WEEK 4 - ELECTRONICS PRODUCTION

ASSIGNMENT

- Make an in-circuit programmer by milling the PCB, then optionally trying the other processes

MAKING A FAB ISP

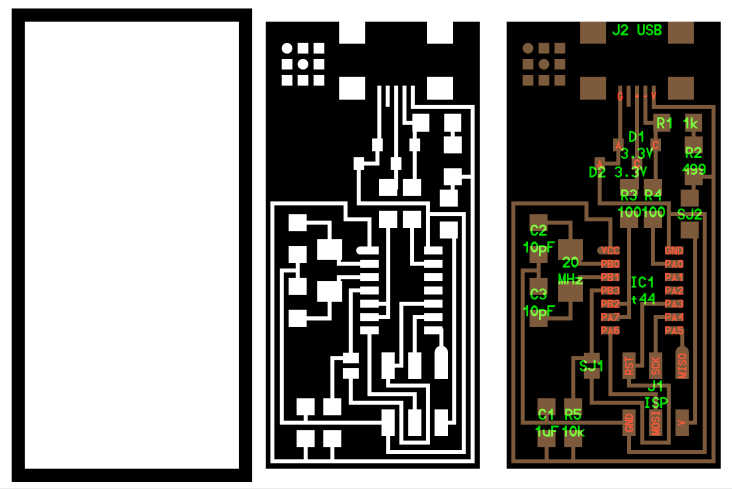

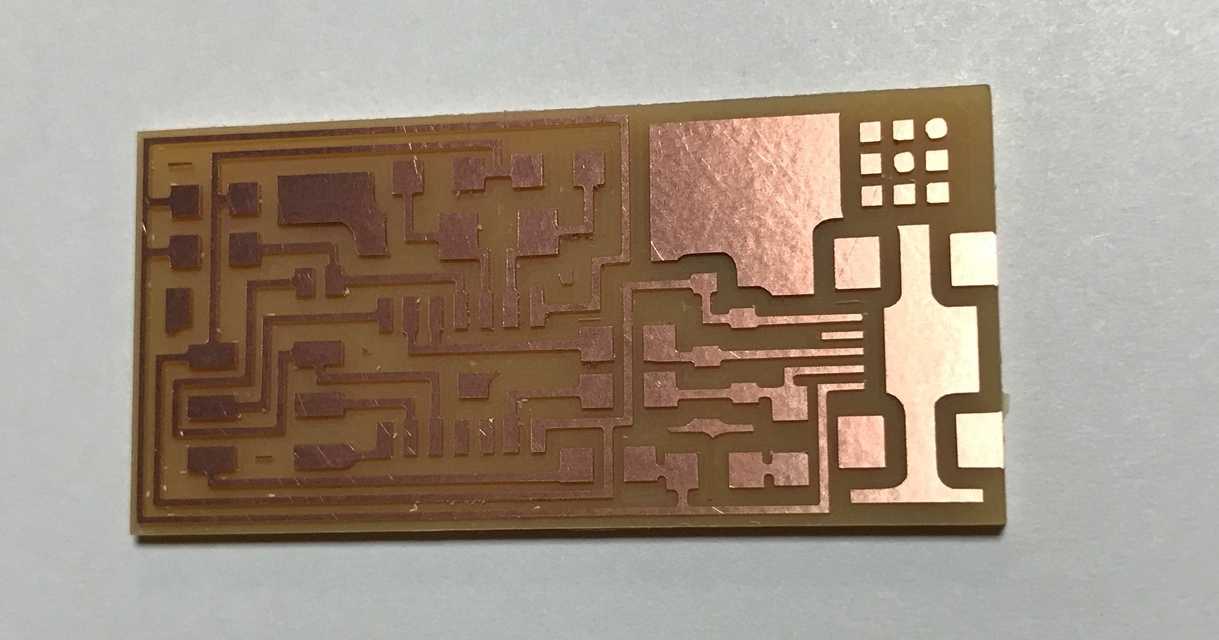

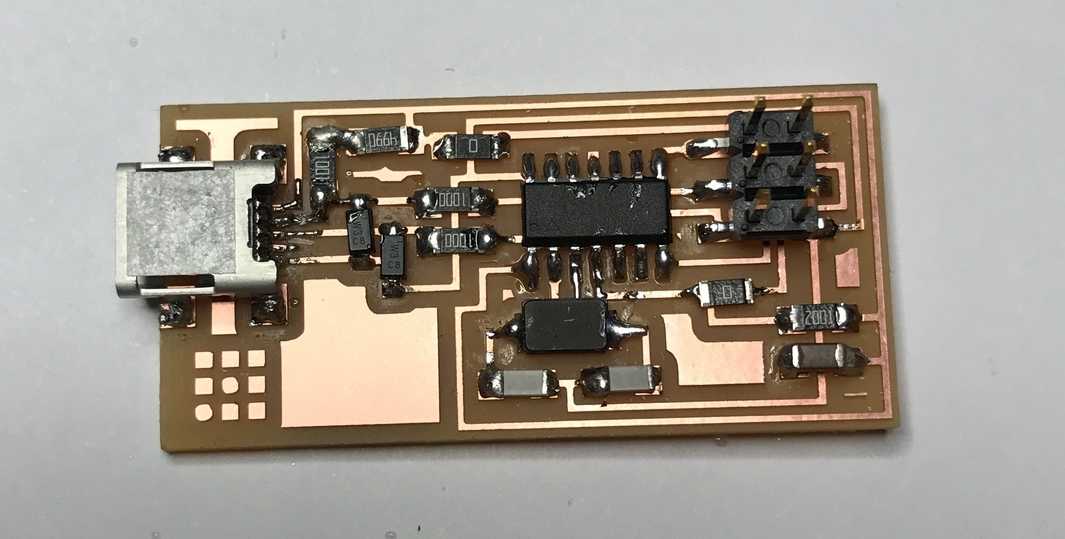

This week I made a Fab ISP programmer. Fab ISP is an in-system programmer that is designed to communicate with other software programs. The first photo is a PNG image that cuts the board from