WEEK 12

3D MOLDING AND CASTING

Assignment: Design a 3D mould, machine it, and cast parts from it.

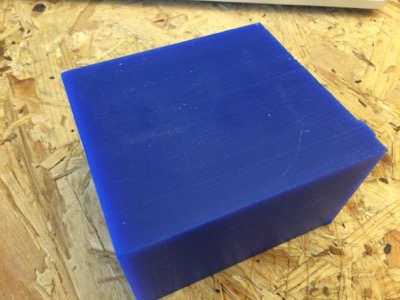

Material: - Machinable Wax

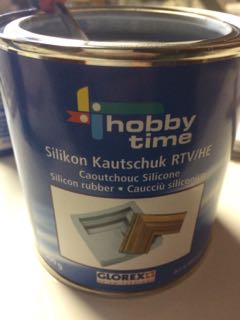

- Silicon Rubber RTV/HE, from Glorex

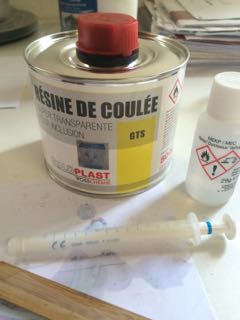

- polyvinyl alcohol, Polyester Resin Softwares: - Rhino3D, 3D design software

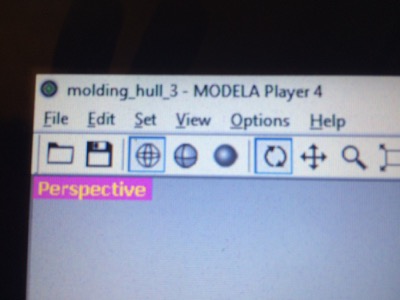

- MODELA Player 4, CAM software that calculates and displays the cutting tool path from 3D STL file

DETAILS

Design a moldand cut it in the Wax

I decided to mold a small hull of boatusing the small CNC (Roland monoFab SRM-20)

|

Here is the Machinable Wax piecein which I will do my mold

|

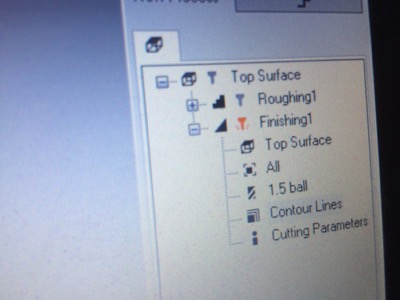

Using the software Modela Player 4coming with the Roland monoFab

|

|

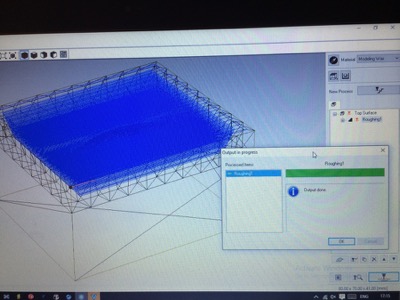

Compiling the Roughing jobwhich is the first milling job

|

Here is the previewand the positioning of X/Y Zero and Z Zero

|

|

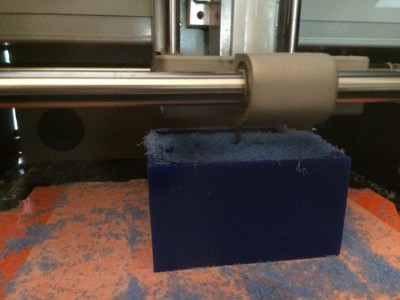

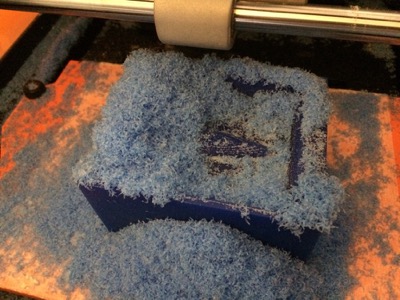

Milling in progressusing a 4mm Square milling bit

|

Milling finished

|

|

Here is the result of Roughing

|

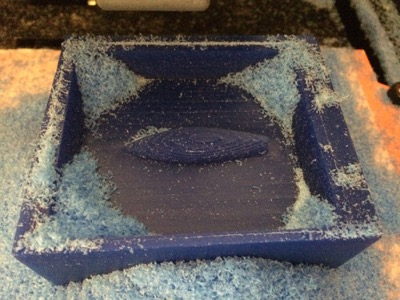

Configuring the Finishingusing a 1,5mm Ball milling bit

|

|

And here is final resultgreat machin this Roland!

|

|

Doing the Mold and Casting the Hull

Doing the mold with Silicon Rubber RTV/HE (same as used previously for the recast job, see extra below)

|

Silicon Rubber in placewaiting for 1 day to harden

|

Here is the mold in Silicon Rubber

|

|

Casting of the hull done, waiting ...

|

And here is the final "mini Hull" :-)

|

Extra Credit : (Re)casting from an existing object

As I was not able to go to Woma FabLab the week of the assignment, I decided to do a mold from an existing object, and (re)cast the object

Doing a moldfrom an existing object

I took a Chess piece, the white queen, and I did a mold of the piece using some Silicon Rubber

|

Here is the Chess piecethat we will duplicate

|

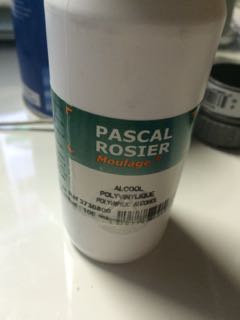

The piece is brushed with polyvinyl alcoholso that the Silicon will not stick or mess the piece of wood

|

|

Putting the piece in a tubein which we will do the mold

|

Here is the Silicon Rubber usednamed RTV/HE

|

|

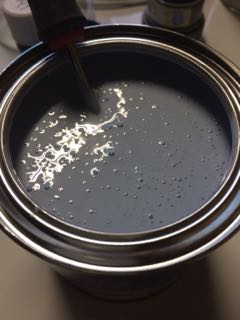

Mixing the Silicon Rubber

|

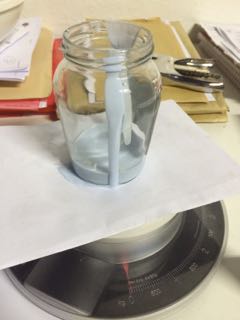

Weighing the Silicon Rubber

|

|

Mixing it with the good quantity of hardener

|

Casting the Silicon Rubber inside the tube

|

|

And waiting for 1 dayso that the mold can harden

|

Mold is taking out from the tubeit is solid now

|

|

The bottom is cleanwe can see the bottom of the wooden piece

|

Taking the Chess piece out of the Mold

|

|

Using a cutter to open the mold

|

|

(re)Casting the Chess piece in Resin

Using polyester resin to recast the piece

|

Closing the moldusing scotch

|

Doing the mix of Polyester Resin with the Hardener (2%)

|

|

Casting the piece

|

Top surface is plan

|

|

And here is the new piece ... a crystal queen!

|