Roosvelth Cántaro's Academy

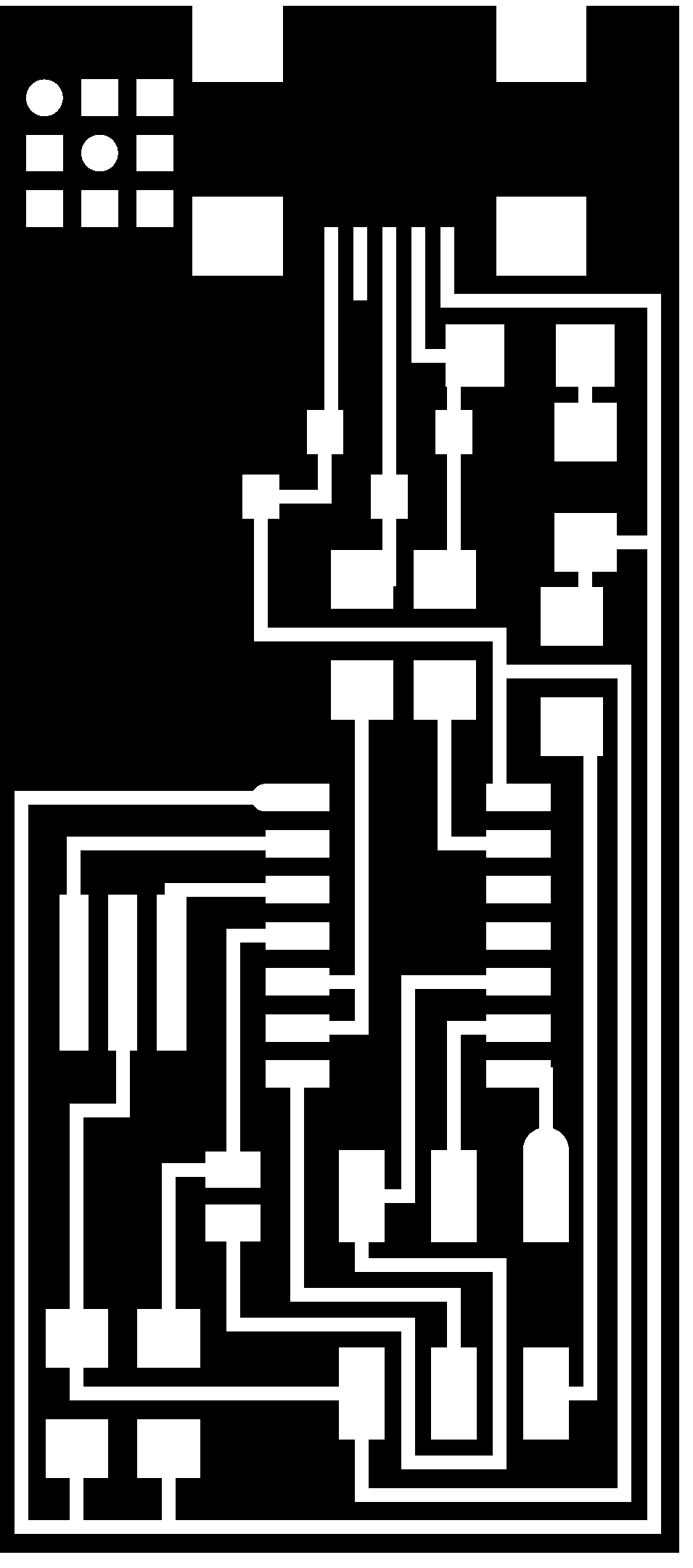

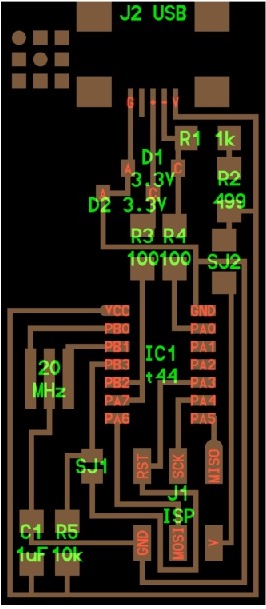

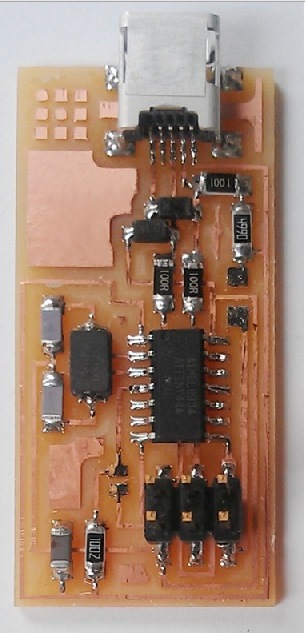

I have chosen the ISP model that will be implemented for my project. I decided to use the David's fretwork. These images presented below are the from a board design, here it shows the components connected in the way we need it in order to made the circuit functional.