the PCB plate. The second photo is also a PNG image of the circuitry that the machine will mill. The machine mills around the white parts and forms a thin circuit on the copper on the PCB board. The third photo shows the installations for the components.

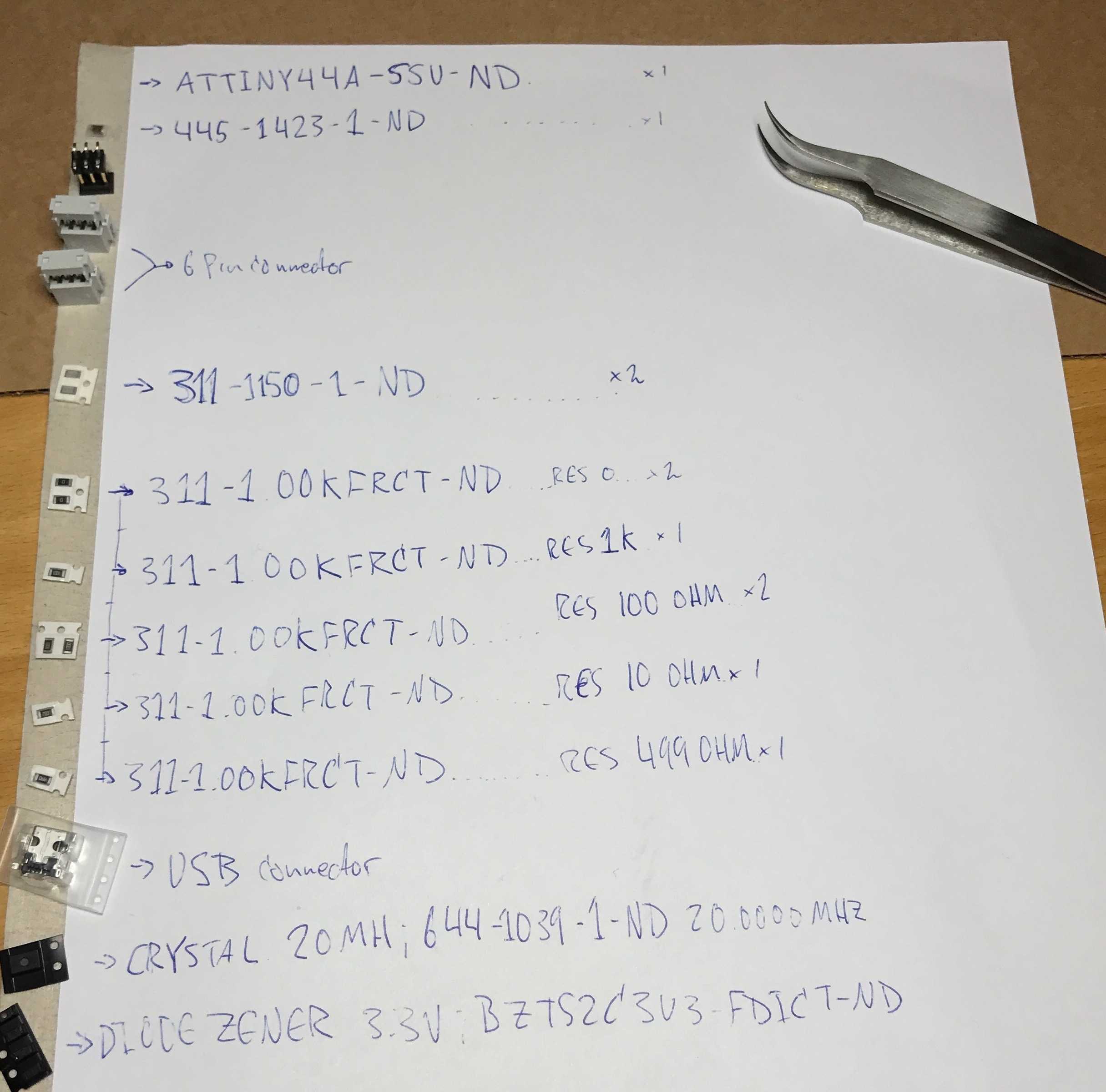

The Fab Lab here in my hometown has a electronic workshop which contains everything I need to make circuit boards. The list of the components for the Fab ISP are on the image below.

