Assignments

#1 Test the design rules for your printer(s) (group project)

As this is the group project, we work in our group to define design rules for all available for us 3D printers. We collect data for Prusa i3 hephestos, Ultimaker, Woma "Dom Kit".

When we prepare the model to be printed on 3D printer we need to follow some important rules. They are related to the technology we use, to specific printer limits, to material limits and so on. We can determine some main rules and we need to follow

them when we prepare our model. It is quiet complex task and it is related to tests and printing of the test models that include all different points and that permit us to check quality of print any difficult shapes on our printers and to align our

settings. But to simplify we need always think and check:

- each layer need to have support. We can not print flying layers.

- each next layer add some weigh. So the lower layers will support it.

- material is melted. So it need to cool down to become again hard. Until it is not cold it support less weight and pressure

- printer has a resolution that is not infinity sharp. So any very sharp points have risk to be not printed

- speed of movement on different axes may be not very precise and depends on speed of movement. So exactly distance between walls need to be calculated and checked

- Make a test print before you start. Do not start huge and long printing model at the beginning.

#2 design and 3D print an object (small, few cm) that could not be made subtractively

Design of object

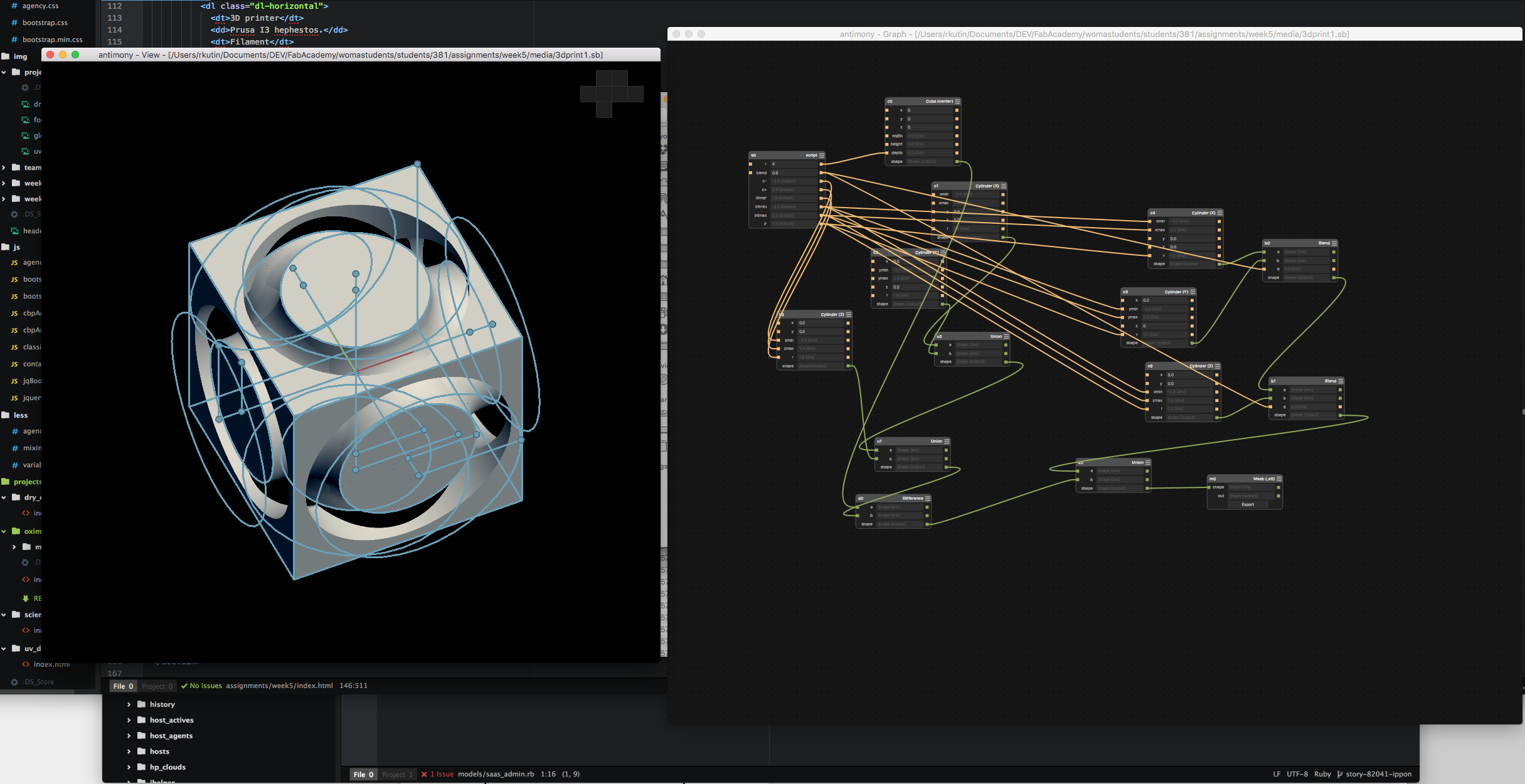

As during previous weeks I decided to use Antimony as a tool that will permit me to generate parametric design in very fast and simple way. I did not wanted to create something huge and complex, but I think more about the point that my object need to be "could not be made subtractively". So I think that if I do one object jailed inside another in this way that it can not be taken out - it will be difficult then to produce it in one piece of material without cut it on parts and glue them after. I decided to design the cube with some blended cross-tubes inside. You can see source code of antimony file here