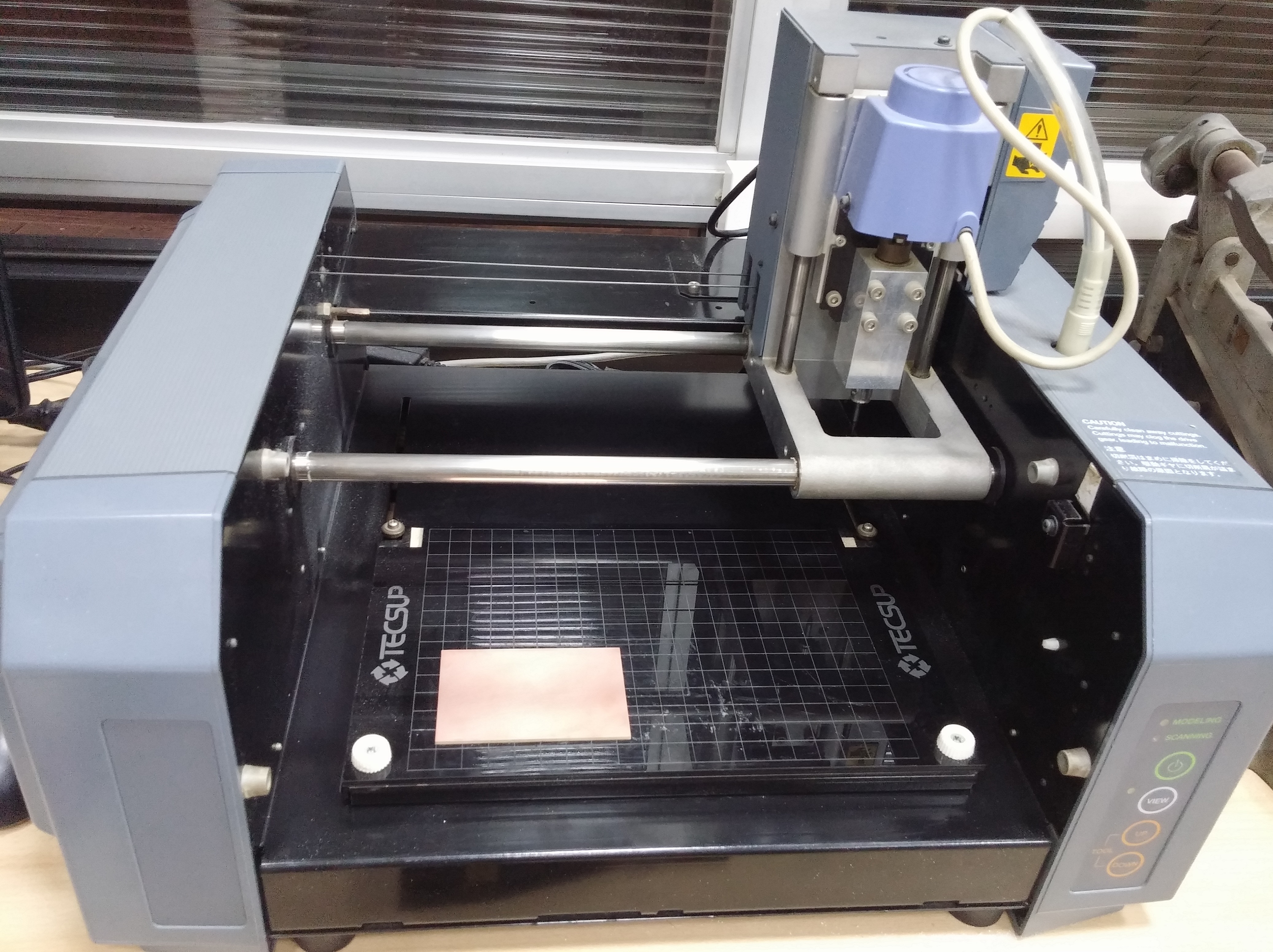

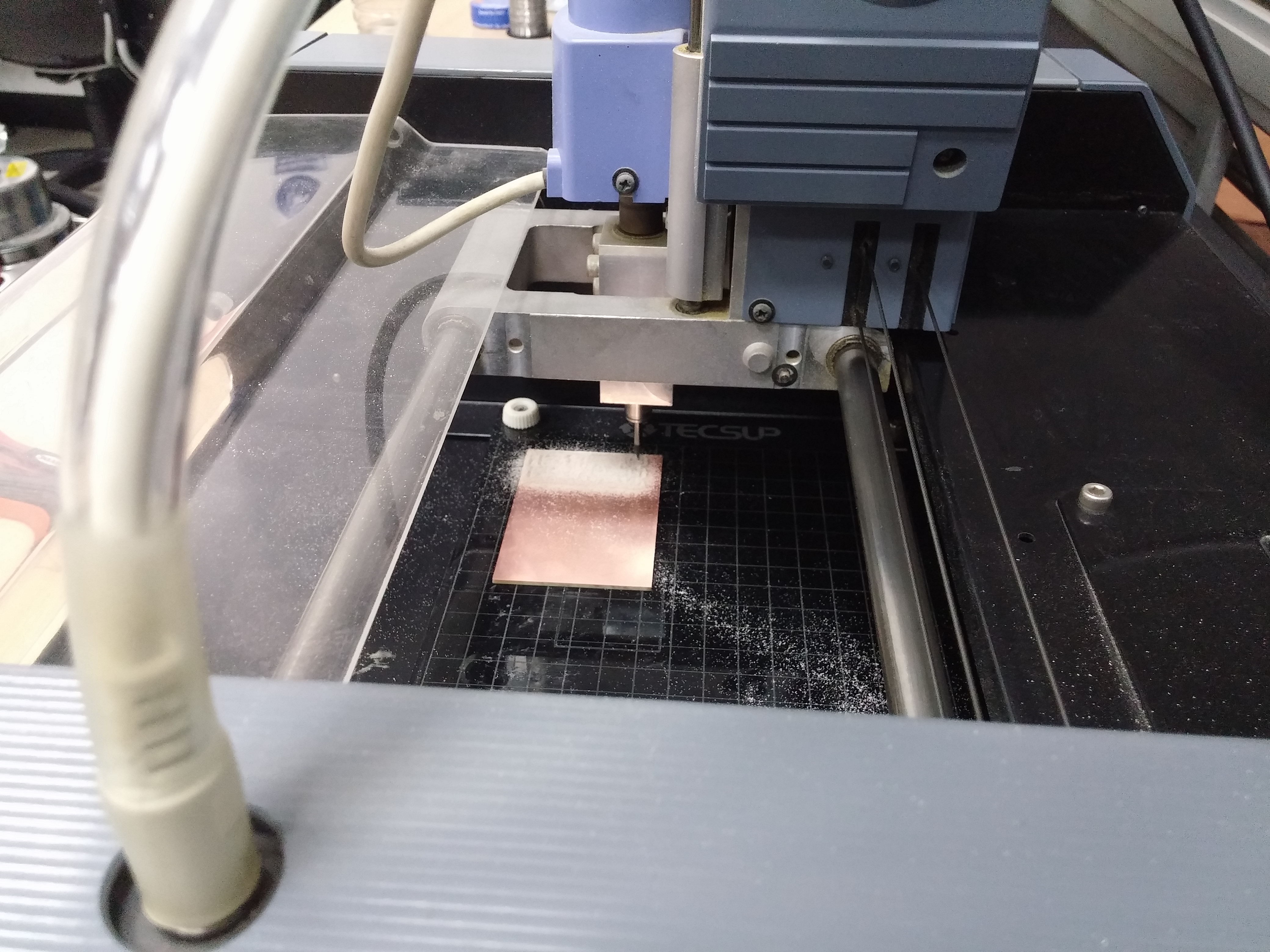

The process of fabrication was not easy; learn the tooling for milling and the dimensions of the pieces was the challenge. To mill the board properly you will need: Precission milling machine.

