Assignments 3

Computer - controlled cutting

LASER CUTTER

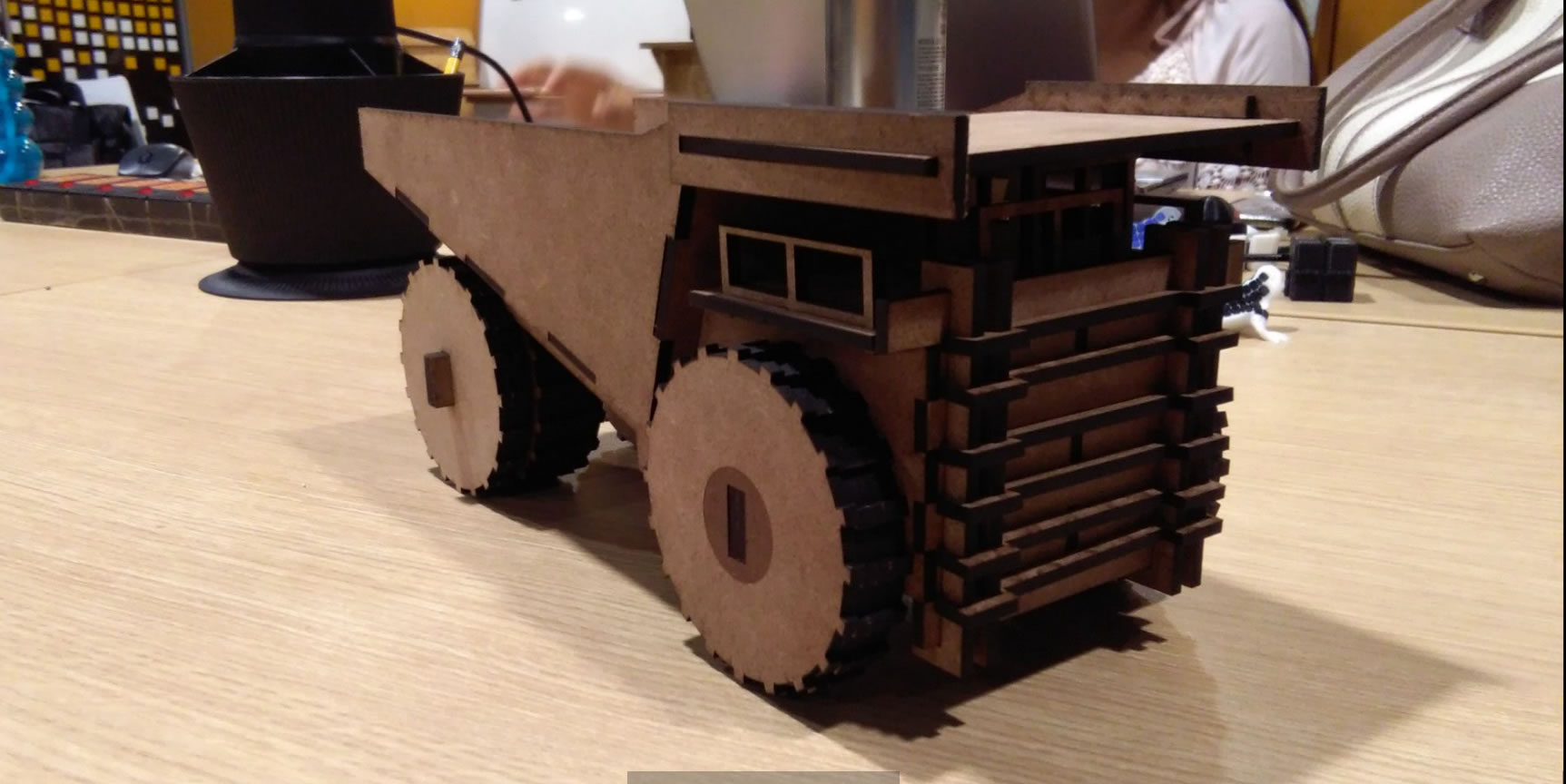

In this assignment I decided to manufacture a mining truck, because I worked as a pre-professional engineering practicing in the mining company Minsur , once of the Minery biggest in Peru and i wanted to take advantage of to make a reminder of my work experience.

