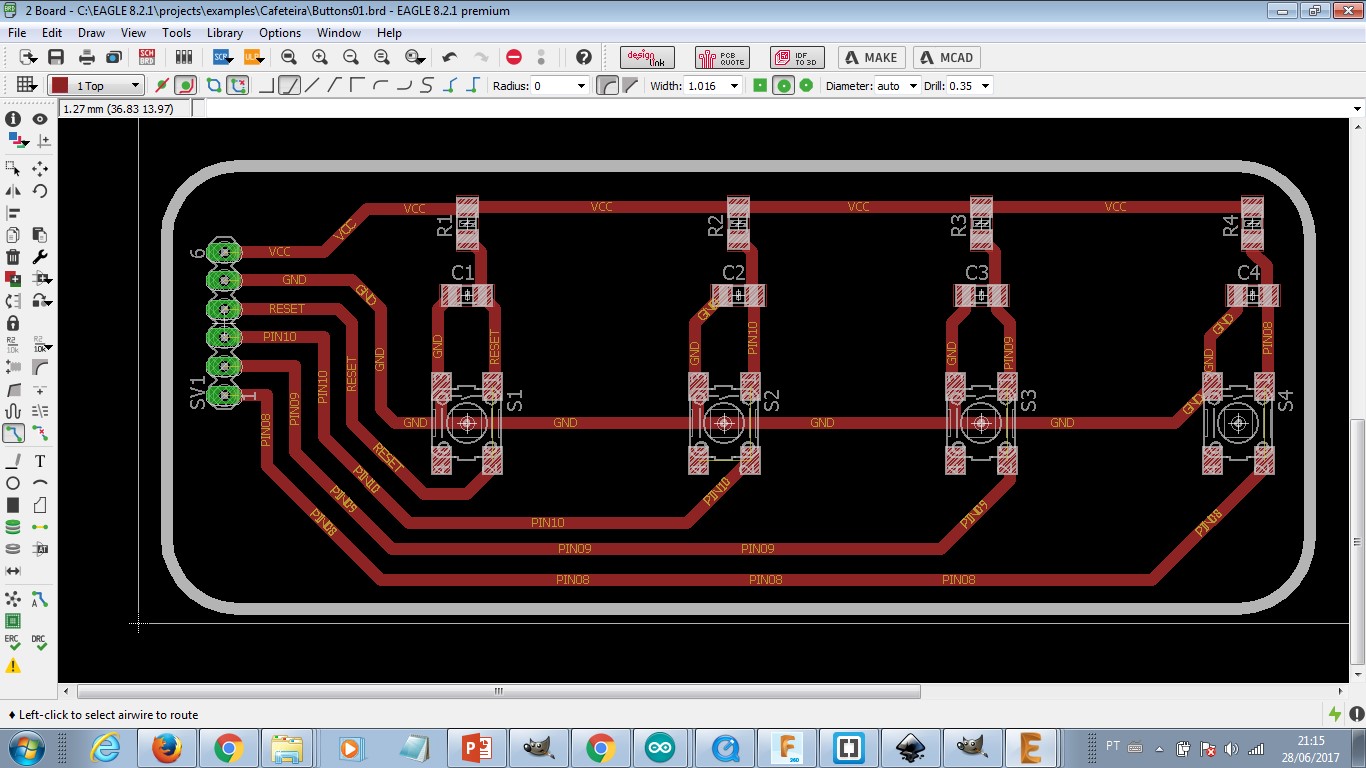

In order to perform the user selection of its best coffee mode I programmed 03 different modes. I also added a Reset - StandBy mode - button to the keyboard. A LCD display shows to the user what is going on.

Energy supply is supposed to be 220V power source for the heat actuator. I have a second energy source - 5V - for the control board. Unfortunately, there wasn't time to put those together at this FabAcademy round.

The project as it presents itself has a very reliable controled heat actuator. I imagine to have a good coffee from it in the future, but besides that, the bad coffee of today and the whole amount of different applications a controled heat source has is, in my opinion, a good achievement.

The tasks I still have to complete are: finding a nice way to fix the filter and the coffee so it works properly and produces a nice drinkable coffee; make a better case for the eletronic part, put the cables together and create some harmony and order with display and keyboard layout; make the BOM.

Questions about a better documentation and how to build a good website always return. This is a skill I learn just the little bit and find it handy. I understand that keep researching webtools and make future websites better. This is going to be a key personal development, once communicating through internet is standard at our times.