Antimony model in dev

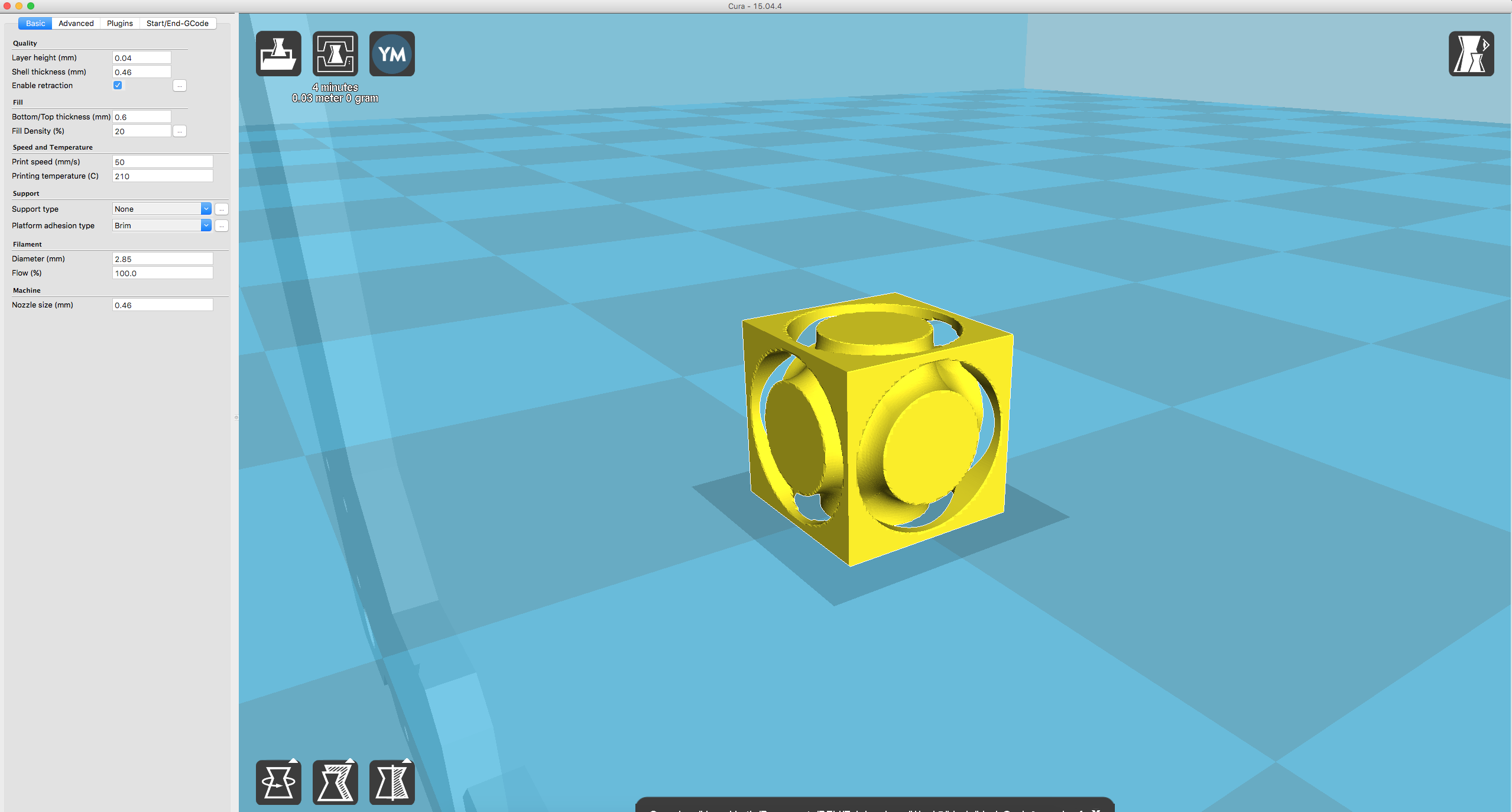

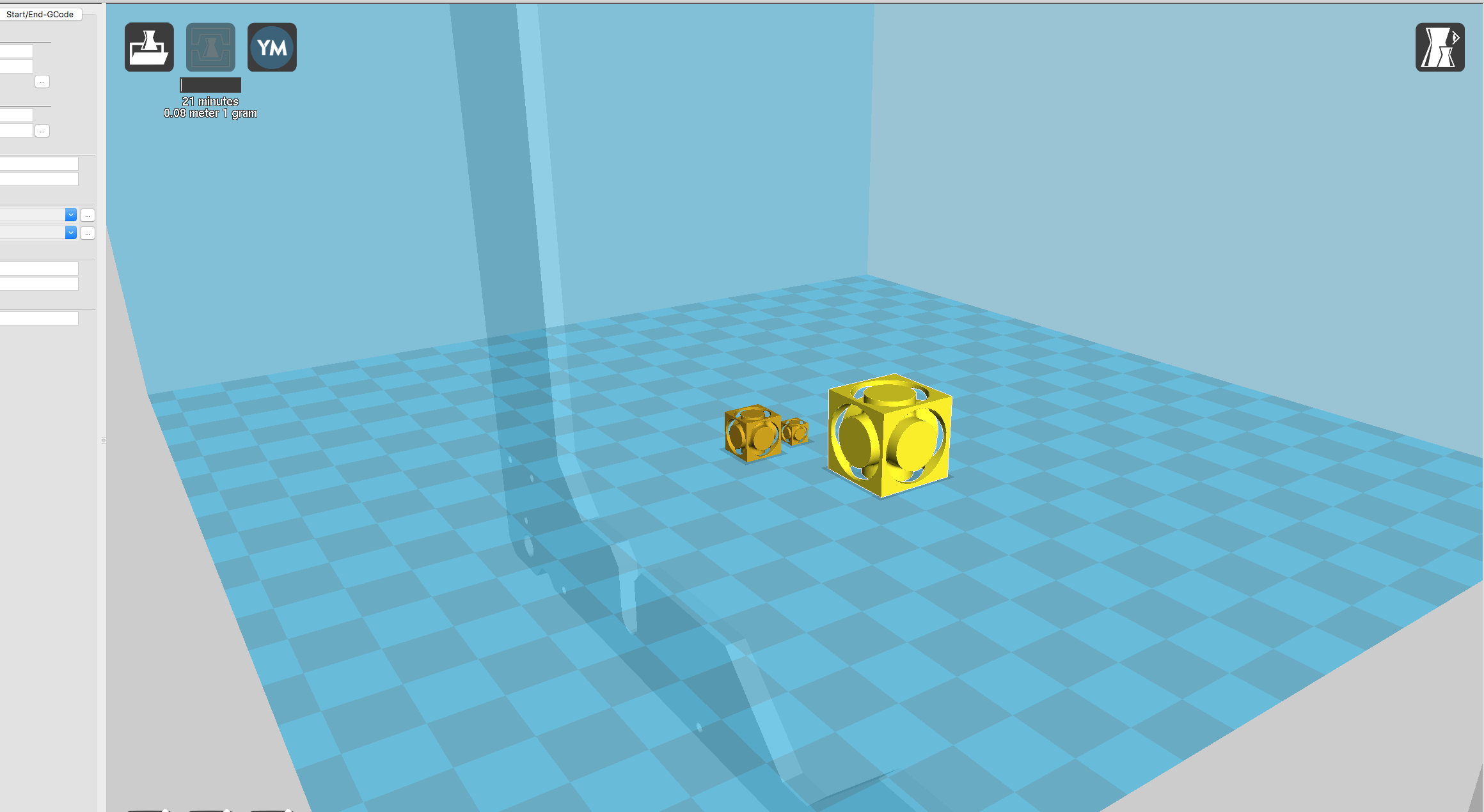

In antimony we have stl export node - so I export it in .slt file. Then open to Cura application and I see that my result in fact is too small... Let make it bigger - changed one parameter in Antimony file and during export increase also resolution. Then again and we looks good.

