Tools Used

- Fusion 360 | Download (Education Version) | 98 MB

- Rhino

- Shopbot 8 feet X 4 feet

- Partwork ( Software is given by Shopbot itself)

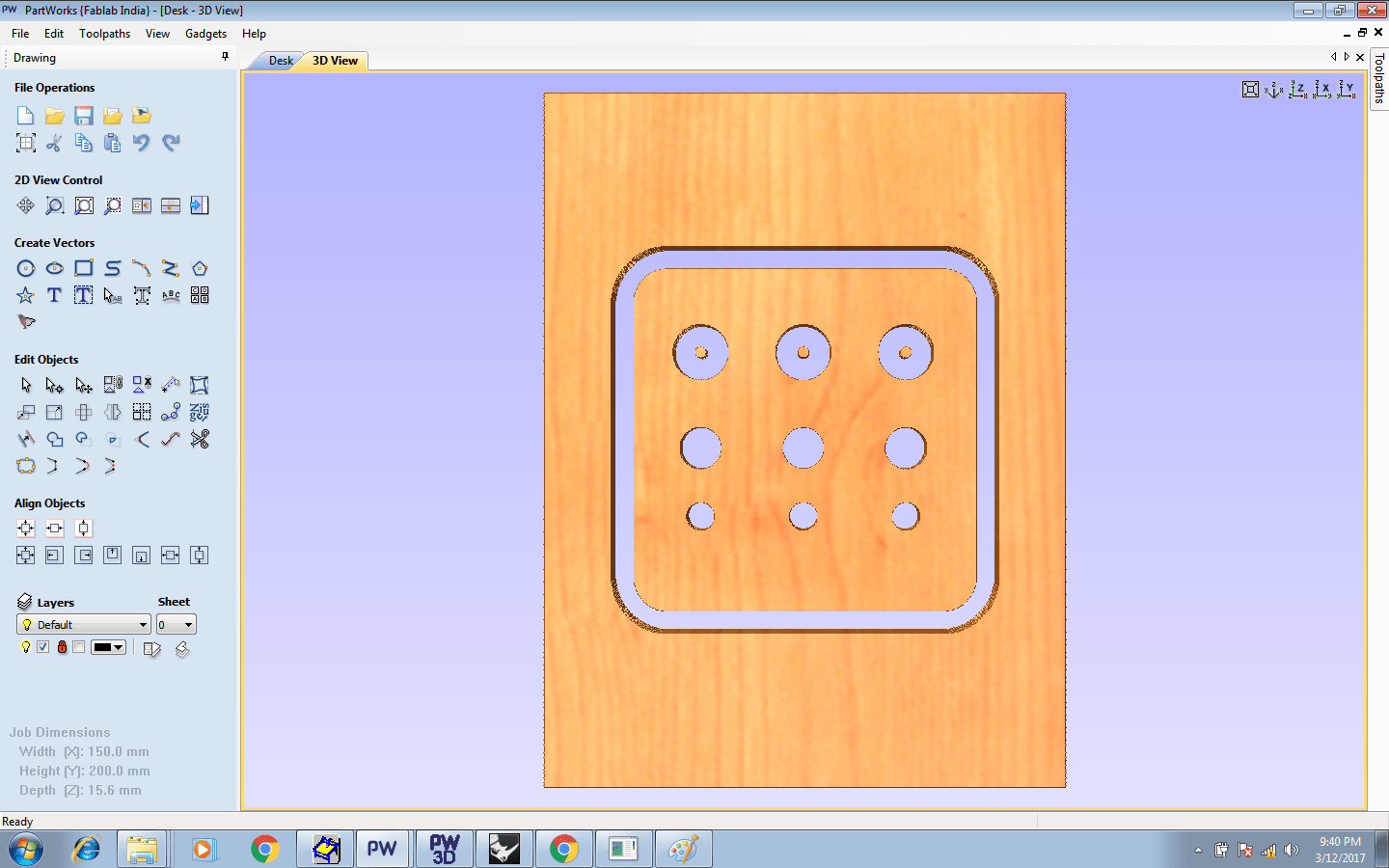

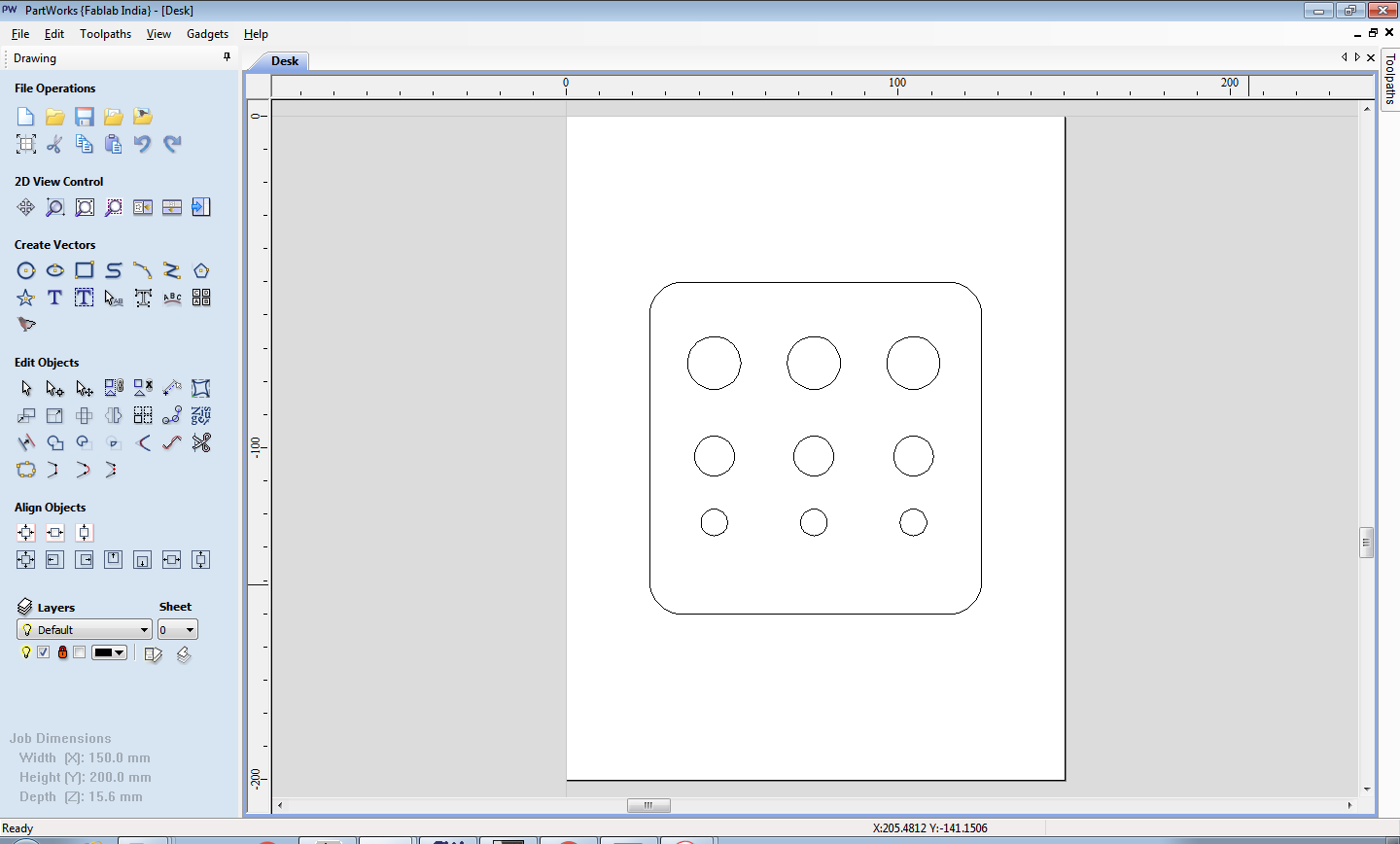

Pen Stand ( 2D Cutting | 15.6 mm MDF)