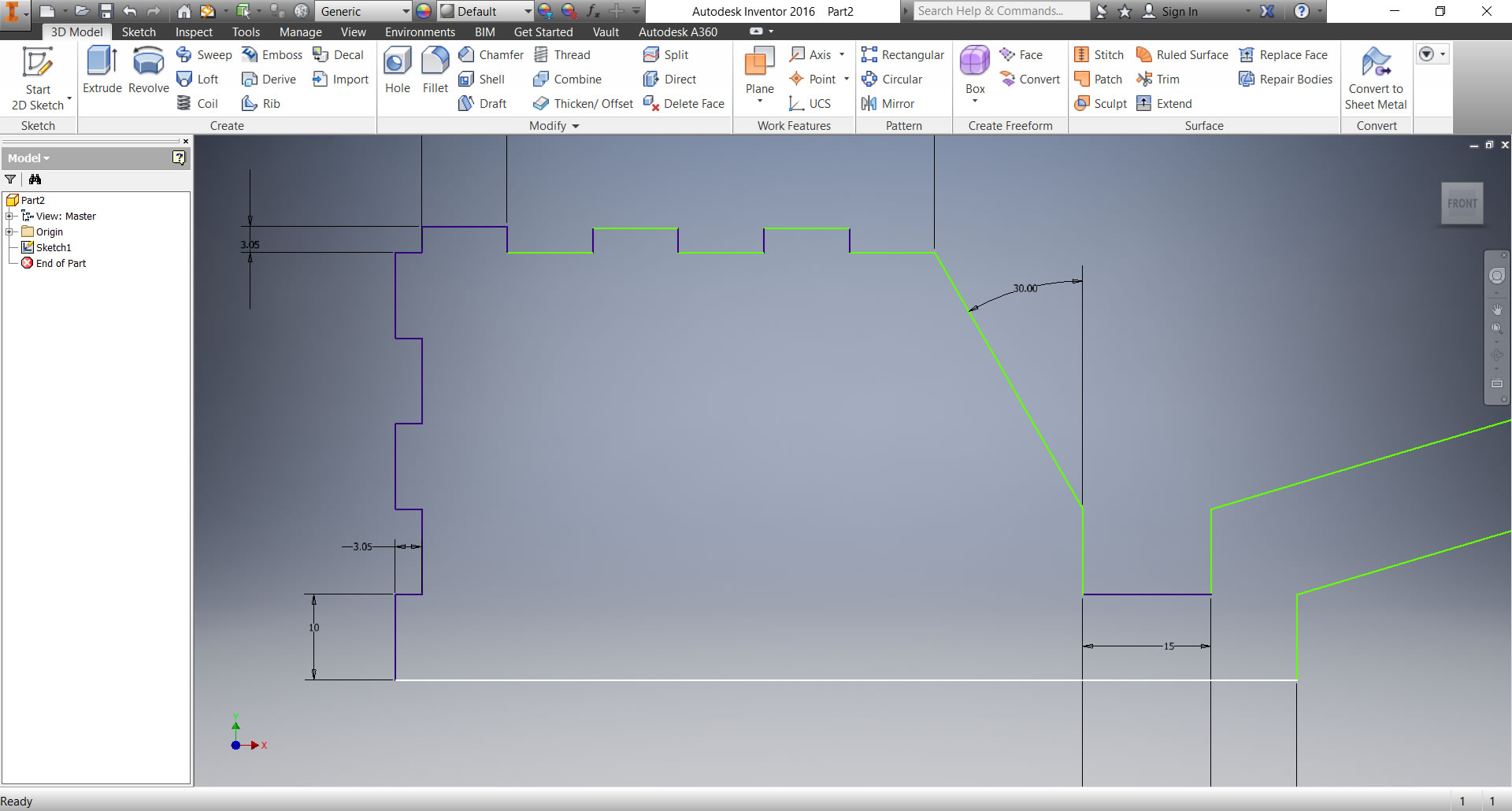

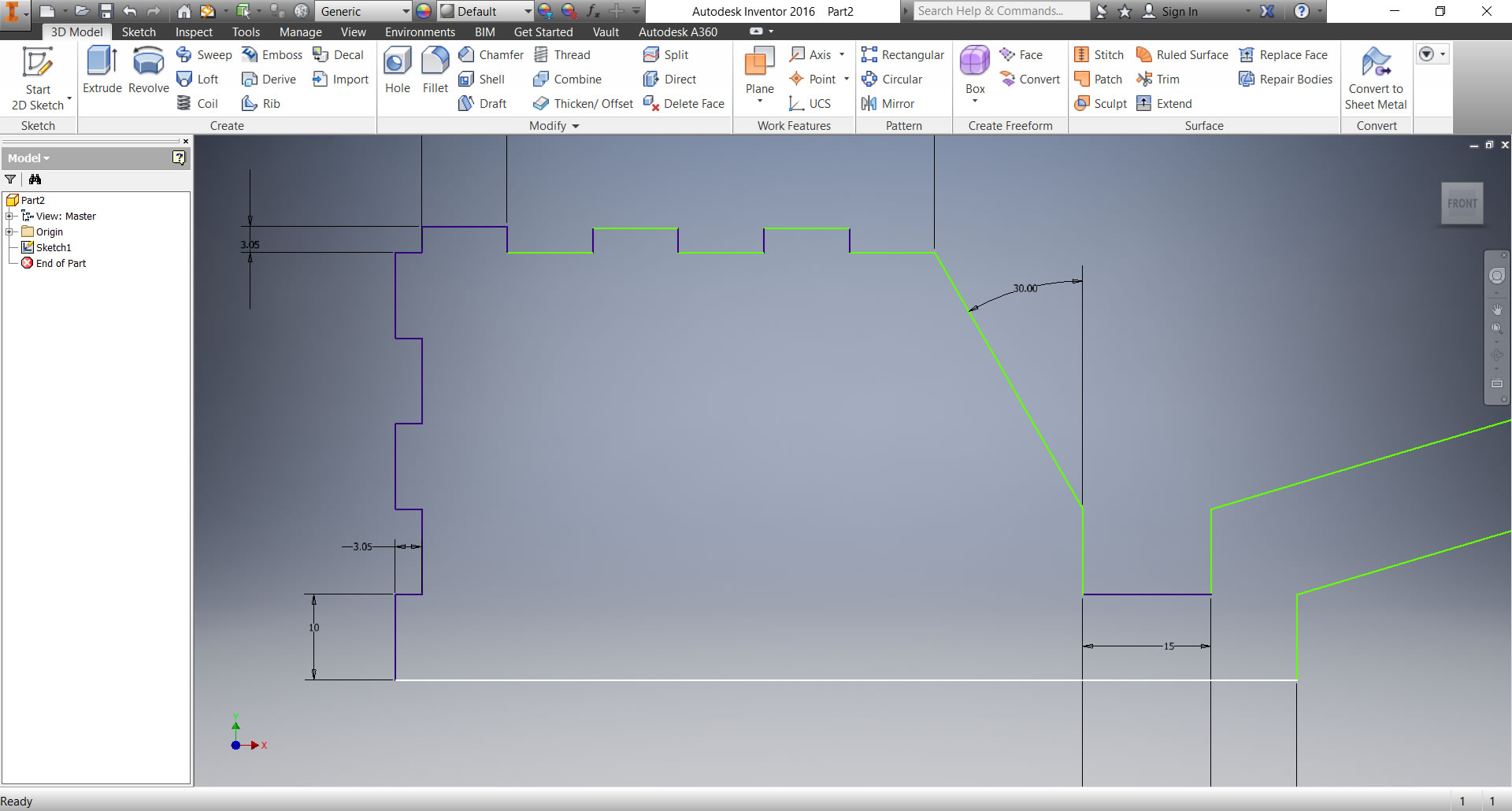

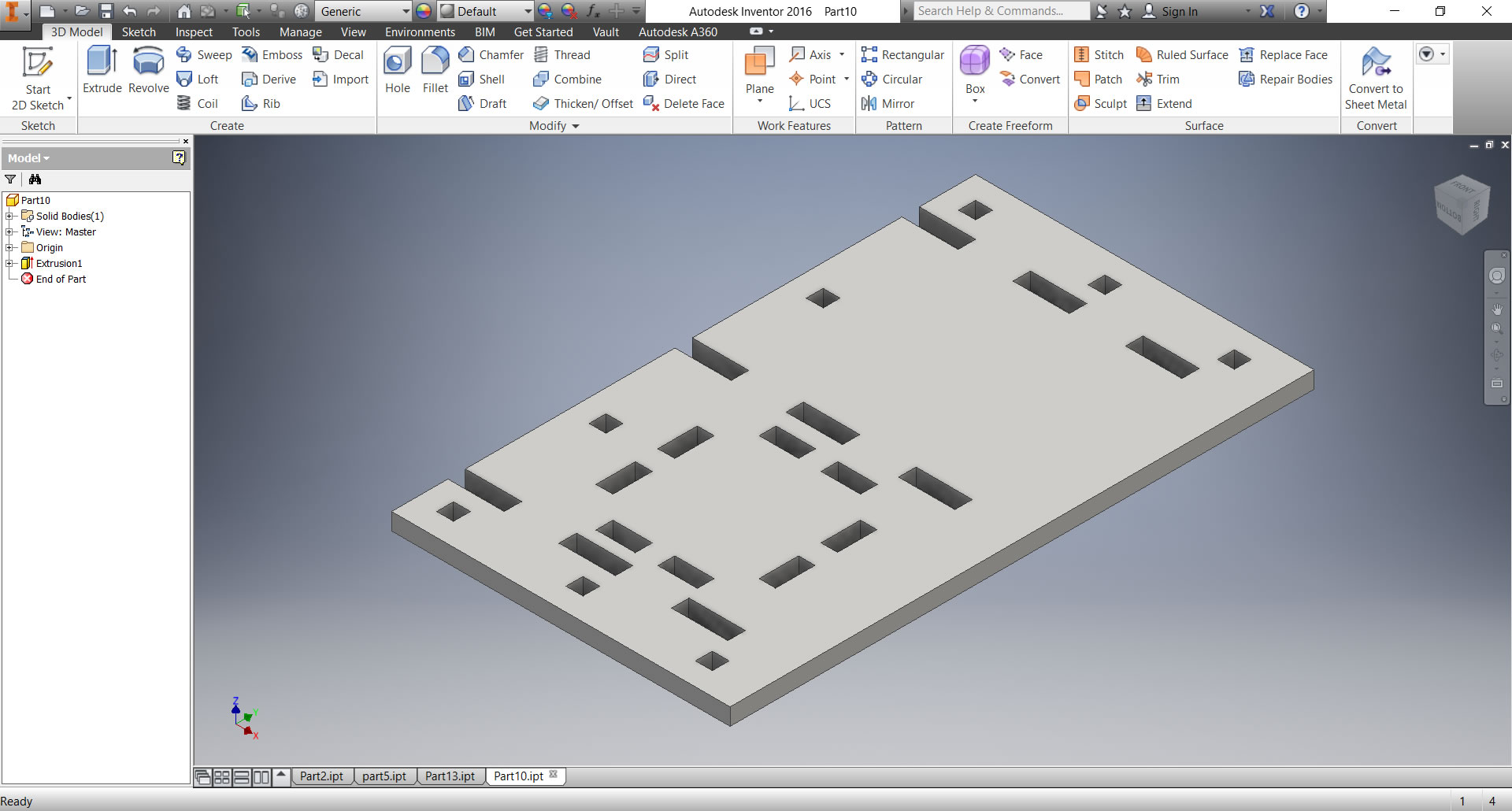

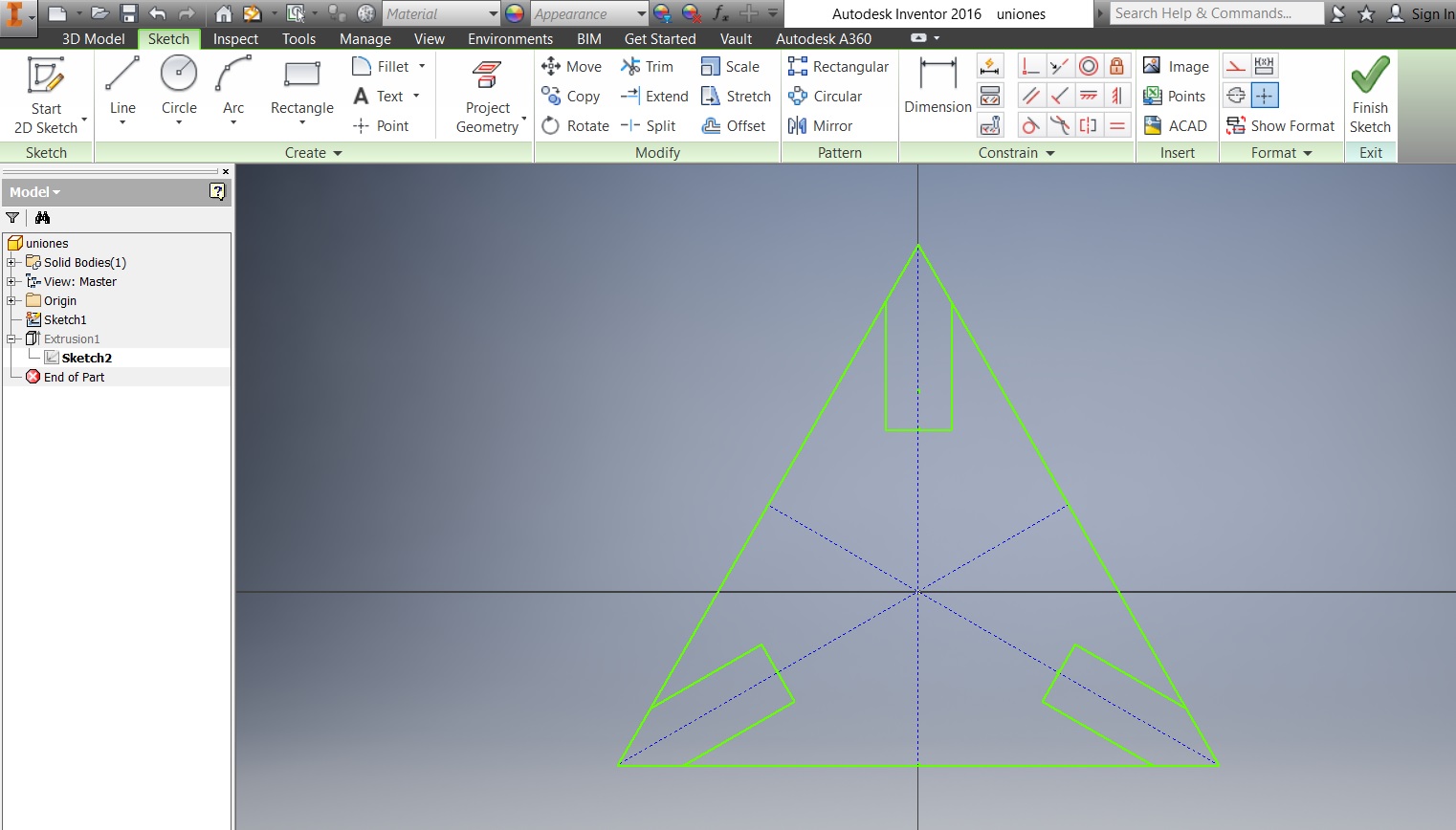

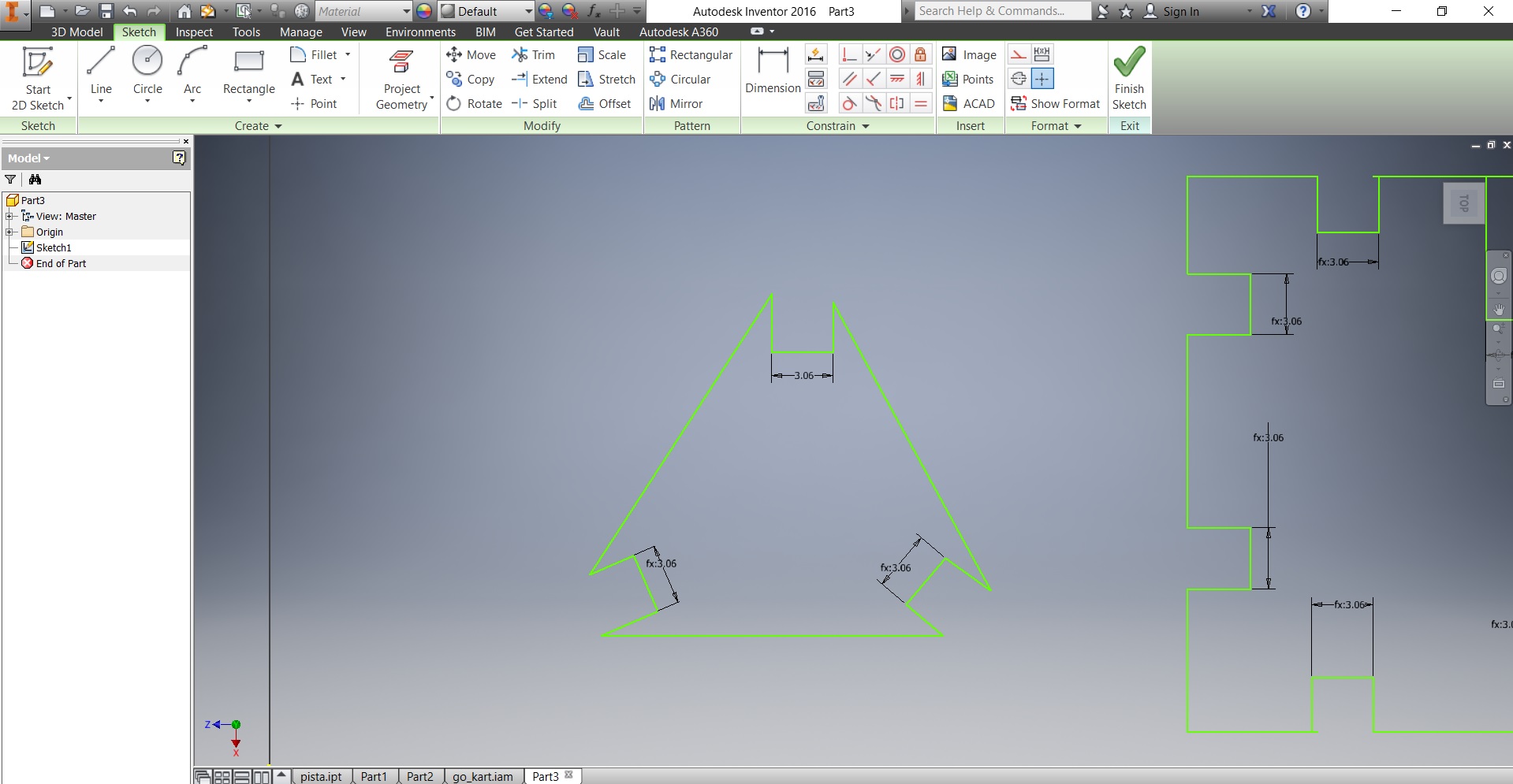

So I started designing the parts to be cut in Autodesk Inventor 2016.

