Roosvelth Cántaro's Academy

• Make a machine, including the end effector.

• Build the passive parts and operate it manually.

• Document the group project and your individual contribution.

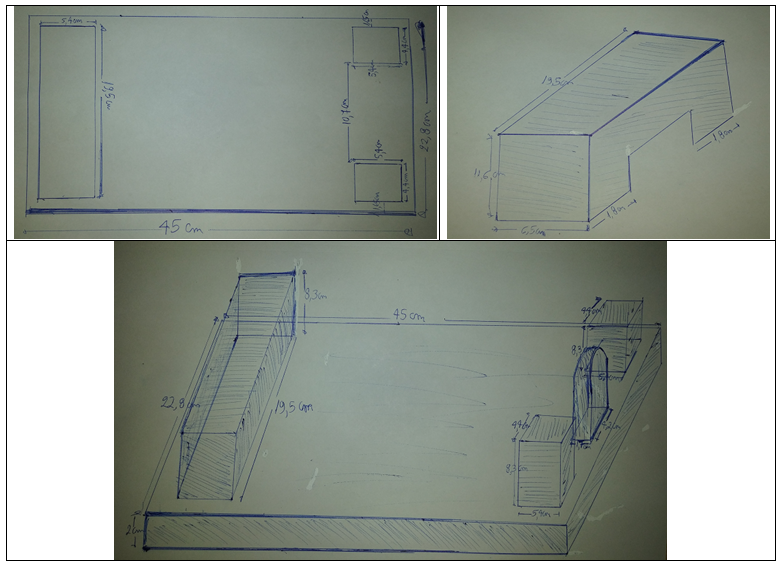

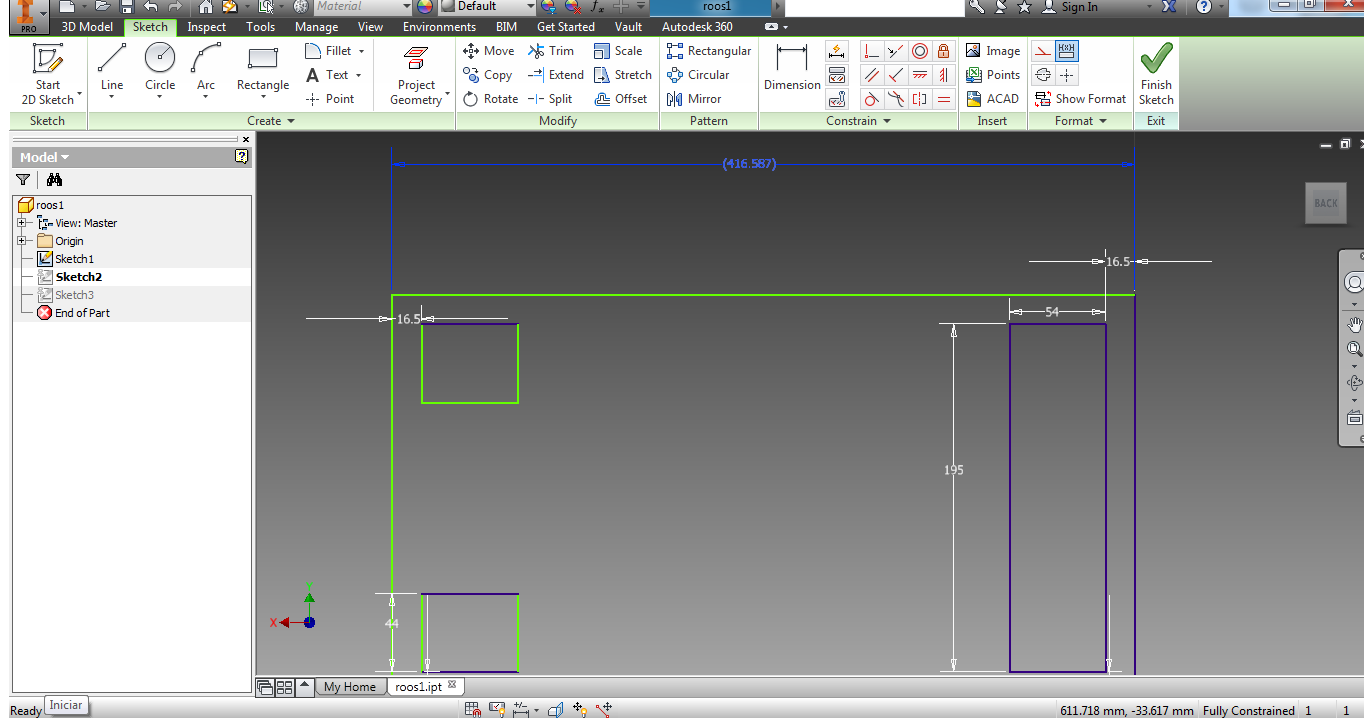

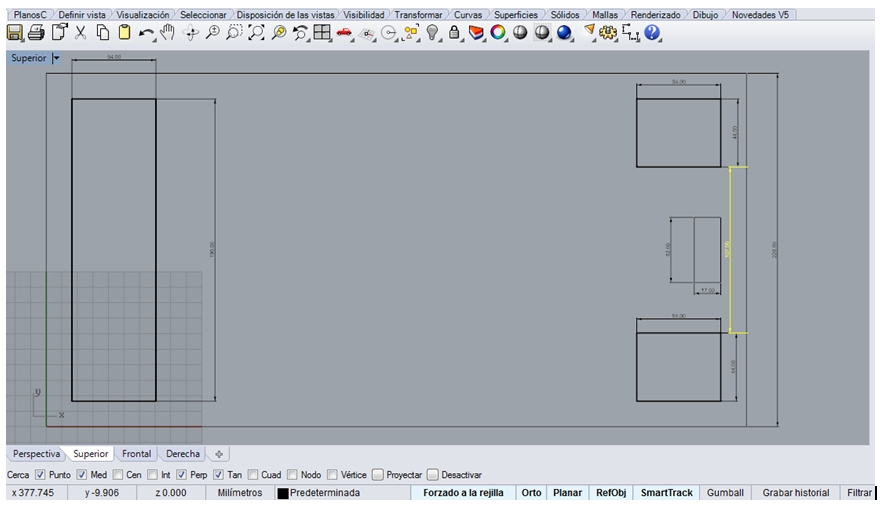

In this assignment my contribution has been the 3D mechanical design and the electronic programming of the CNC milling machine pipe, using corrugated carboard of 1.5 millimeters thicknes.

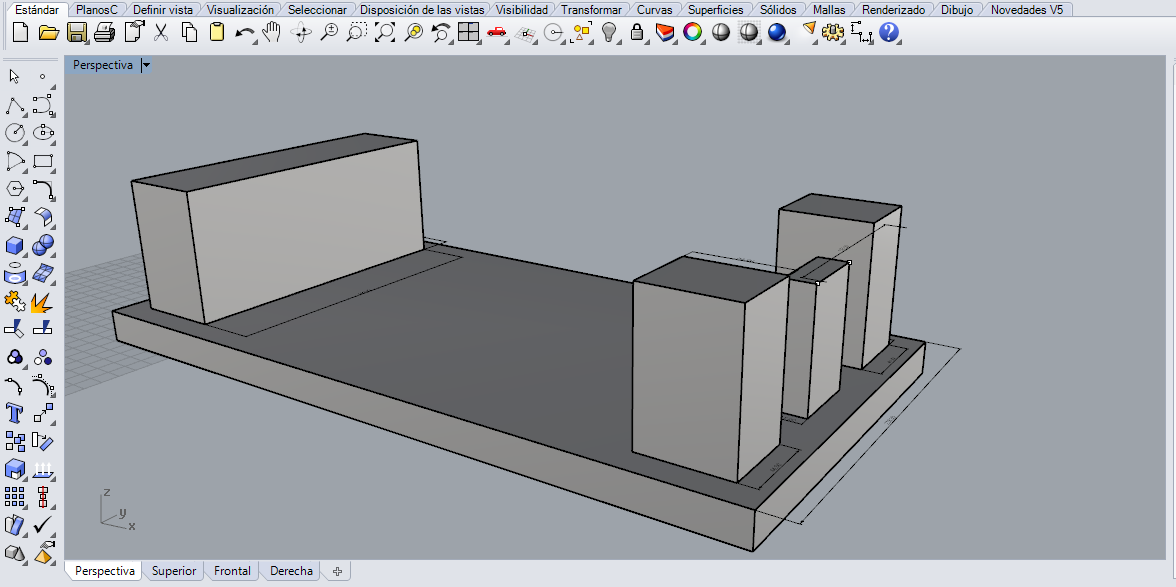