Starting with Small to Understand working and function of ShopBot

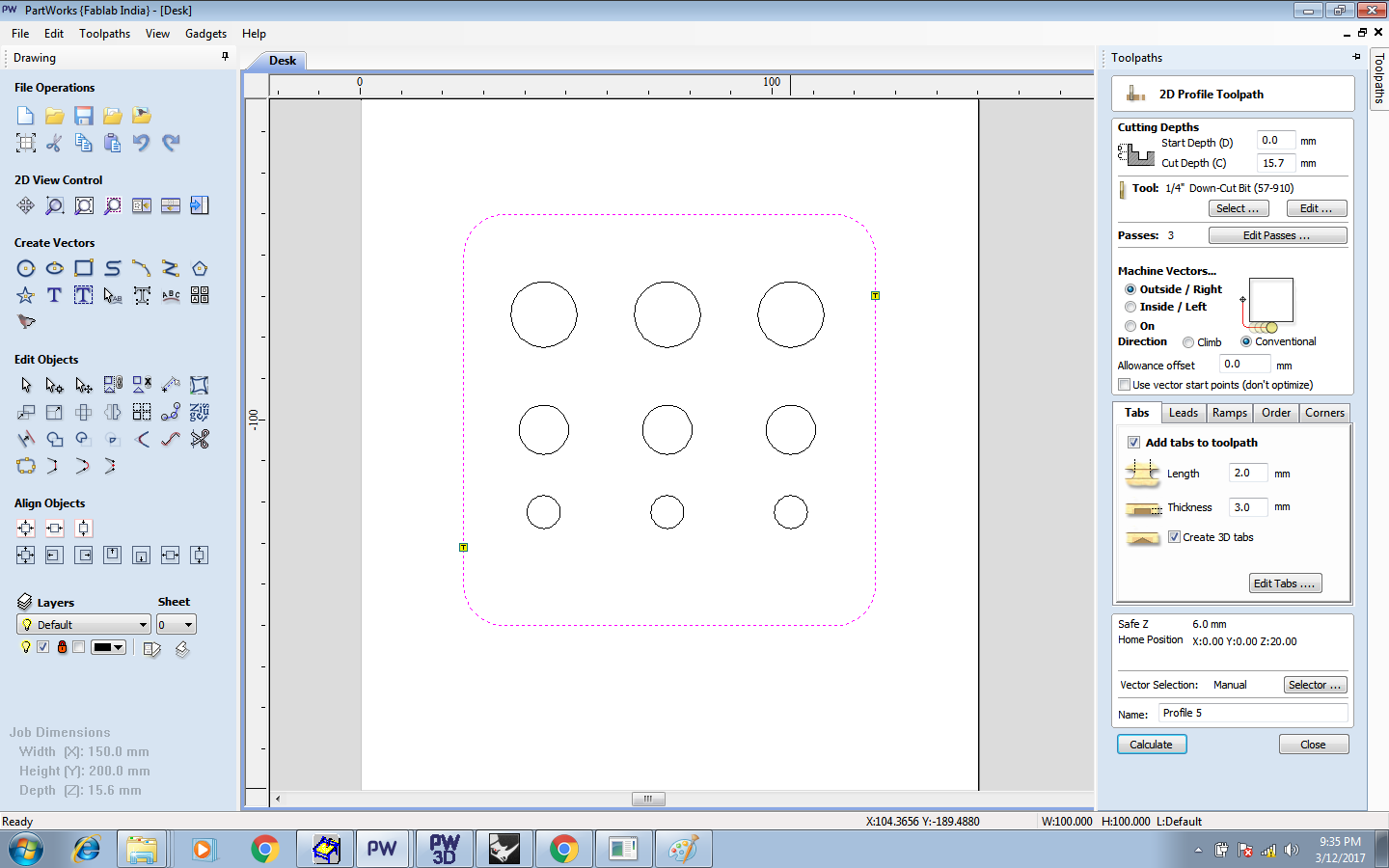

- You need to make a drawing in 2D file save as dxf (its universal format)

- Open that file in Partwork 2D.

- Now you need to setup margin and location of origin

- Open toolpath (right side upper corner)

- Different icons are listed

- Starting it will ask for Thickness ( Use Vernier )

