Computer-Controlled machining

Assigment objetive:

1.- Make something big.

The experience that I received making this project is really useful to understand the magnitude that digital fabrication has when you apply it in different scales. What I did to this assignment is an ideal design solution to the waste that the CNC produce normally in wood furniture fabrication. For example when you cut parts of a prototype you get some wood that is not part of a product and it results in a waste of resources. Waste problem that is common in digital fabrication laboratories. So, I tried to solve this issue with an industrial design focus.

Planning

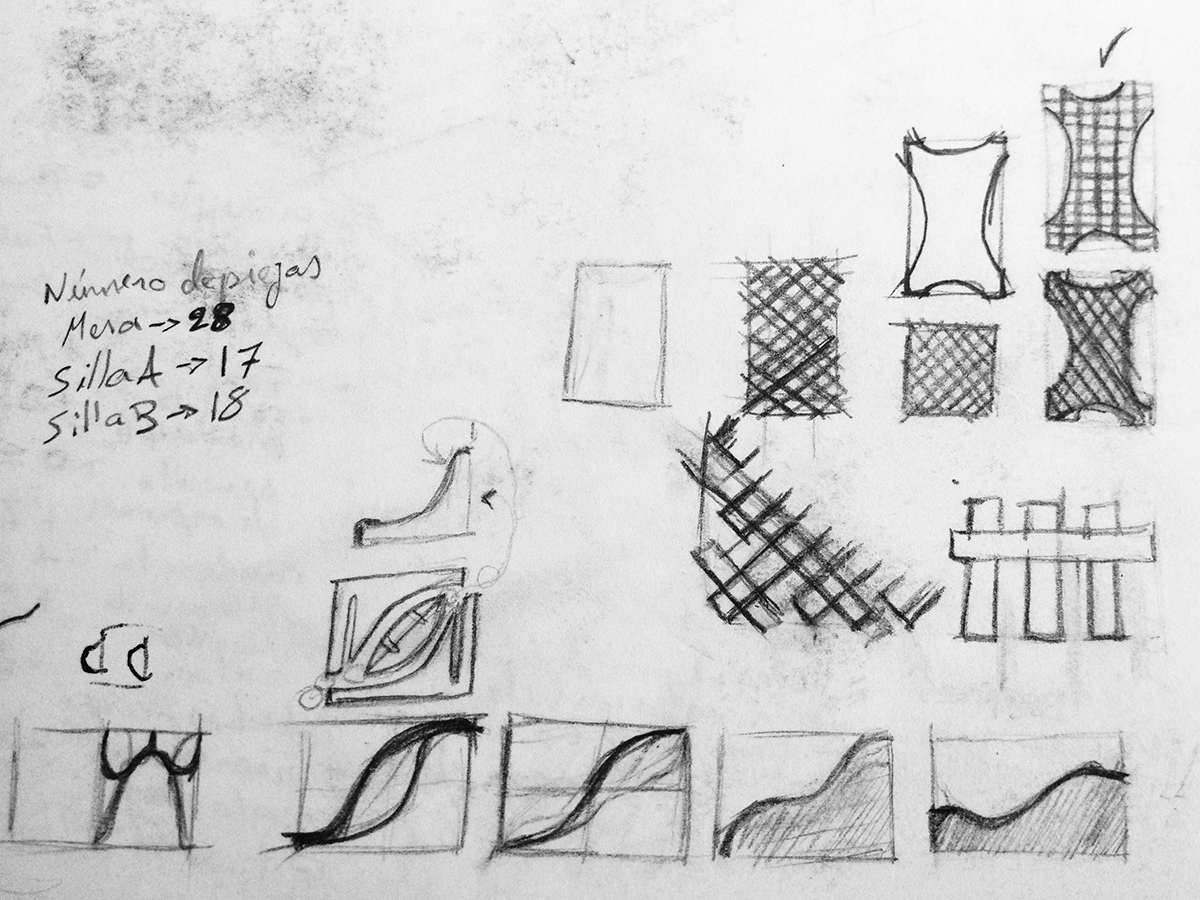