As I have previous experience with 3D printing and cnc milling, the eletrocnics and Arduino IDE whole project were the most important learn experience - regarding practical knoledge. The systemic view of a project and the idea of network development that FabAcademy presents is really the best I learned. It is, for me, a new way to communicate, distribute and share information and knoledge. This course is very demanding in time and energy, but it pays off because anyone can improuve itself and help other to do the same very fast.

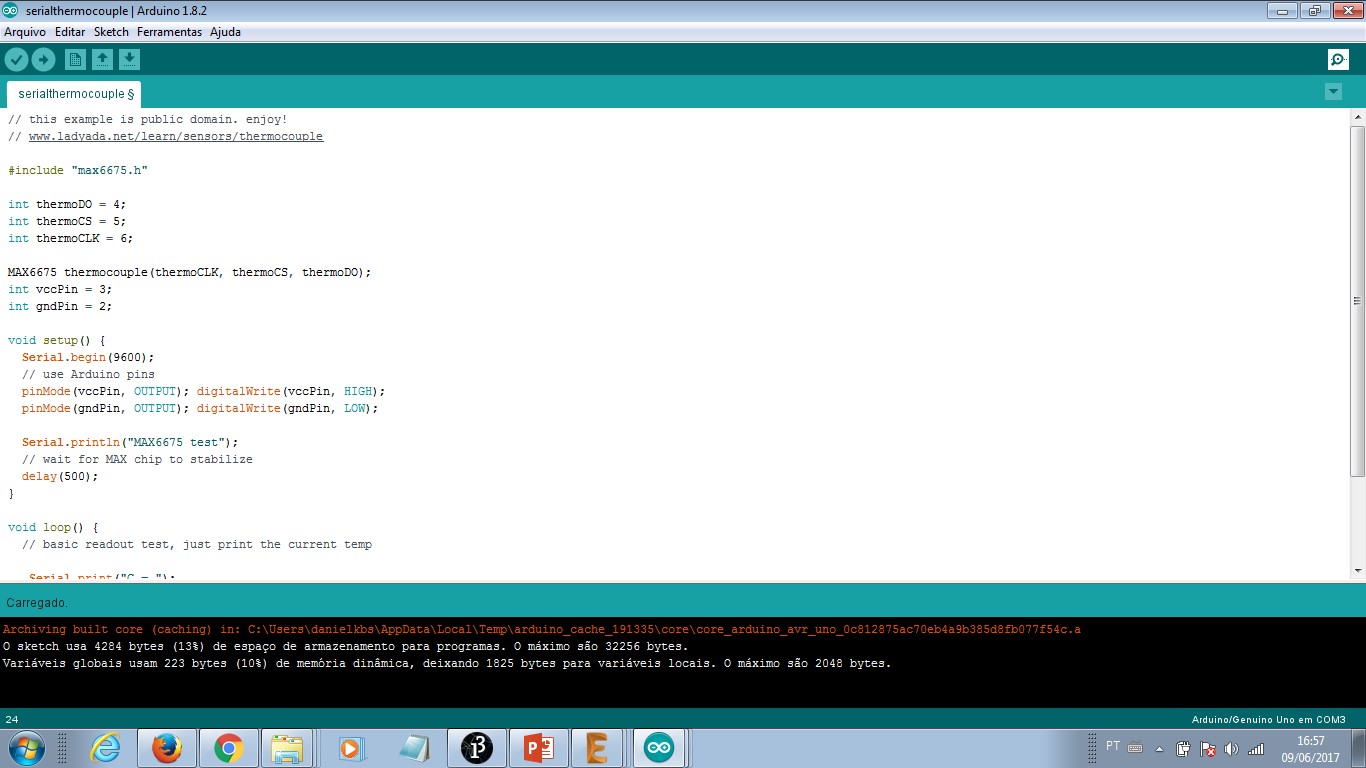

The processes that will be used are: programming (the system integration, microcontroler board programming, user interface and relay control with Arduino standard), output devices (LCD display programming and user interface development - Relay controled heat actuator), input devices (keyboard as user interface and thermosensor as input control to system Modes management), eletronics design (microcontroler board to manage the whole system actuator and user interface), mold and casting (developing a cork that would attach two diferent shaped glasses), computer-controlled machining (final layer design over the rock surface) and laser cut (a final box to put the controls and cables inside it).