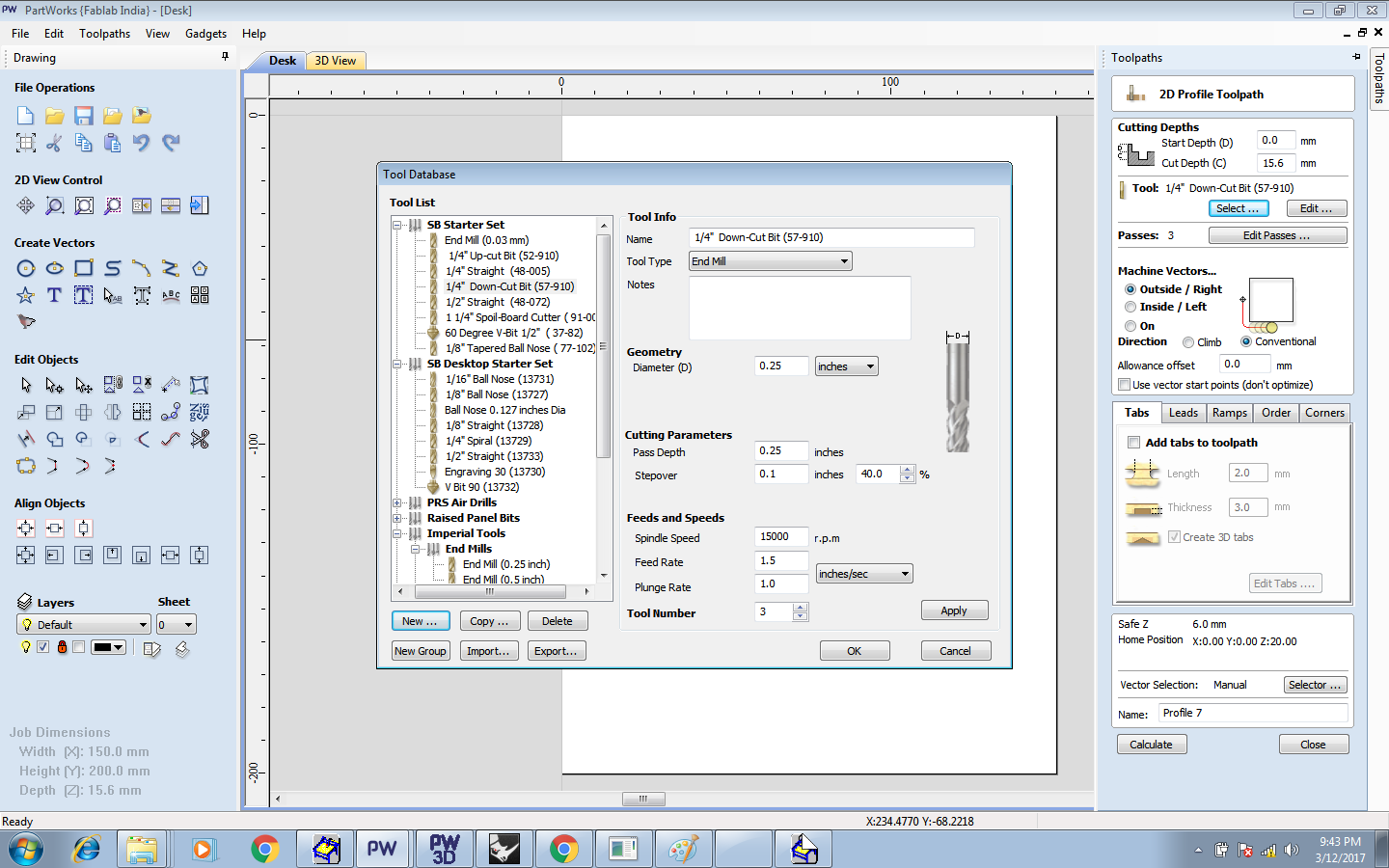

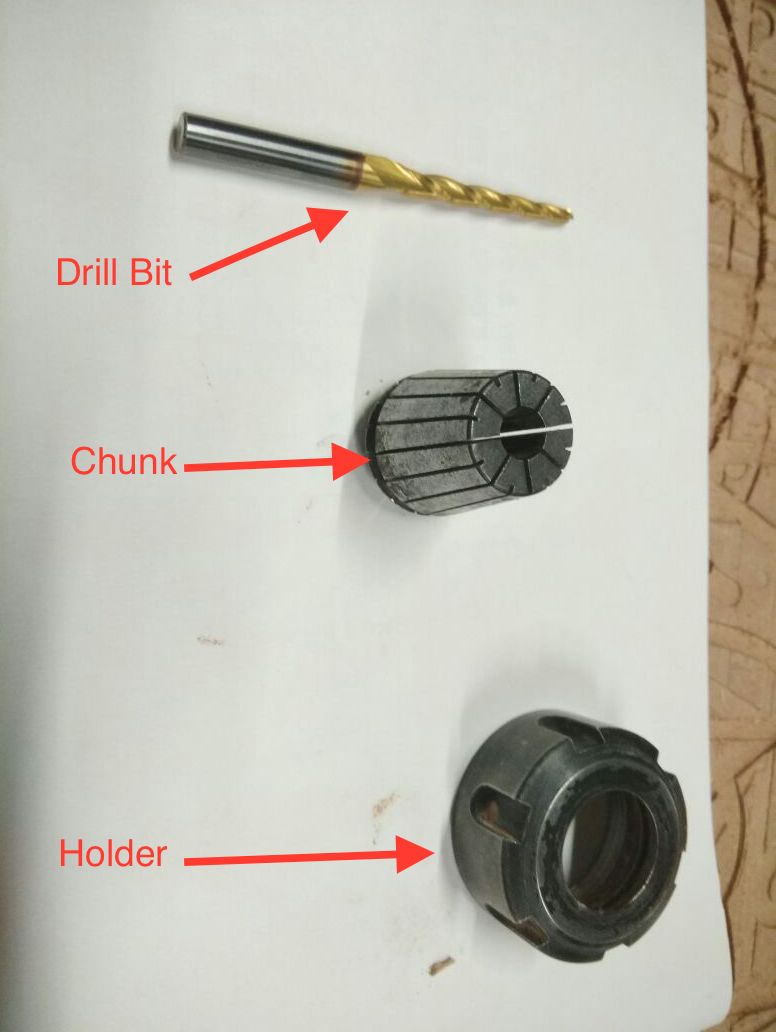

- Select Drill Bit

- After that select drawing and give a tool path ( Check it is Out | In | Online ) Because a mistake over here can spoil your material

- Then as required set for drawing in you project. ( I set OUT for outer cut and IN for holes )

