4 - 4

<

>

2 - 2

<

>

1 - 6

<

>

3 - 12

<

>

7 - 10

<

>

15 - 15

<

>

VIDEO: TEST 1

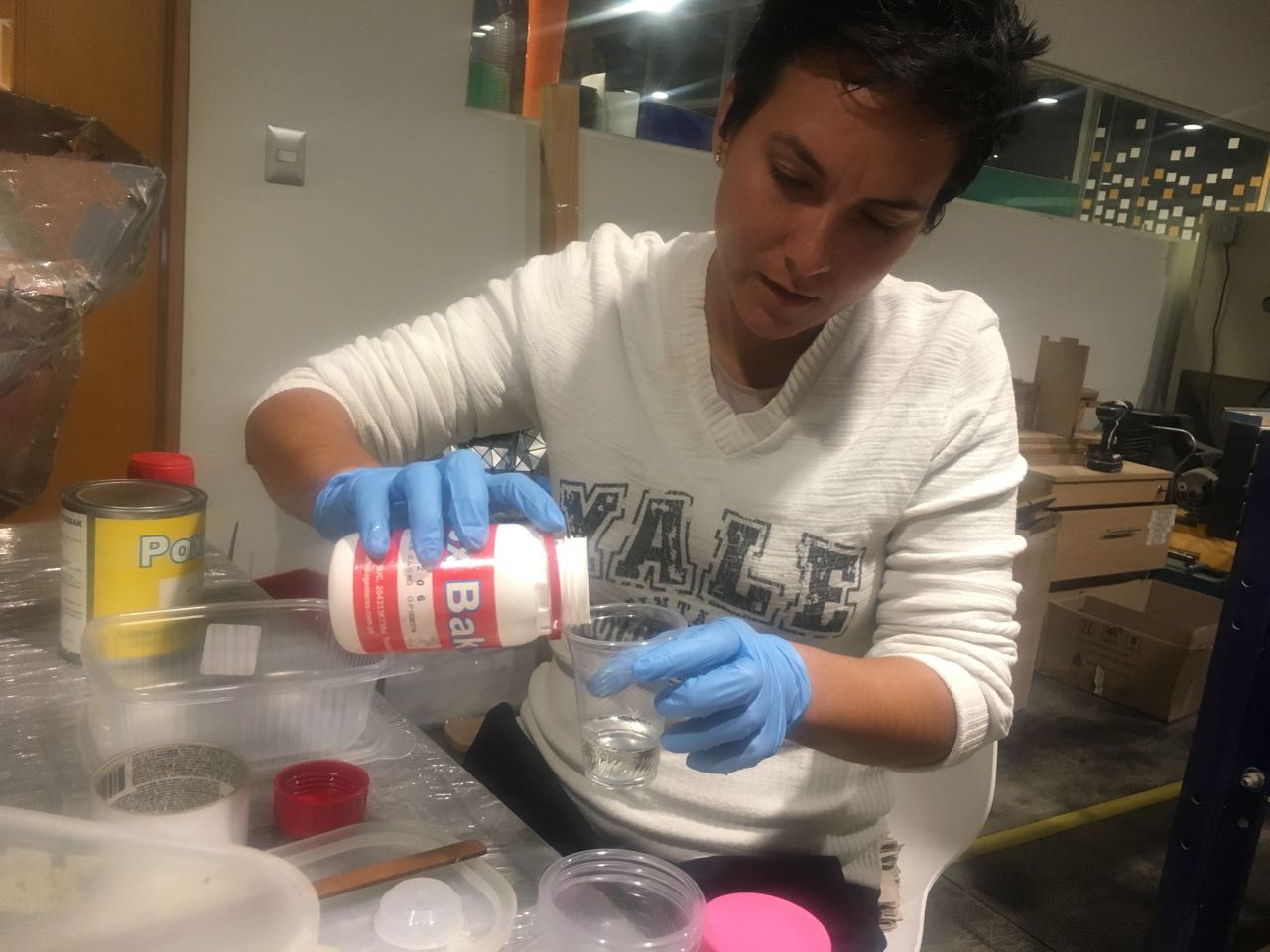

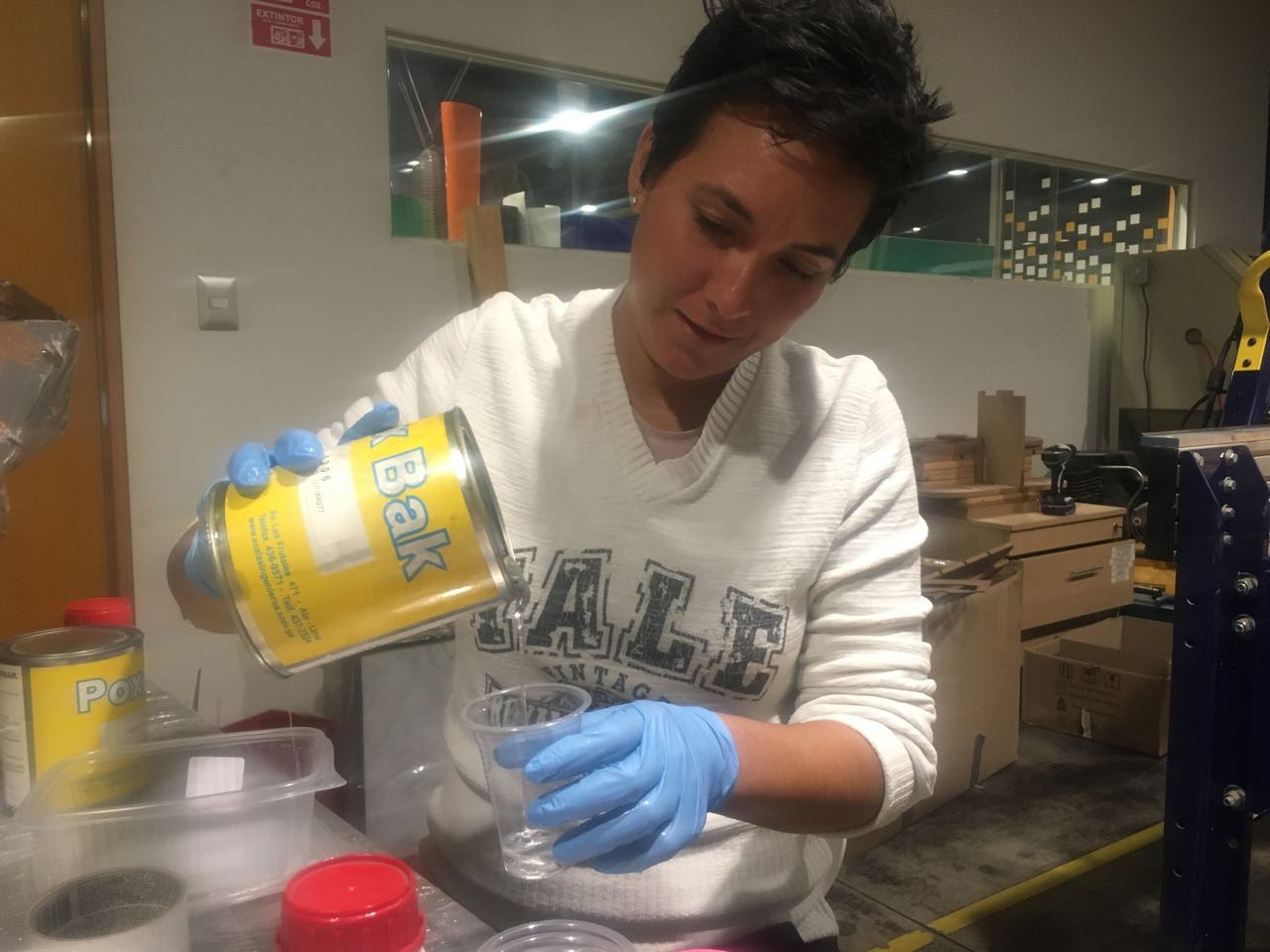

