|

|

|

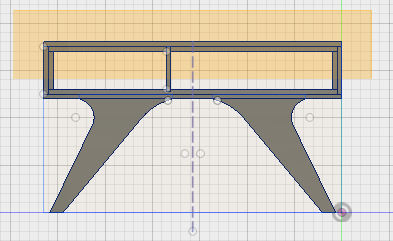

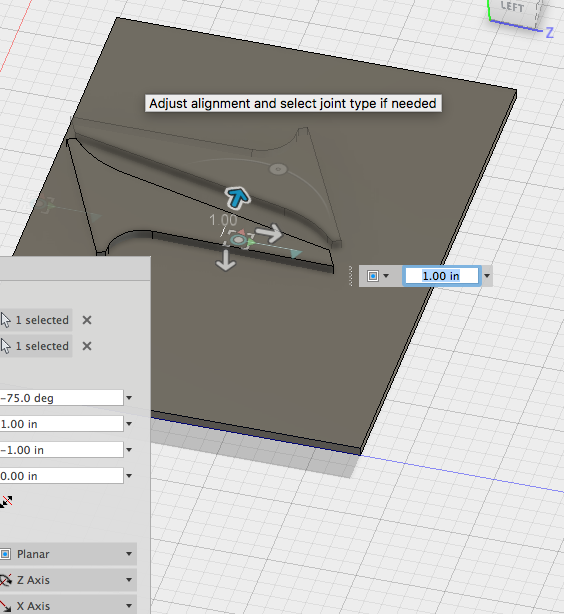

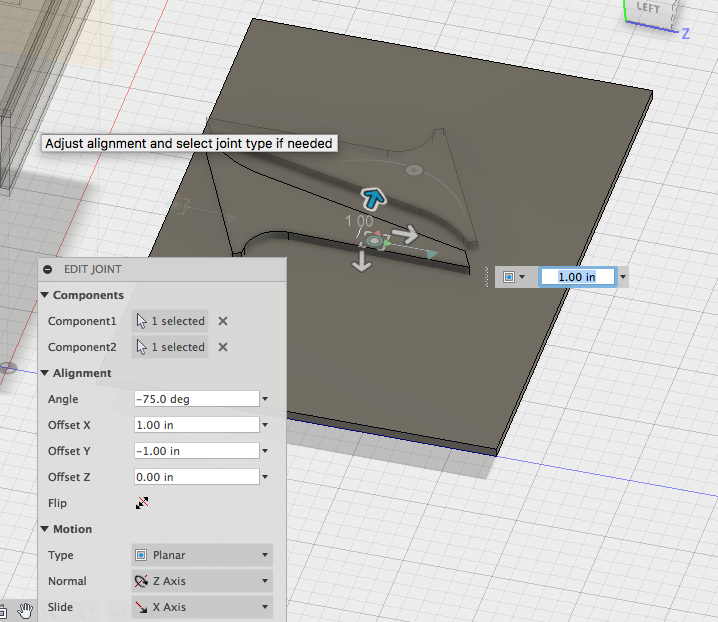

| I prepped some 24X32X0.5 surfaces and joint the components on it. |

Now a view of two legs on a surface. |

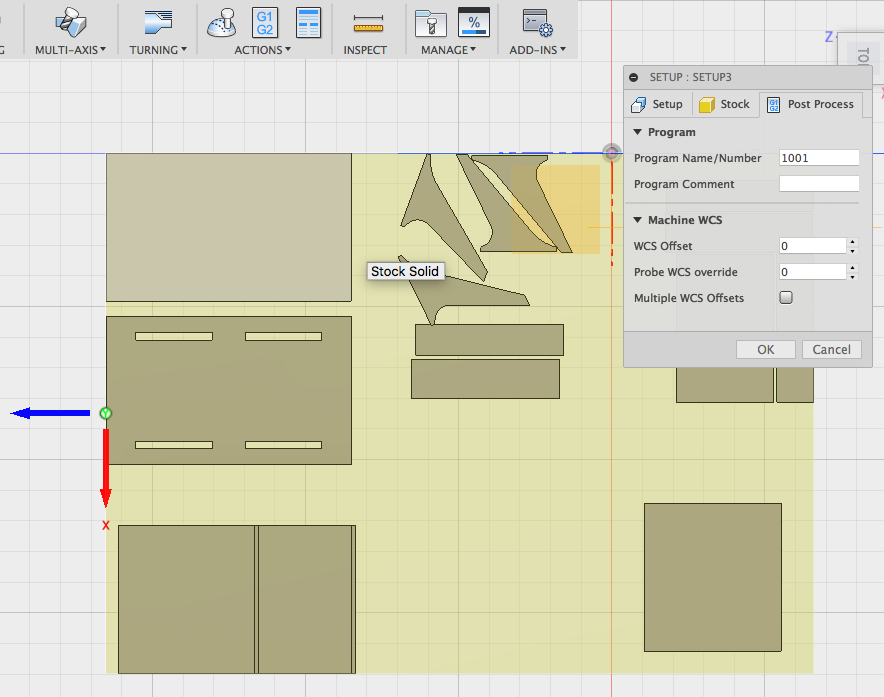