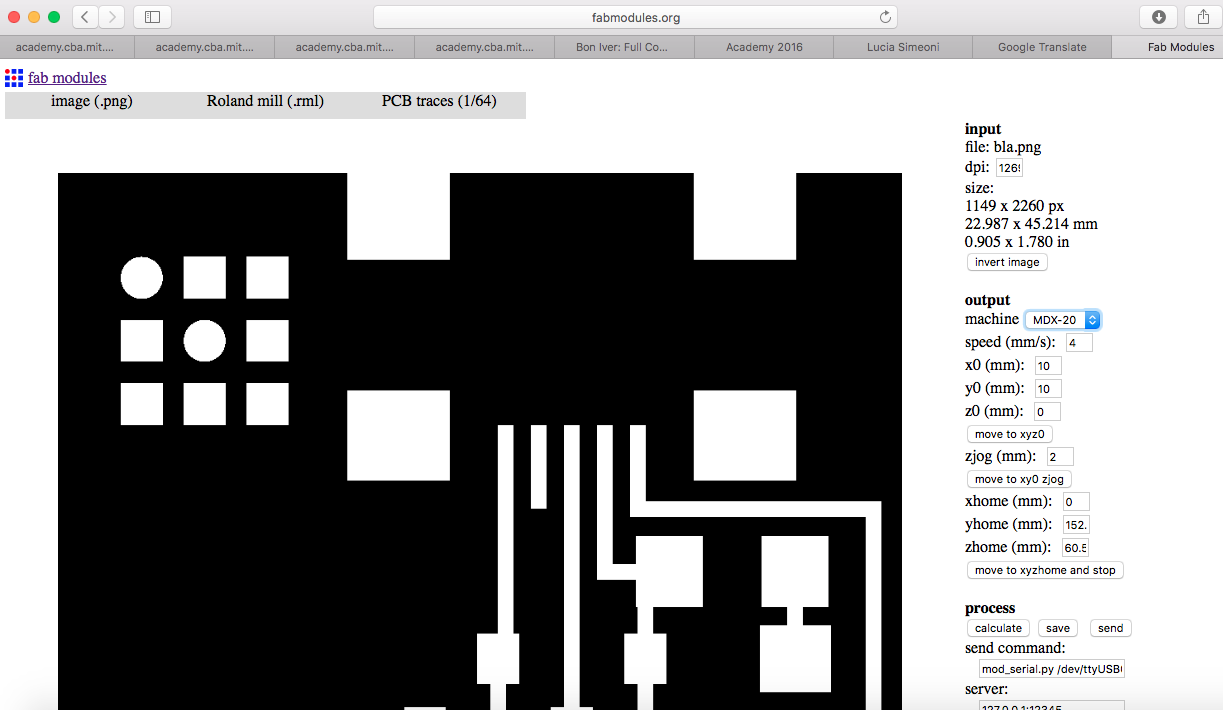

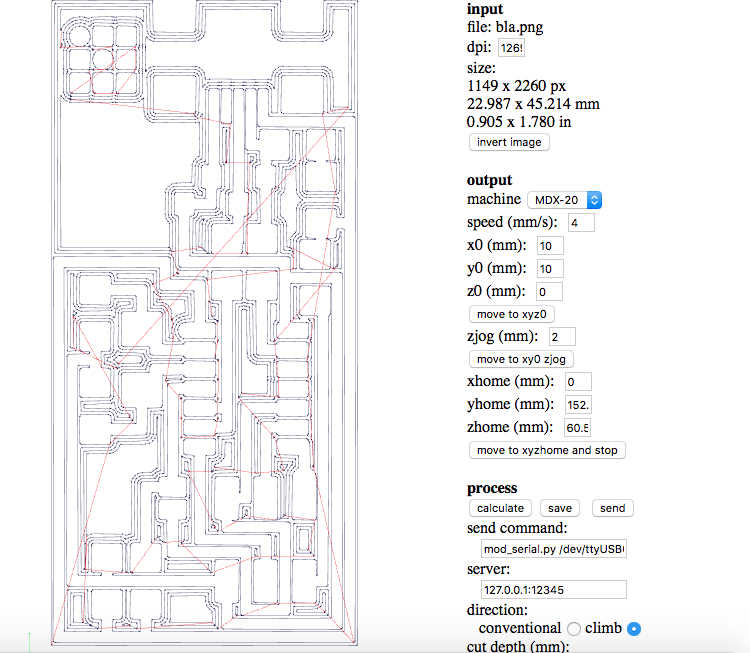

There are four steps to follow before the milling. The website Fab Modules allows you to make toolpath for the milling. I went to the website and insert the PNG image of the FabISP circuit board. Then I chose the Roland Mill (.rml) which is the machine I used. After that I selected the PCB traces (1/64) in the process window, 1/64 is the size of the milling bit). Then in the output window I chose the MDX-20 (Roland Modela).