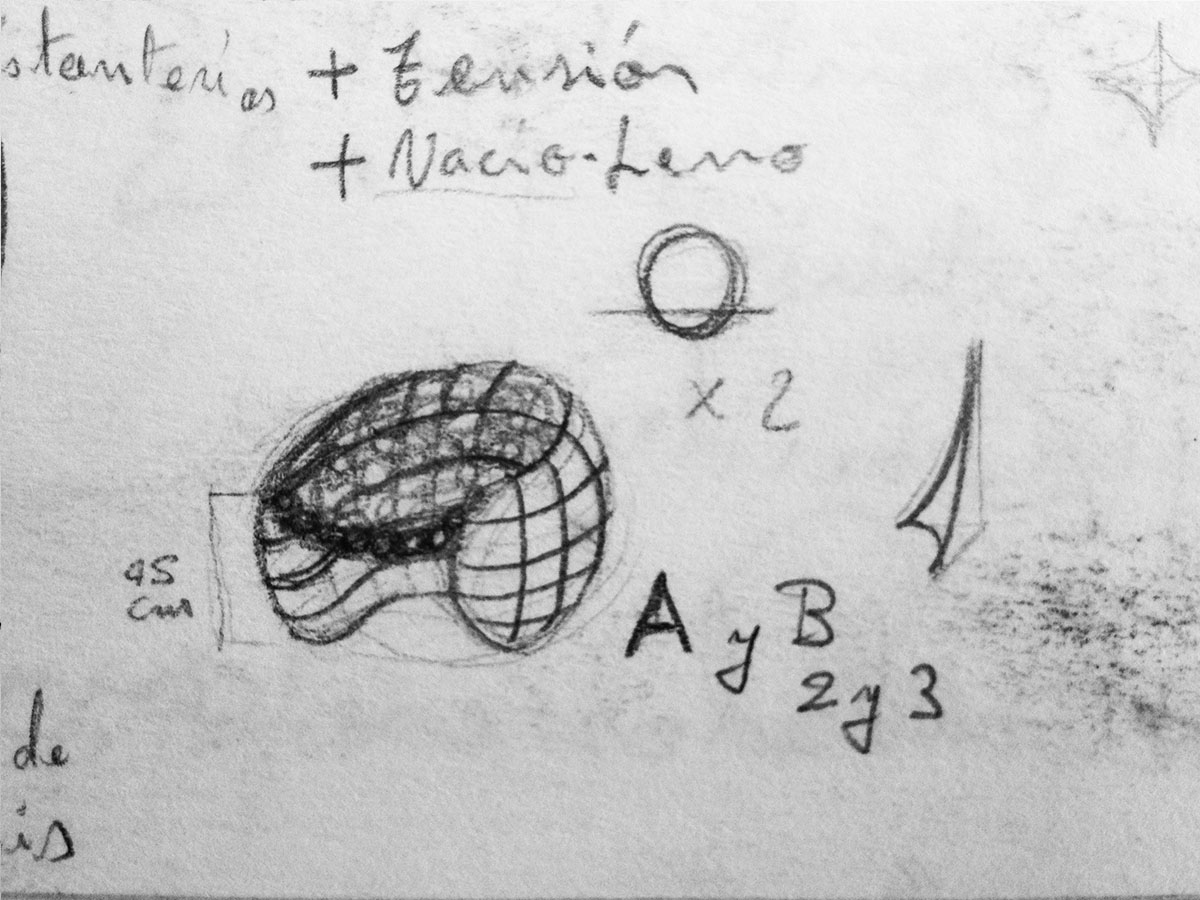

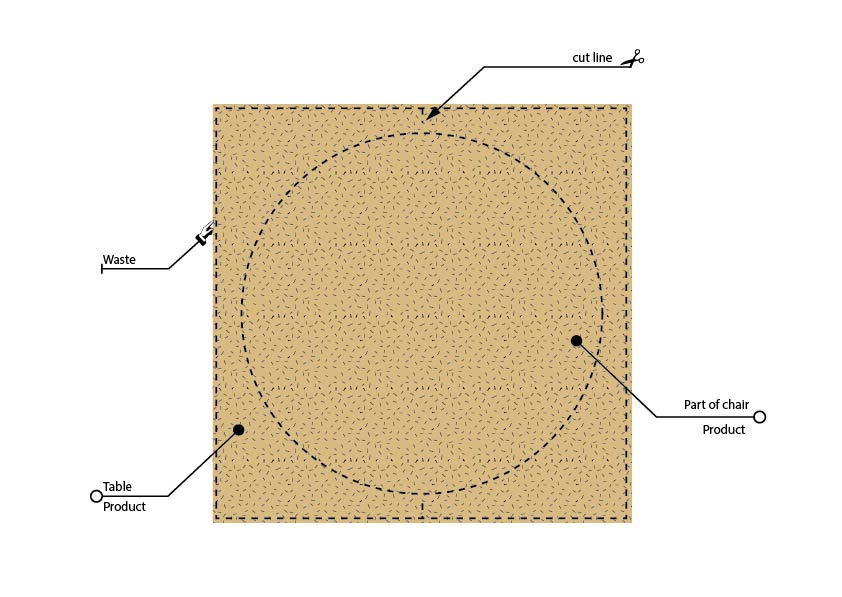

I started with the conceptualization of the solution in a paper, wondering how I could use all the material that I have to produce furniture. So I have started with two main shapes the square or rectangle (format that we normally get Playwood or MDF in Ecuador) and a circle (because is the most complex shape to cut from a square without waste). You can see that process in the next images.

As you can see in the last graphic the plan of this system is focused in optimized the MDF board at much as possible finding the way to obtain more products with less material.