- you will have profile to set and check sequence and its animation

- Now export to .sbp file

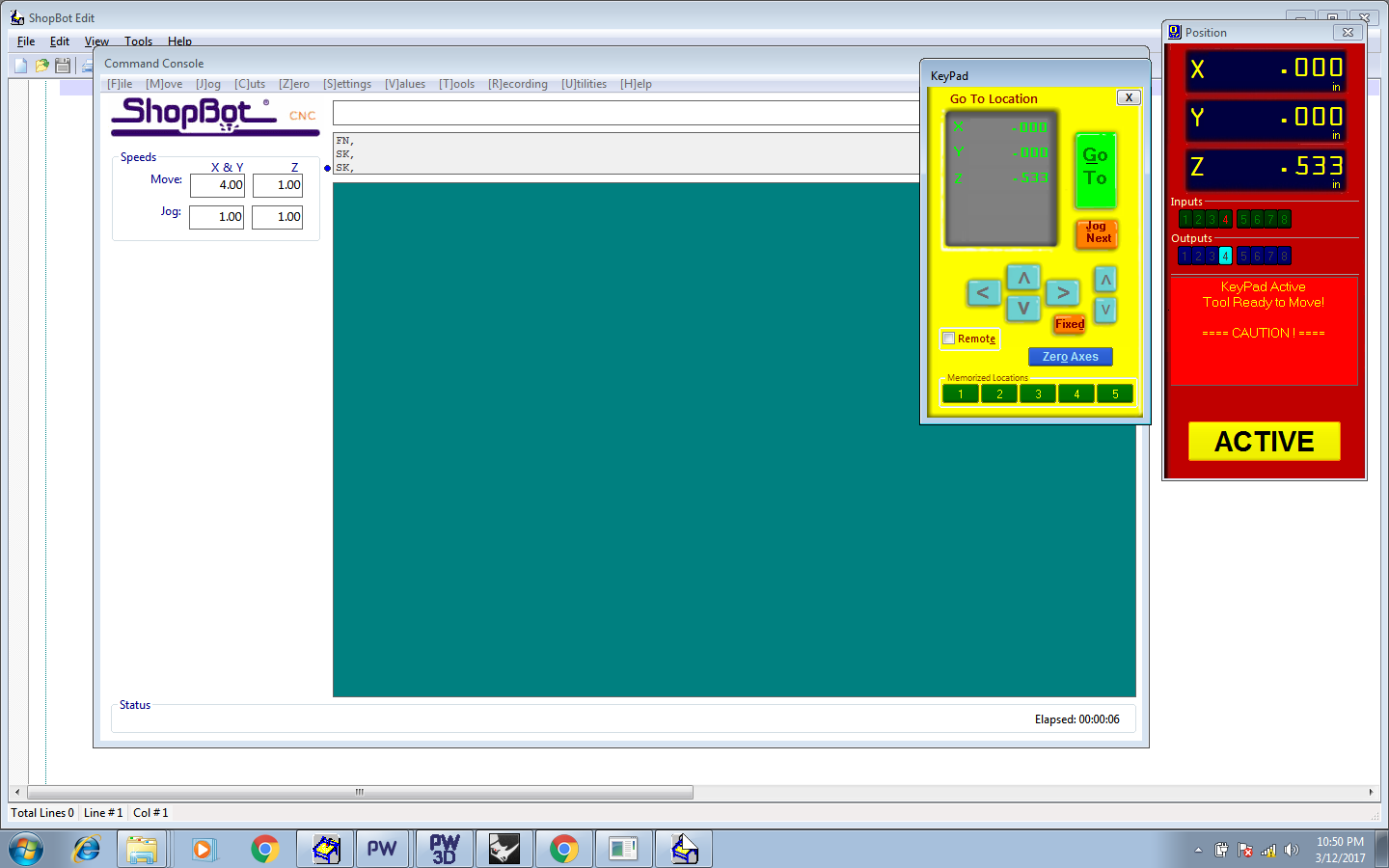

- open Shopbot software

- adjust a ( X Y Z )