Too small

Resized

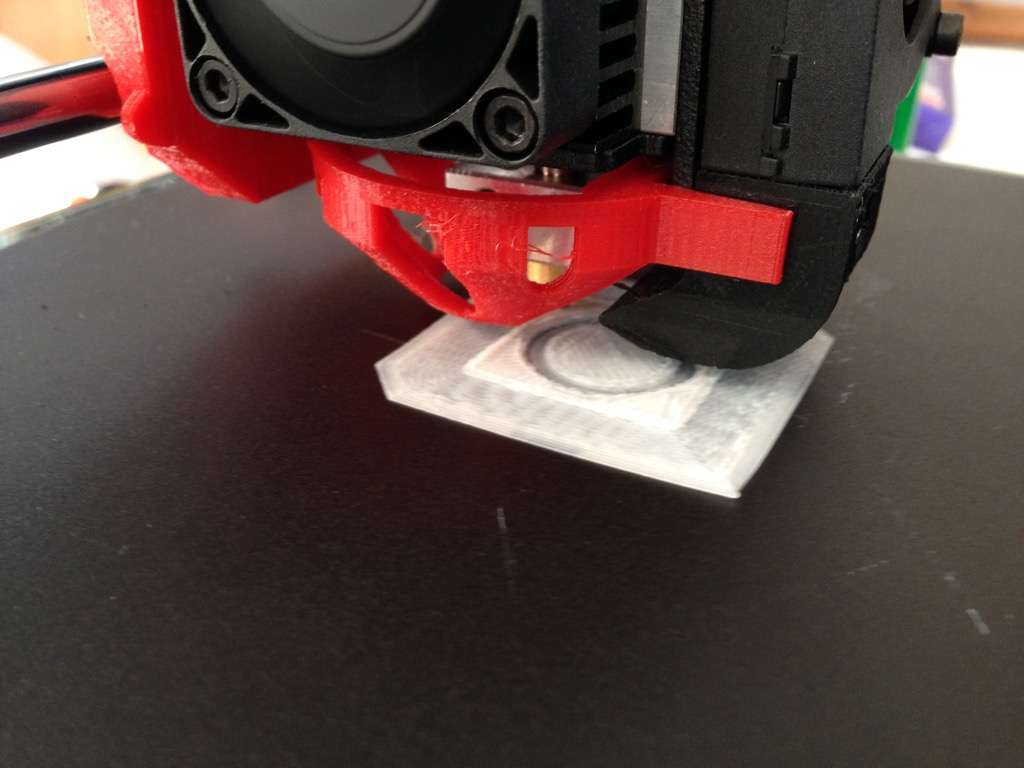

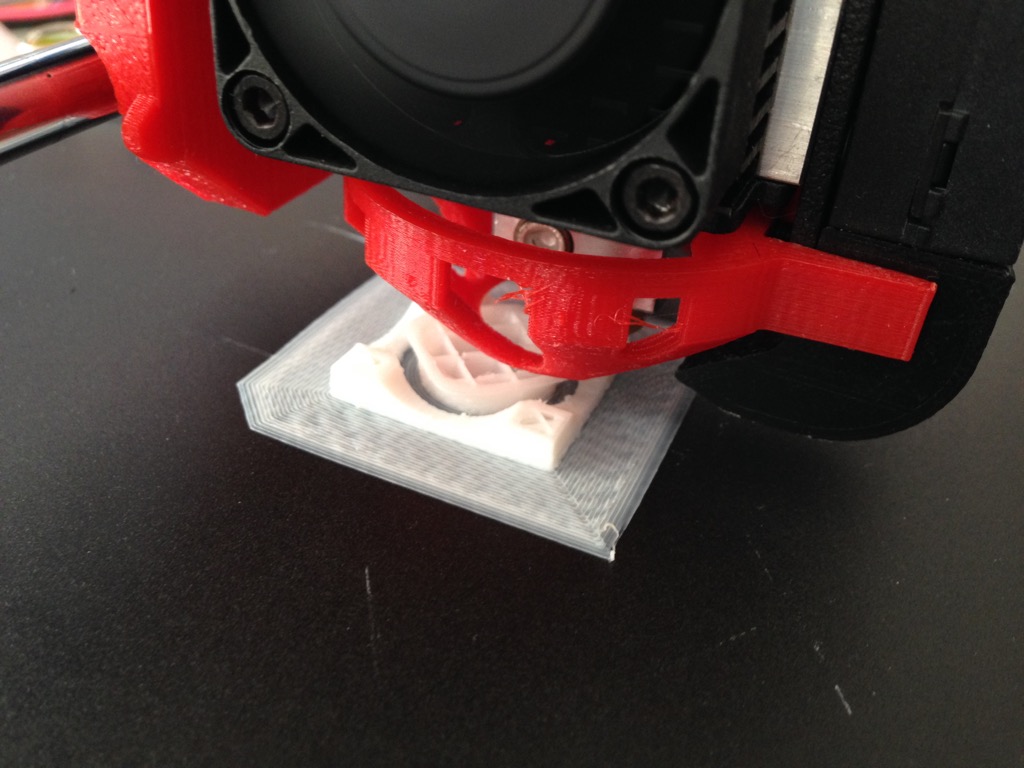

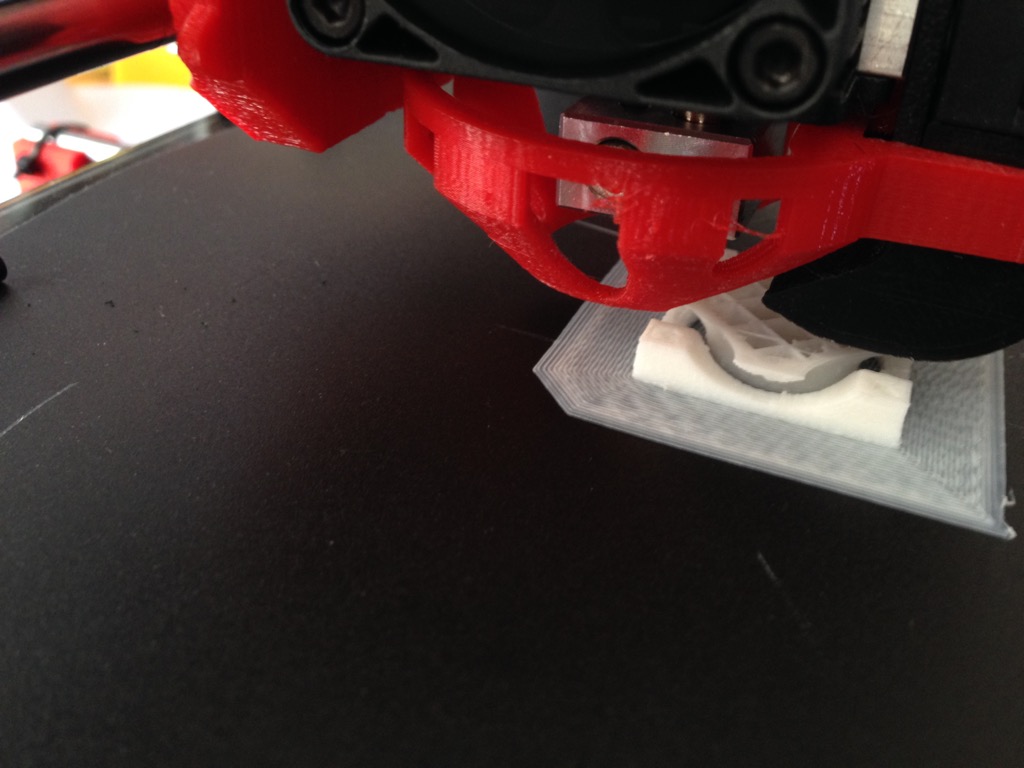