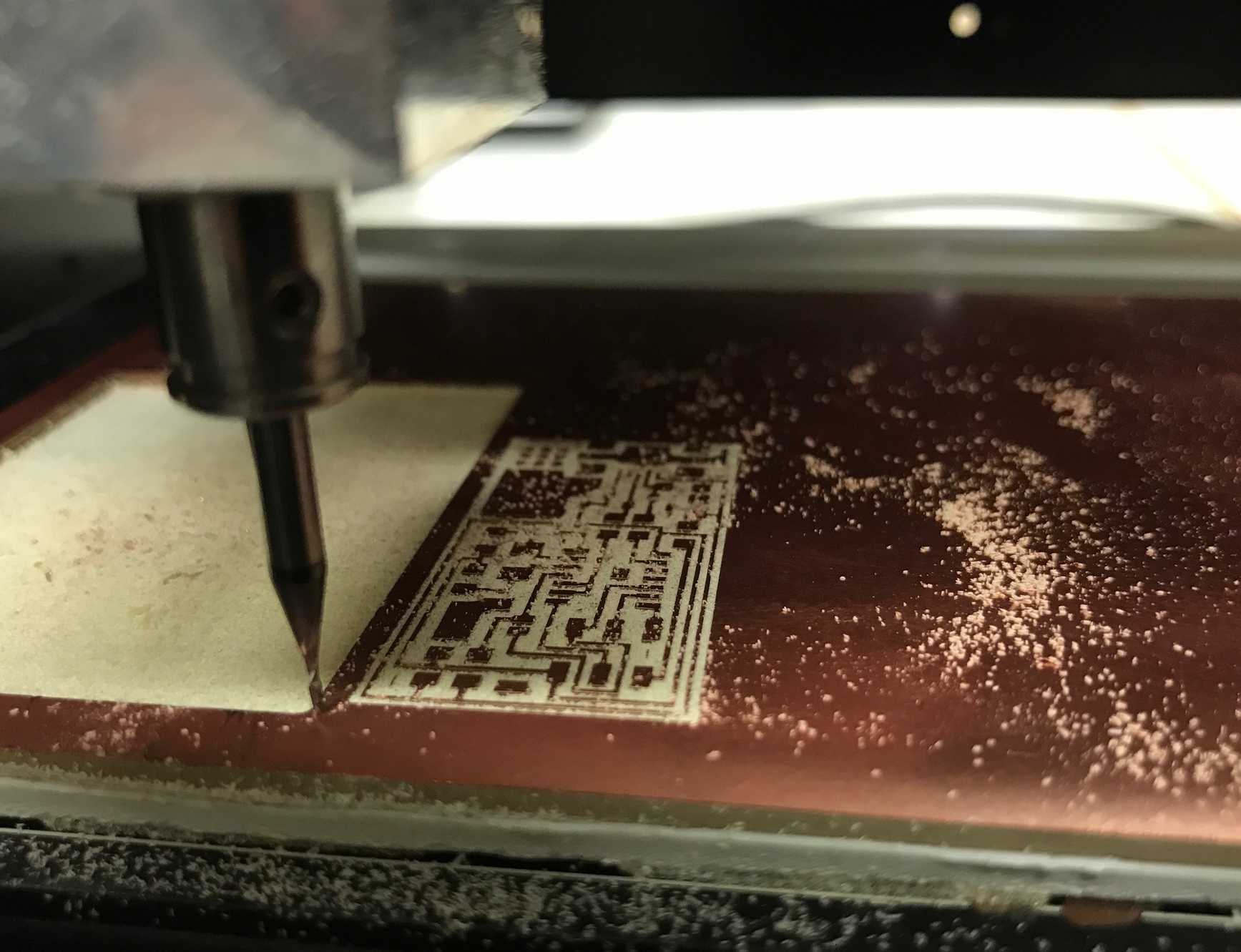

The image below shows the two different drills I used to mill the board. 1/64 for traces and 1/32 for interior.

I put the milling bit inside and located the milling bit and the height. I put the cutdept to 0.1mm.

Then I selected the calculate button to calculate the tracks that the drill would follow.

