During this week we were asked to produce one Fab(tiny)ISP in-circuit programmer.

Here you can follow the steps I made.

Milling

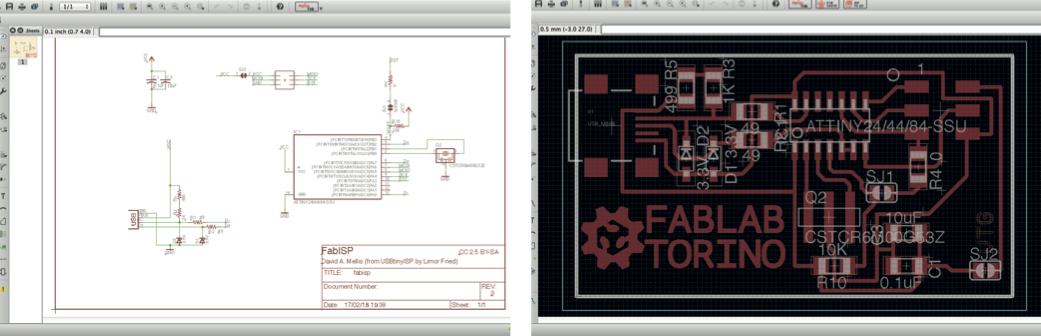

In our Fablab we started using Eagle software to design the pcb and than the pcbgcode plug-in in order to create the gcode.

After that I tried to use the fab modules as well.

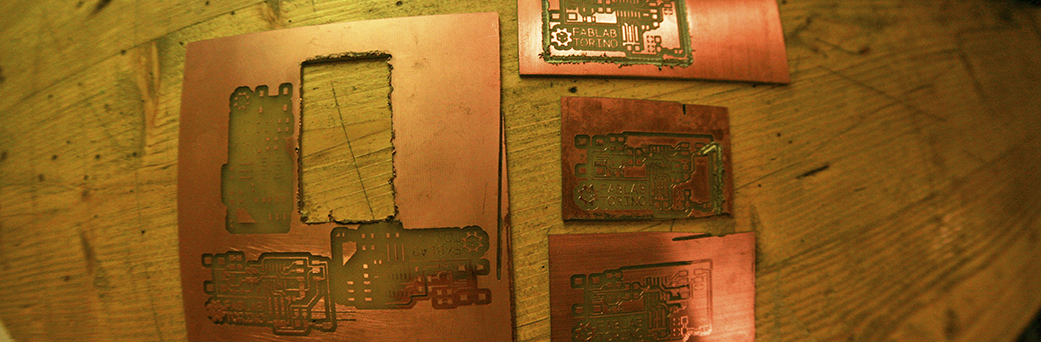

For the process we used the Roland MDX-40a milling machine. We spent a lot of time setting all the parameters in order to get exaclty the trace thickness we want to produce. The new step for me was using this awesome technology of a led connected between the cupper board (0.035mm copper thickness) and the endmills (vshaped, 0.1mm) to setting te correct z-axis distance. That worked way better than the roland z-axis sonde.

Than we started milling. We hade some problem anyway with the non-planarity of the copper board and those are some of the first attempts.

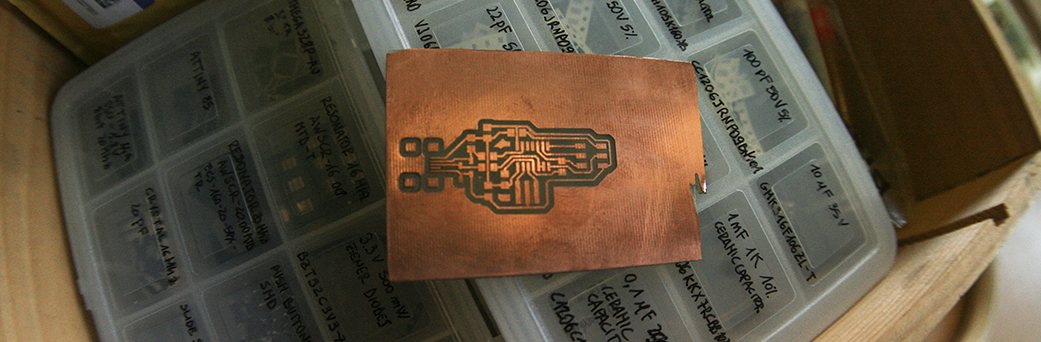

After that we change a bit the board design and we arrived at this version of the ISP - based on the David Mellis version, modified by Federico Vanzati, Gianfranco Caputo and Stefano Paradiso.

Soldering

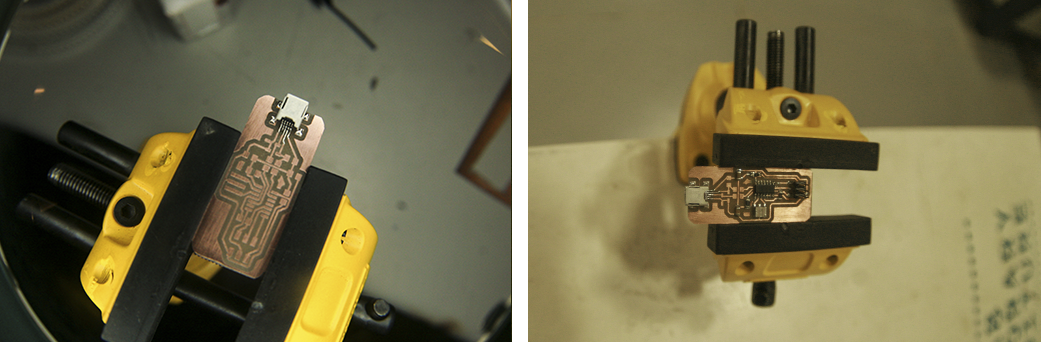

I started soldering the usb connectors (advice from the more experts Fablab's guys) cause it has the smallest trace. After that the ATTINY and than all the others.

Compiling

I've compiled once but after that FabIsp wasn't programmable anymore.

I ain't sure yet of the reason but its probably

cause I used the wrong resonator (20 MHz instead of 16 MHz).

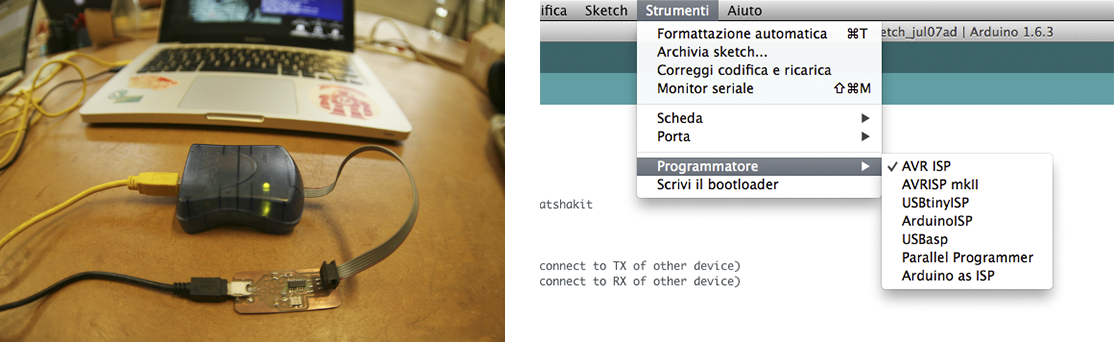

I've compile it through an AVRISP we got in lab and the Arduino ide.