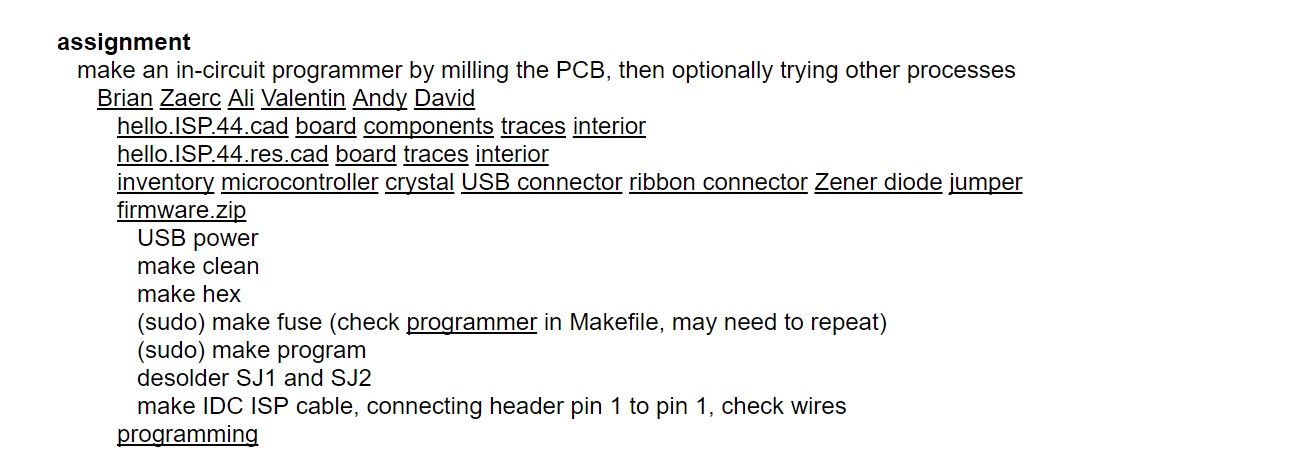

Assignments 4

Electronics production

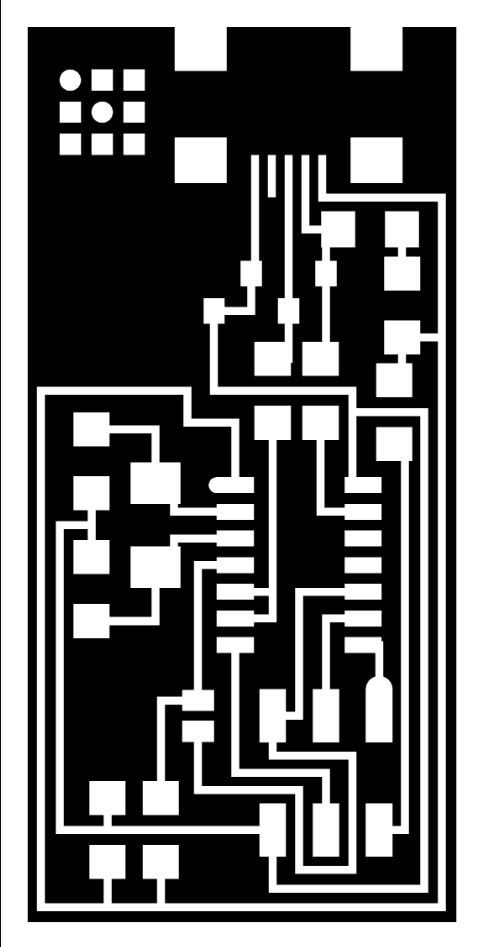

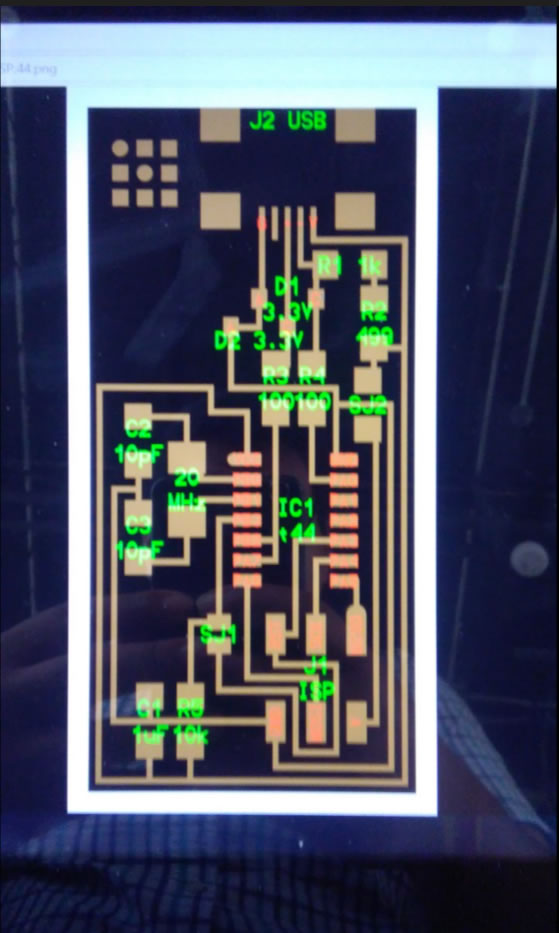

To start, I chose this model from the board suggested in the ASSIGNMENT.