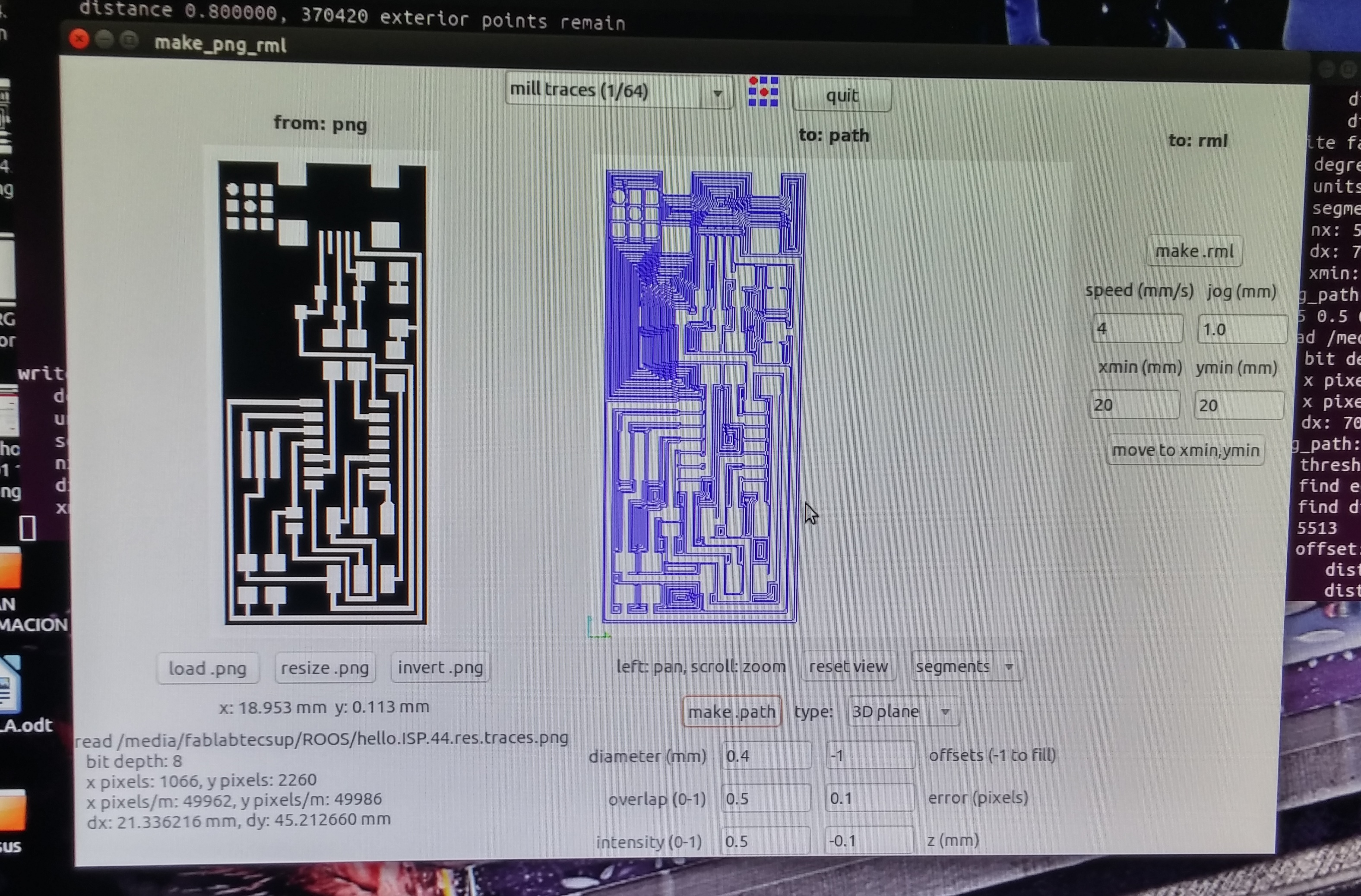

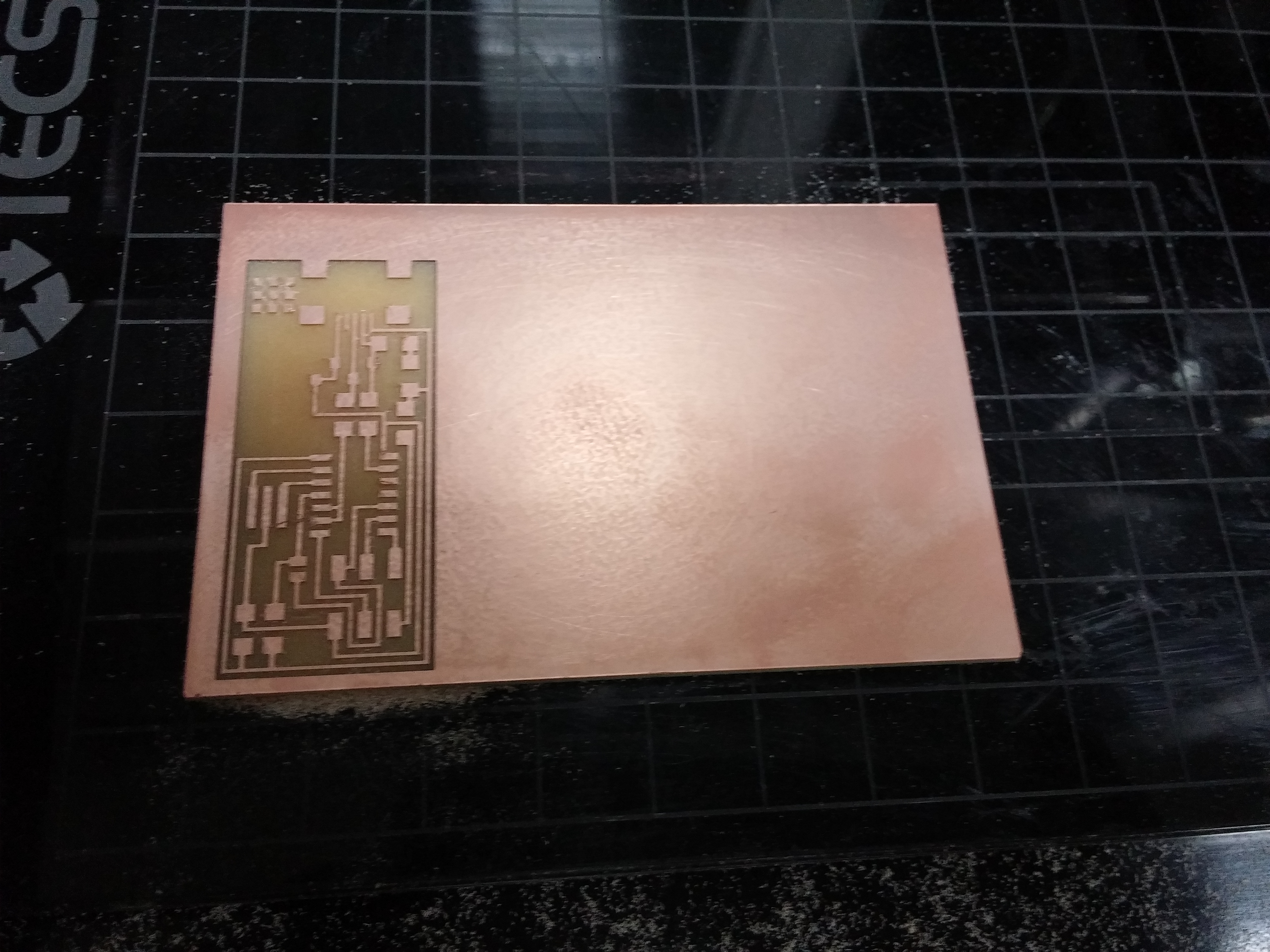

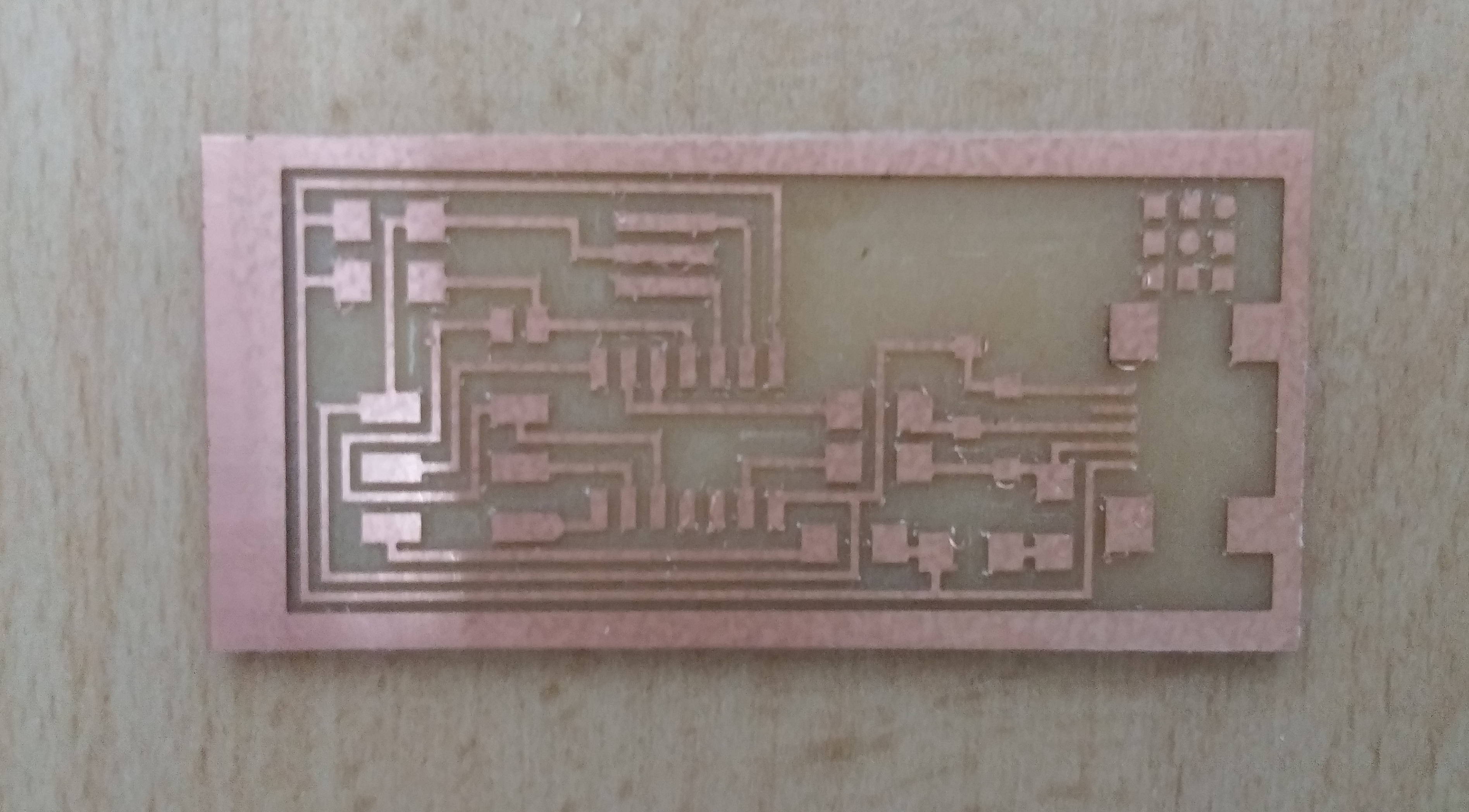

Downloaded the image in PNG format, changed the size, resolution, and customized it in order to have an adequate image for its use on the Modela Roland MDX20 equipment.

In the milling we use a Modela Roland MDX 20 with a 1/64 and 1/32 (cut) tooling. The order to mill with the machine is calibrate the x-y-z (adjusted the reference point to “0”), import the illustrate file to Modela software; establish the cutting parameters of set machine speed and depth and the engraving-cut function.