Trying to maximize all my pannels. |

|

|

|

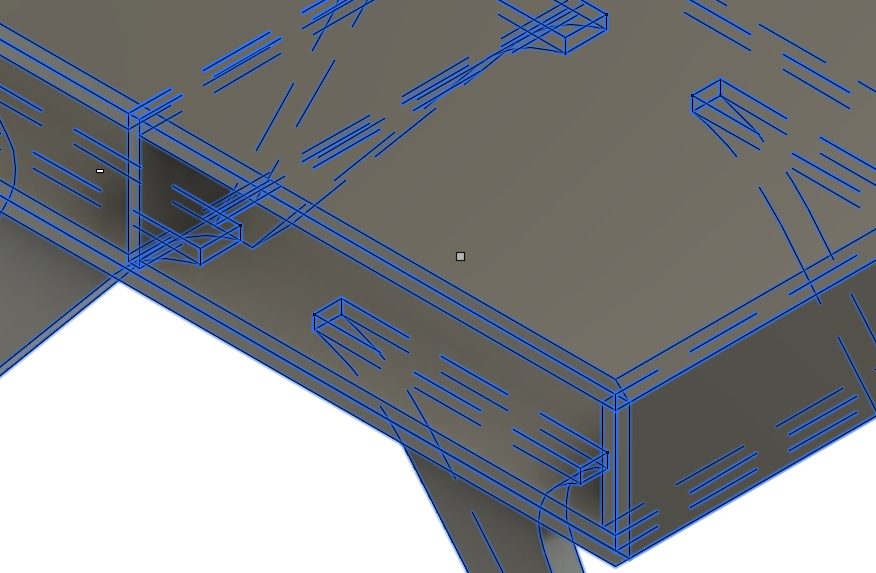

| Here's the results. I can remove the pannels to view all the flat parts.. |

This through view let us appreciate the joints and where the parts connect to each other. |