Then refer to the sketch, the necessary components on the board, DIODES, CAPACITORS, JUMPERS, etc ...

Click here for download the files of the board

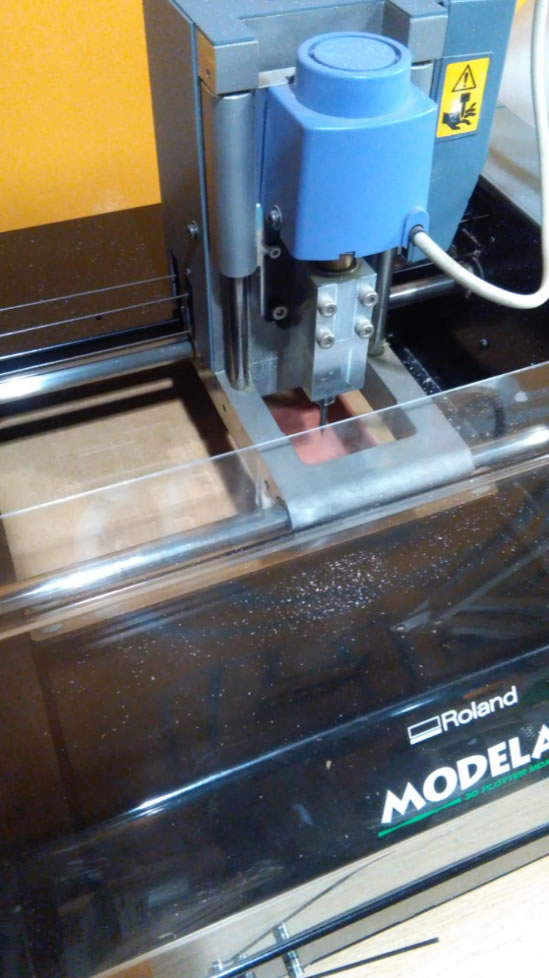

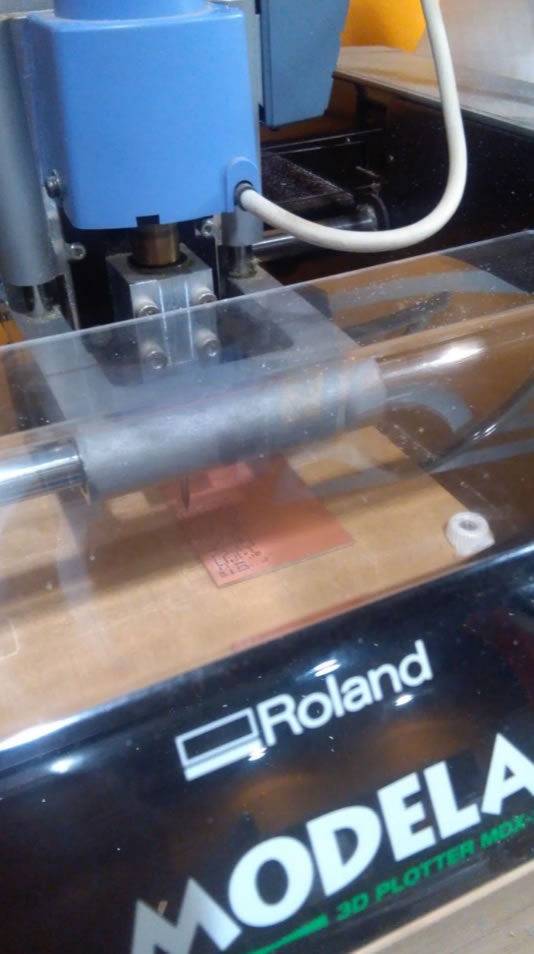

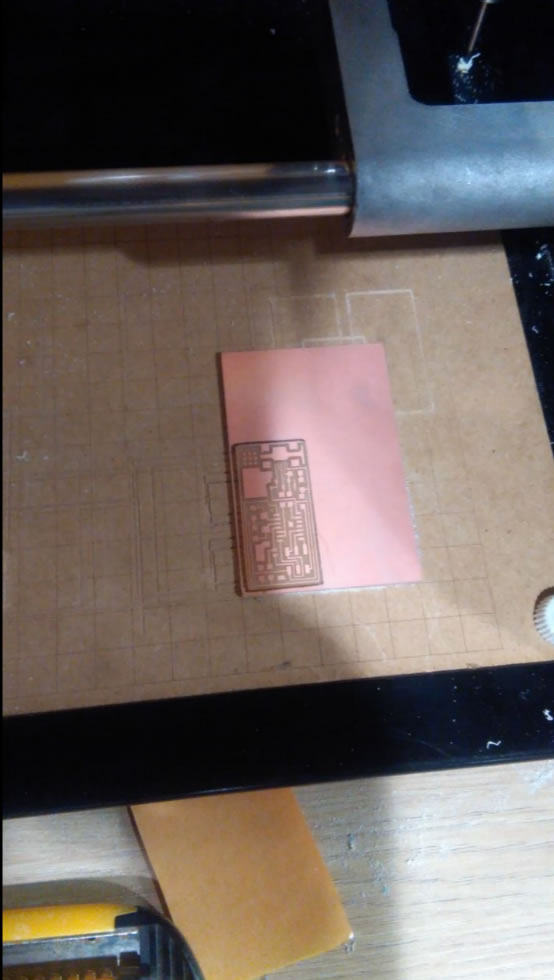

To make the electronic board, I use the MODELA machine to mill the board and create the paths.

First, cleaned the bed of the MODELA.

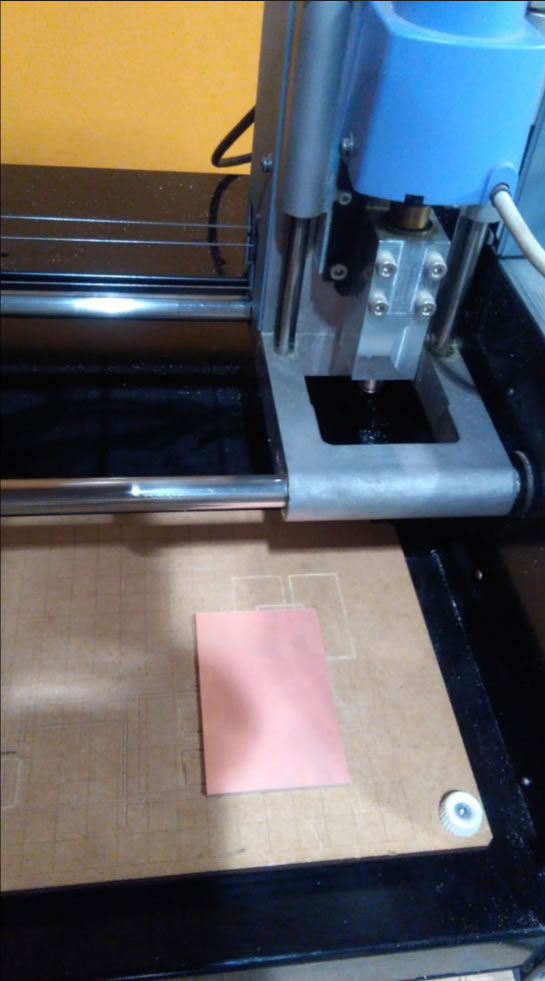

Then, placed the copper clad board on the bed and place it in the quadrants x: 130, and: 2