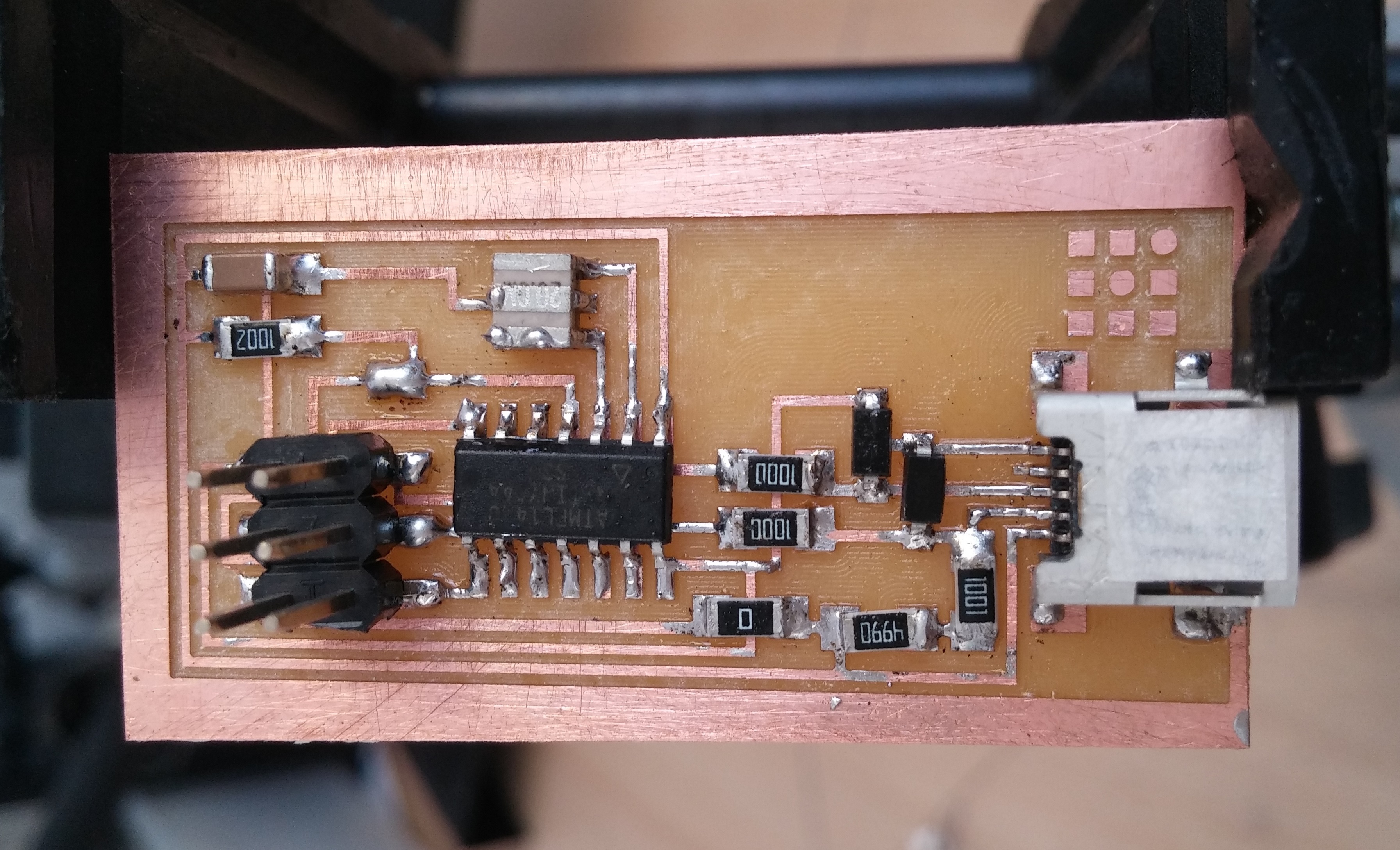

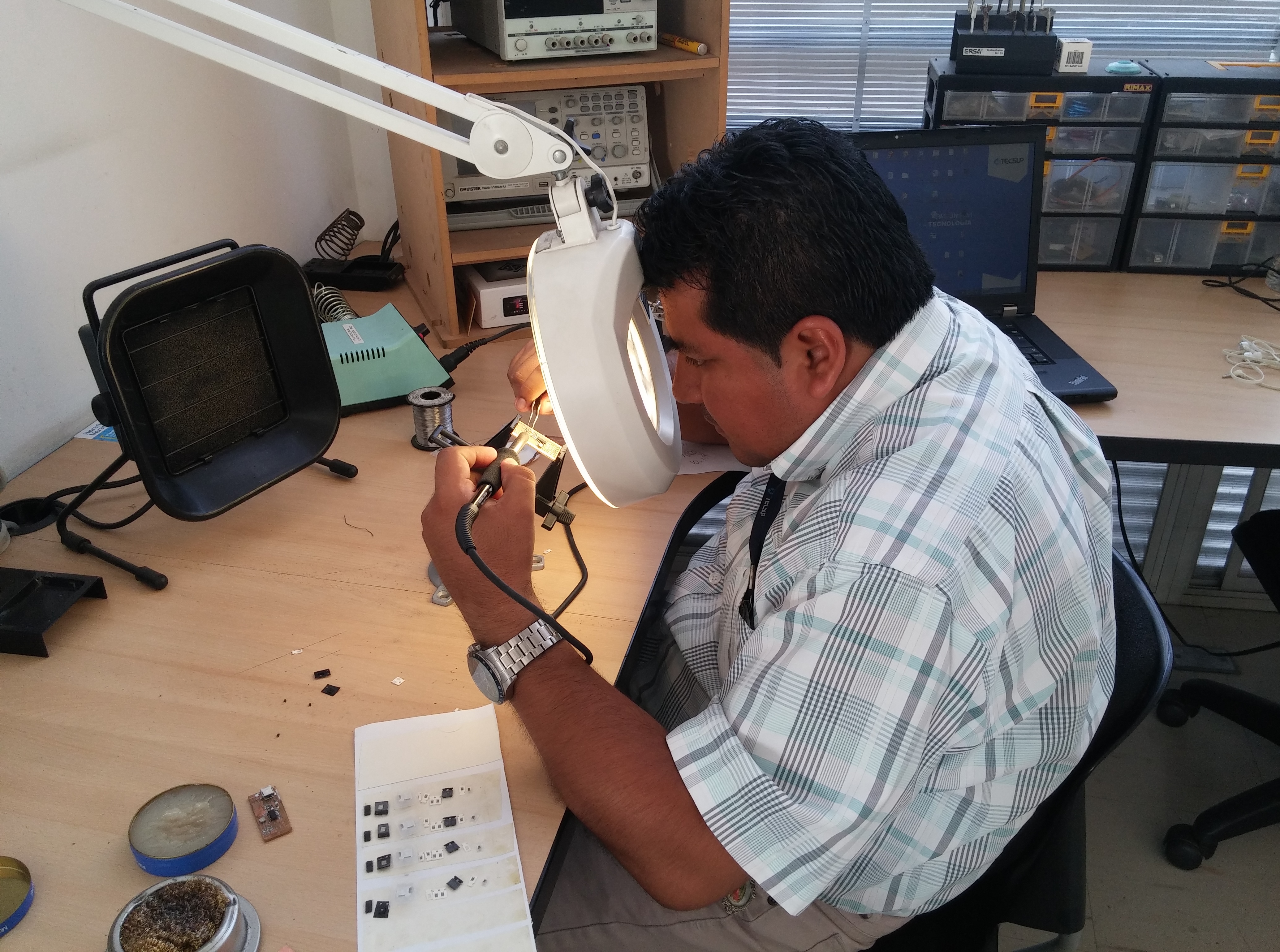

Look for all the components and stick them to a piece of paper for easier organization (it's a good idea to print out a list of the components). We need to prepare our comfortable working area.

Some recommendations:

The next step is joint the components starting with the smallest and center to borders order. After finist to solder is good to check if there is no connection between vias.

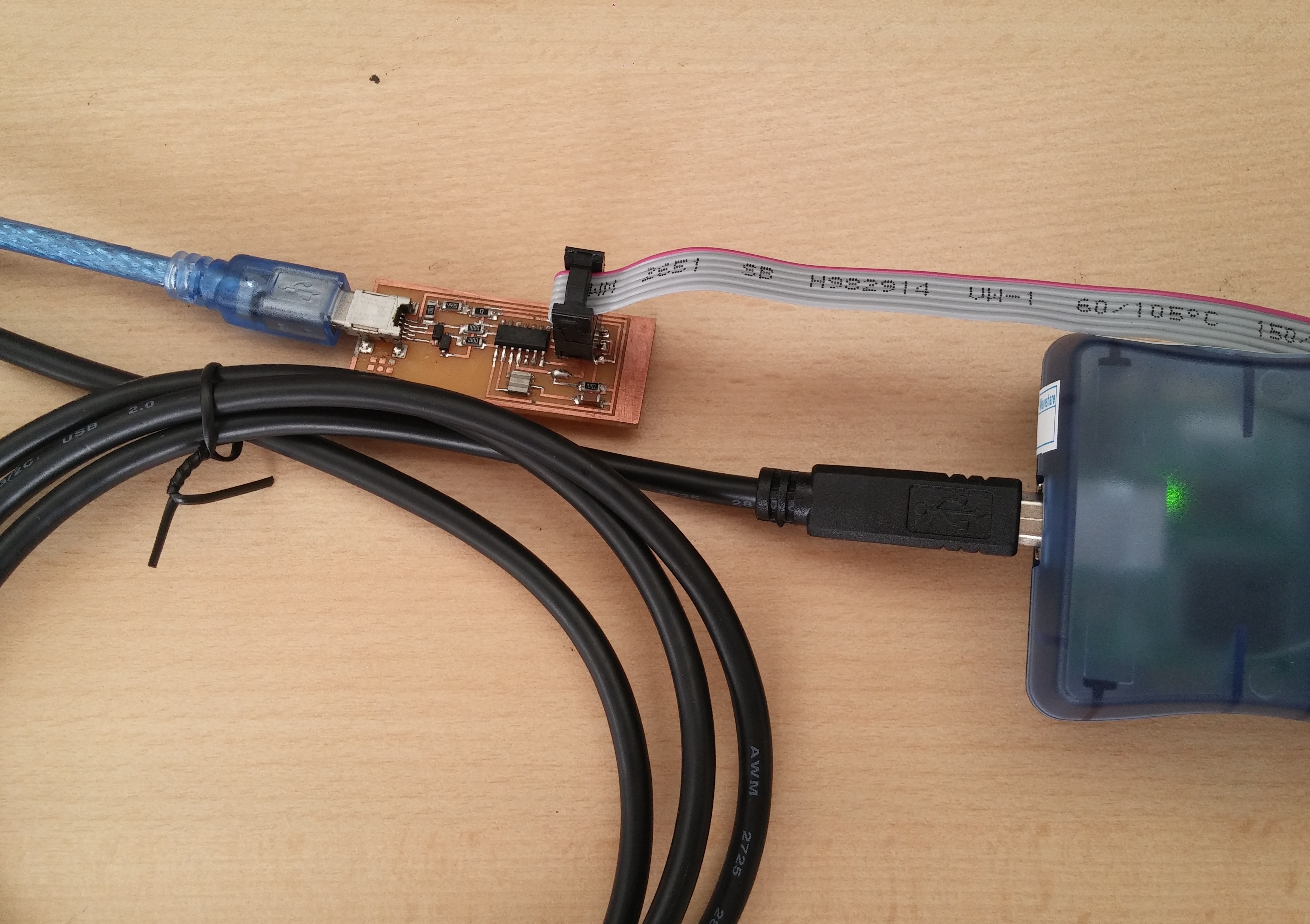

I connected the Fab ISP To computer. Downloaded and installed the necessary software for AVR programming. Fab ISP was finally recognized by the computer. I made really works!