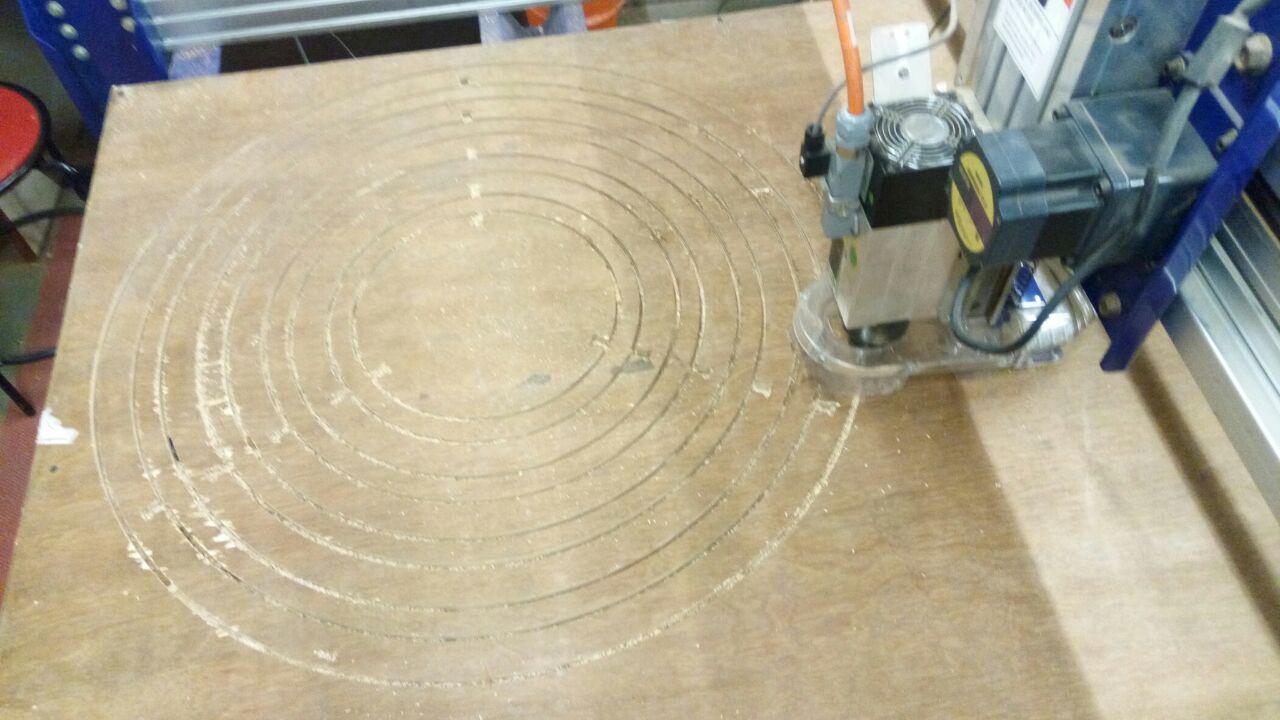

- Follow to matching step below Important Below Image has a Problem in it (There is no tabs , without out that it can create a problem in cutting and also accident can happen