MILLING THE BOARD

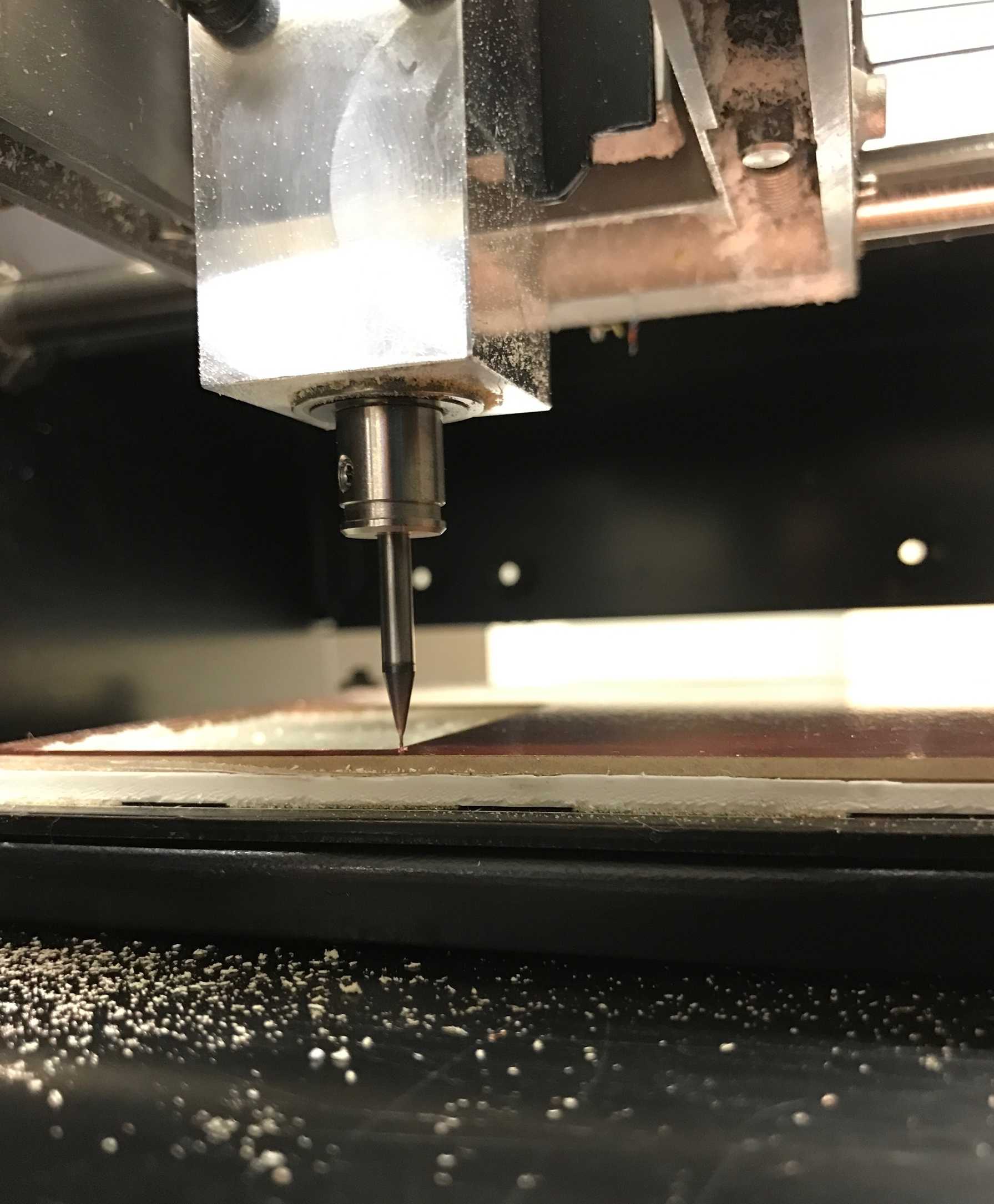

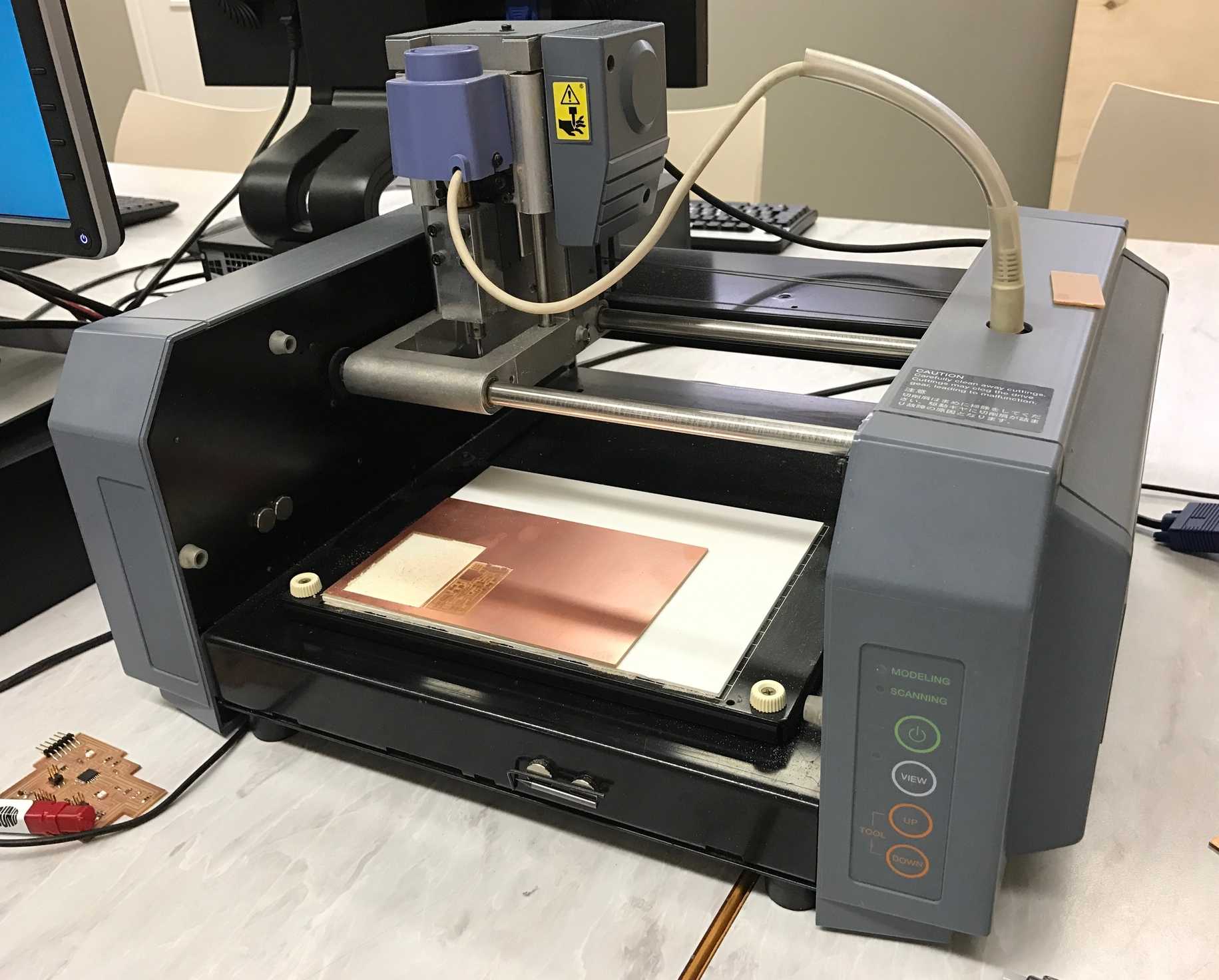

This is the Roland Modela milling machine.