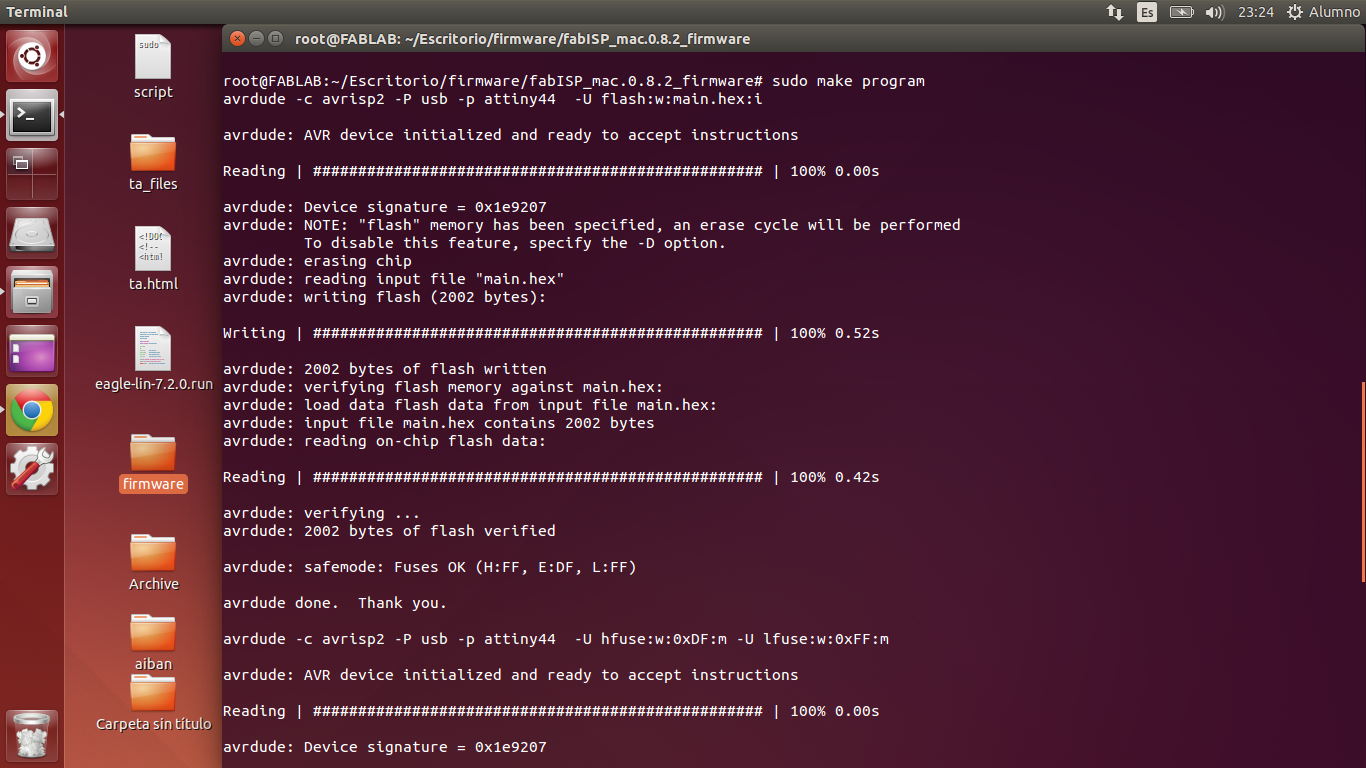

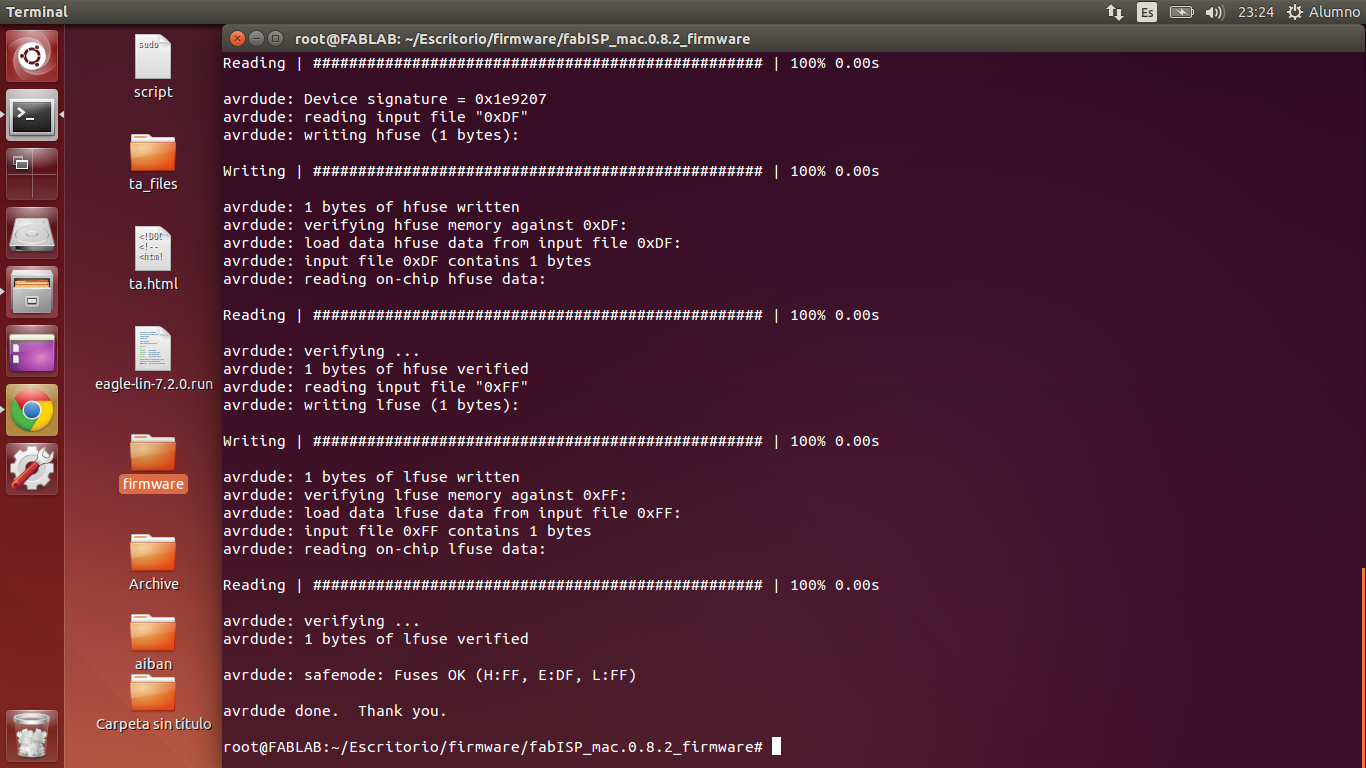

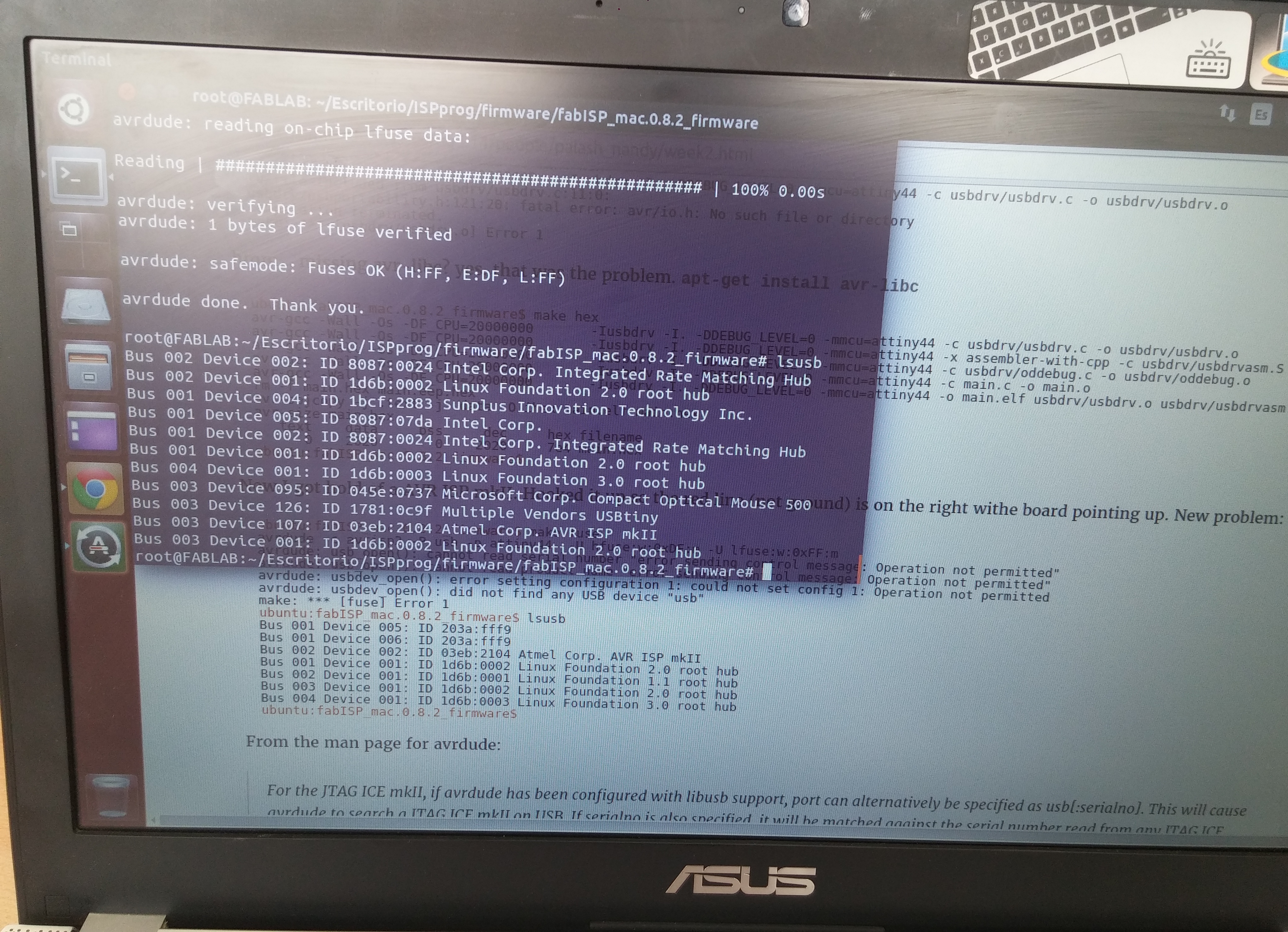

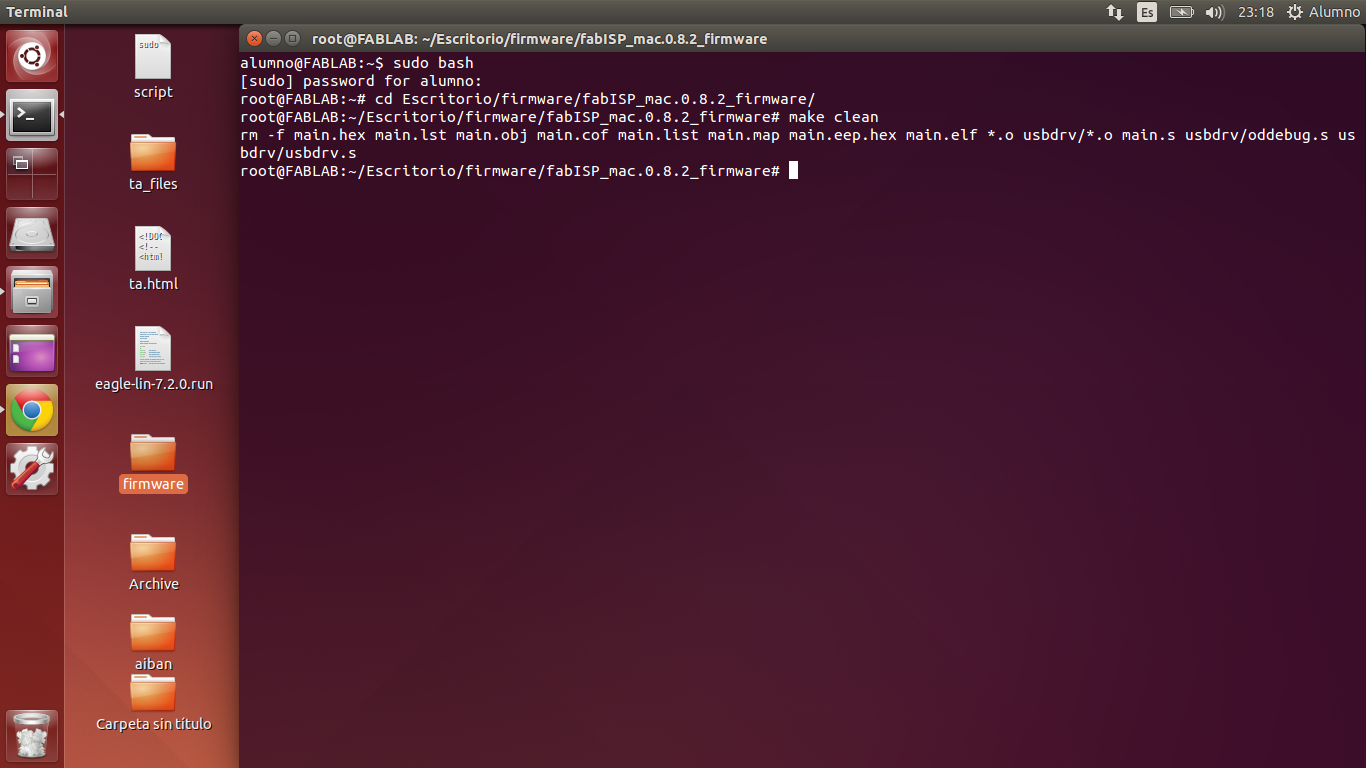