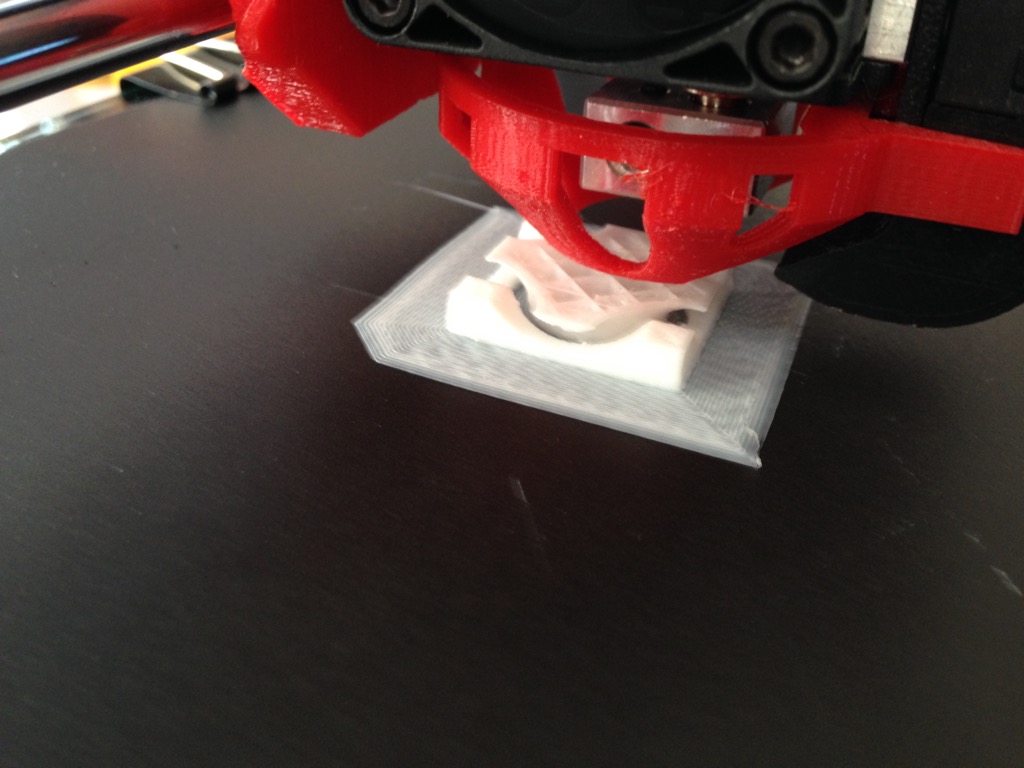

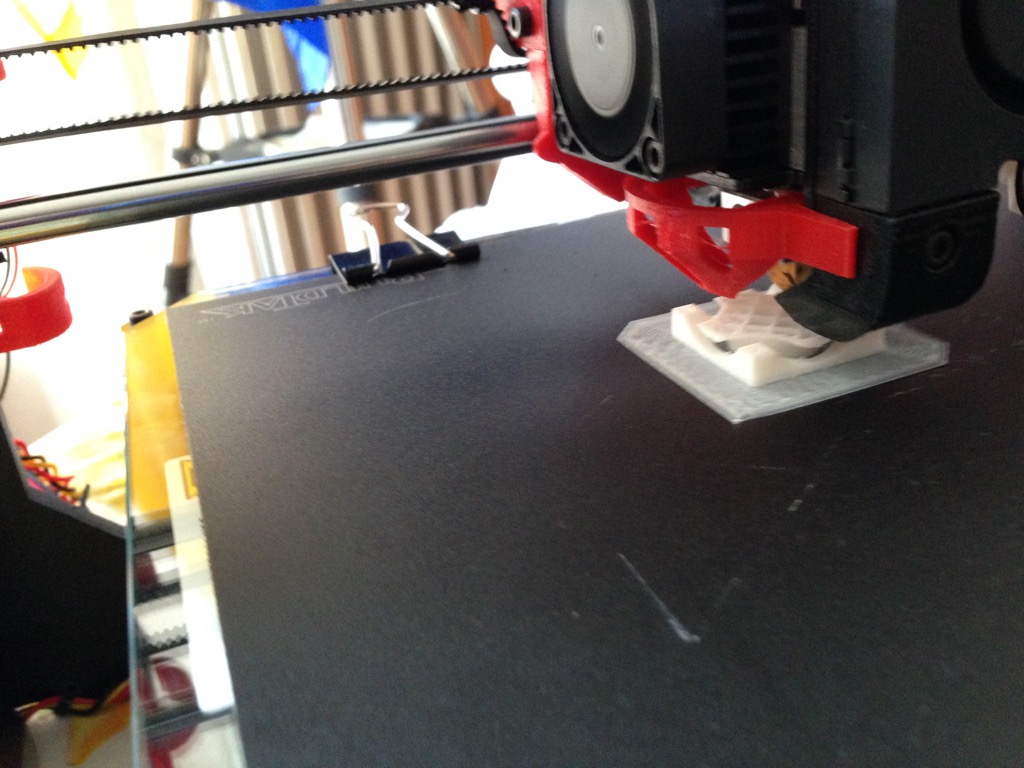

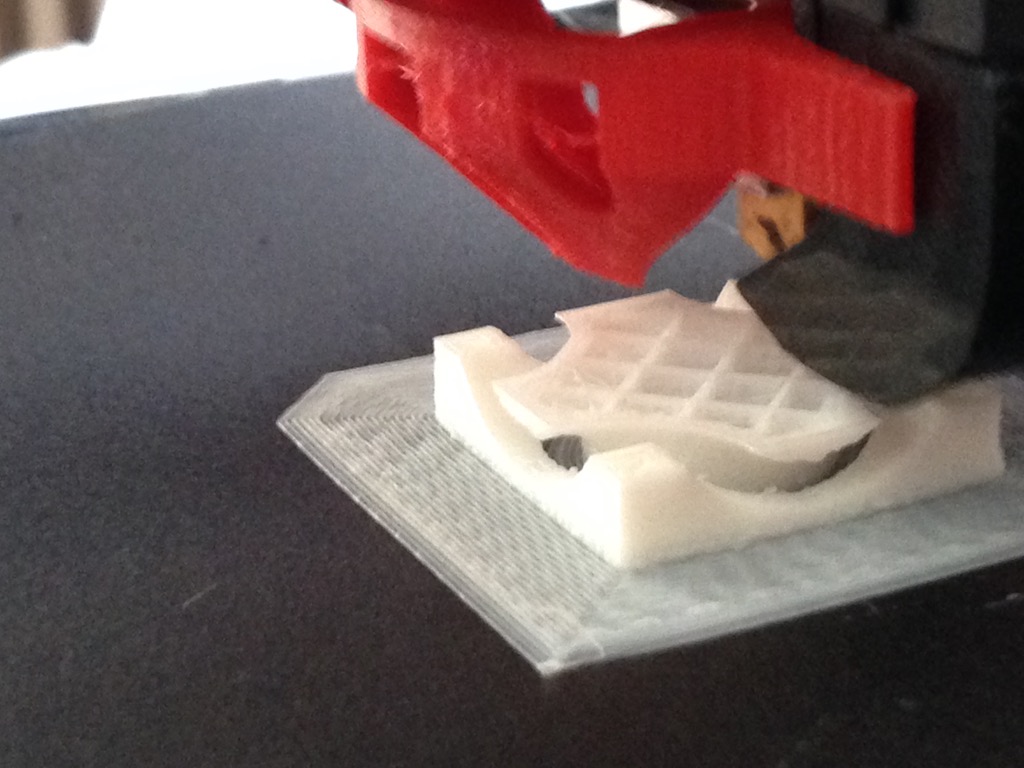

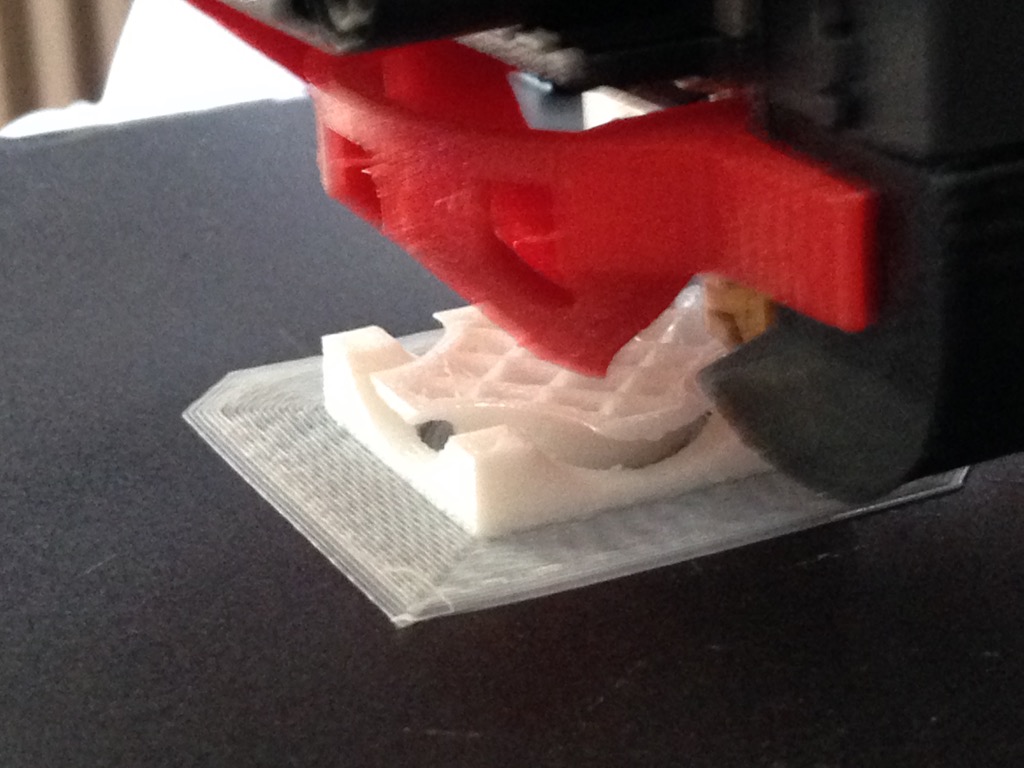

Let print object. To do this I built from kit the Prusa I3 Hephestos printer and after some tuning prints - my first print is the object.