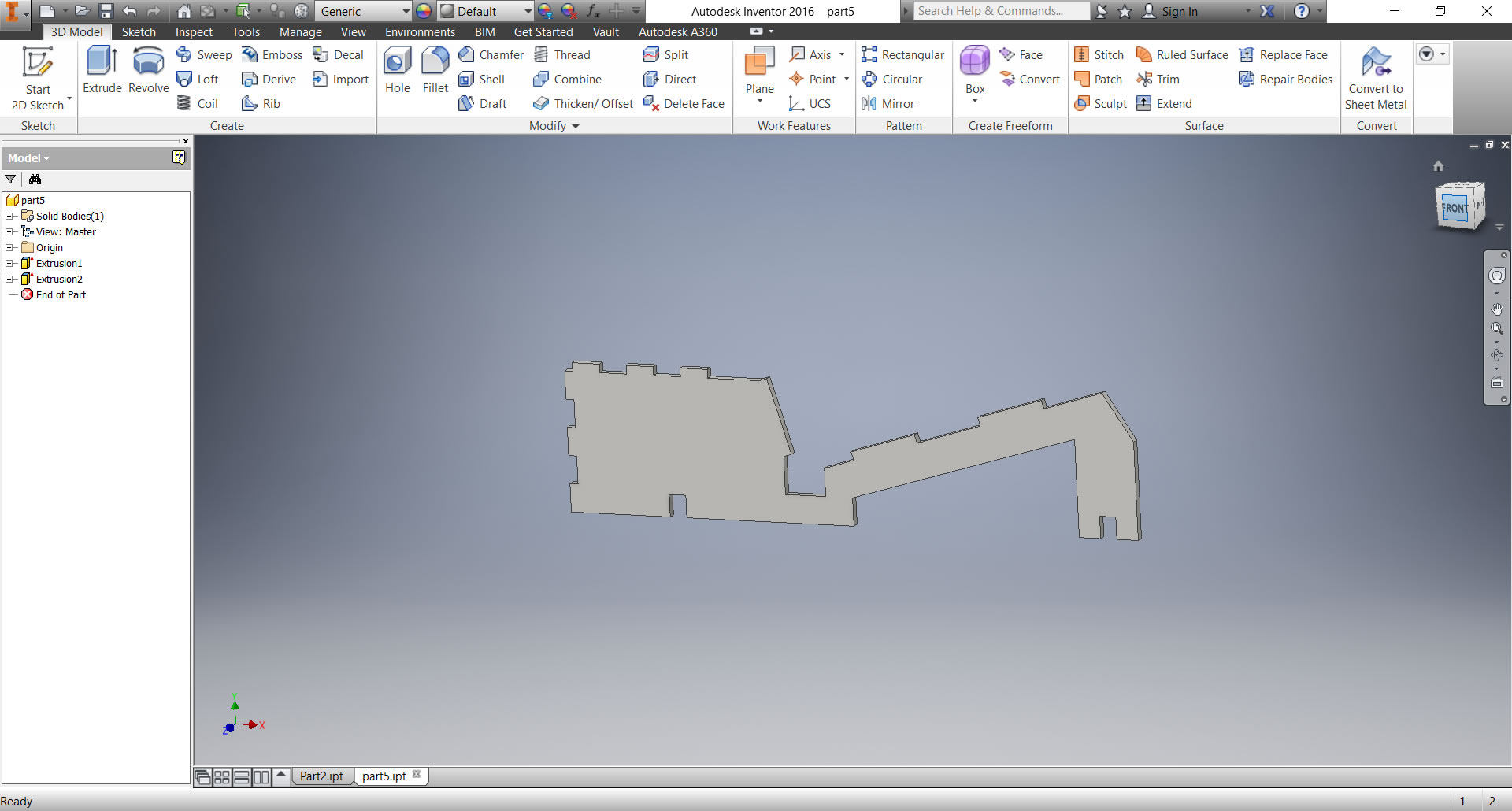

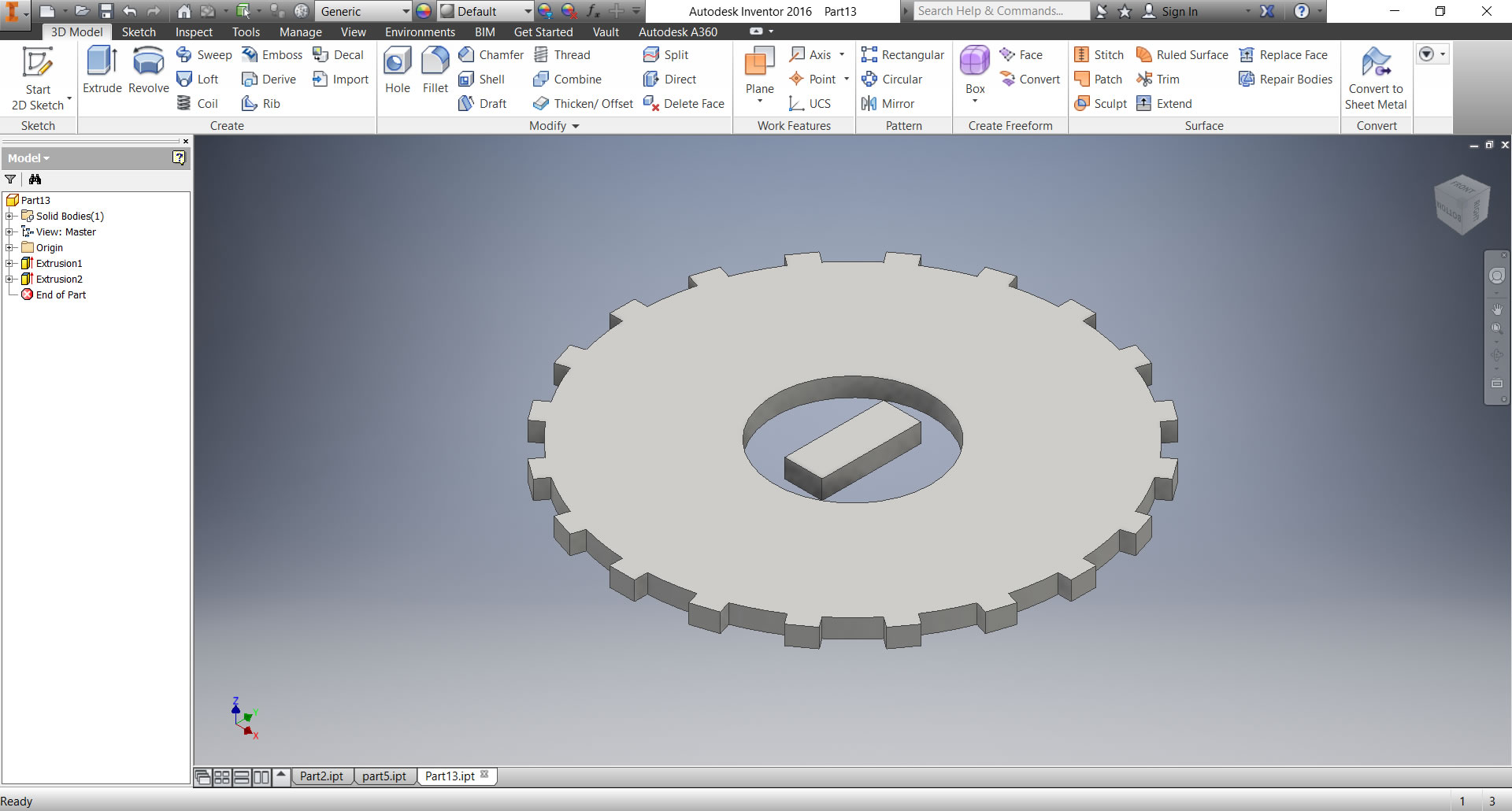

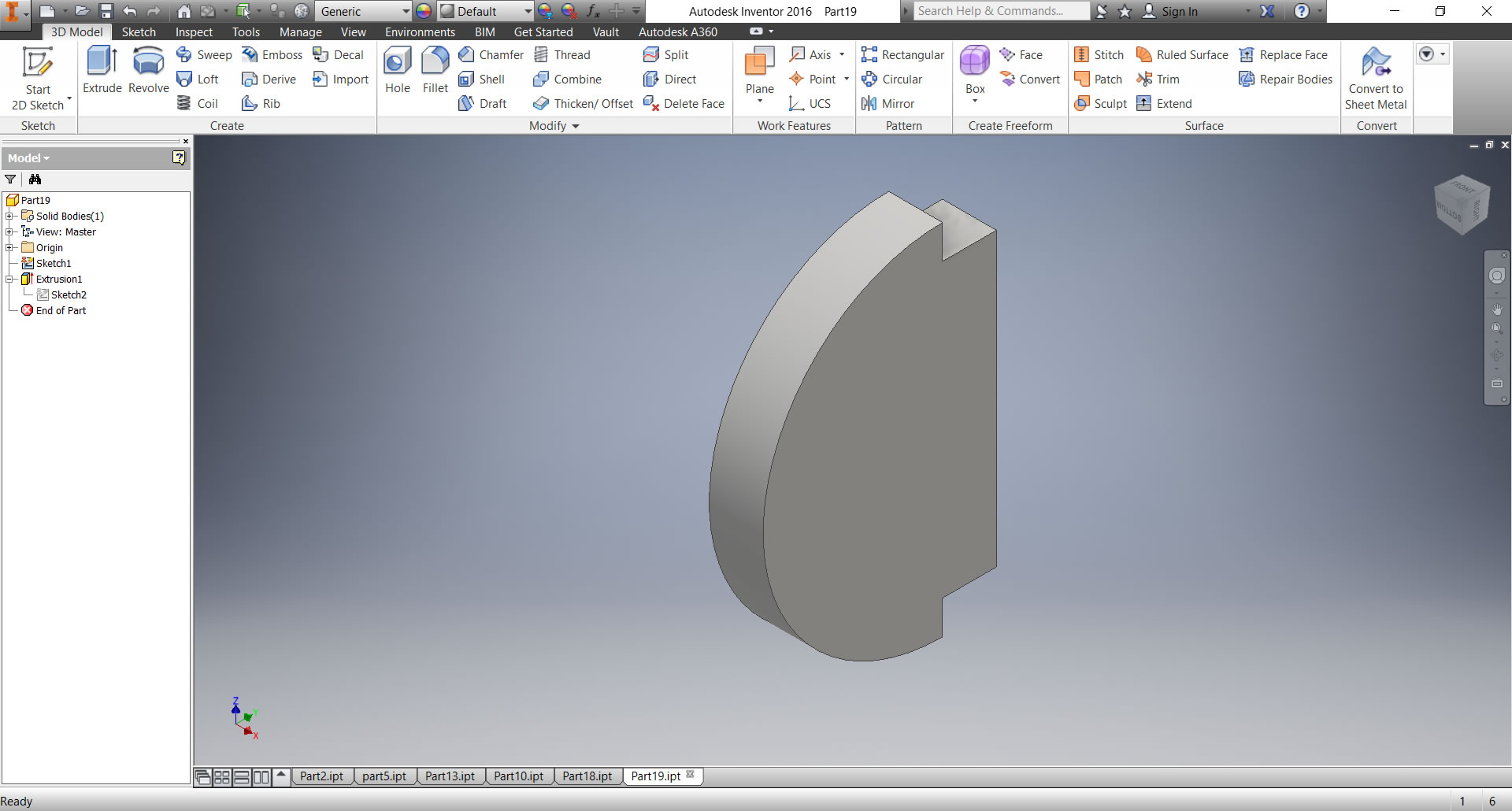

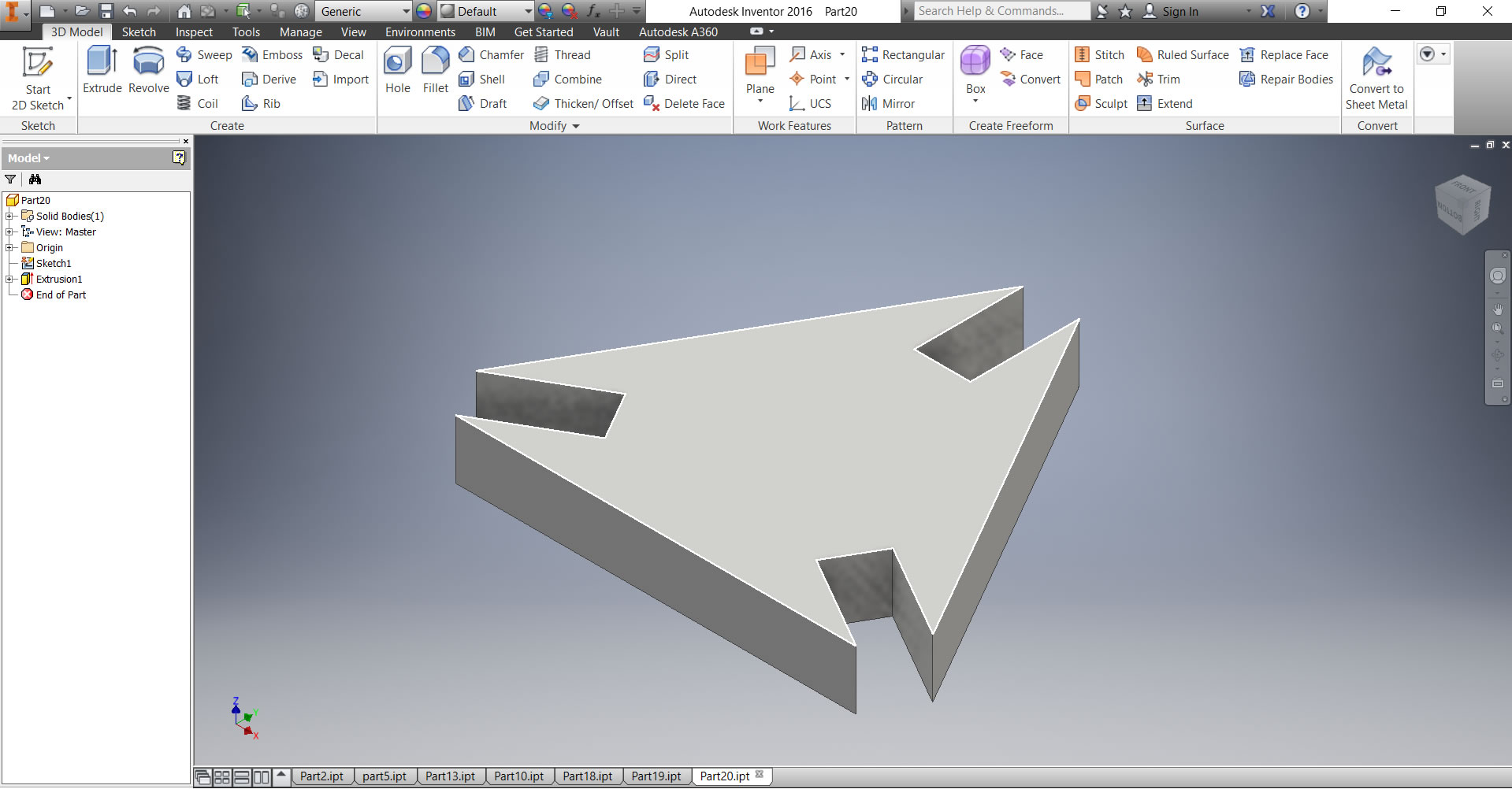

Then extrude the plane, to obtain the faces and to be able to export it in DXF format.

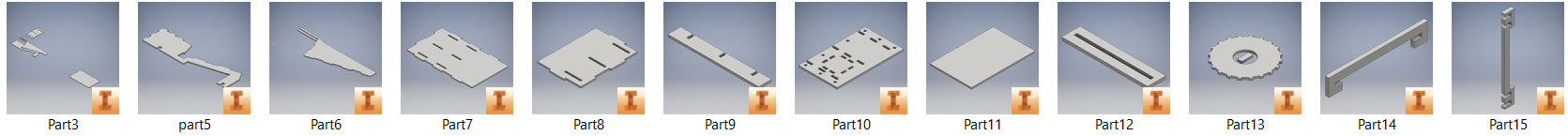

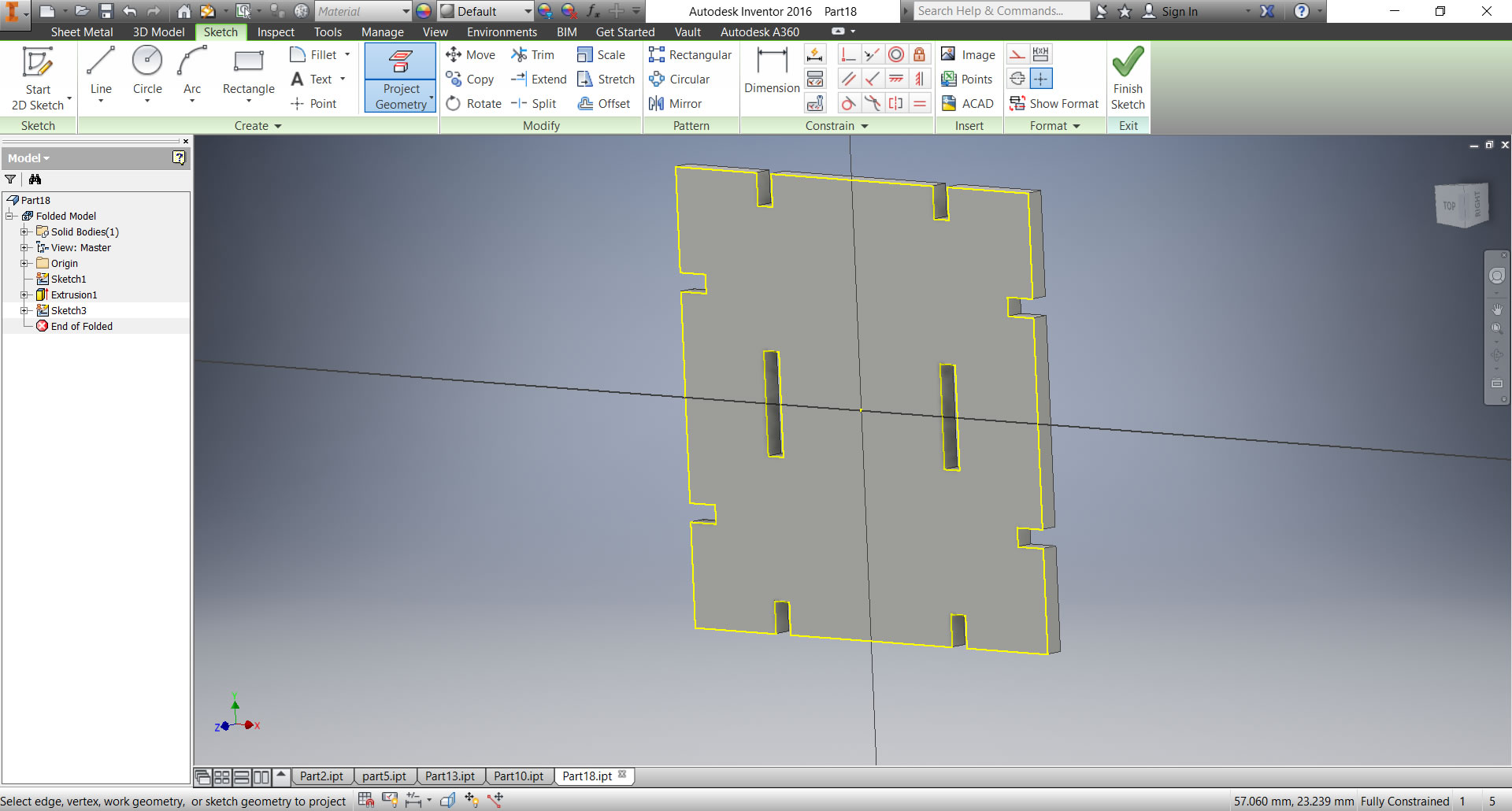

And these are all the files in INVENTOR that I need to be able to manufacture my Truck.