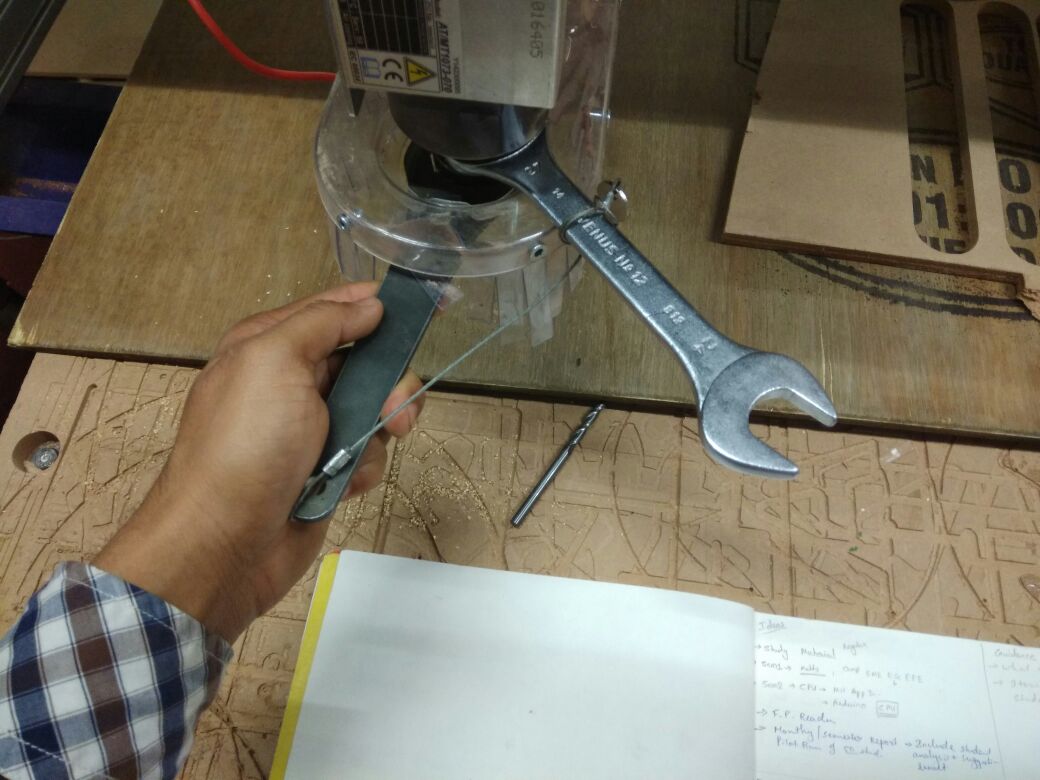

Photos of the Process

Important I made mistake in selection of drill bit I selected ball nose instead of End Mill for cutting

Select Drill-bit according to your requirement and check with Machine rules for RPM according to Material and Drill bit flute.

In Part work you can select Path and arrange tool path.

ImportantAlways do inside cutting first then edge cutting. to avoid displacement of material on bed and add tabs at required distance

Raw file ready now we can proceed to set XYZ axis.

