1. Laser Cutter

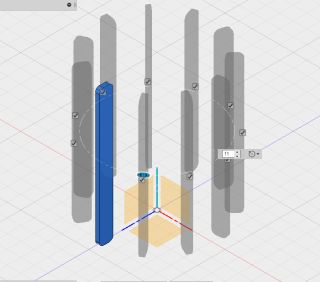

1.1 Module design

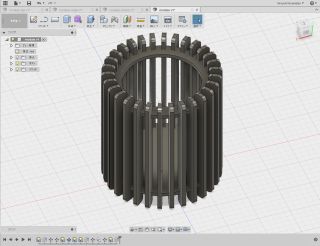

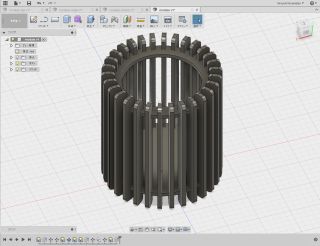

I want to make the tubular module a pen stand.

It is easy to organize if there is a pen stand or a tool holder on the work desk of our Fab. I devised a design that can be extended to any number of stages by combining modules.

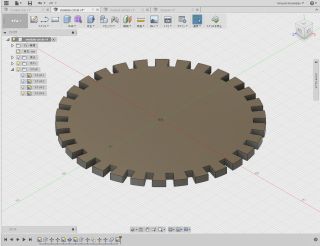

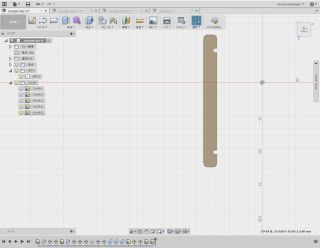

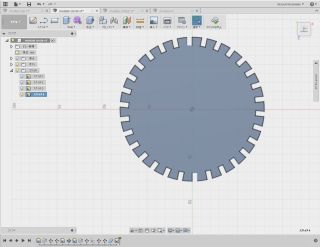

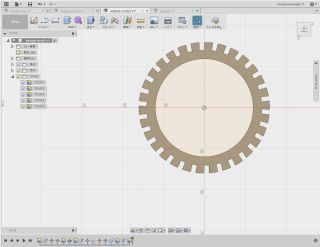

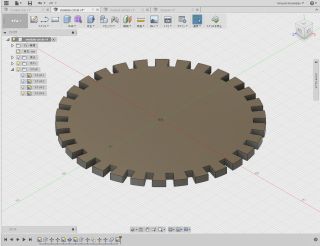

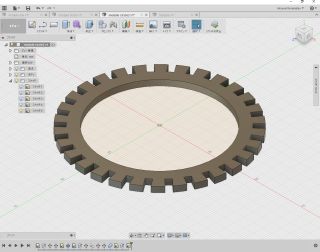

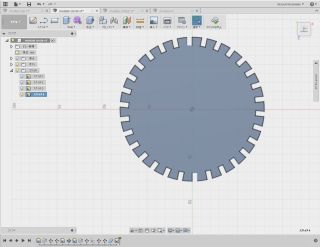

Firstly, I copy the basic parts circularly using Fusion 360.

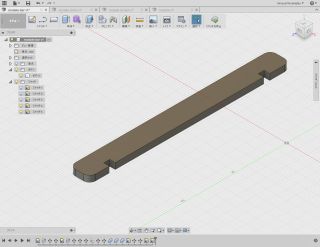

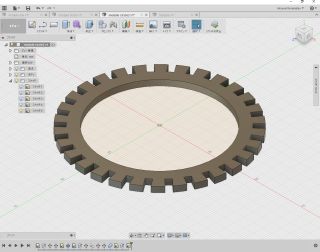

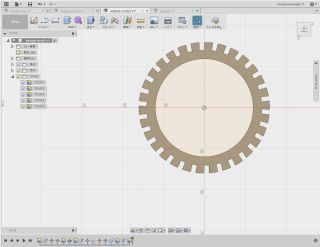

Next, the bottom and lid parts were made. The lid part was cut out by extruding the bottom part.