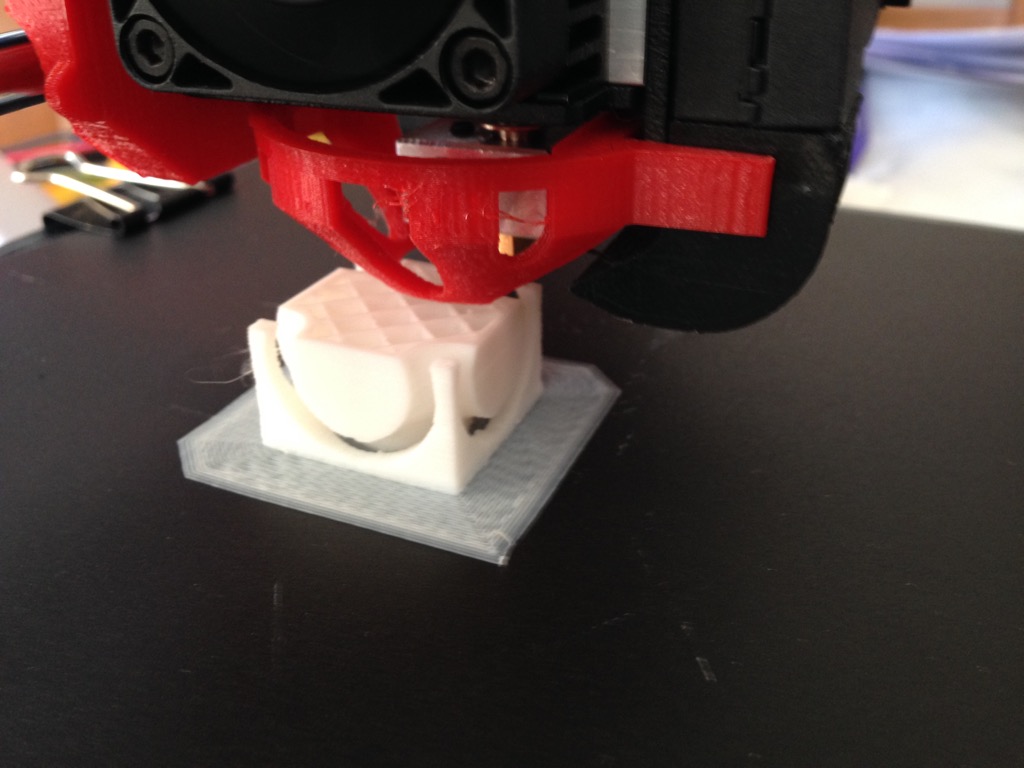

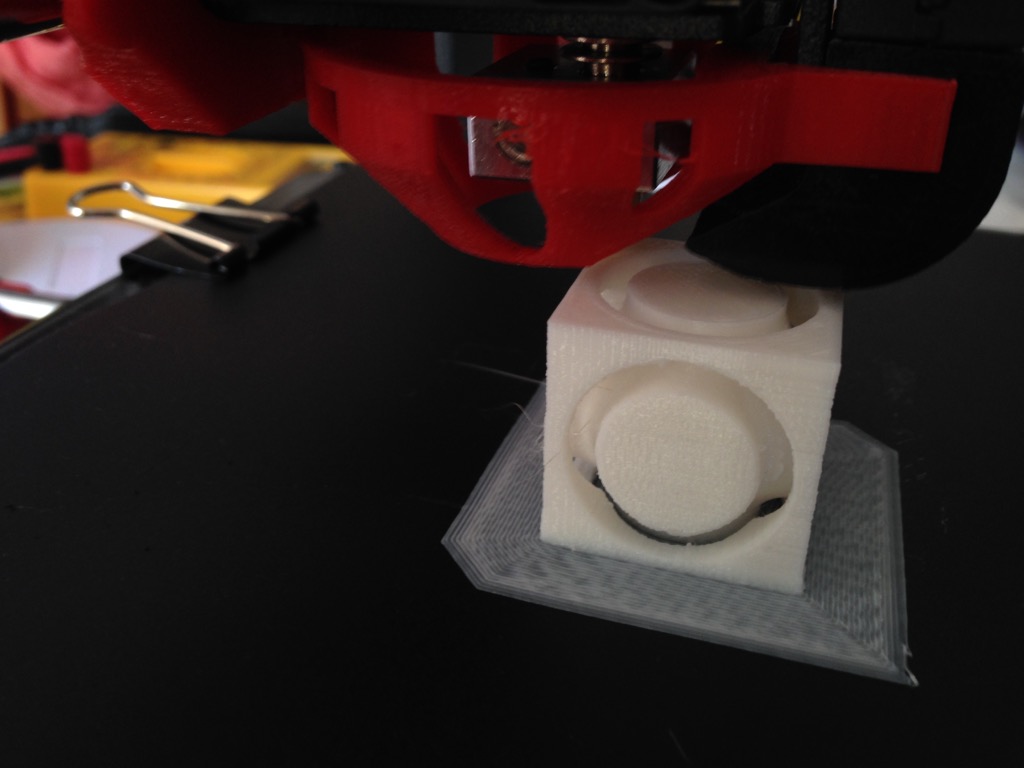

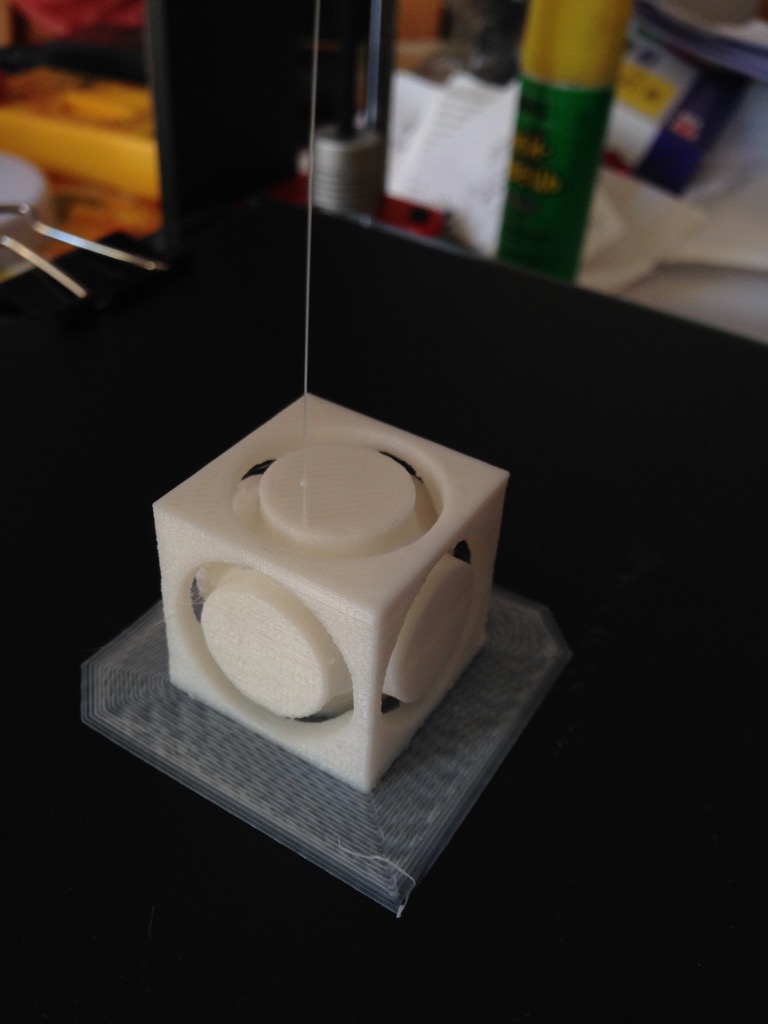

Now we have printed object! It is was first object printed on this printer (except cubes of test) so quiet good! Here are results:

The result is good. It was printed in "normal" quality just to win the time. Inner object is bigger then can pass through the holes of outer cube. So this object can be difficult produced in another way then by printing.