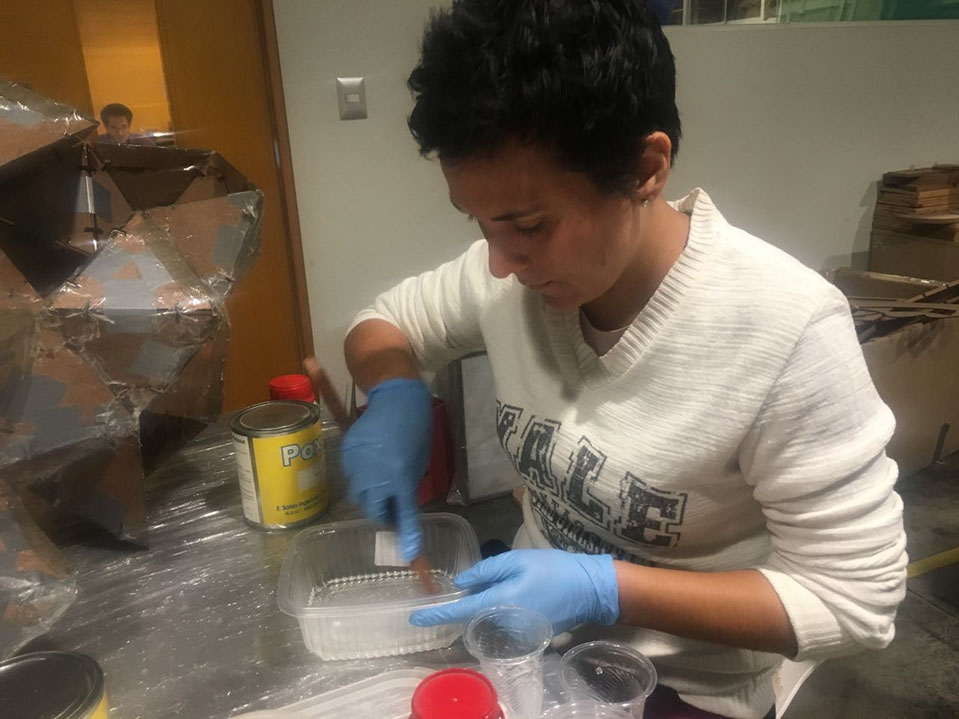

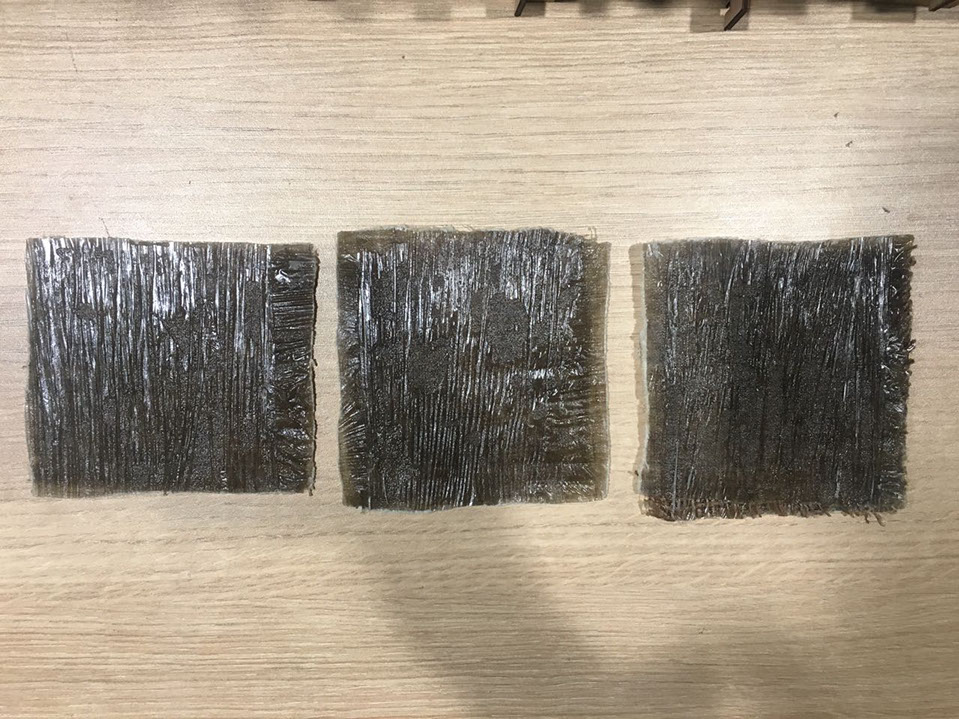

The first test we did was to remove the resin with the hands tightening as strong as possible. We let the tests dry outside. It took two days to dry well and the result as seen in video 2 was: irregular texture, very compact and non-flexible material.