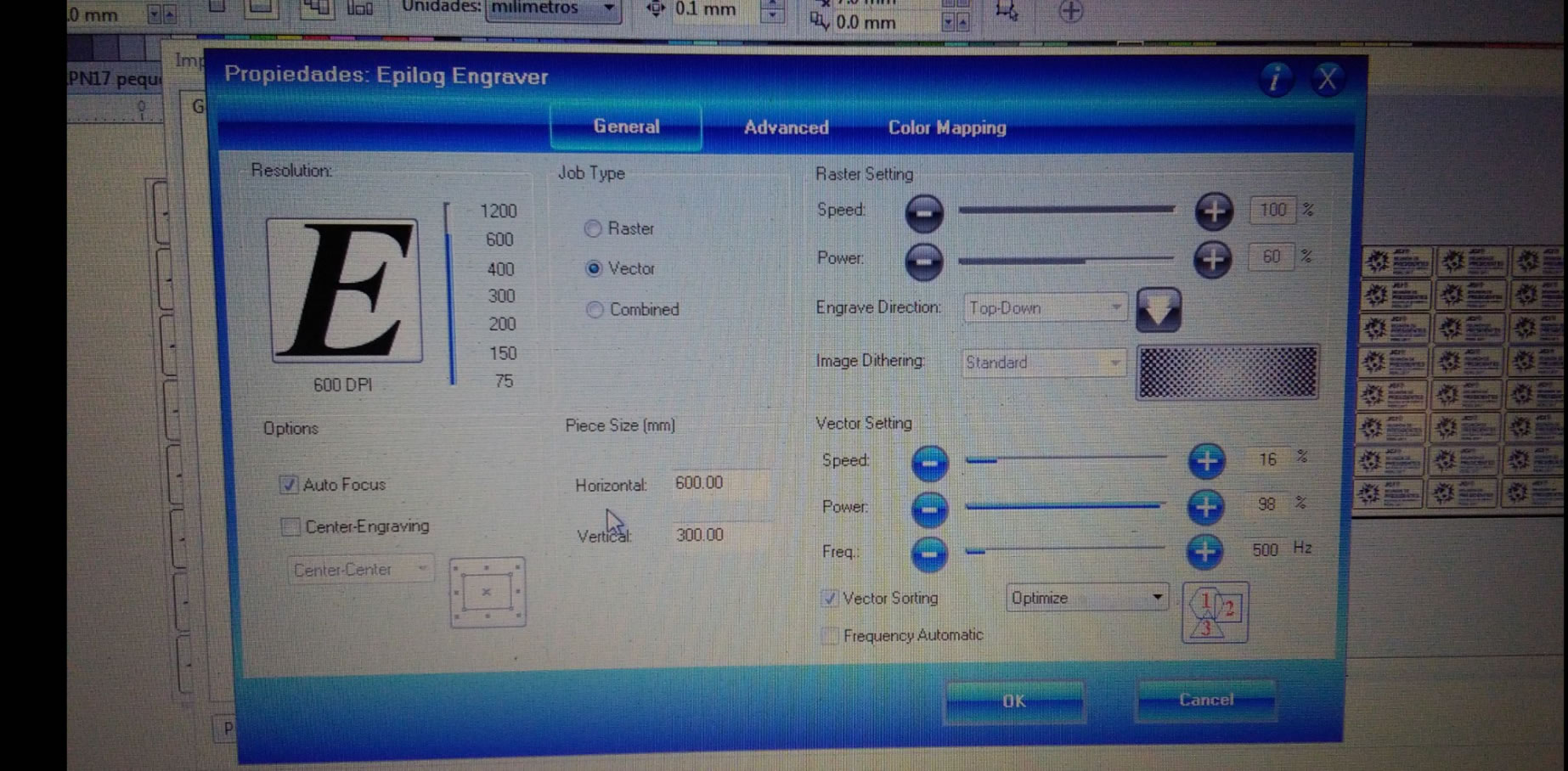

In the FABLAB ESAN we have an EPILOG laser cutter that works with CORELDRAW software with DXF files.

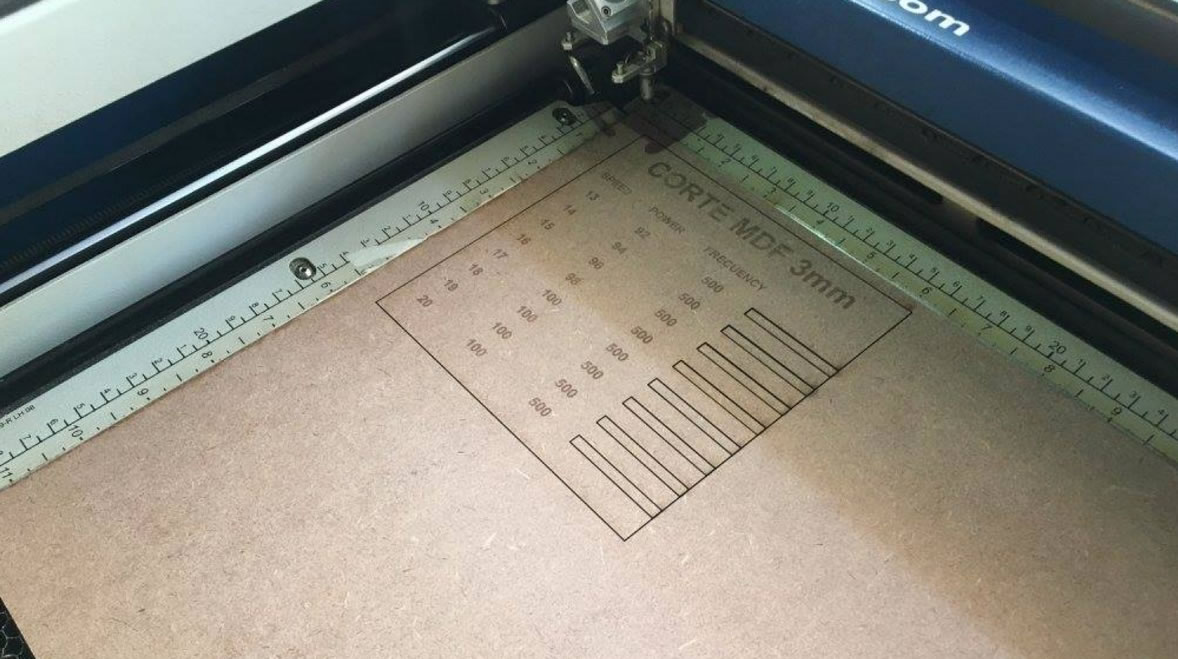

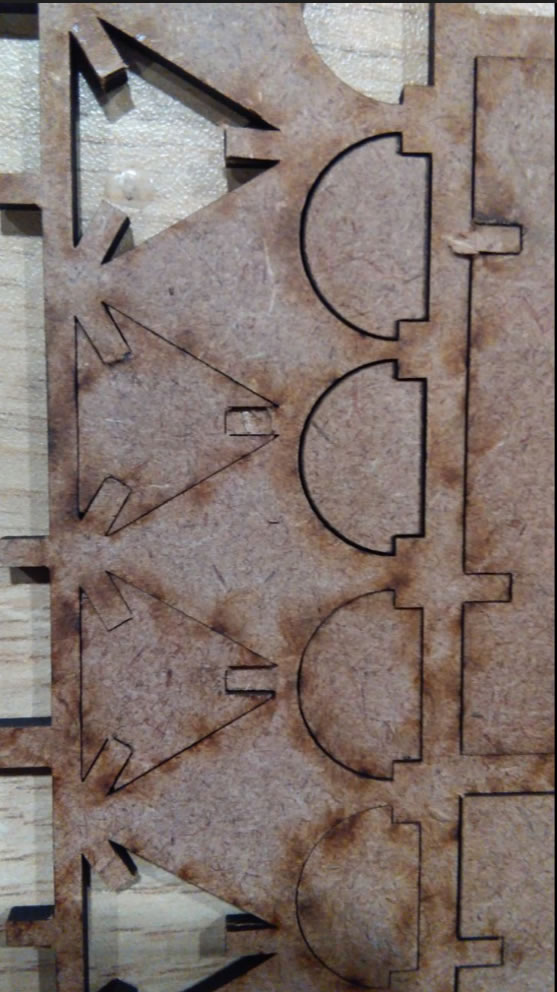

First, perform tests to know the measures of tolerance in PRESS FIT to be able to mount my design and also the cutting characteristics like SPEED, FREQUENCY and POWER suitable according to the material.

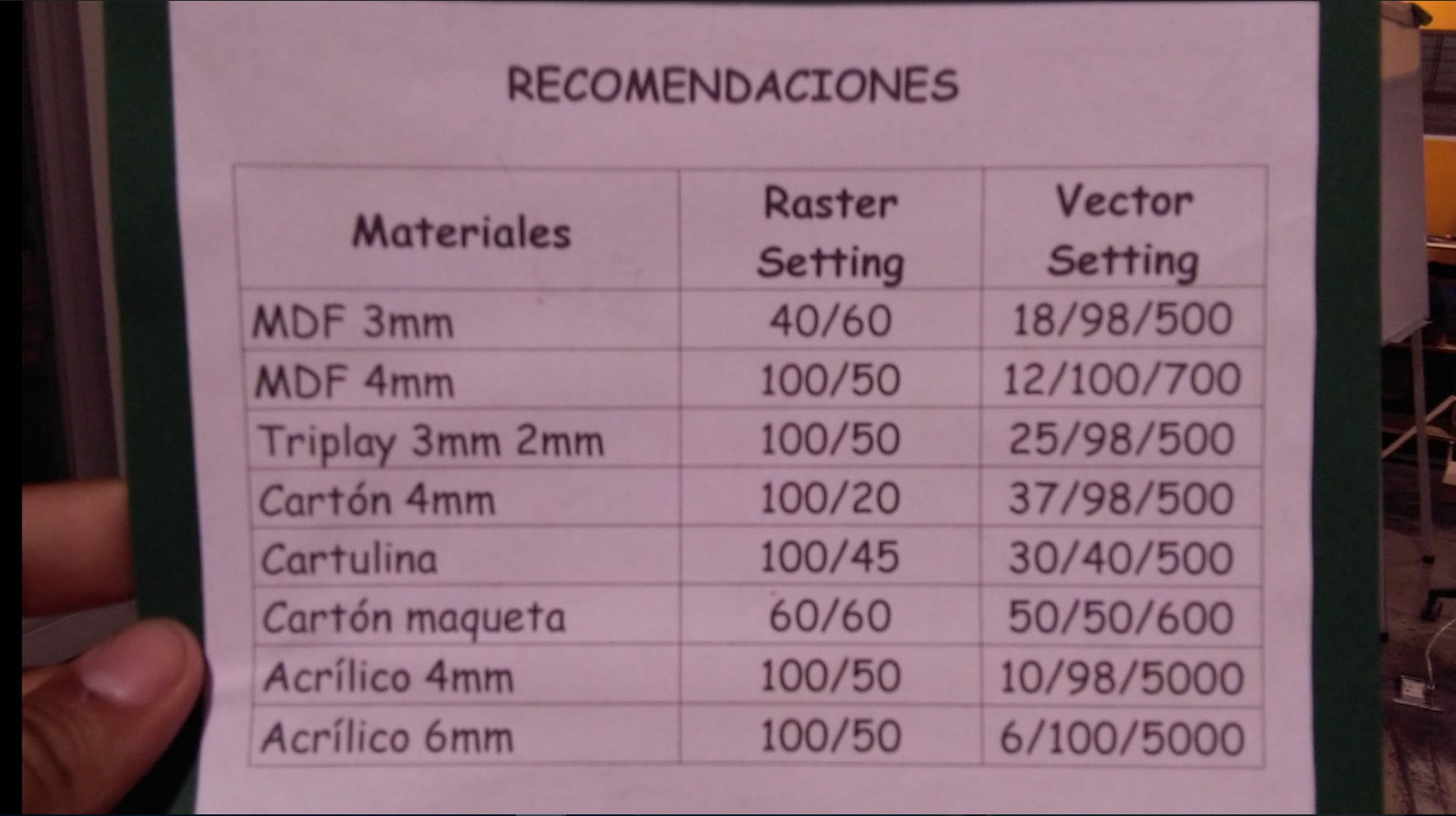

And the result of all the tests could obtain the following cutting characteristics for each material.

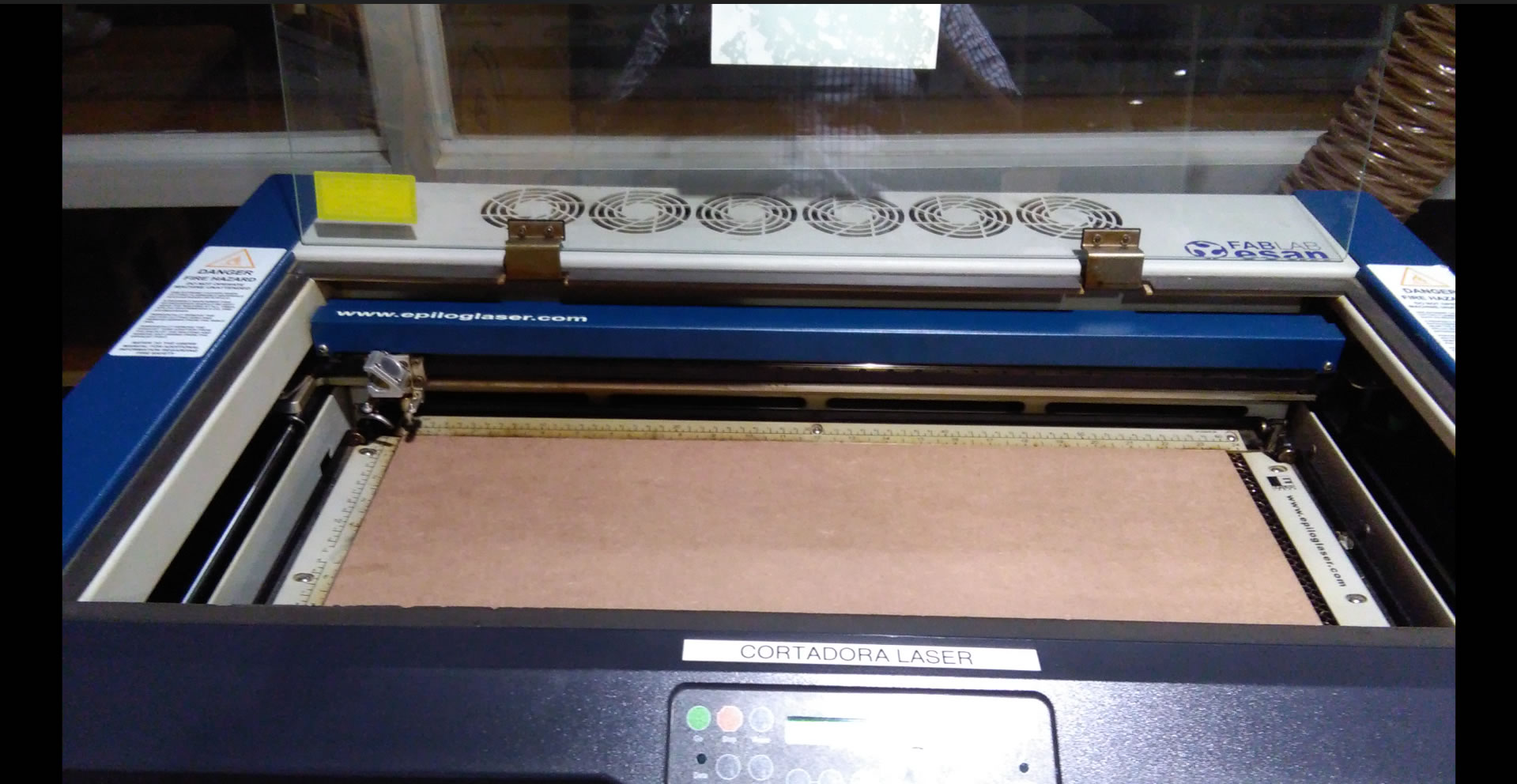

To start cutting, a MDF 3mm sheet is placed on the cutting grid.

I also turn the extractor on, because the EPILOG emits gases through the laser cut.