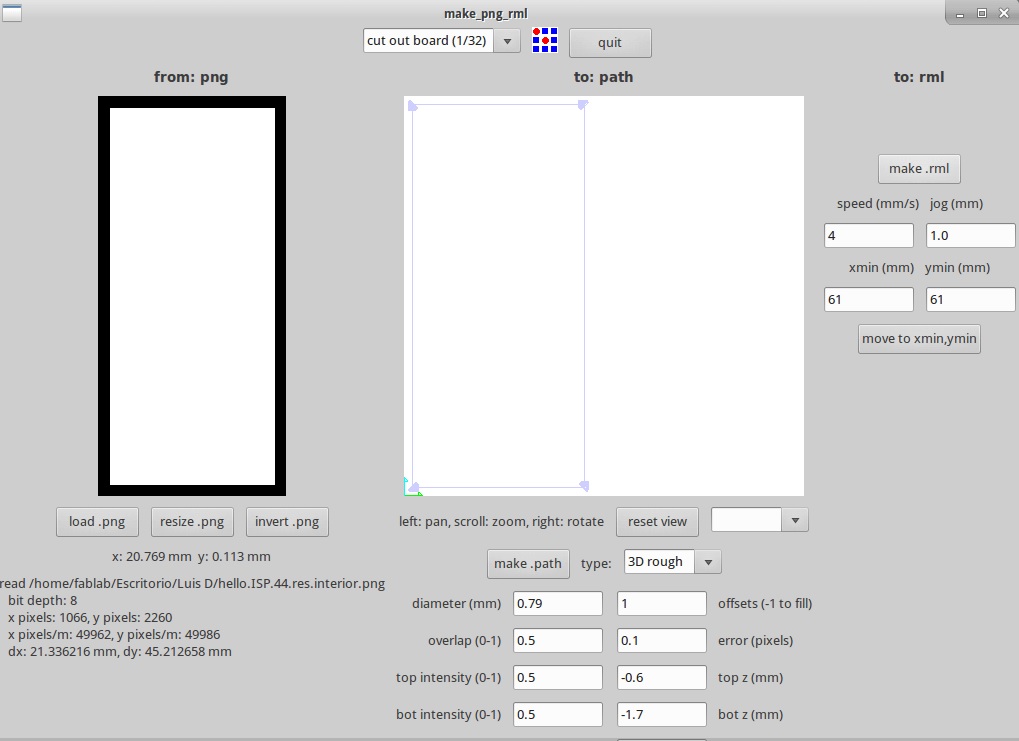

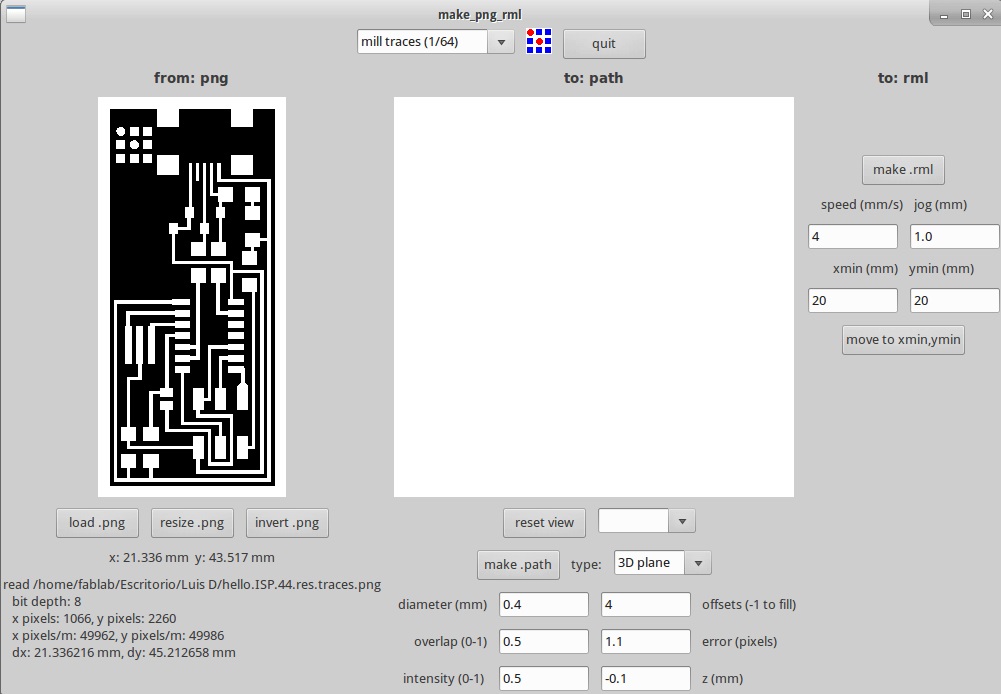

Then, change the milling cutter according to the type of milling to be made (1/64) and (1/32).

Then, open the terminal in LINUX and this is the milling template for the MODELA.

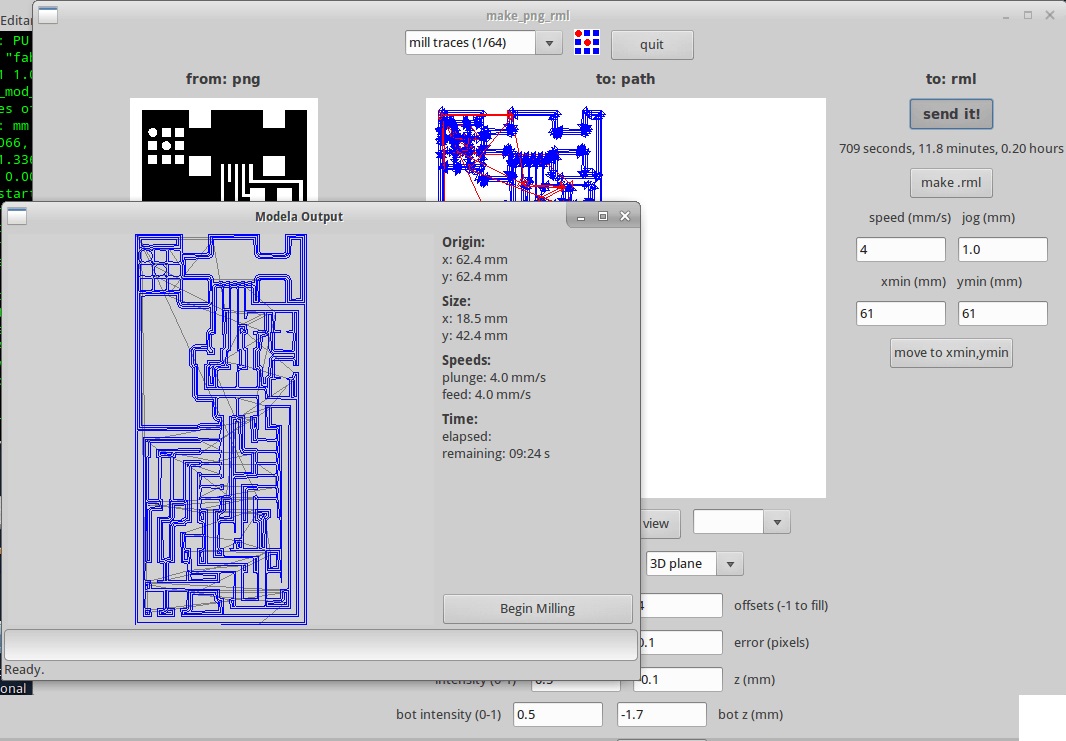

Fab Modules

In order to use the MODELA software, the SUDO FAB terminal is opened, which if configured (FAB MODULES) but we will

use the previous version, since we consider it more reliable to use this version by its validity time, and also because

This has been the module used by other colleagues of the past years, and also because it was recommended by our Local Instructor.