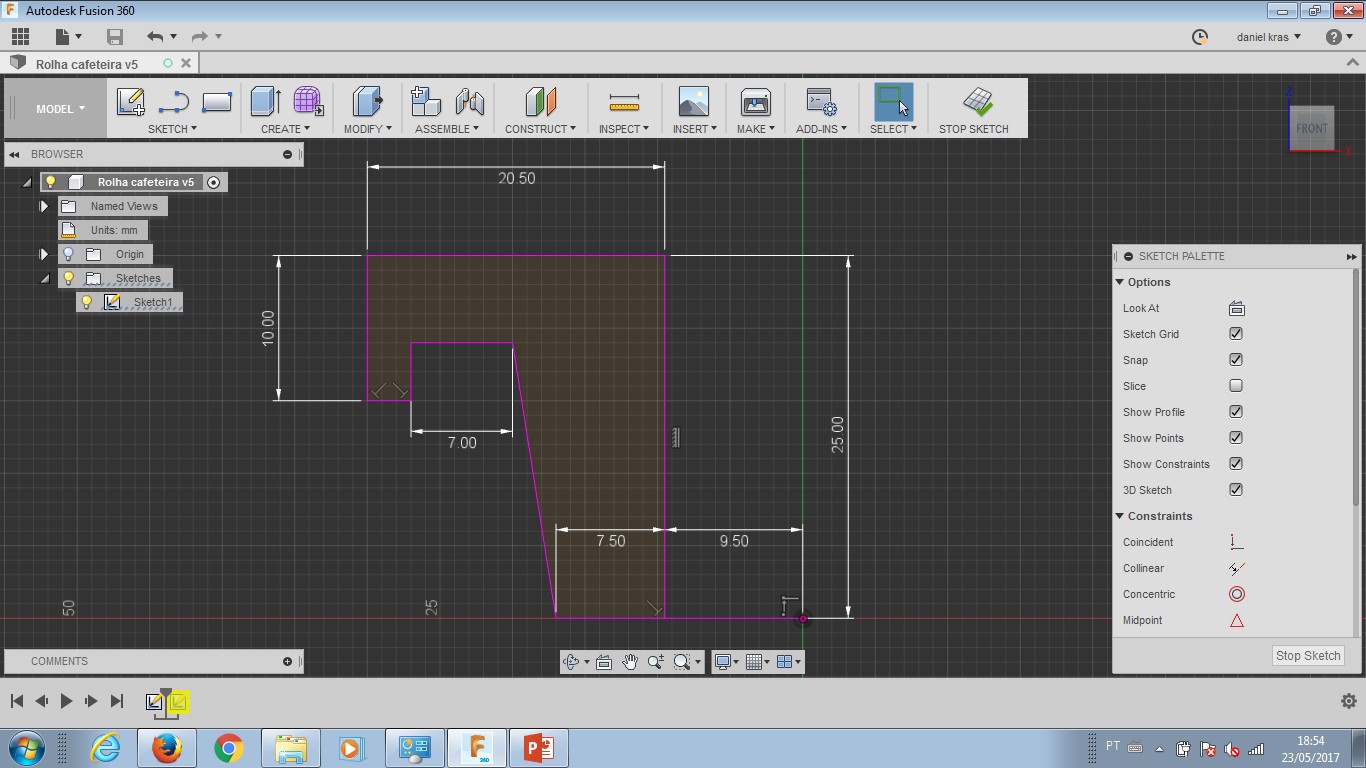

Design files: rock work

- I design straight in VCarve the shape I wanted to have from the rock block.

- All VCarve files will be found: in this folder.

Extra design files will be found in exercise13 and exercise15 regarding control system.