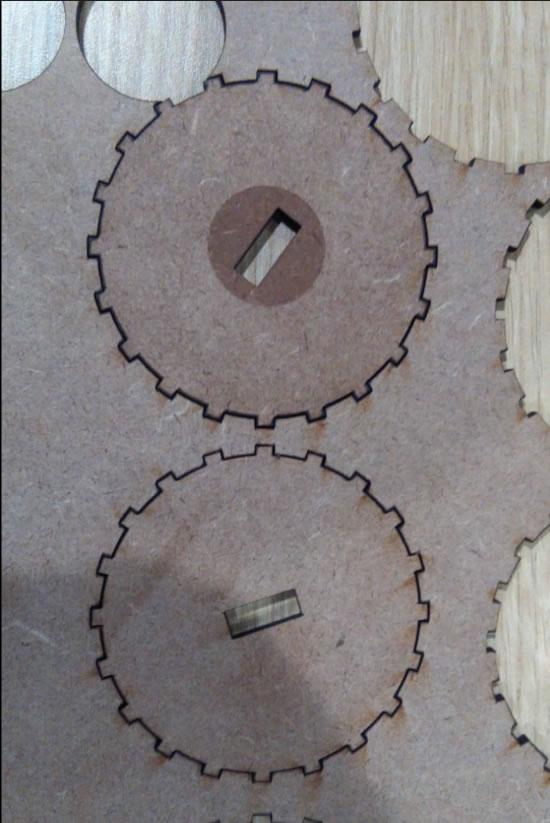

And we get the designs cut into the grille of the laser cutter

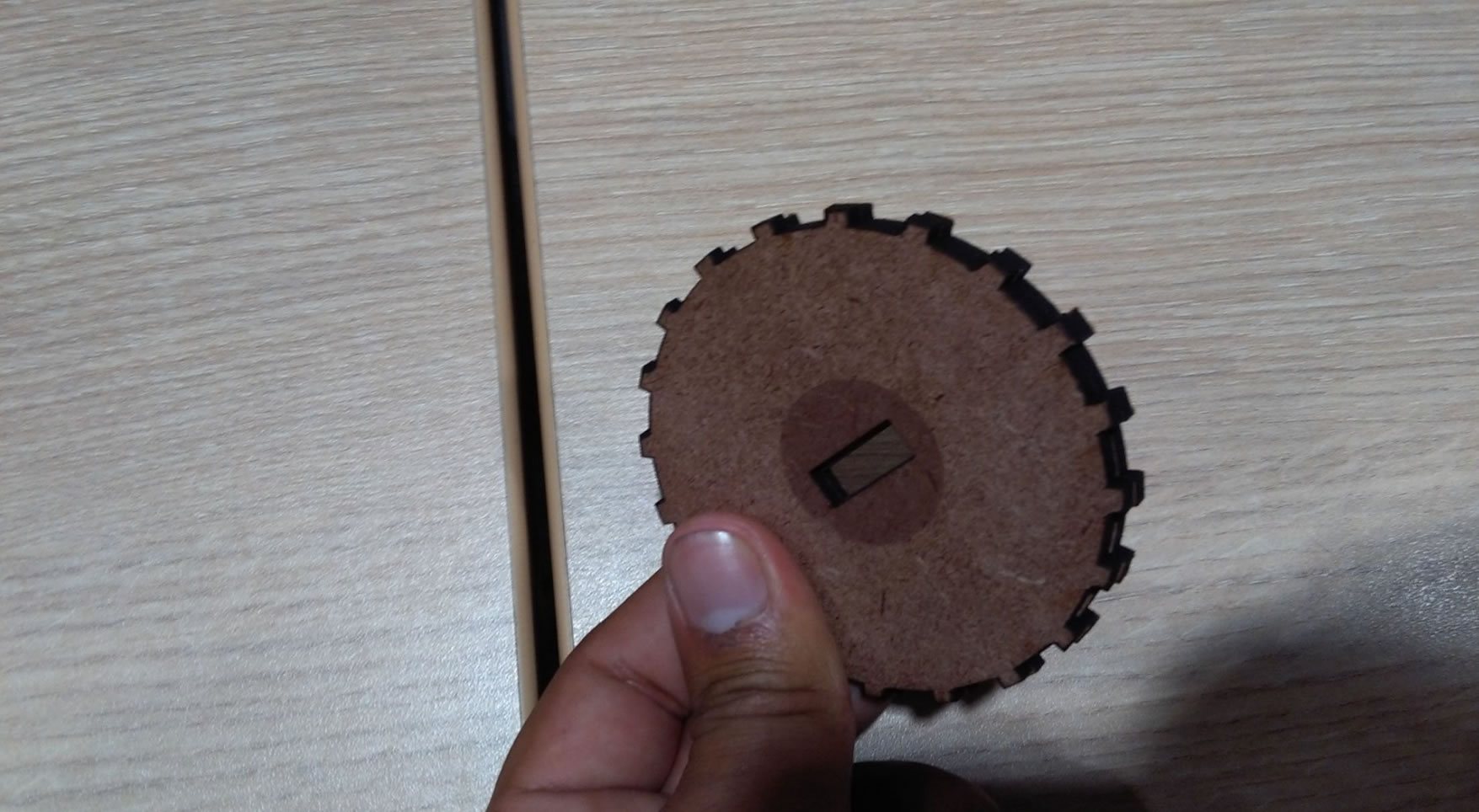

Then, I remove the cut pieces from the residual table, and begin to assemble and assemble my designs.

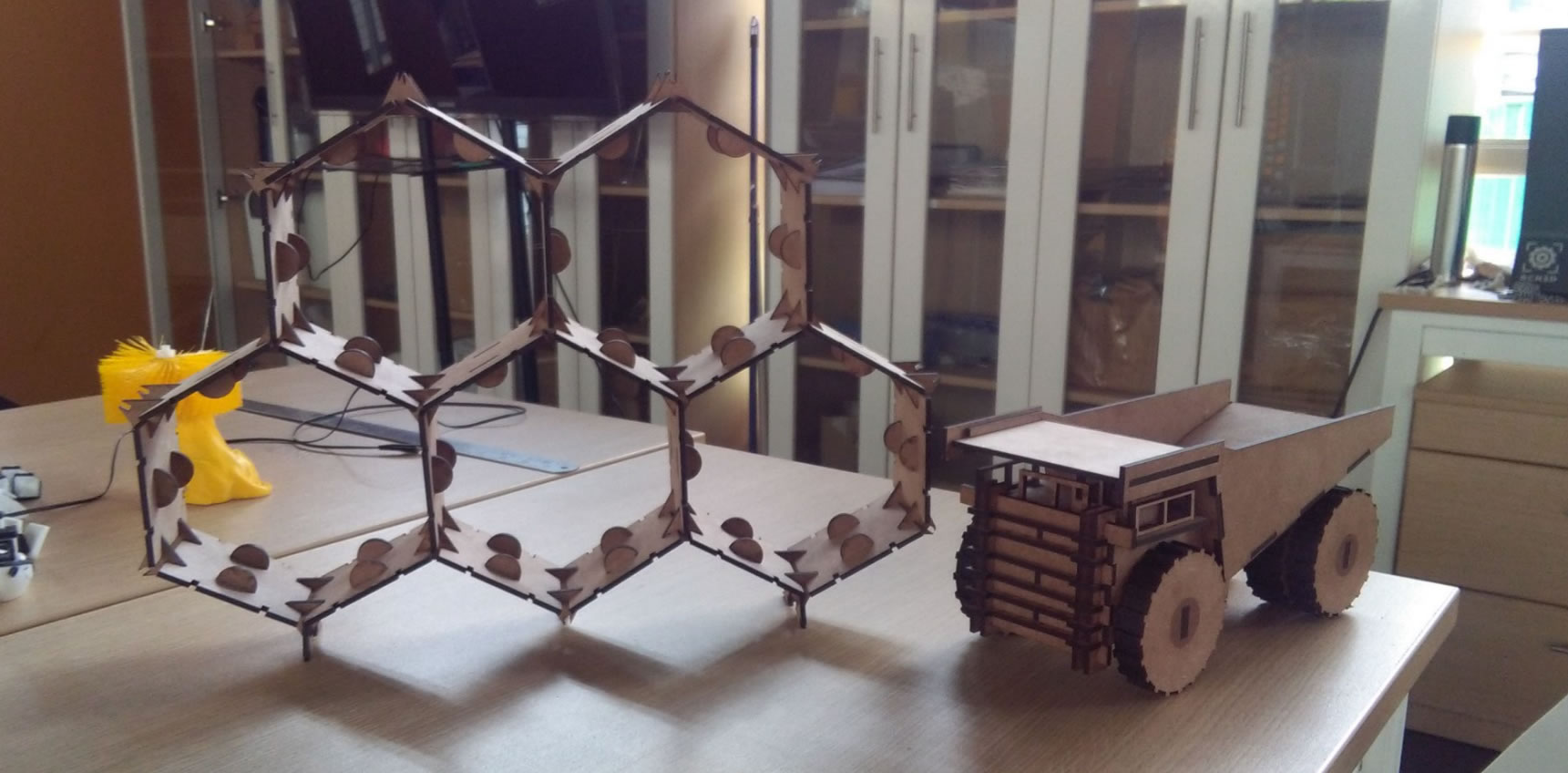

And finally, this is my TRUCK Minning.

Click here for download the files

Testing Parametric design

This was my first time trying "parametric design", previously I only used simple setting of measures in Inventor. My instructor showed me how to easily link the different dimensions, so one depens on another. This way, my design is set up in a way that if I change one measure, like the pressfit one, the other changes accordingly. With this little trick, it is now easier for me to design and modify stuff using Inventor.

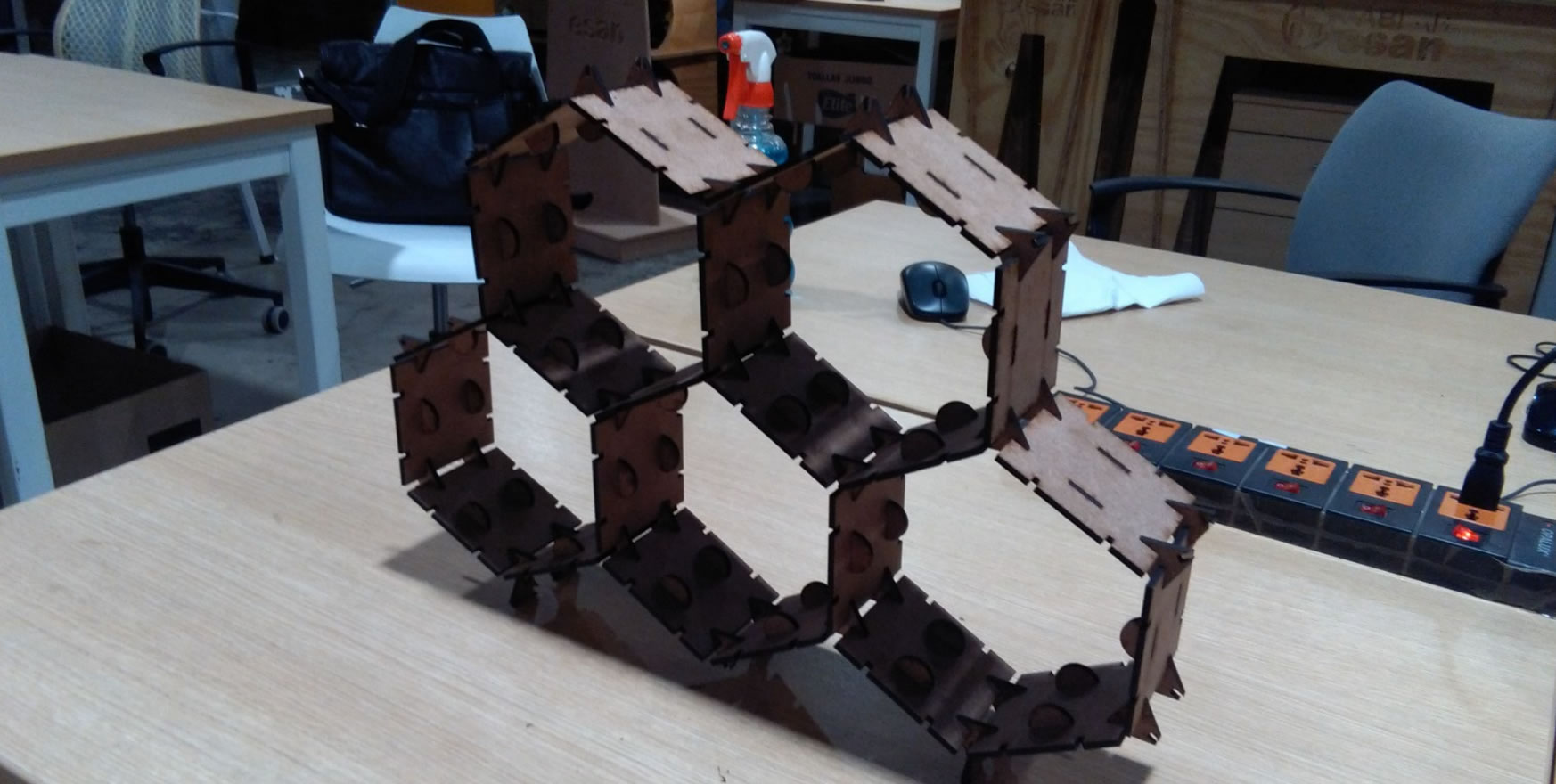

For my second design in LASER CUTTER, I decided to make a wine shelf, because I consider it useful to be able to store drinks in cylindrical packaging.

Start by designing the parts to be cut in Inventor Autodesk.

Something curious about this wine shelf, is that you can manufacture a whole shelf with only 3 pieces.