VIDEO: TEST 2

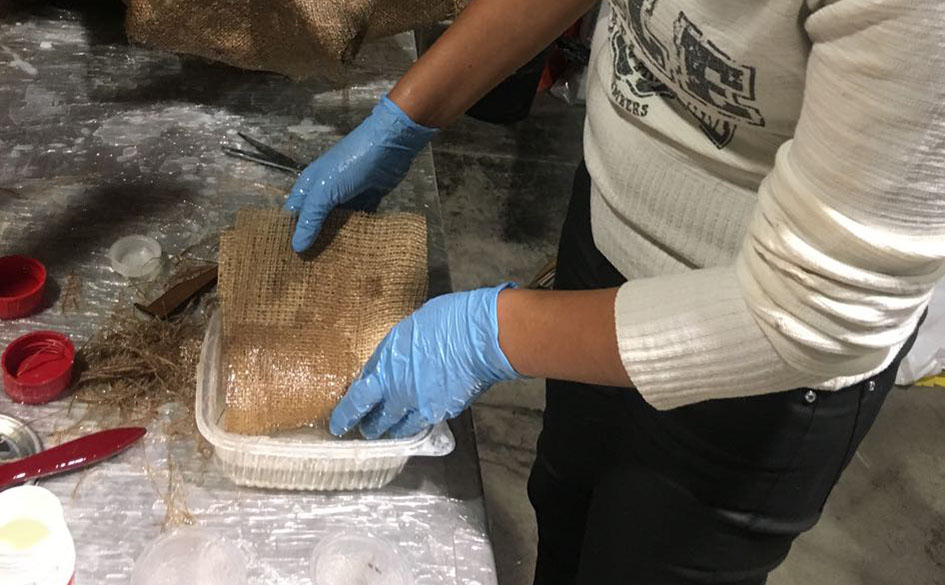

The second test was to compress the material between two mdf using presses. We let the samples dry outside and it took just under two days to dry well. The results as seen in video 2 were: very even texture, you can see the natural fiber and the material is tough but flexible. This was undoubtedly the best result.

VIDEO: TEST 3

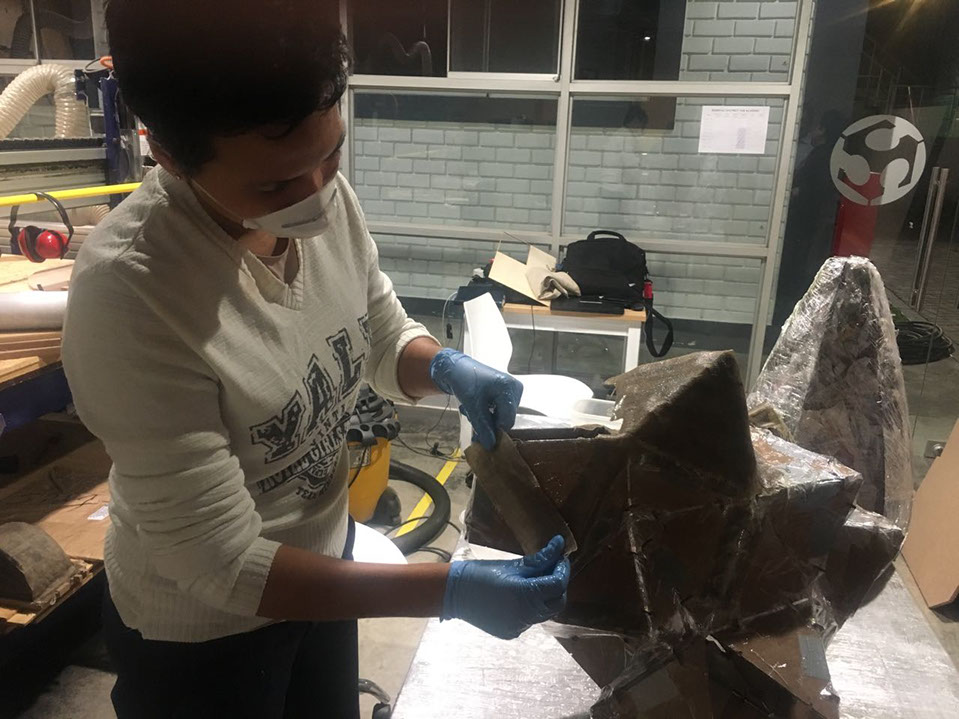

For the third test we remove the resin with the hands tightening as much as possible. We place the samples inside mdf supports and place them inside a plastic bag that has a valve to extract the air with a vacuum cleaner. It took two days to dry well. The result as seen in video 2 was: Texture not very even, material more or less flexible and more or less compact.