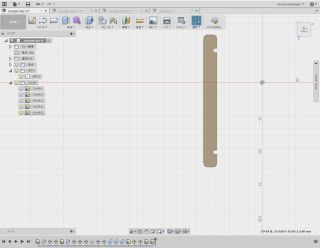

Crossing parts of parts were cut out and disassembled for each part. Cutouts were made in both parts so that they could be firmly joined.

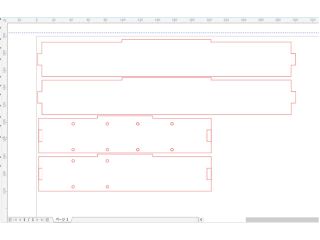

Each part data was saved in DXF format for laser cutting.

Designed parametrically. The basic parts were arranged along the circumference of the bottom part pattern. By designating the number, the necessary number of parts could be properly placed.

1.2 Module processing

1.2 Module processing

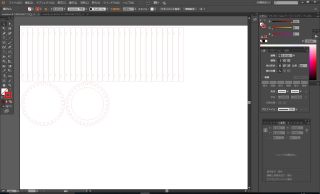

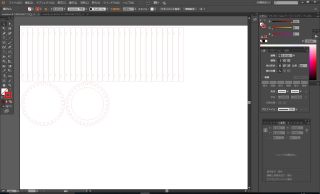

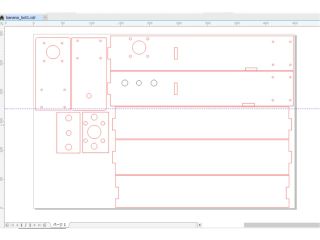

Parts saved in DXF format were read by Illustrator(CC).

The line color was changed to red (R255, G0, B0) so that each part could be cut. Each part was placed and cut.

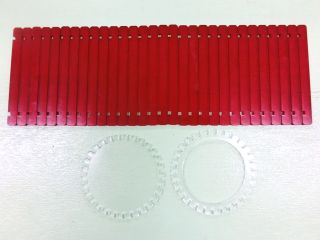

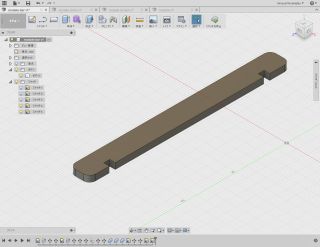

I used laser cutter (

Rayjet,Trote,CO2, 30W) and acrylic plate(thick 3mm) was used as the material.

Setting of laser cutter

- Engraving power = 100%, speed = 65%

- Cut power = 75%, speed = 1%

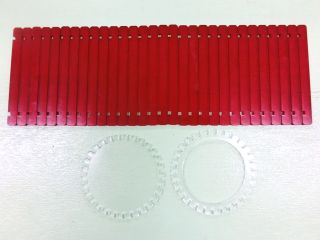

As a material, an acrylic plate having a thickness of 3 mm was used. This is cut parts.

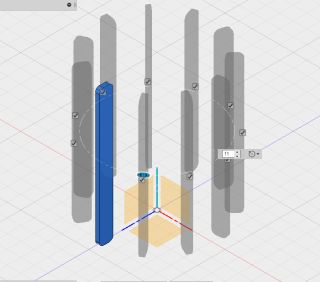

One step is a pen stand. Two step is a tool stand. Three or more steps are possible when joining.

We can wound up the Fab's desk.

2. Cutting machine

2. Cutting machine

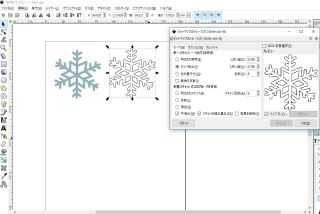

1.1 Module design

Our lab is in Nagano prefecture of Japan which is highland area. For that reason it is snowing outside.