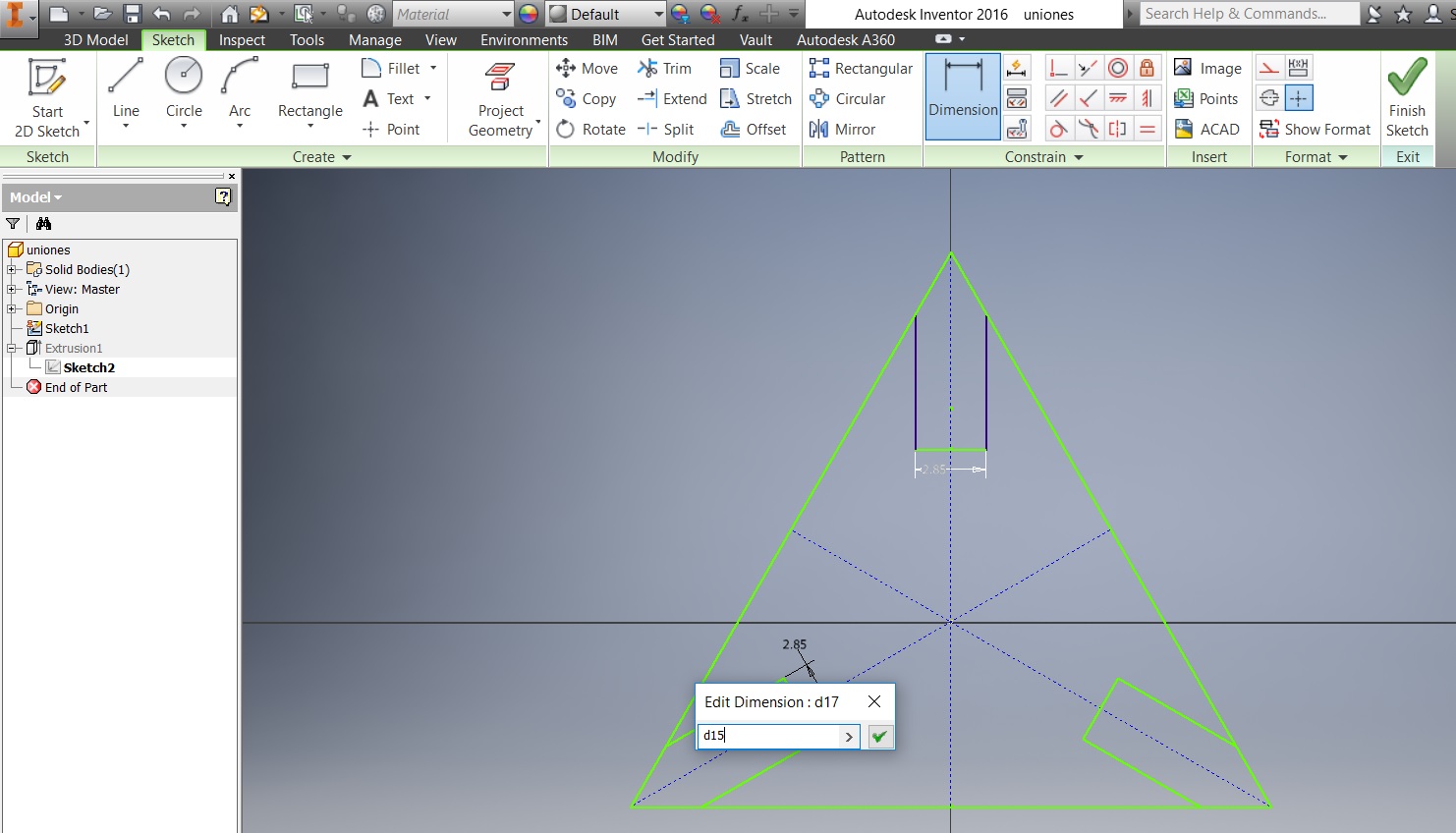

Parametric design: the sketch of what is to be manufactured is first designed in the program, even without exact measurements.

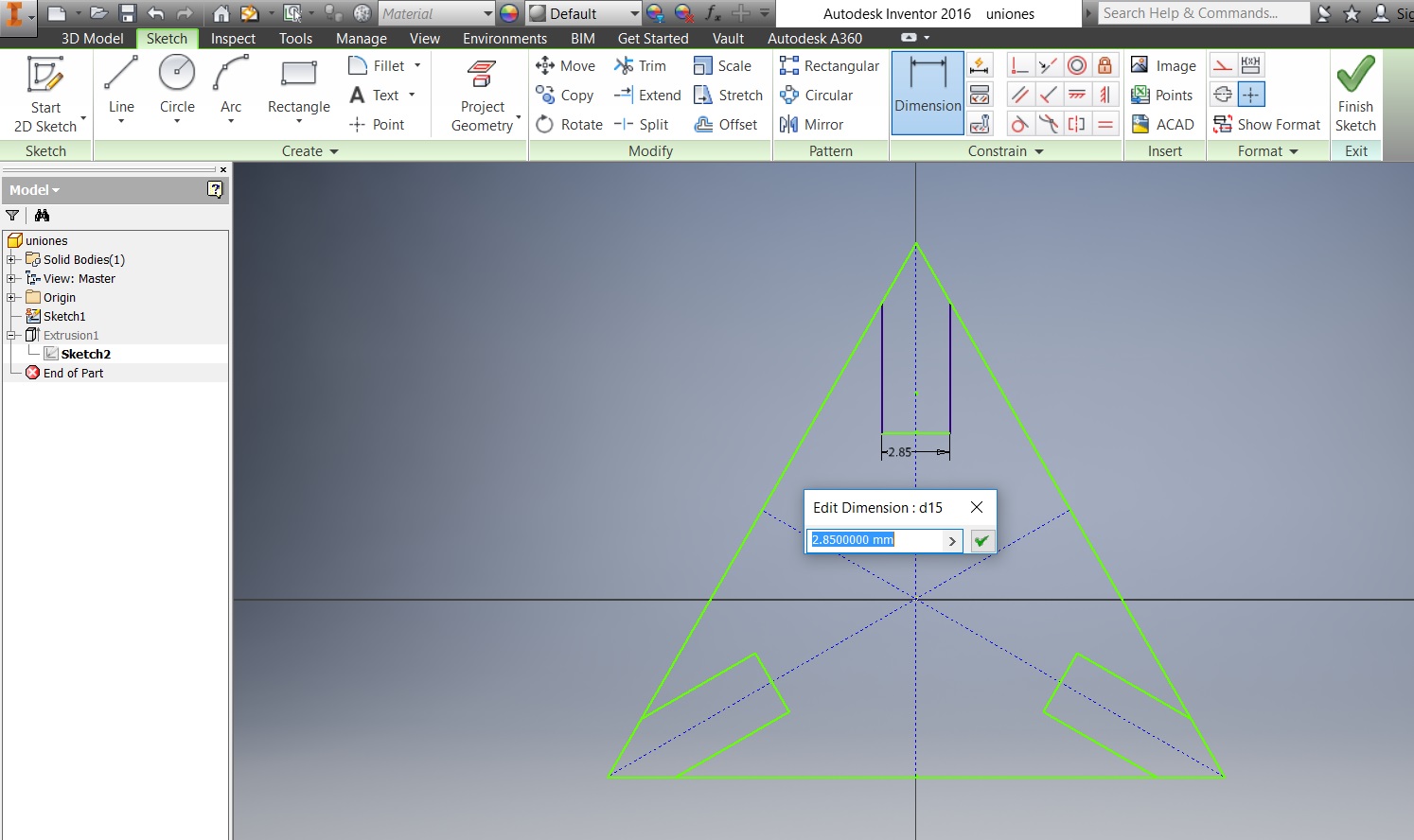

Then, through the tools to dimension of the program Autodesk Inventor, the first side or dimension of which will be the design parameter is dimensioned, in this case it is dimensioned with 2.185 mm

Then, proceed to size the other side or dimension that will depend on the initial dimension or parameter.

But, when you enter the measure to be dimensioned, you click on the dimension or initial parameter.

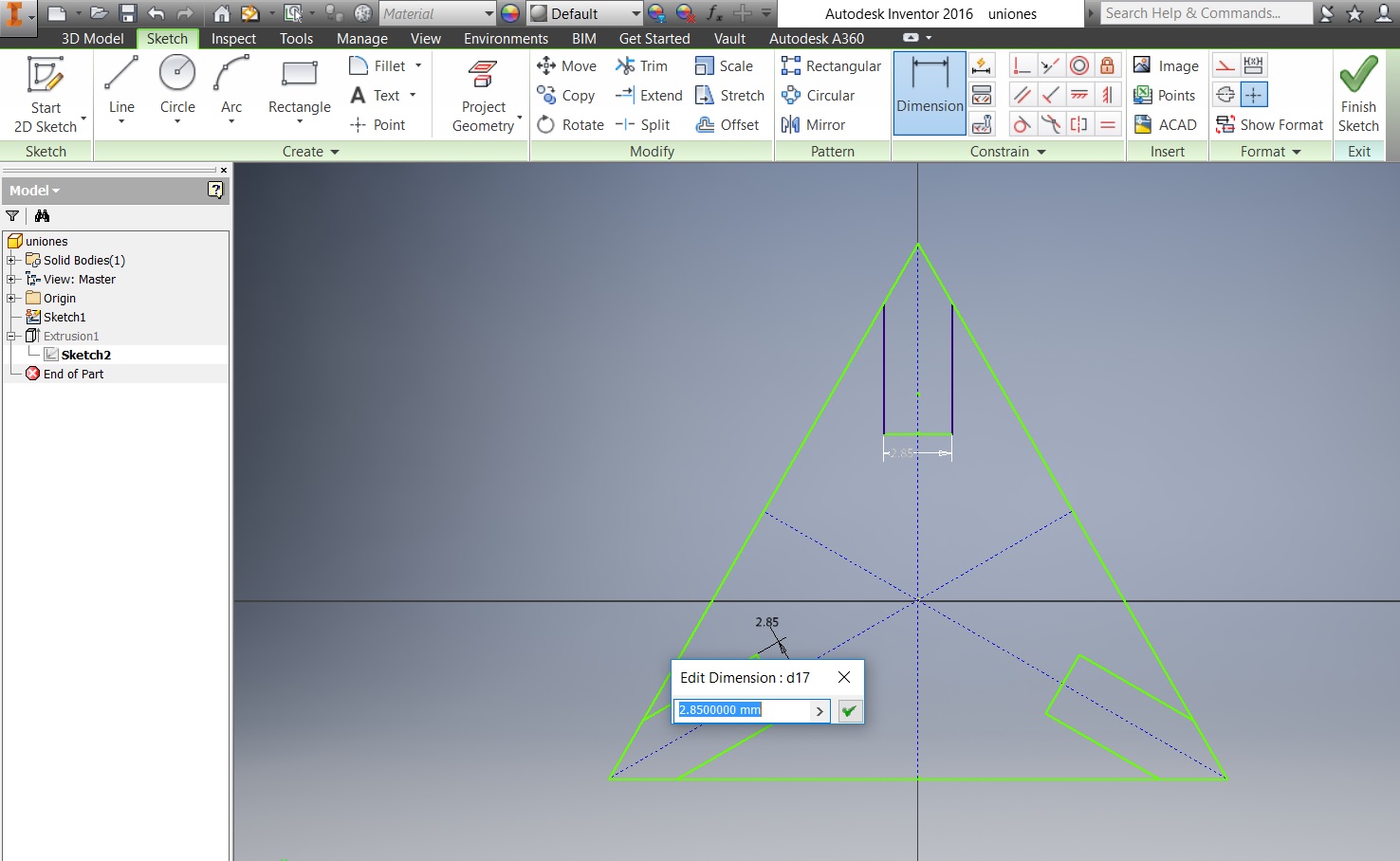

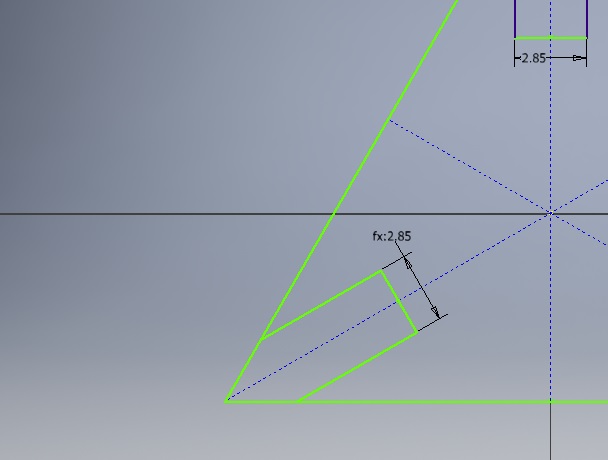

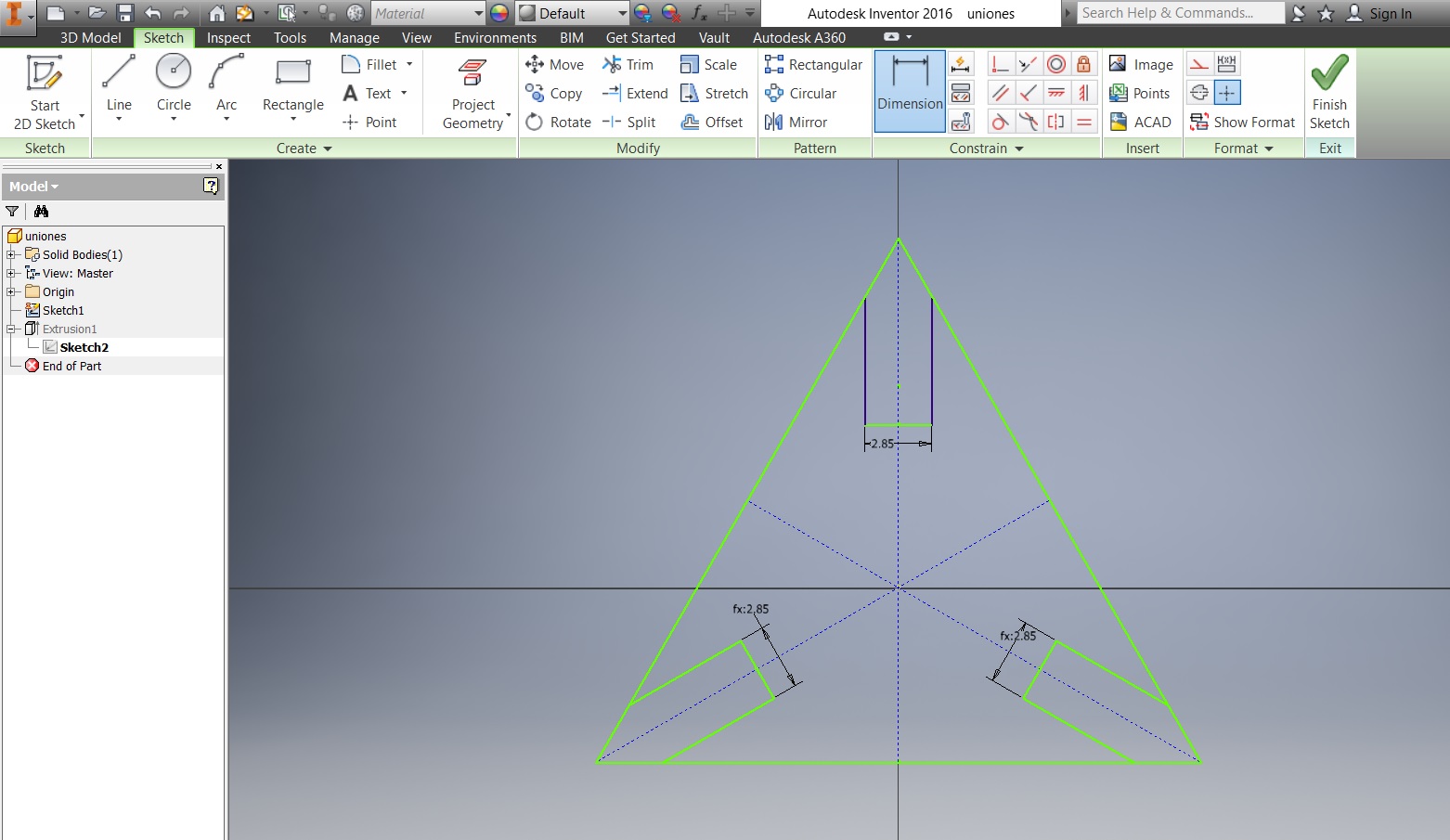

And immediately, the dimension changes to a symbology of "dependent function" that is represented with "fx" this indicates that the dimension depends on one side or parameter "x".

Then, it is completed to dimensioned all the other sides that will serve as "pressfit" and that will depend on a specific parameter or dimension.