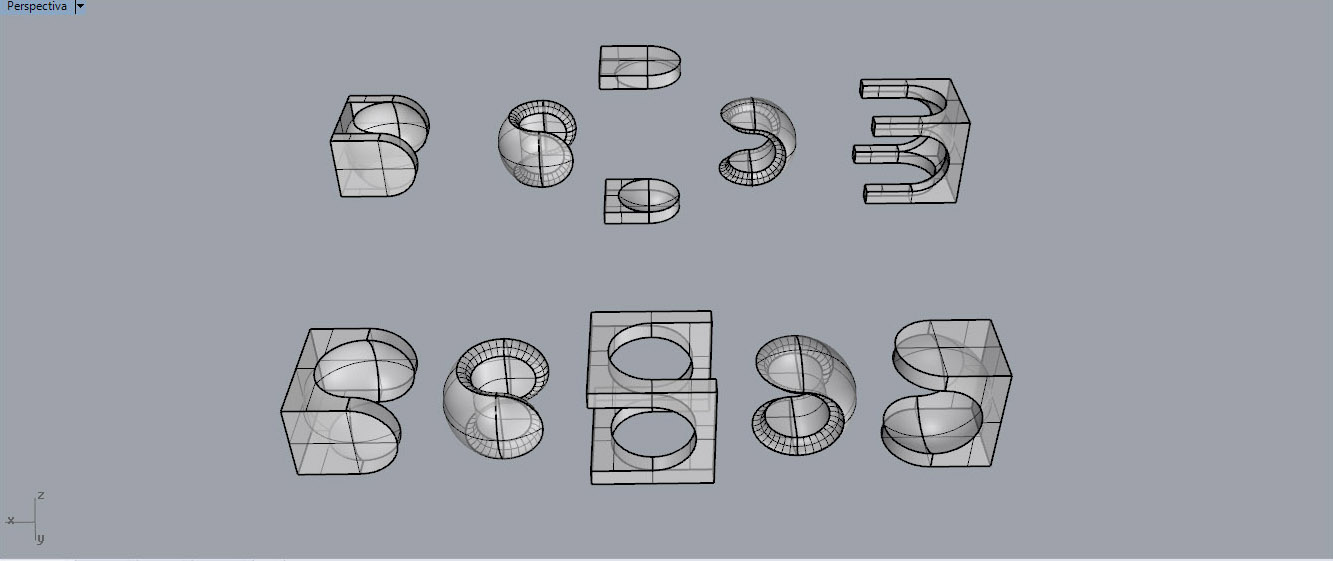

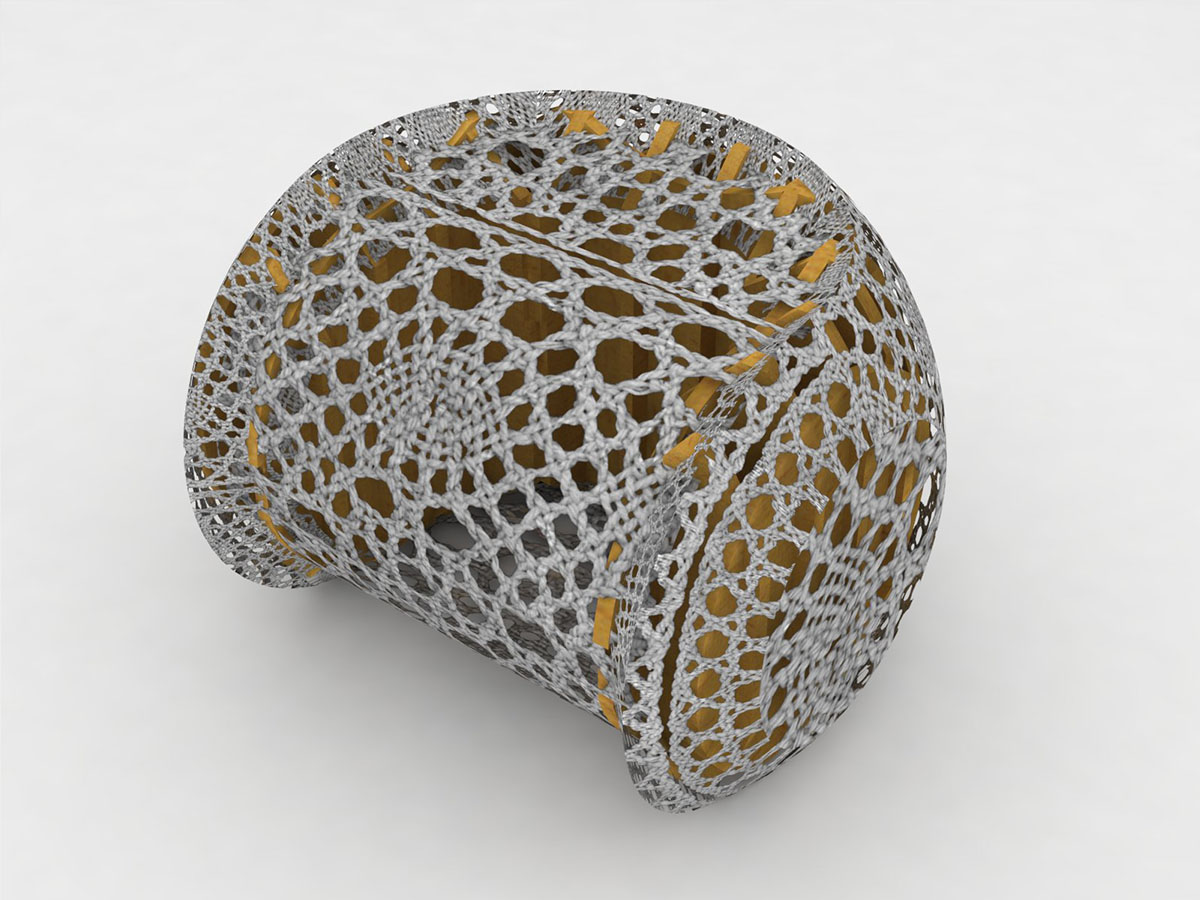

Once I got the main idea I used computer-aided design software (Rhinoceros) to get a precise model to the furniture. The furniture at this point is a modular system that uses the cube as origin.