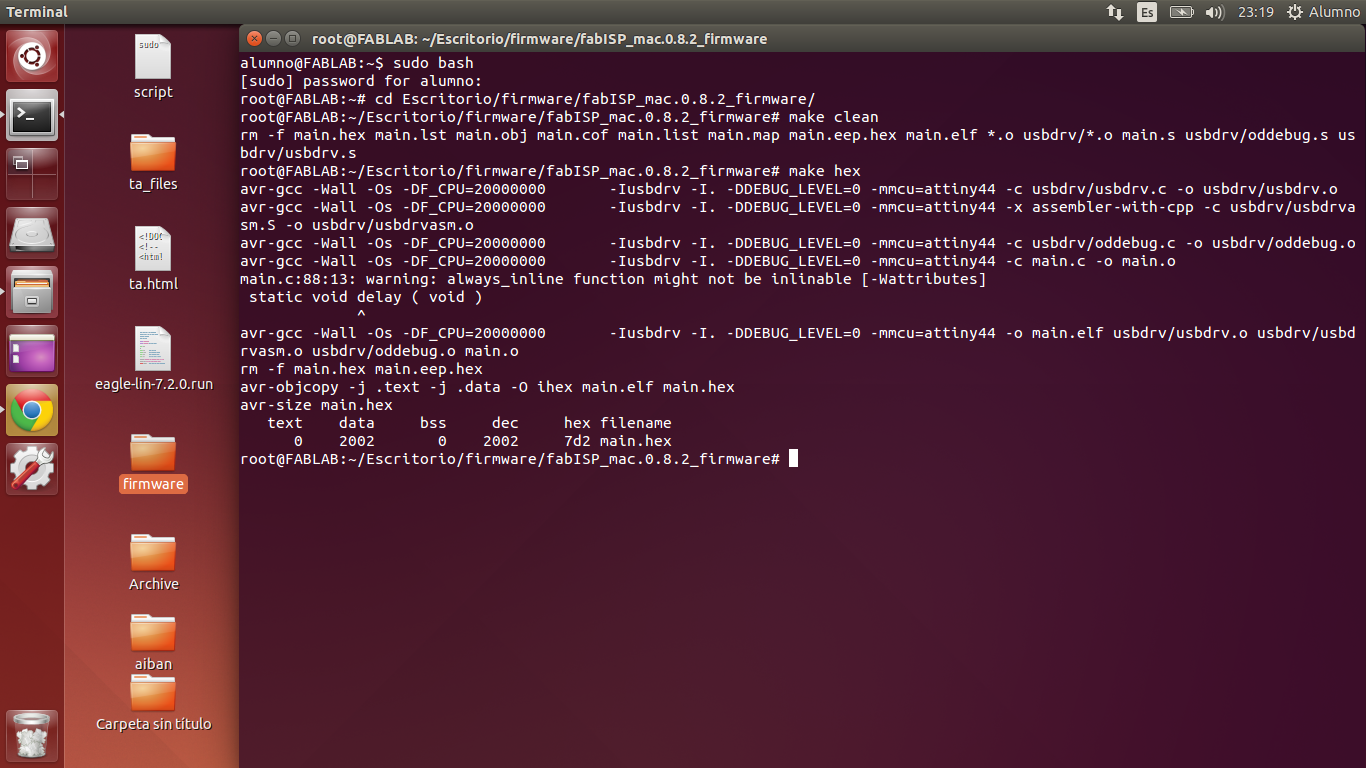

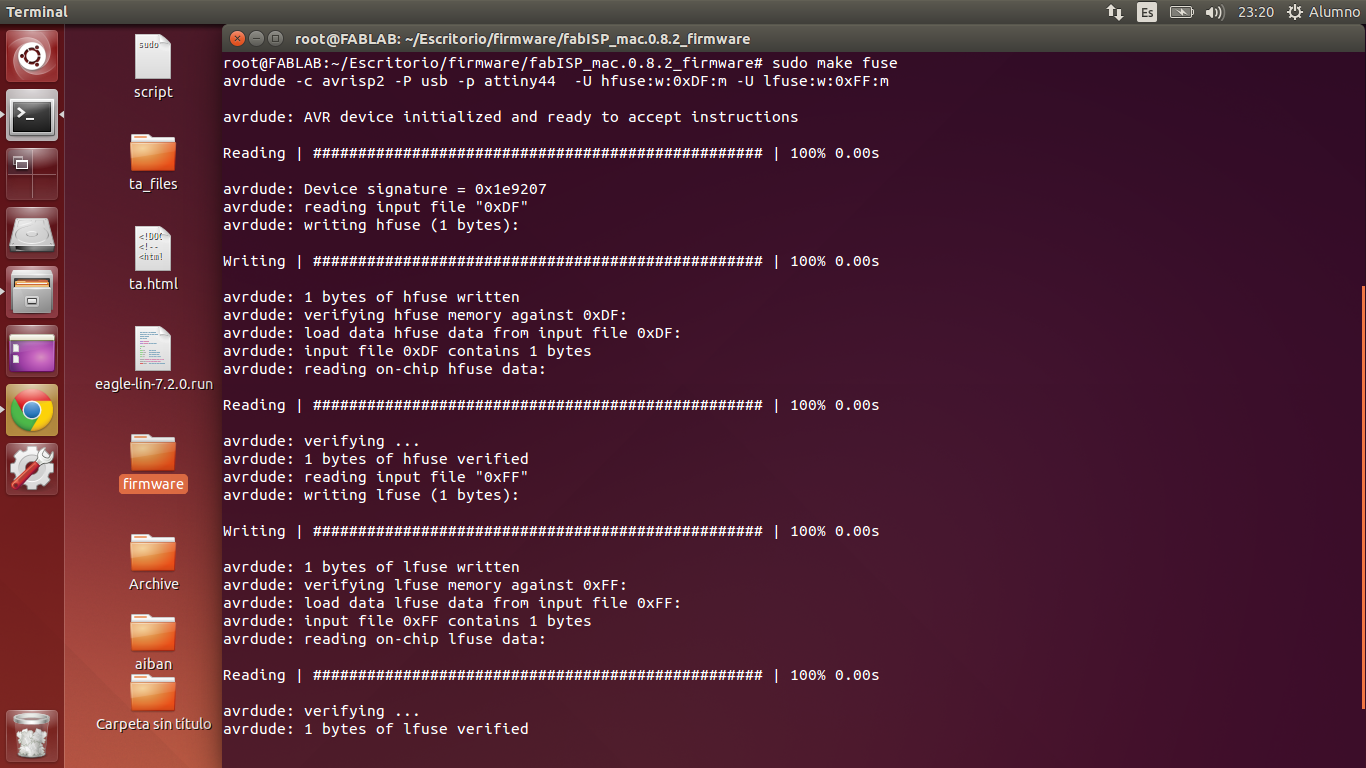

The commands I used and their results are shown in the next images

1st: In sudo state, I moved into the firmware folder and execute the command "make clean"

2nd: execute the command "make hex"

3rd: execute the command "sudo make fuses"

4th: execute the command "sudo make program"