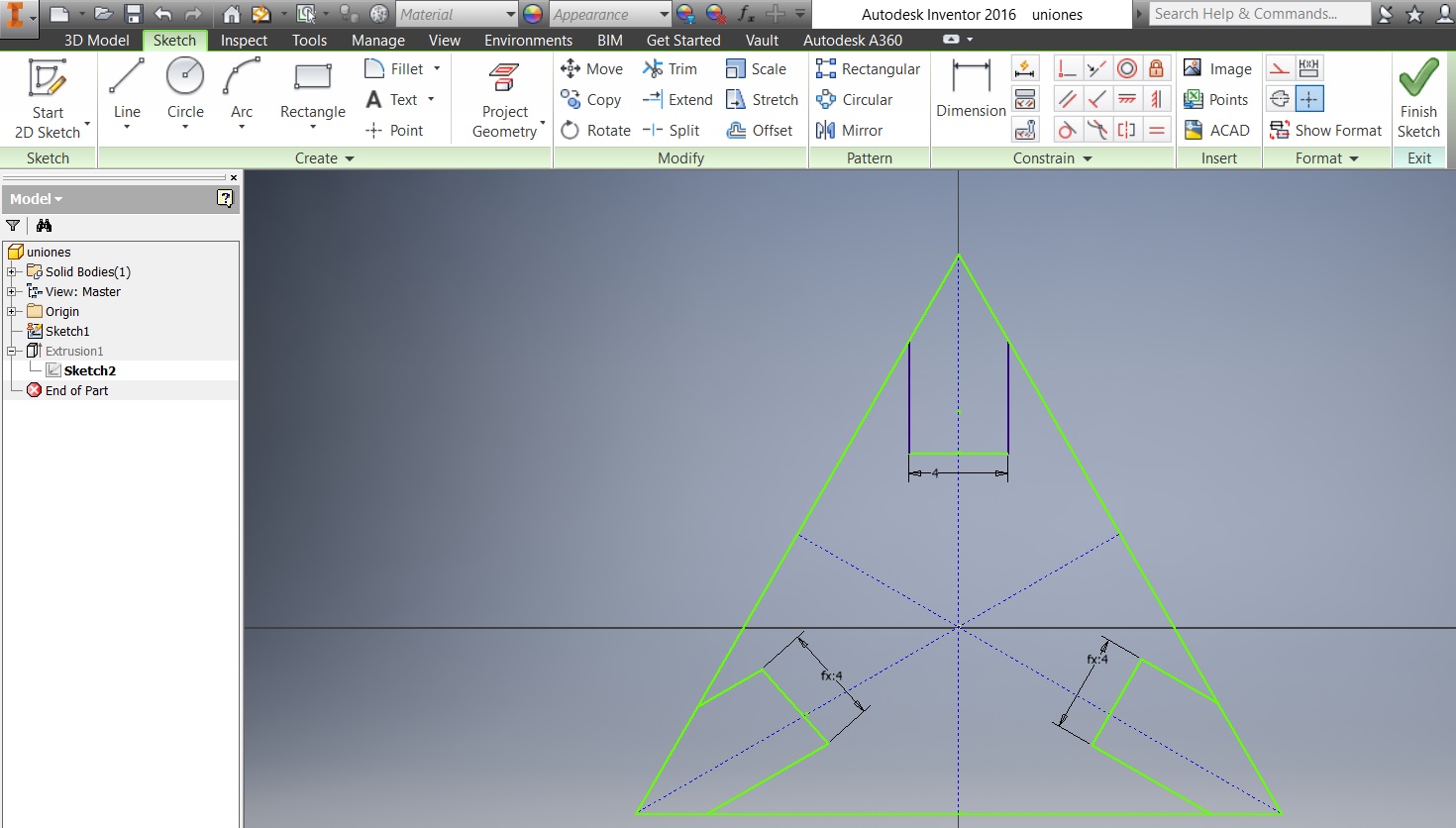

Also perform a test of the parameterized dimensions, and modify the dimension from 2.185 mm to 4 mm, and as you can see the dimensions are all modified equally.

And finally, the dimensions of the other designs of the "wine shelf" are parameterized.

And finally, extrude all the design in the plane and then export the faces in DXF format.

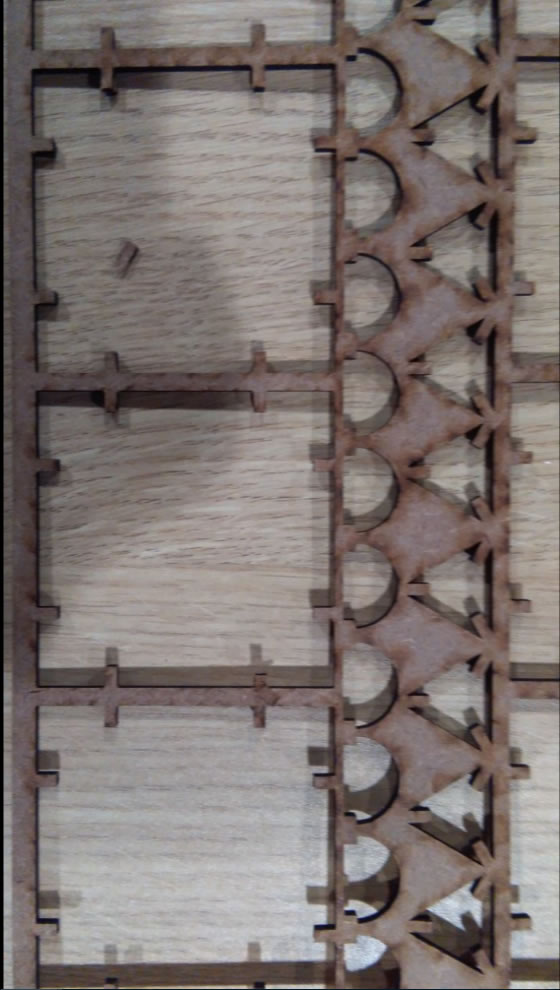

These are the 3 pieces that are necessary to make the WINE SHELF.

Then export the faces in DXF format, and cut it in the EPILOG.

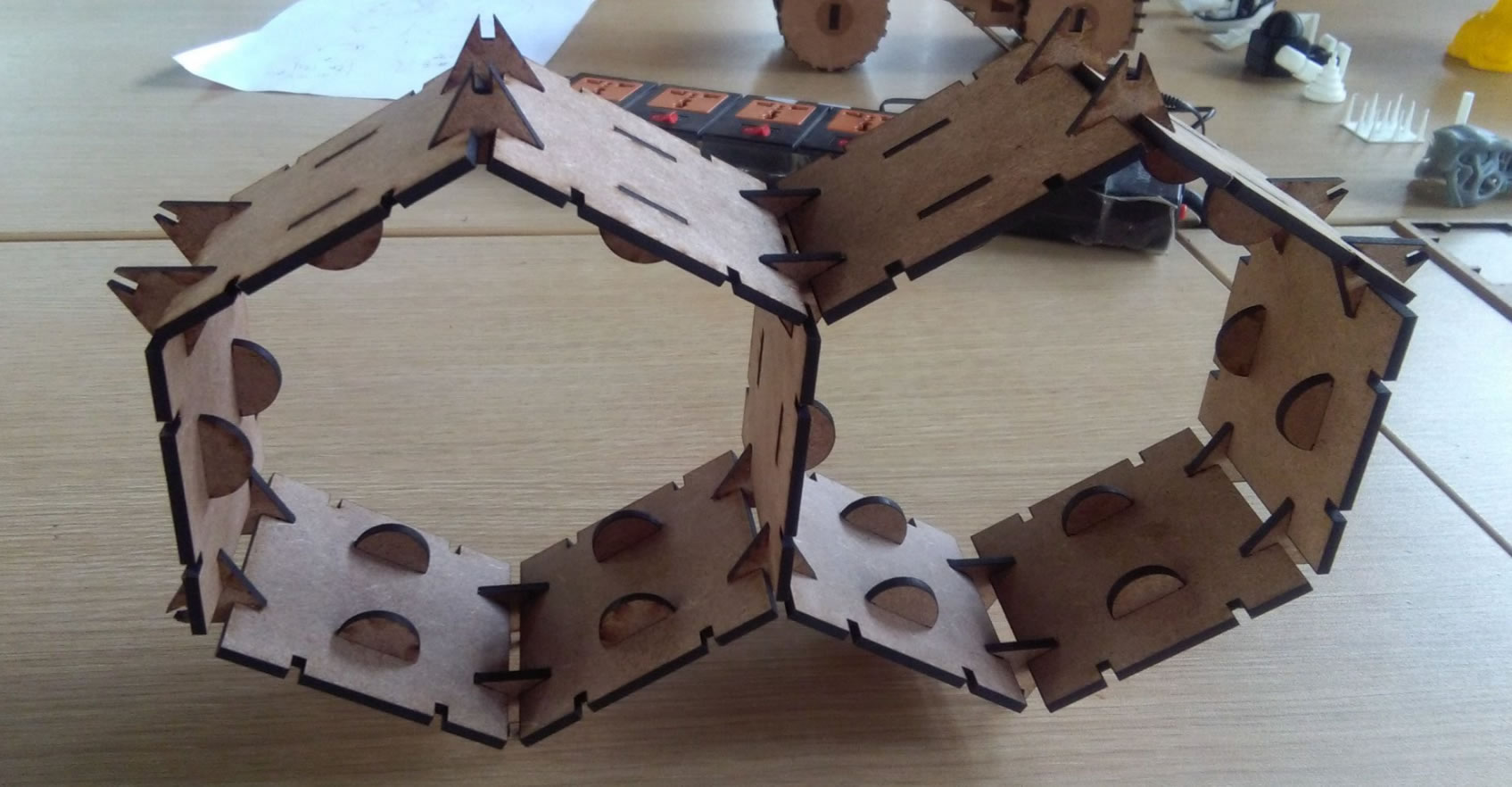

Then, I started to assemble the cut pieces.

As you can see, the shape of each shelf are HEXAGONsS

And this is my WINE SHELF

Click here for Download the files

VINYL CUTTER

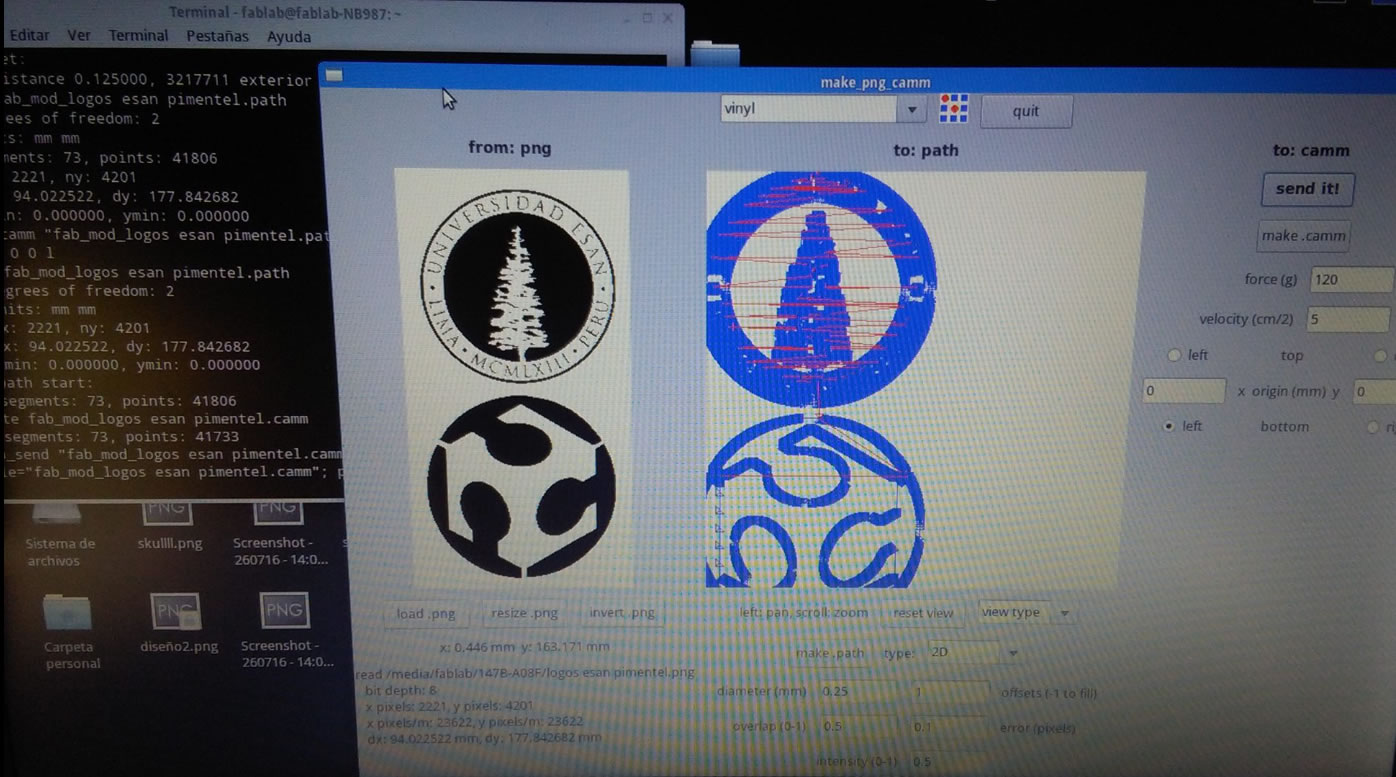

In the laser cut, I decide to manufacture the LOGO of the FABLAB and the ESAN University for my car.