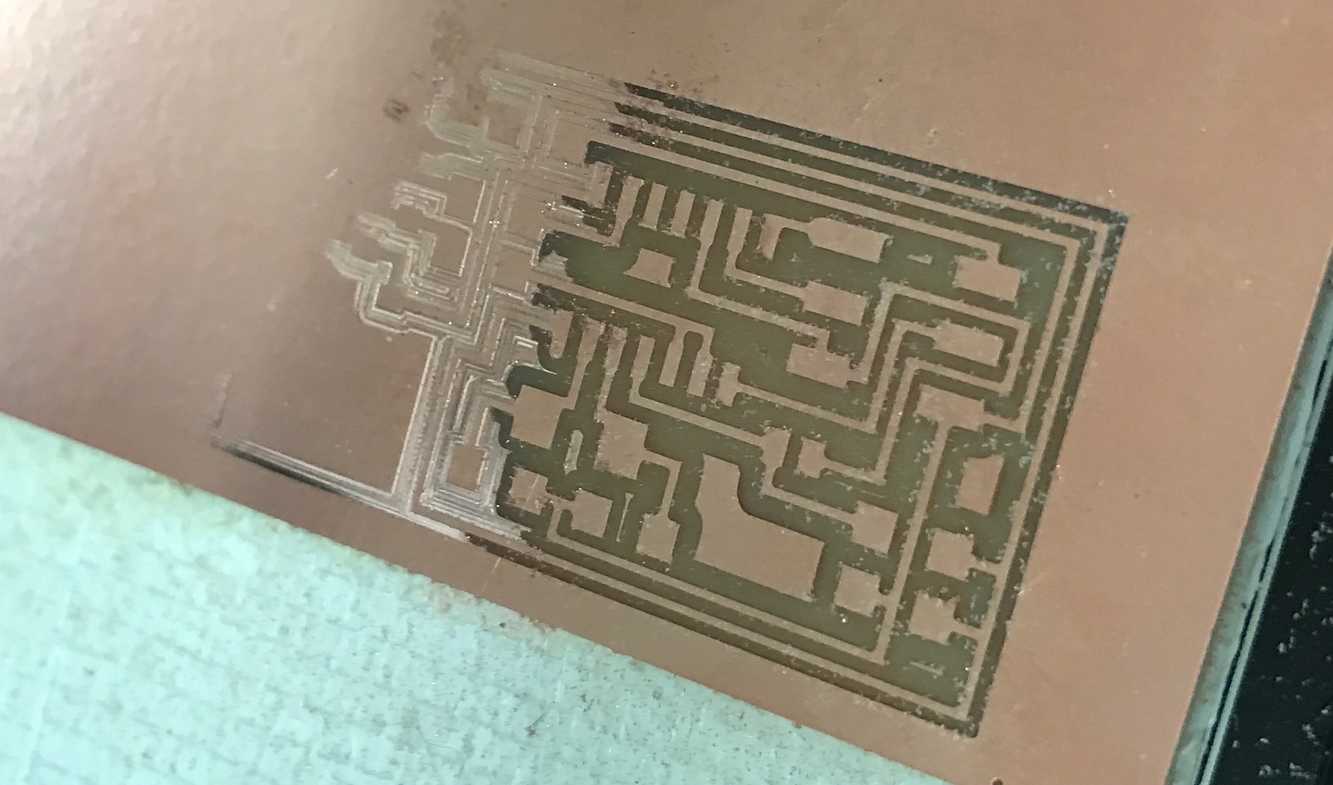

The first circuit board failed because of the height wasn't the same all around, so I had to make a new one.

I had to adjust the milling bit a little and it went the same path like before and everything and was okay.

Then the drill cut the board from the PCB plate. It was really stuck so I used a screwdriver to take it out.

After that I cleaned it with water and then it ready for next step.

This is the electronic workshop we have in Fab lab here in my hometown Höfn. The soldering machine is about 316°C.

It was my first time soldering, it went well. The next step was to program the board.