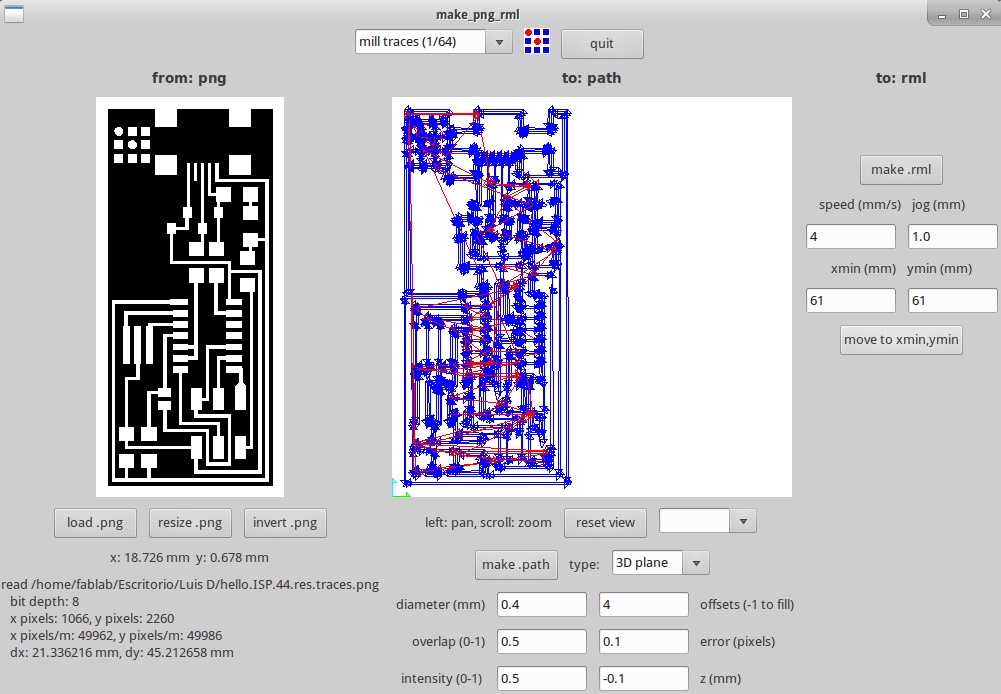

Then, load the file into PNG, choose the mill traces (1/64), and the position per quadrant where the copper clad board is located.

And, I ejecuted the file.

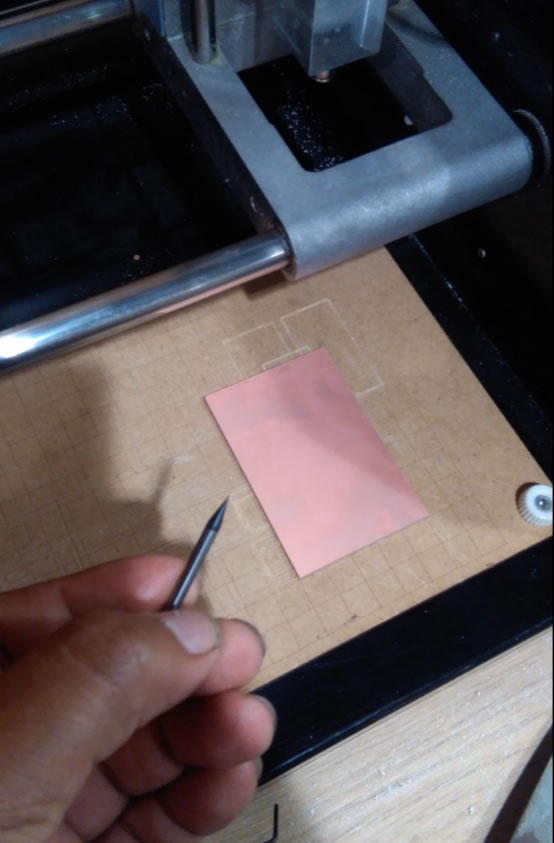

Then, I remove the milled plate from the copper clad board that remains as residue.