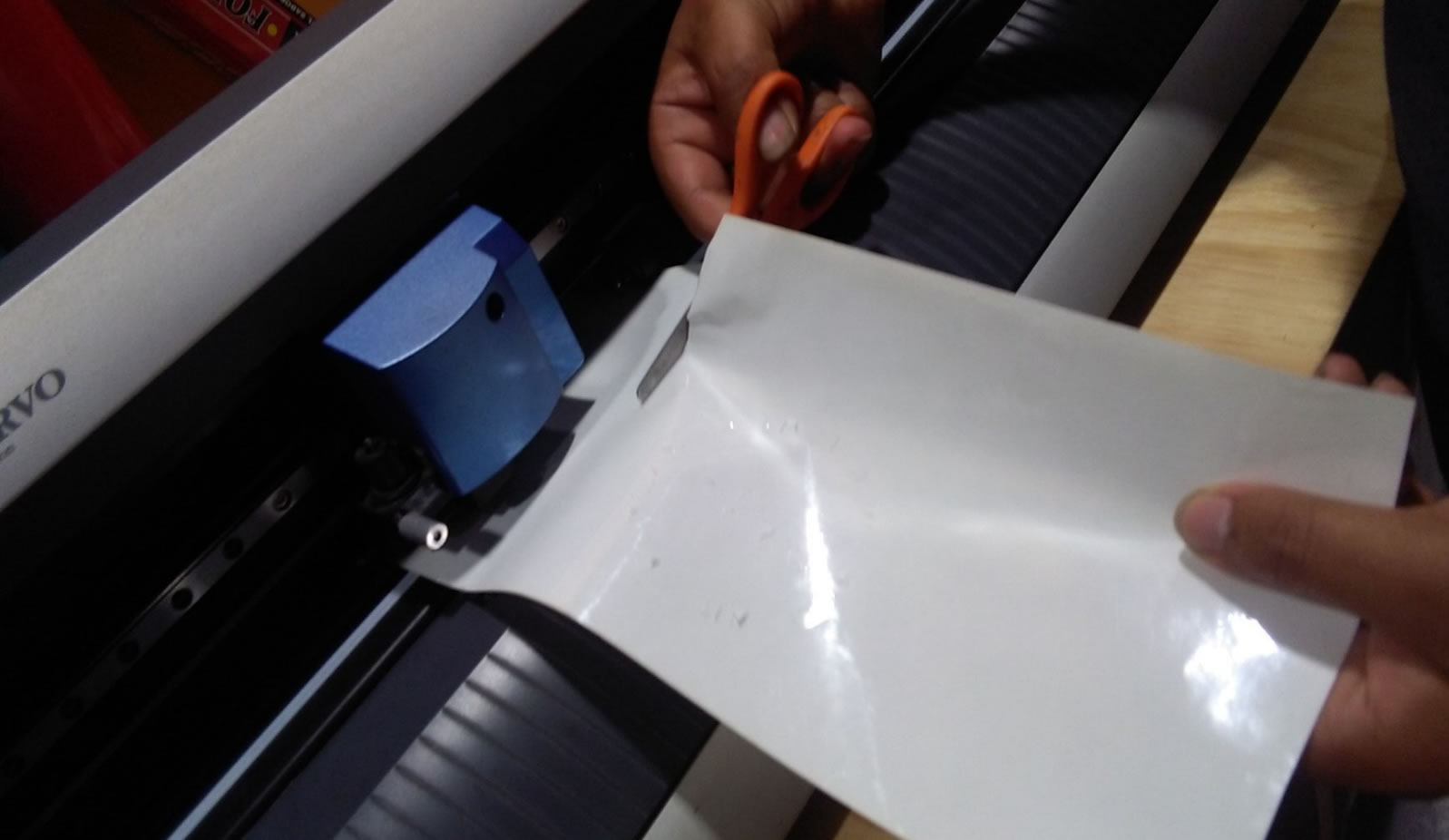

I use the VYNIL CUTTER ROLAND.

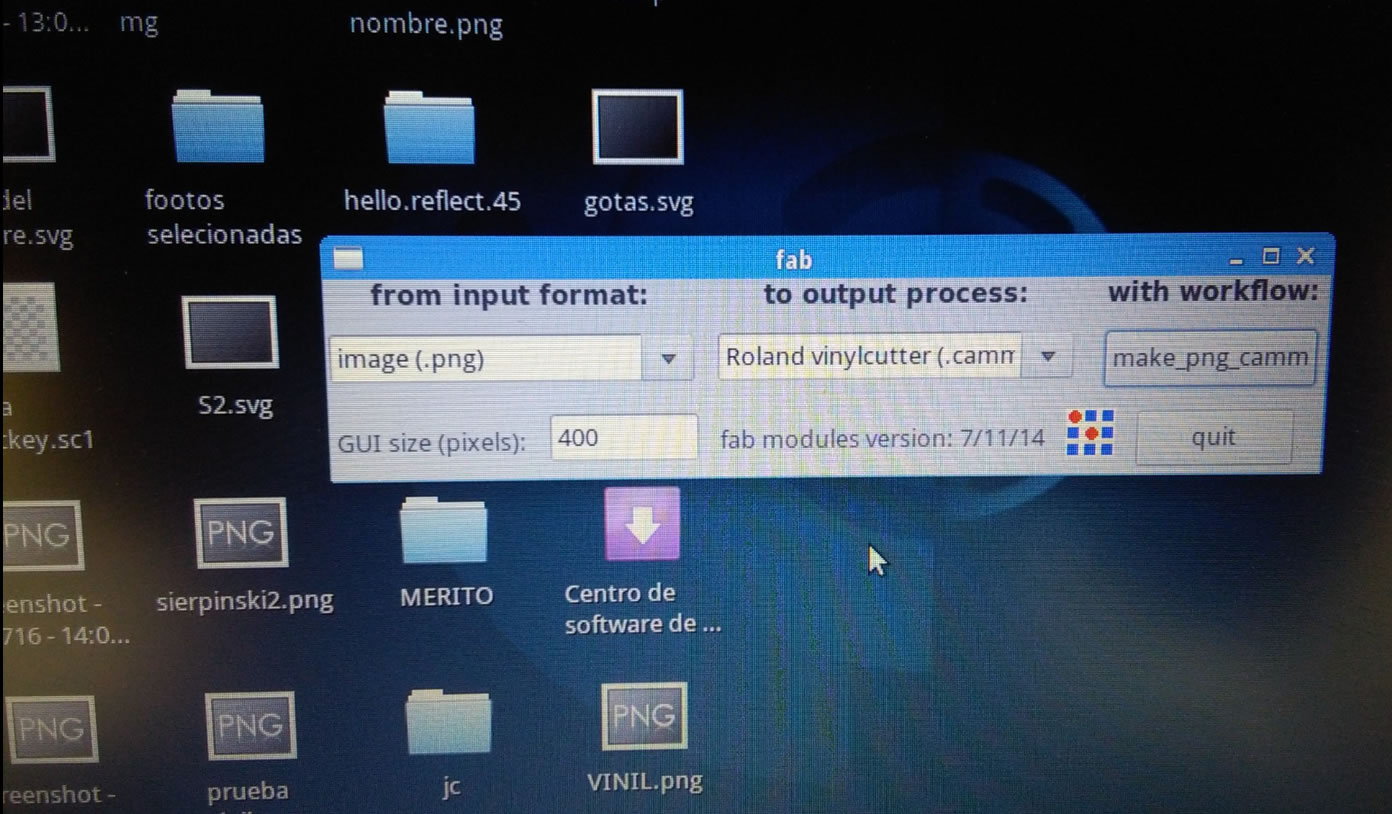

First open the TERMINAL in LINUX, having as consideration image, PNG format and the machine.

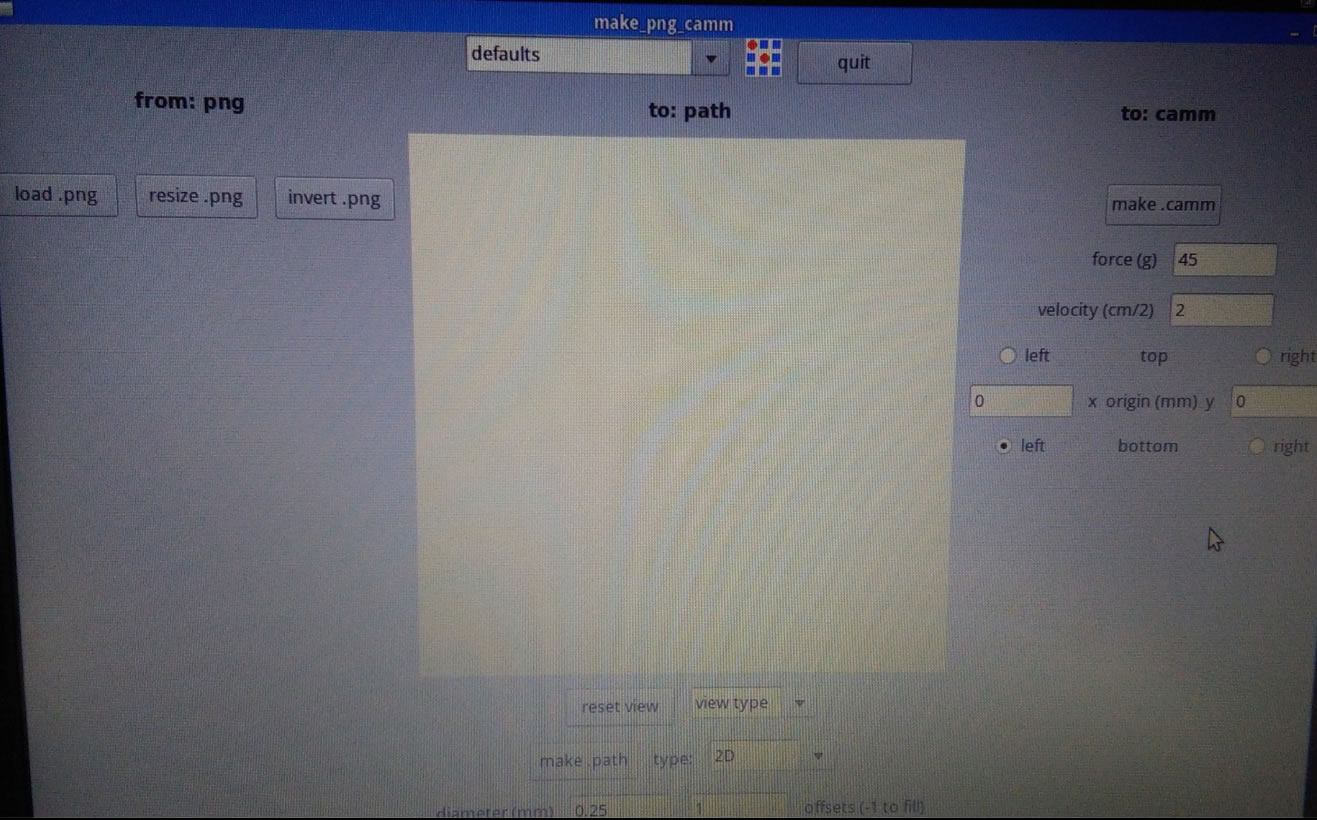

Load the designs in PNG format into the template of the VYNIL cutter, and enter the cutting characteristics, velocity 5 and force 120.

And ejecute the file.

Then, with a scissors, cut the VINYL base where the cut of the LOGO was made.

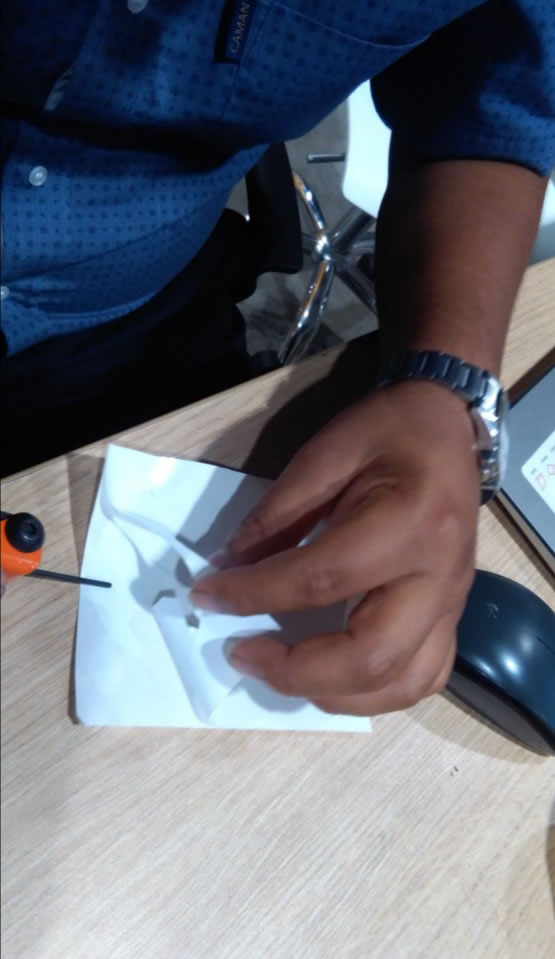

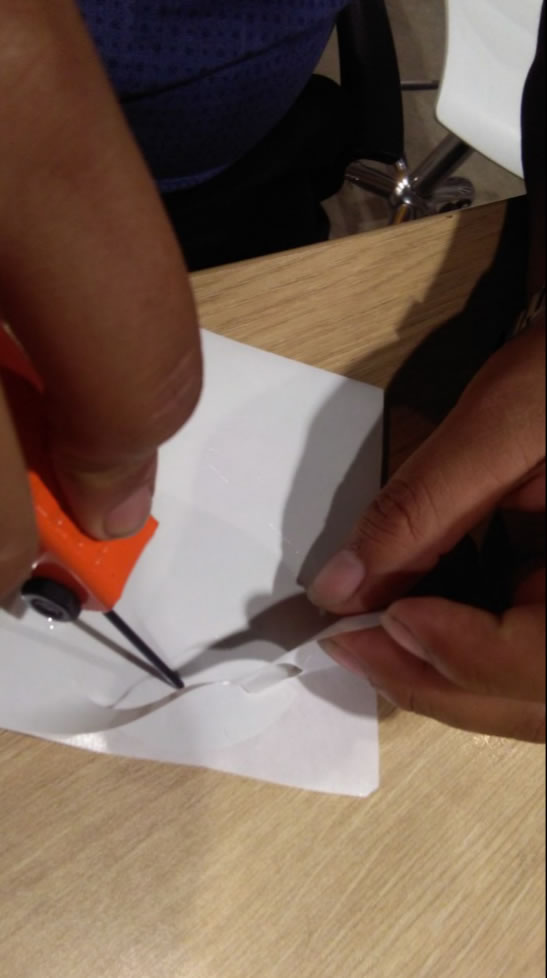

And separate the adhesive residue.

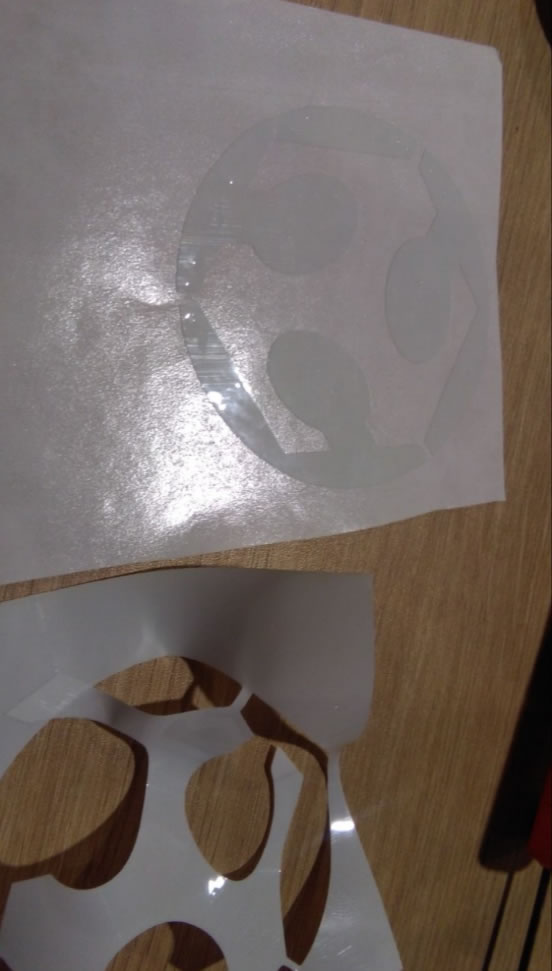

This is my logo FABLAB and ESAN.

Finally install logos of VINYL in the back door of my car.

Click here for download the files