Digital process

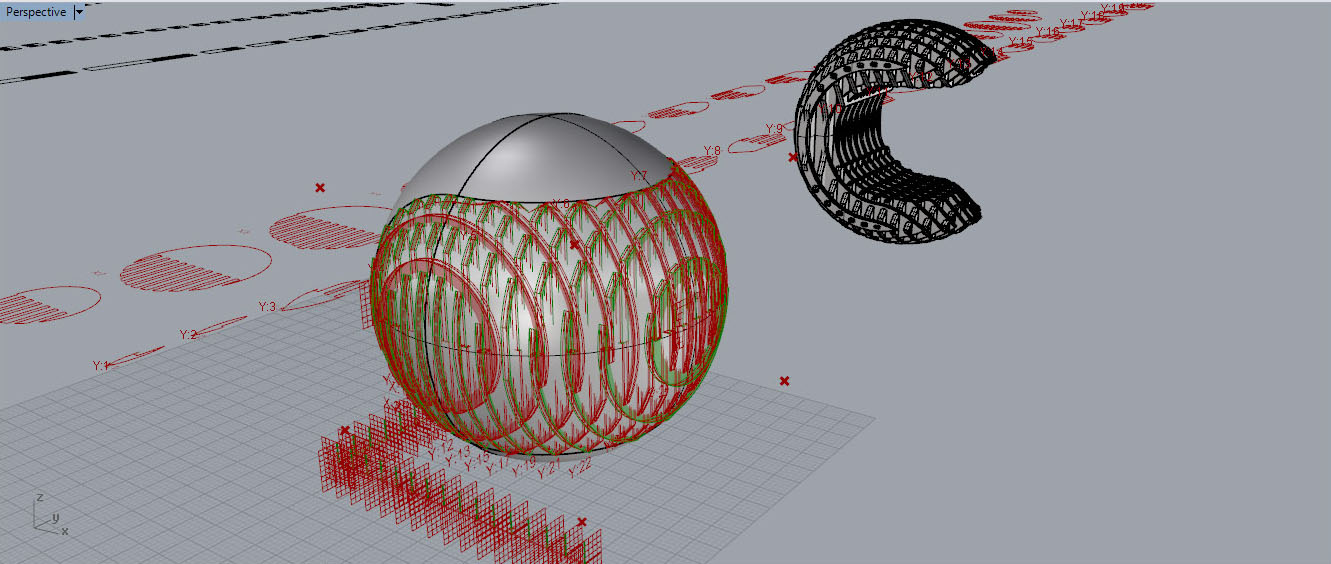

Then I found two options to define the design and I decided to use Grasshopper parametric function to cut each piece in order to get the cut lines to introduce in CNC machine.

There I realize that the parametric cut was not