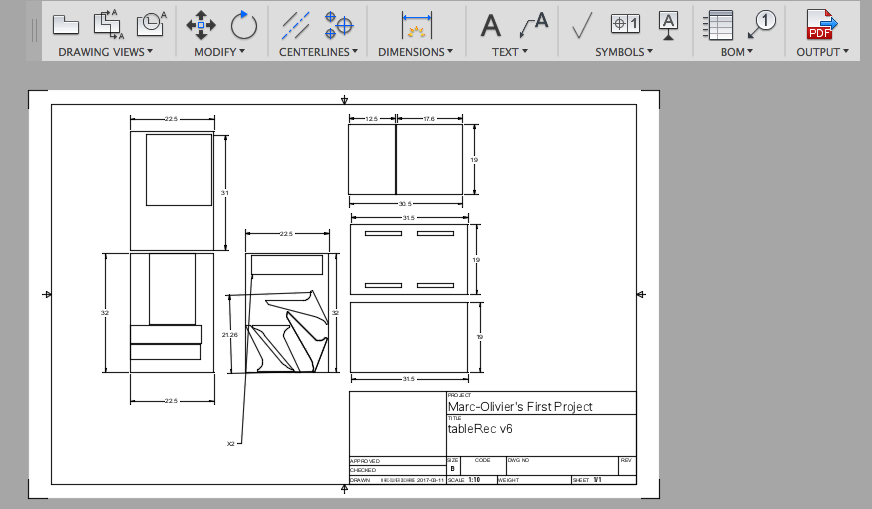

And I used the drawing function to create an assembly and part guide. I did not had much time to play around and it require quite a powerfull computer otherwise it lag. But I will try to work with that later on. |

|

|

|

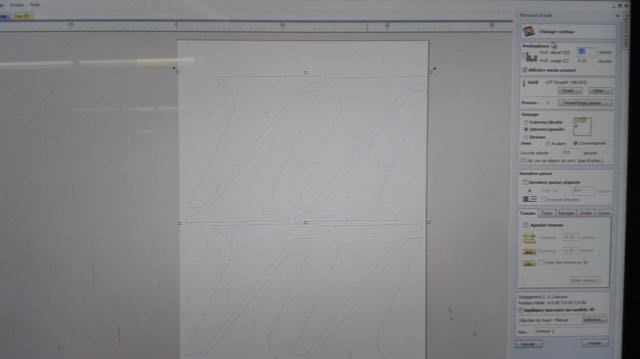

| Importing the DWG in VCarve Pro. Some elements needs to be closed (vectors were opened during export). |

Specifiying cuts. In the case of the legs, I need a outside cutting path, 0.56" deep, using a 1/4 upcut plywood bit. 15000 rpm were calculated using a chart provided with the Shopbot and posted on the wall. |

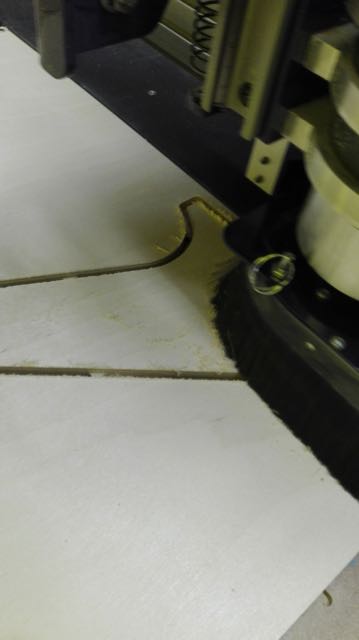

After Zeroing XY using sensors and Z using the plate and aligator clip, I'm ready to route that sh.... |

|

|

|

| I'm truly there, hehe |

the legs are done. I need to remove them from the ply panel by cutting the tabs |

Legs are glued together and pressed in the vacuum table |

|

|

|

| The legs are done. I used Titebond woodworking glue. It set in about 15min and is good to go within an hour. The slots for the legs are done as well. |

Assembly time, using as many clamps as possible. |

Final result, just before varnishing. |

|

|

|

| Felix and I went on for a second project. A large unit to organize powertools. Felix designed the unit in Fusion 360 and we tried to use the milling module to prepare the sheets to no avail. So we used the checkerboard option in VCarve pro in order to process sheets as long as 60" in our max 24" shopbot buddy |

Once everything was done on the CNC, we're putting everything together using long pipe clamps |

The most complicated thing is to keep the geometry while the sides and back panel are not yet assembled. |

|

|

| Installing the back panel and swivel coasters |

Once varnished, the final result! |

-->