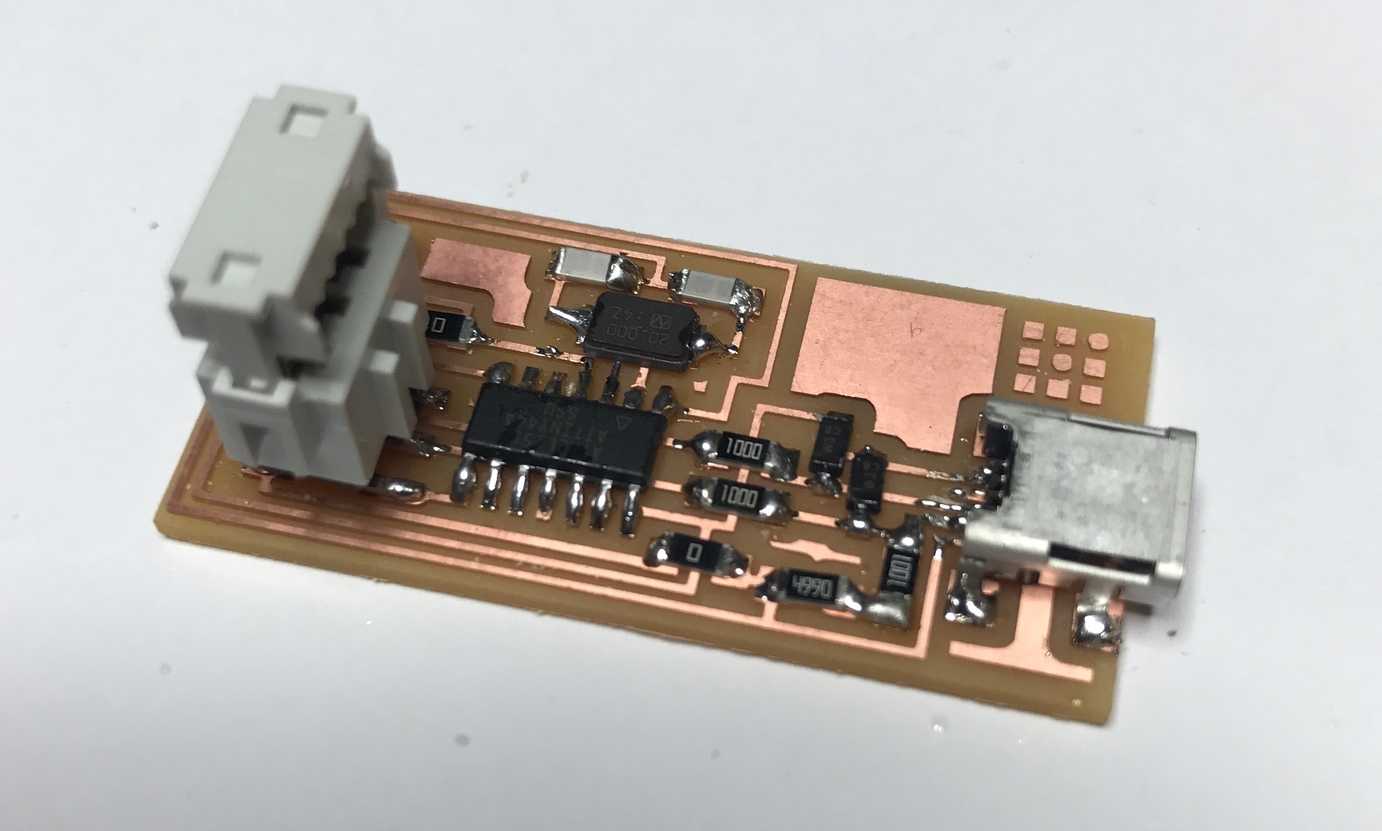

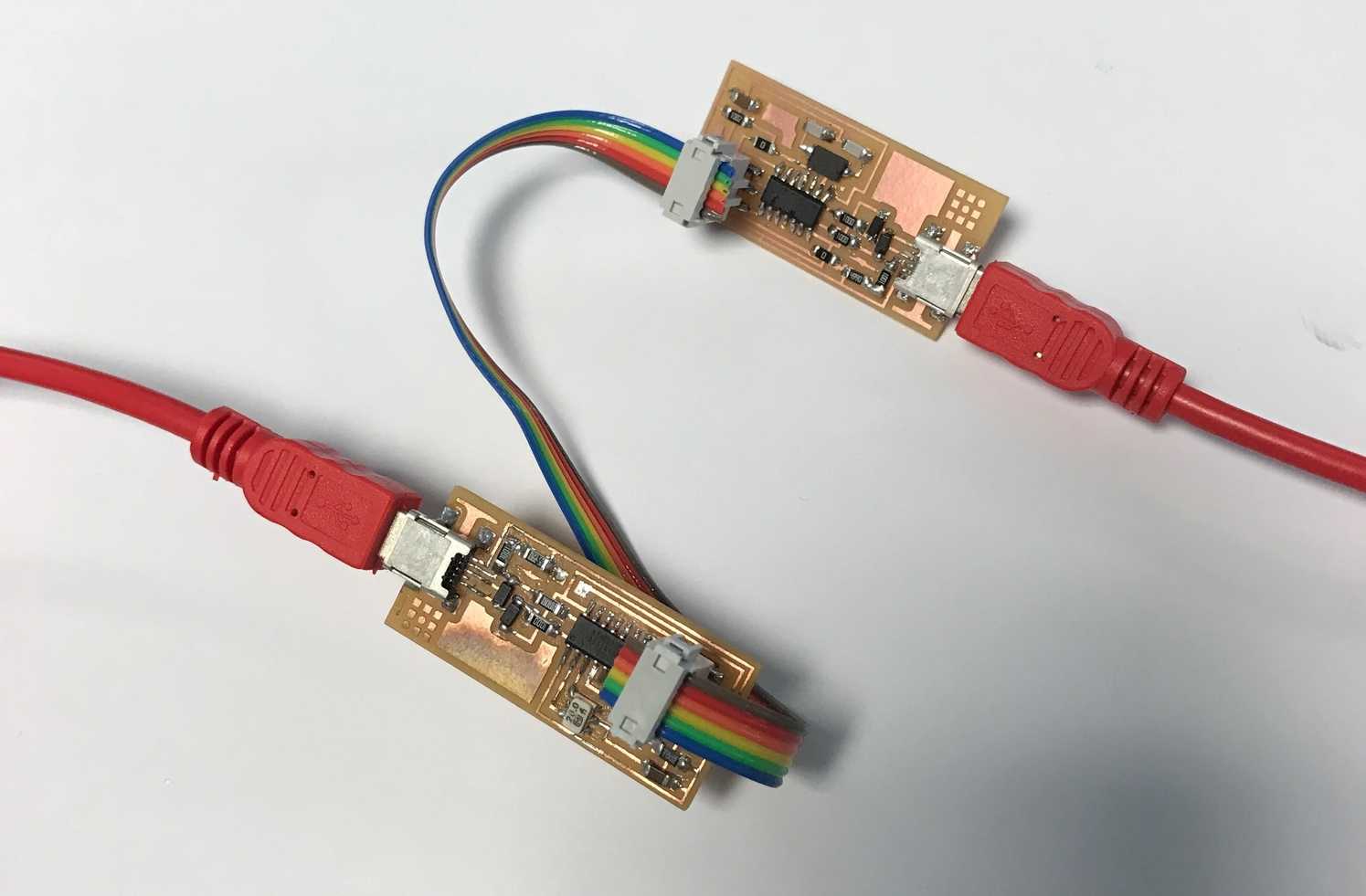

This is a cable I made to connect boards together. I took a six pin connector and pressed it on the cable so it will stick.

Here are two circuits boards connected together. They are both Fab ISP and the second one is programming the first one.

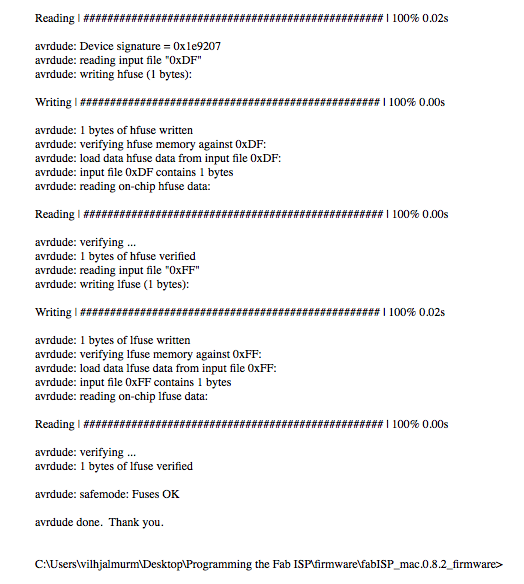

I used Win ARV to program the FabISP. I opened command window and wrote following commands:

make clean

meka hex

make fuse

make program

It was a success and therefore I had made my own program.