We downloaded the modules of the cardboard stages from "Machines that make machines" webpage. I made a diagram of structure with your measurements of the CNC milling machine pipe with reference this webpage.

First I decided to work with the software INVENTOR, but with my colleague we decided to work with RHINOCEROS 5.0 software.

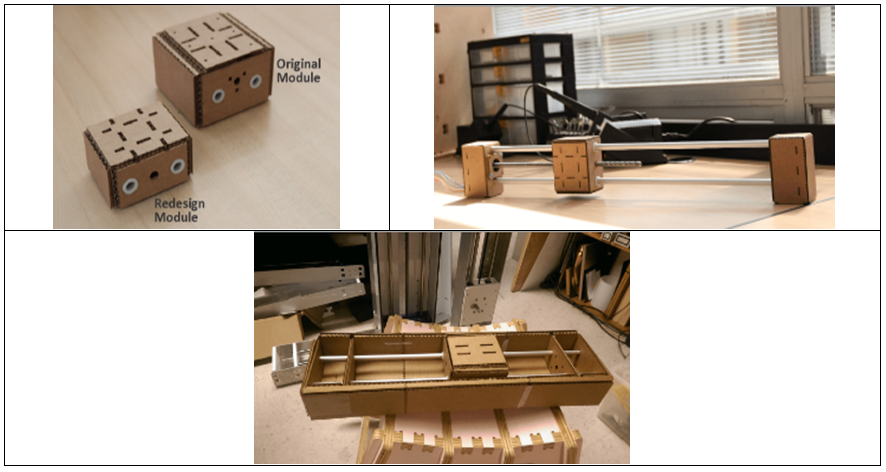

I was observed with my colleagues using many paperboard and redesign in order to obtain a stronger and less base material, the comparison in size of the original module and redesign, saving and simplifying material without losing the necessary strength in the structure.