perfect because some of pieces had structural and logic enabling problems that I solved them redrawing some of cut lines.

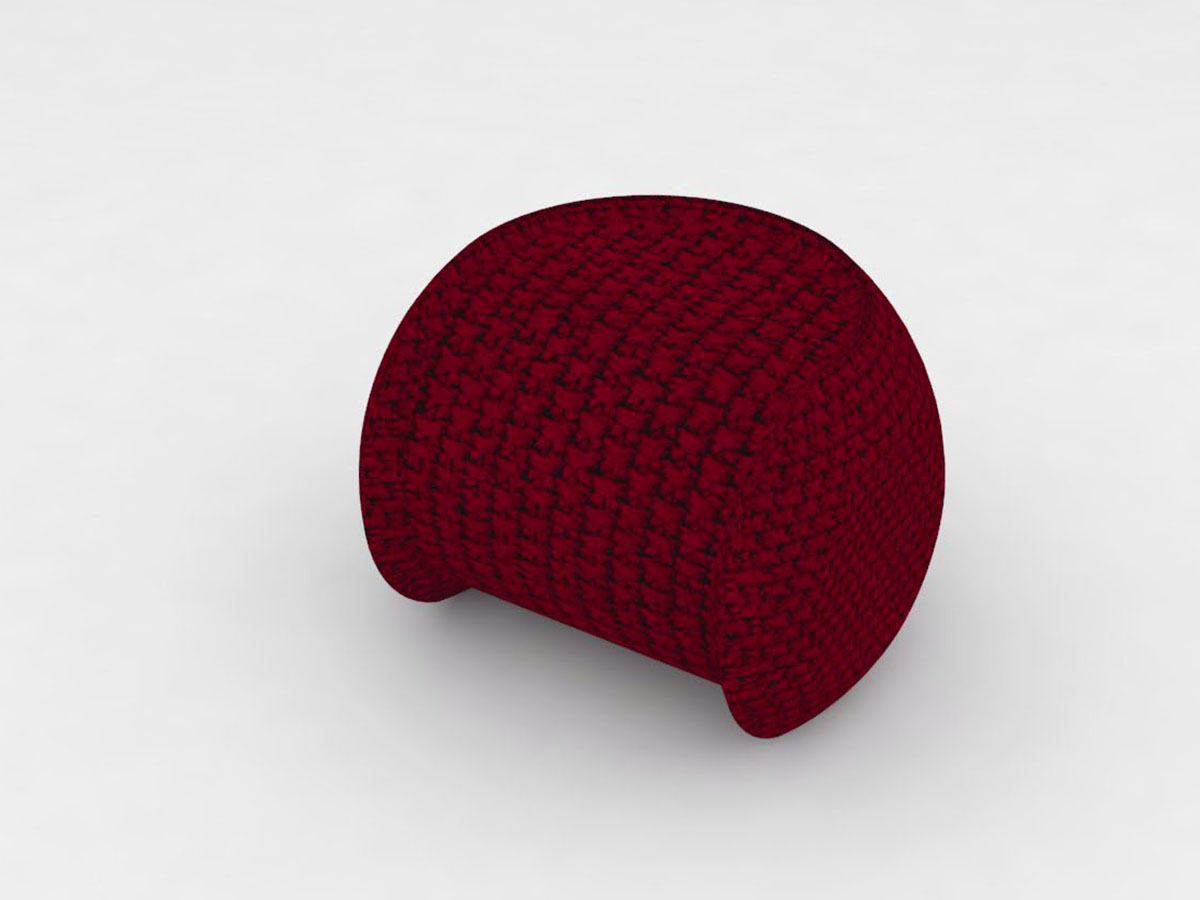

Finally to make this chair confortable I designed a cover to wood structure. The cover would be with fabric industrial waste.