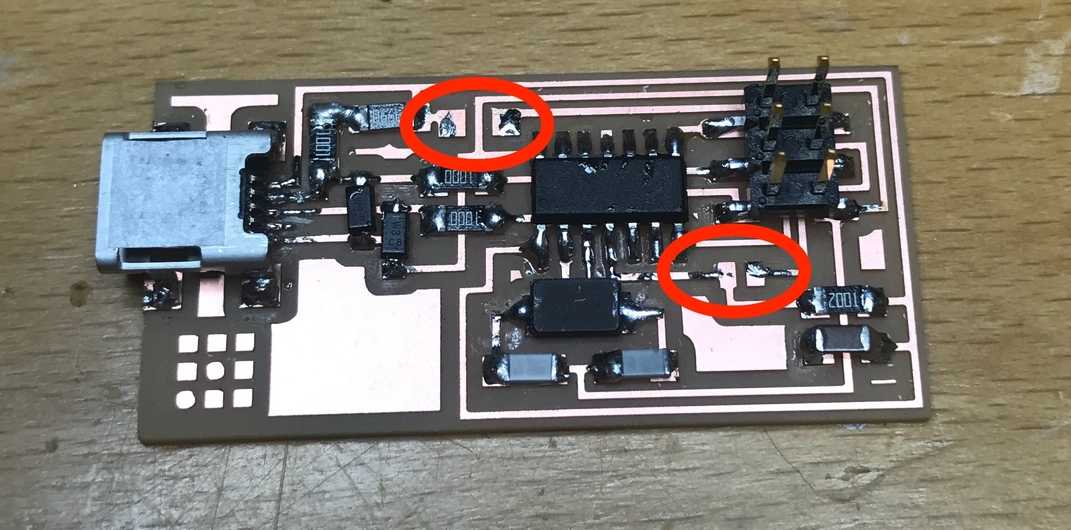

When it had been programmed I had to remove two 0 ohm resistors, one was used to program the programmer and other cut a connection to VCC, so the programmer don’t send VCC out through the 6 pin header.

RELATED LINKS

FILES

Hello.ISP.44.interioir.png - Right click to download

Hello.ISP.44.traces.png - Right click to download

Hello.ISP.44.board.png - Right click to download

HAVE QUESTIONS?

Contact me!

Höfn, Iceland

Email: birkirthorhauksson@gmail.com

Swing by for a cup of , or send me a message :)