#3 3D scan an object (and optionally print it) (extra credit: make your own scanner)

I saw results of 3D scanning by my colleagues using the Kinekt, and I more concentrated on 3D scanning 123D catch scanning software. It reconstruct the 3D model by using the plate simple photos that overlays and have texture that permit to this app reconstruct quiet well the 3D model. This method have many limits, in fact it is not enough precise, it does not permit to scan well object with monocolor (I found it duing my tests), object with reflecting surface and so on. But in the same time it permit to scan really big objects, like buildings, cars flats and so on. So below my tries.

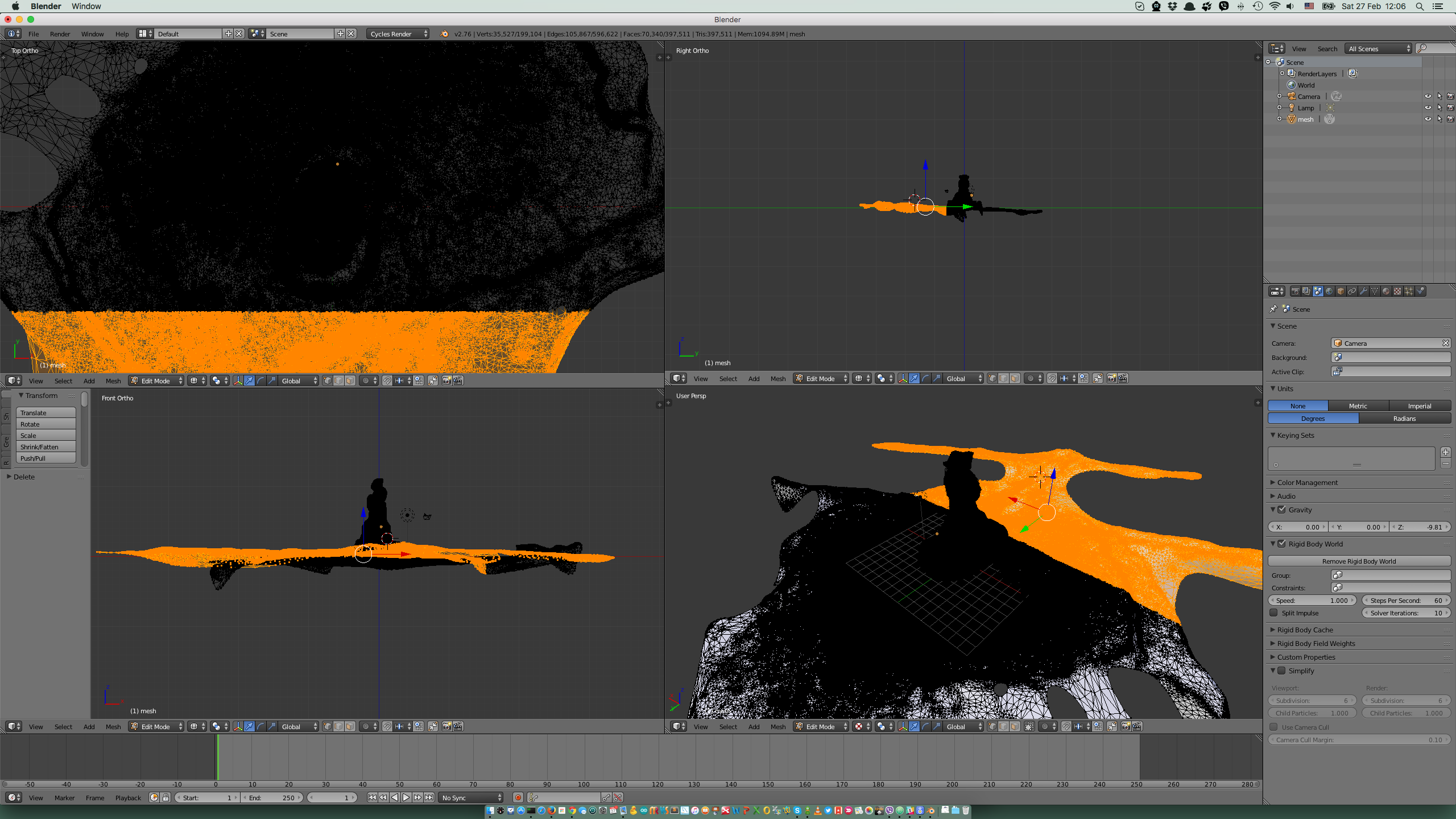

I tried to make a scan of small Yoda. I scanned it using the 123D catch software I gave me good result. I download the result files and then passed them to Blender app. There I removed all not required points and exported file in stl format that later was used in Cura for printing. gcode file is available in the list of all medias.

Original Yoda

Original Yoda

Yoda reworking in blender

Yoda ready to print

I thried another model. This model is passed really bad. You can see just a vide of result and original photo. It did not worked because surface of really simple 3D object does not contain many texture to recognise... So it failed.

Original Thing

Original Thing