Setting X Y Z axis

Working with Shopbot Machine

clamp it or screw it so it become fix

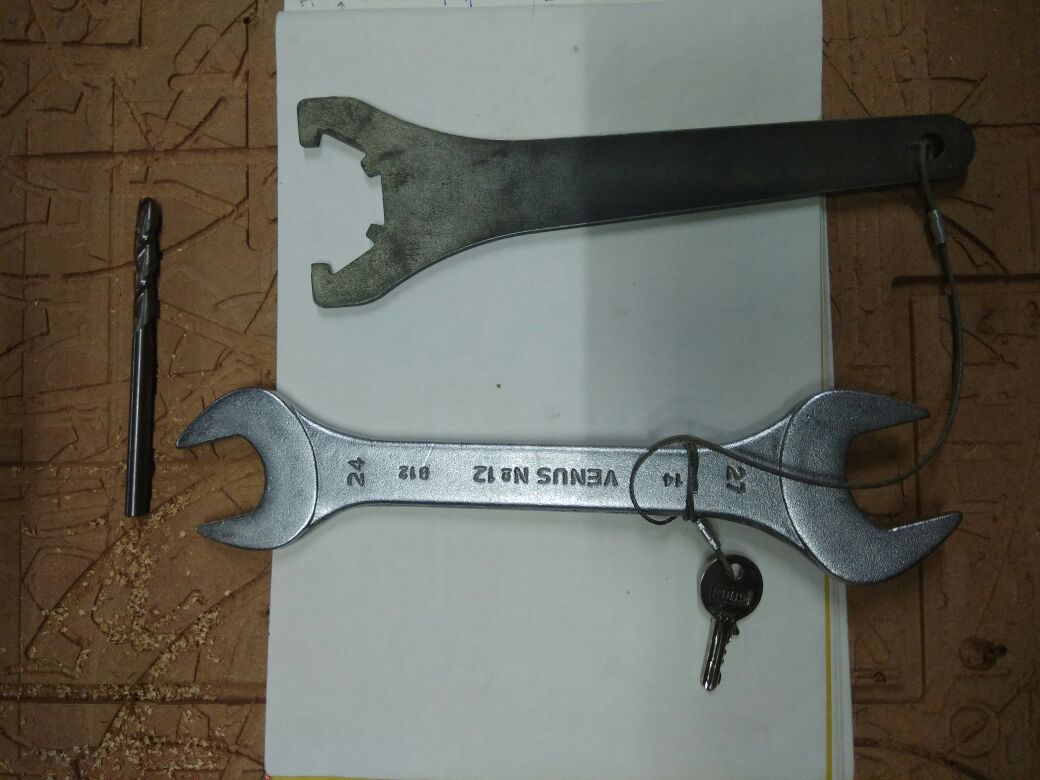

Take Drill bit and check that it is proper then you have to set that

Important Switch off ShopBot while changing Drillbit

Check images for more details.

Drill bit has to be fixed on proper depth in spindle.

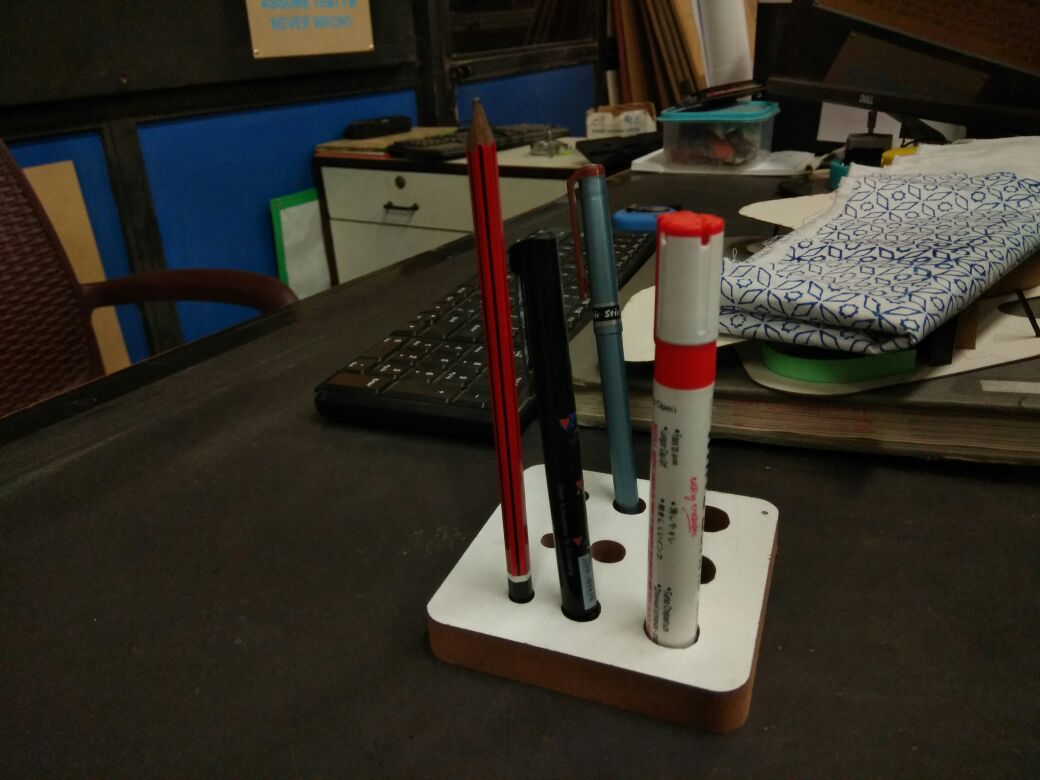

So starting with Small I have made a pen stand with different Diameter

It has inner cut and outer cut. Material used is MDF 15.6 mm Thickness

Pen stand is Ready. Now lets make something BIG

Problem Faced

- You need to research a lot for understanding Joints Bend and cuts

- Selection of material is very important so discuss with expert or do small cut on samples