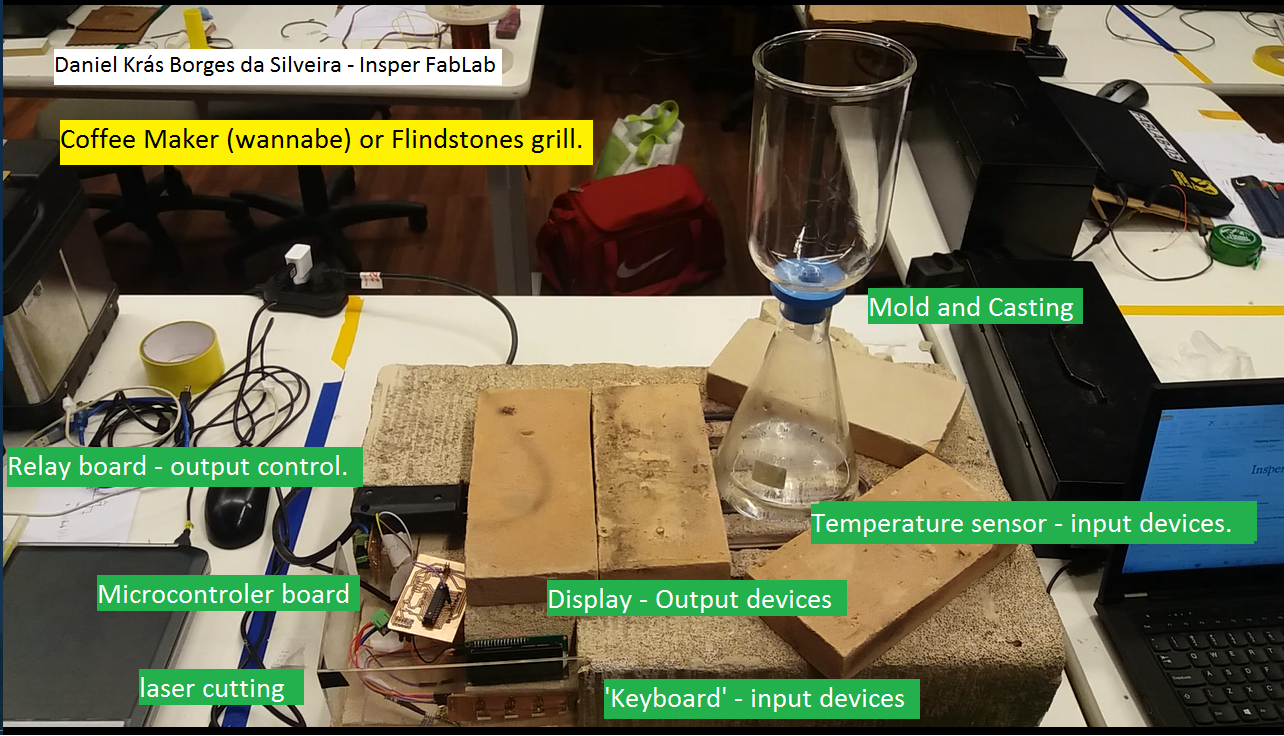

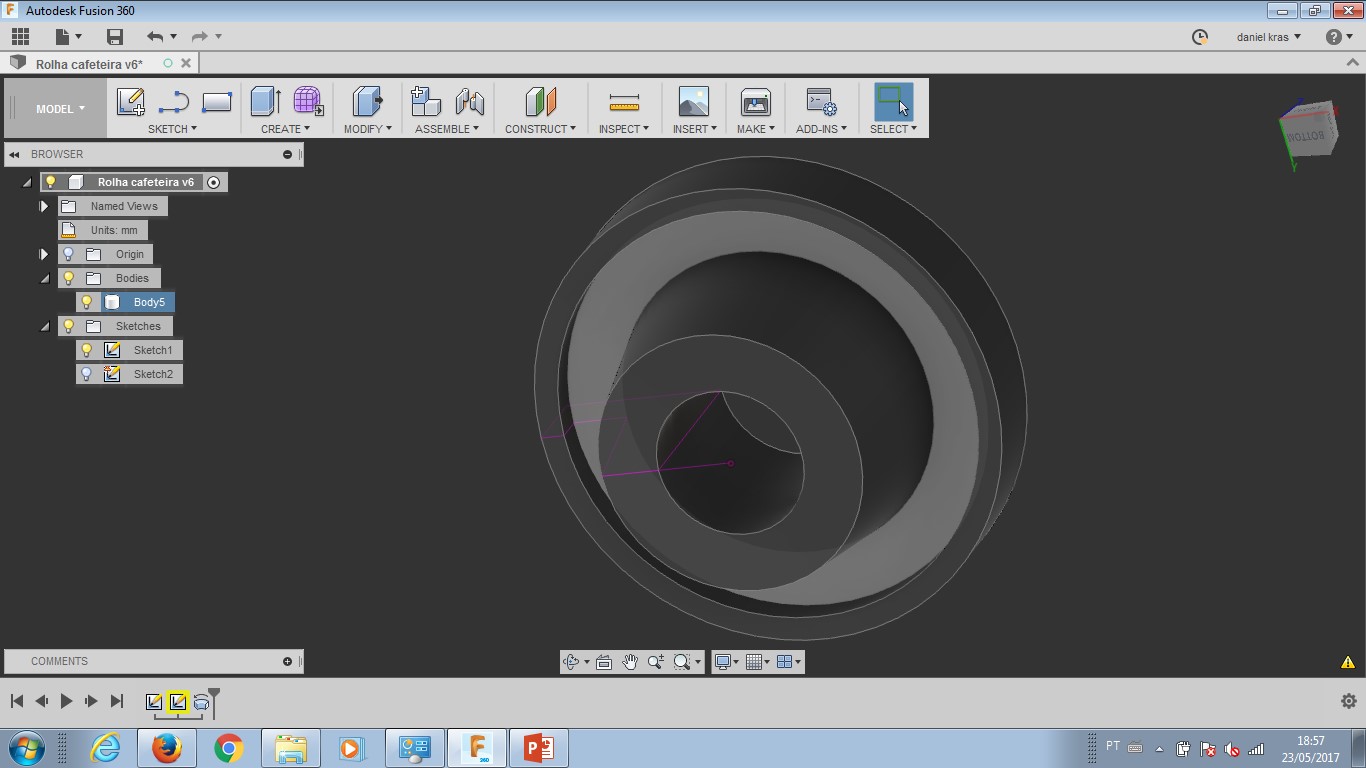

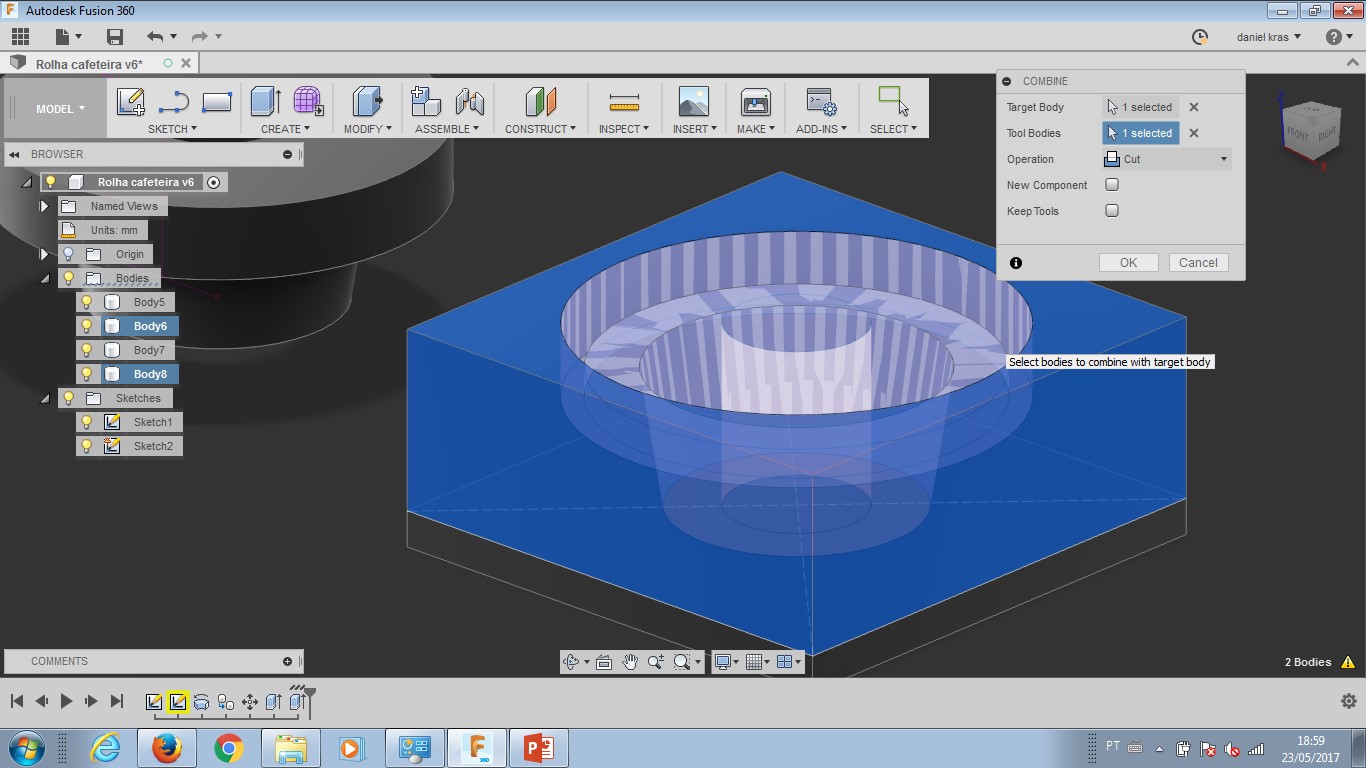

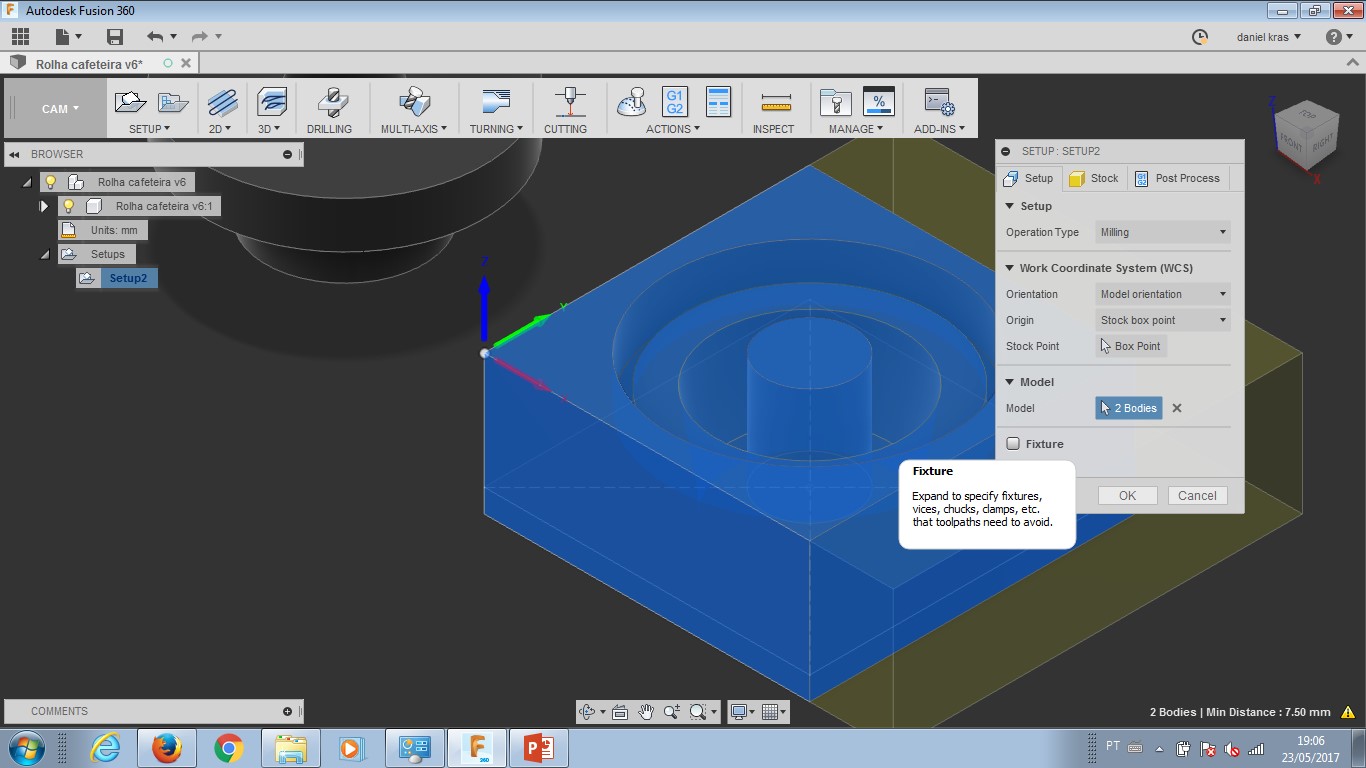

Cork desing files:

- Fusion360 project and STL files in this folder.

Cork production was similar to mold and casting week. Blue silicone rubber was the material I used for the cork itself and green wax for its mold. The same machine and tool setup was used.

Milling the siporex rock (which is a very, very smooth rock) in shopbot was no trouble at all. I had a 6.0mm diameter endmill 4 flutes and I selected woodmill parameters to cut (exercise create something big will give cuting parameters).

.jpg)

.jpg)

-----------

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.