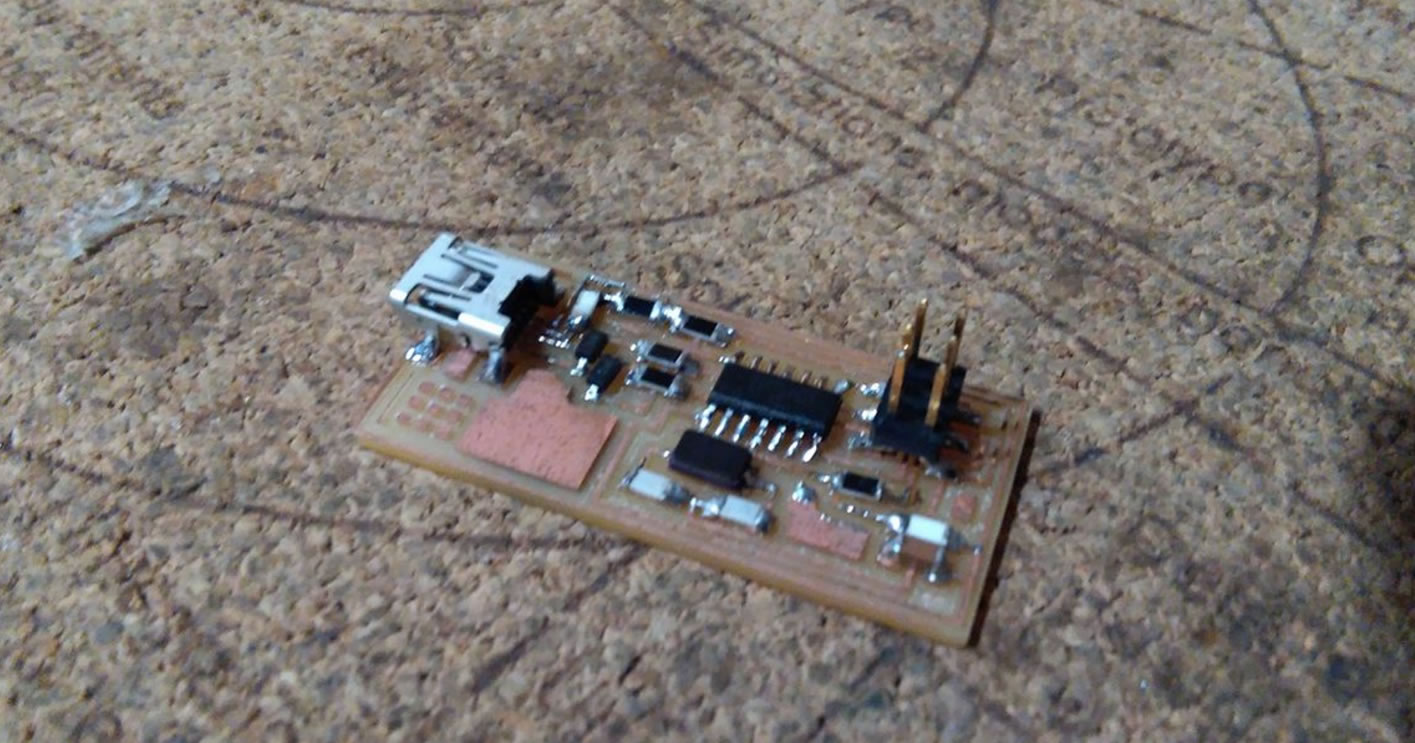

Then, I started to weld the components according to the sketch or model chosen.

First, weld resistors, Atiny, capacitors, diodes, etc ...