So,I want to cut snow crystals. Because the crystal of snow is very beautiful.

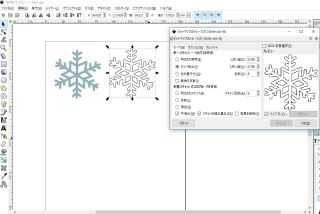

Based on the illustration of snow crystal which was in

the copyright-free site(japanes).

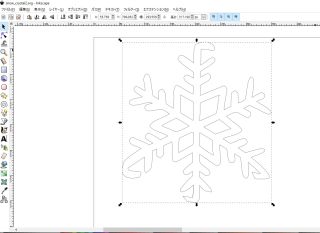

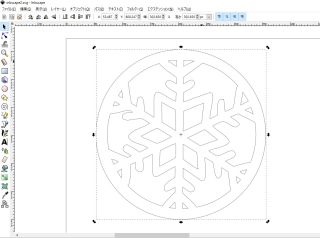

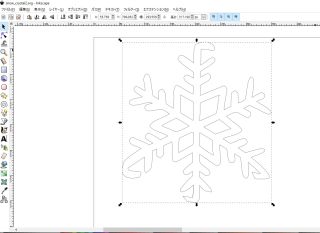

I used Inkscape to outline the image data.

I added a circle to the edge to become a coaster. Also, I created a decorative module.

2.2 Cutting

2.2 Cutting

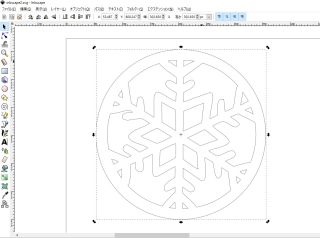

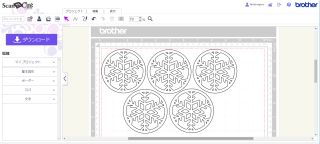

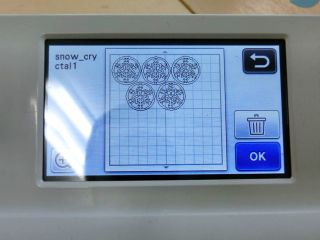

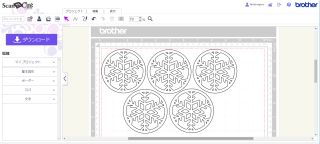

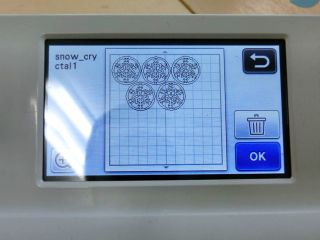

The cutting machine used CM110(Brother)

Paper was cut using dedicated

software of the cutting machine. The data format is SVG format.

This is cut parts.

3.Test parts

3.Test parts

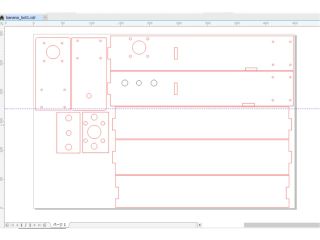

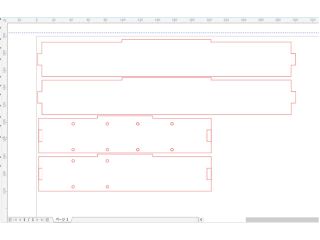

For group assignment, I decided to make machine body from acrylic. I designed the test parts as shown in the figure and cut the laser. The tolerance of parts was designed at 0.1 mm.

Archive

-Laser cutting data of module (AI,Illustrator)

-

Cutting data of snow crystal1 (SVG,Inkscape)

-

Cutting data of snow crystal2 (SVG,Inkscape)

-

Scancut data of snow crystal1 (FCM,CM110)

-

Scancut data of snow crystal2 (FCM,CM110)

This week's assignment is over.