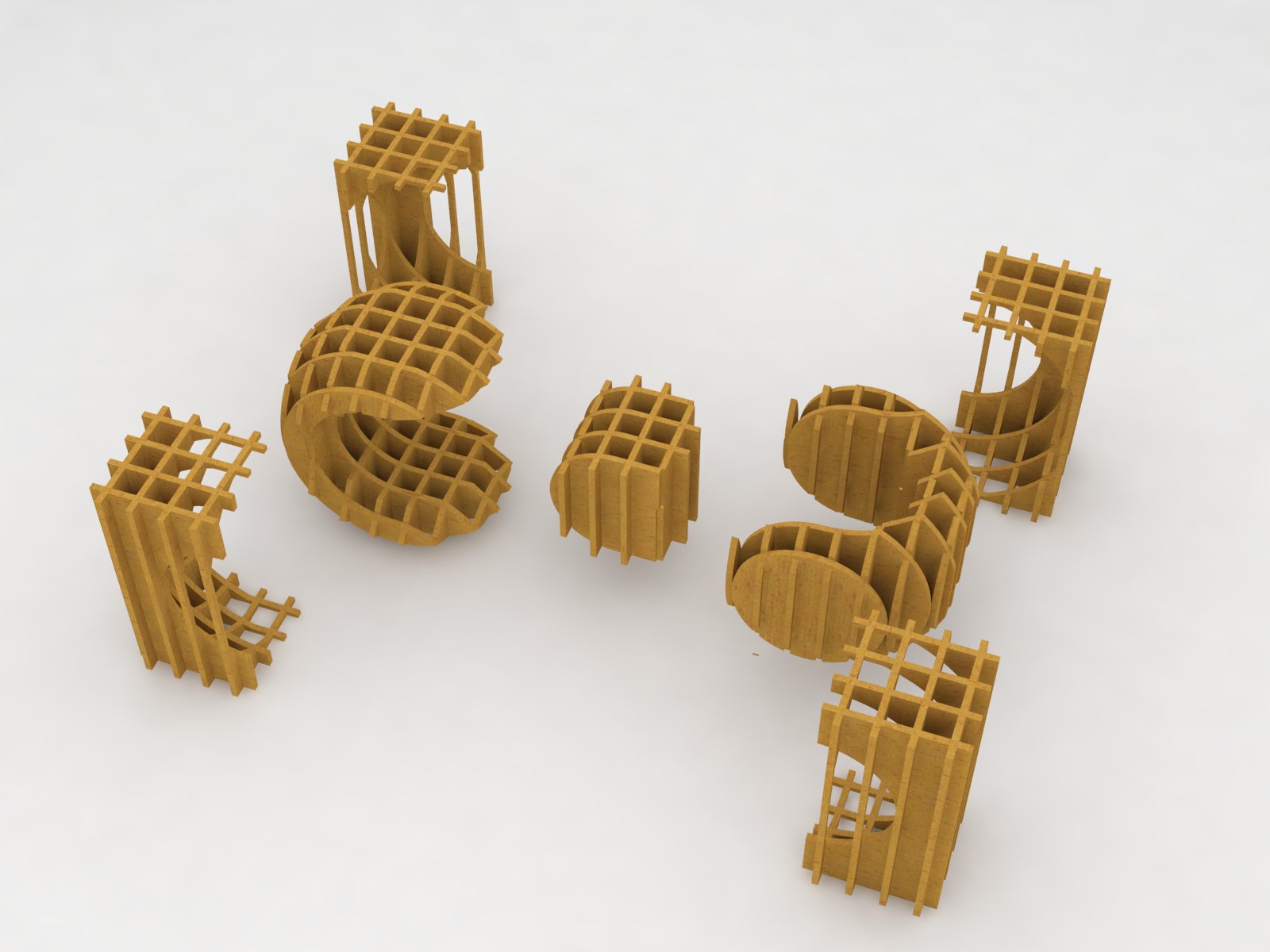

Making scale model

To experiment with the design that I have made I fabricate a scale model in order to fine design errors. In this step I spend some time making the best option. I repeat four times this design in order to get a good result.

Now.. the prototype