The material with I soldered was TIN

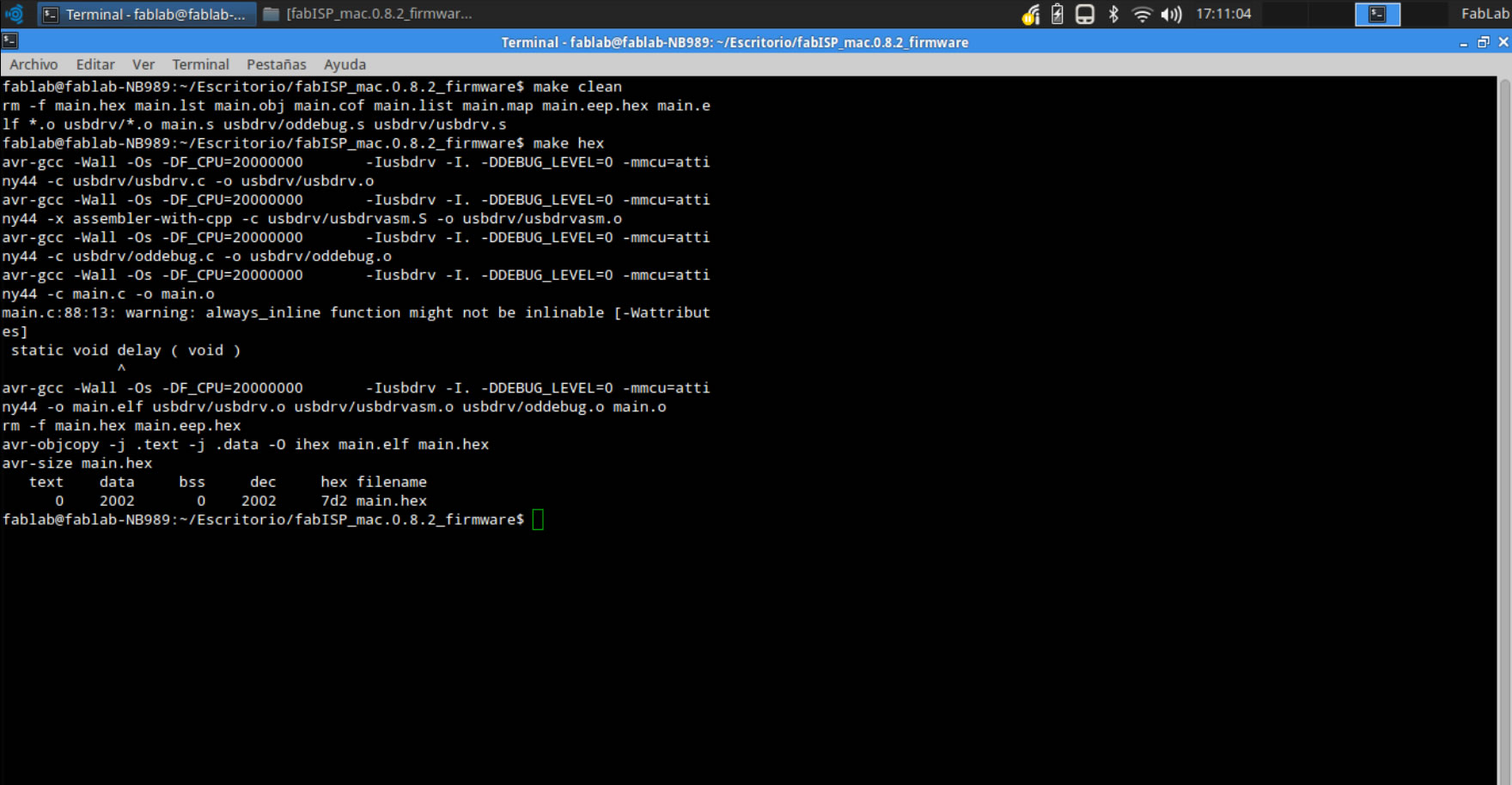

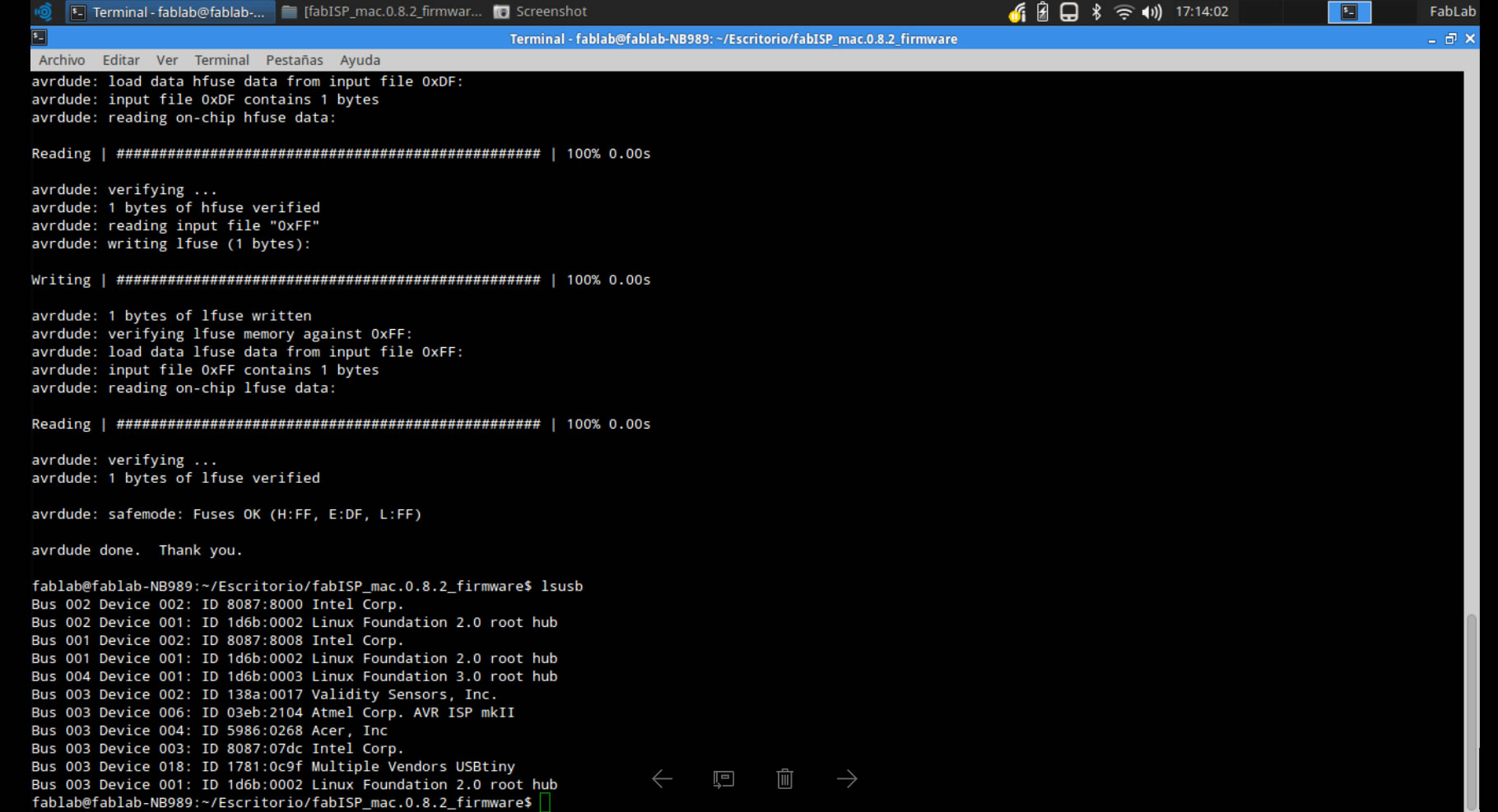

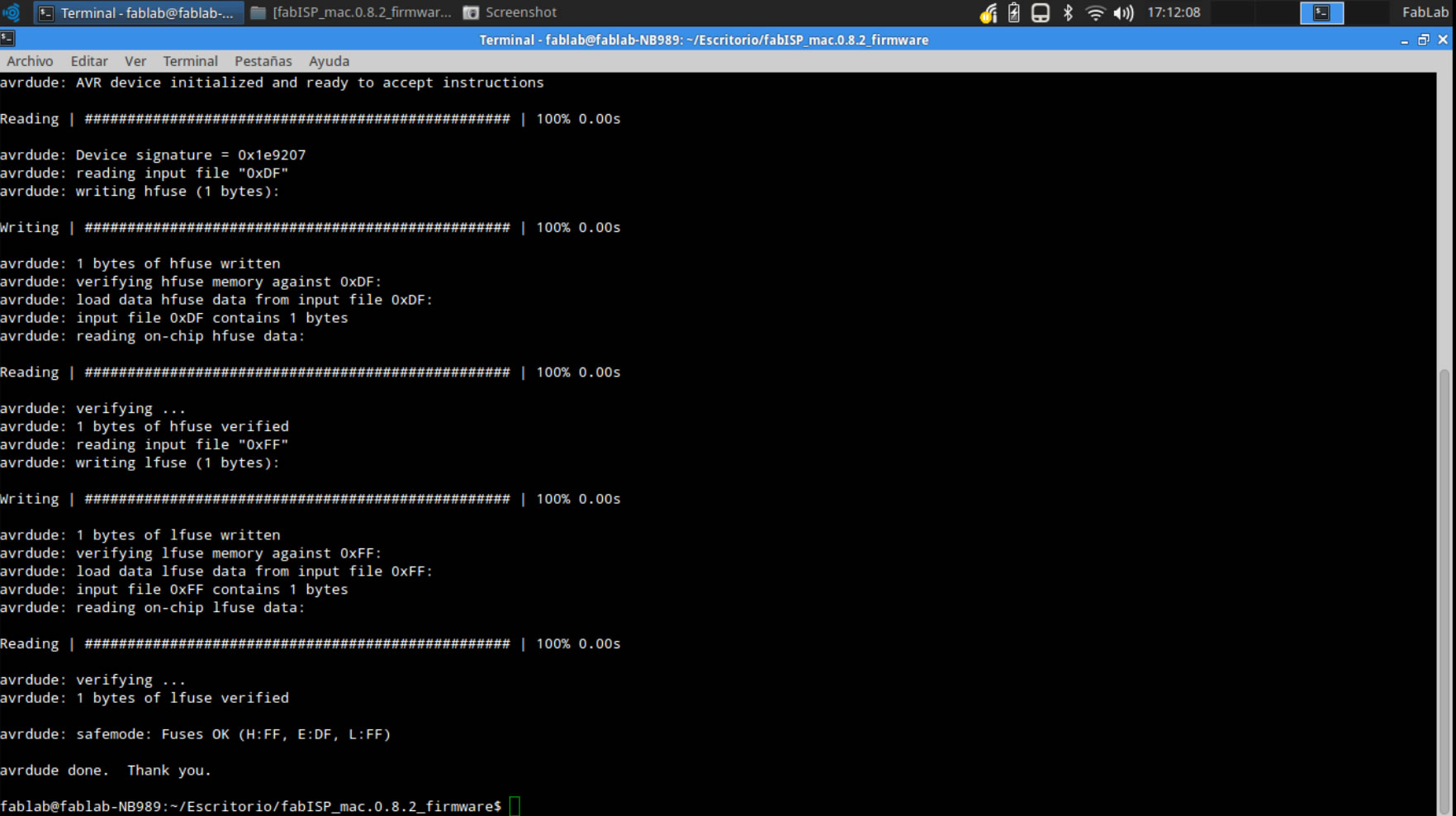

And finally, connect my circuit to AVR to program the terminal and save the programming.

For the programming of my board, I followed the steps of the tutorial that was in the schedule.

To see the tutorial click here

And keep the programming in the FIRMWARE.