This week we have to make a 3D model and produce a fiber composite part in it. I'll be design a channel for the LED strip i used in output devices, for test it will be useful for my "Portable product photography studio" final project.

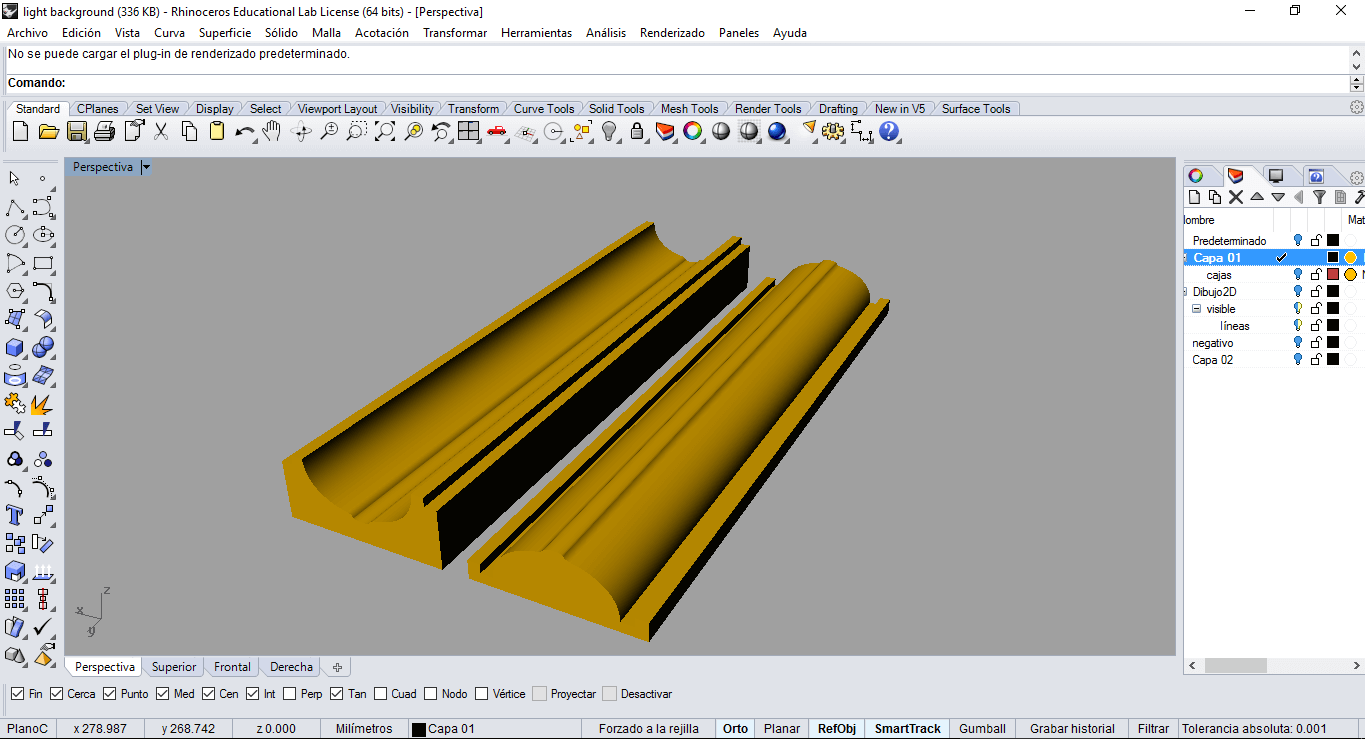

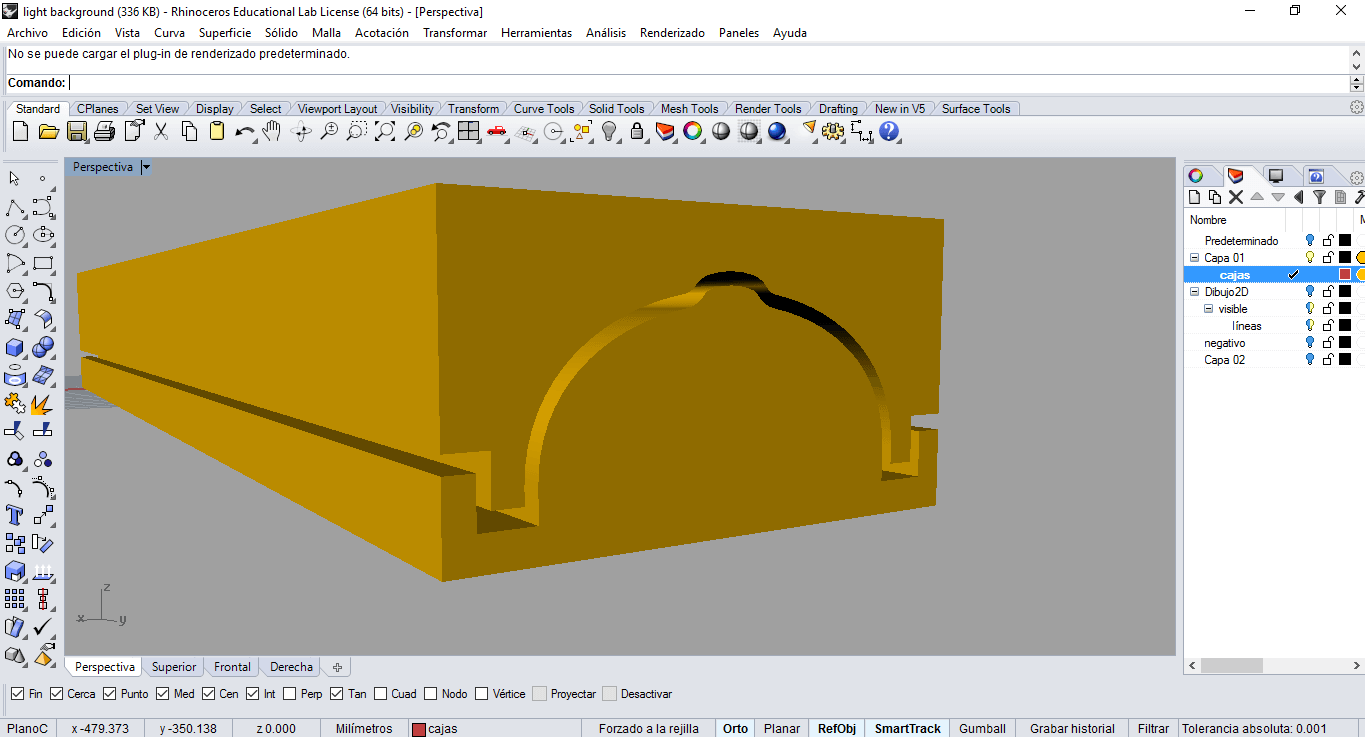

For designing i used Rhinoceros, generating the top and bottom molding.

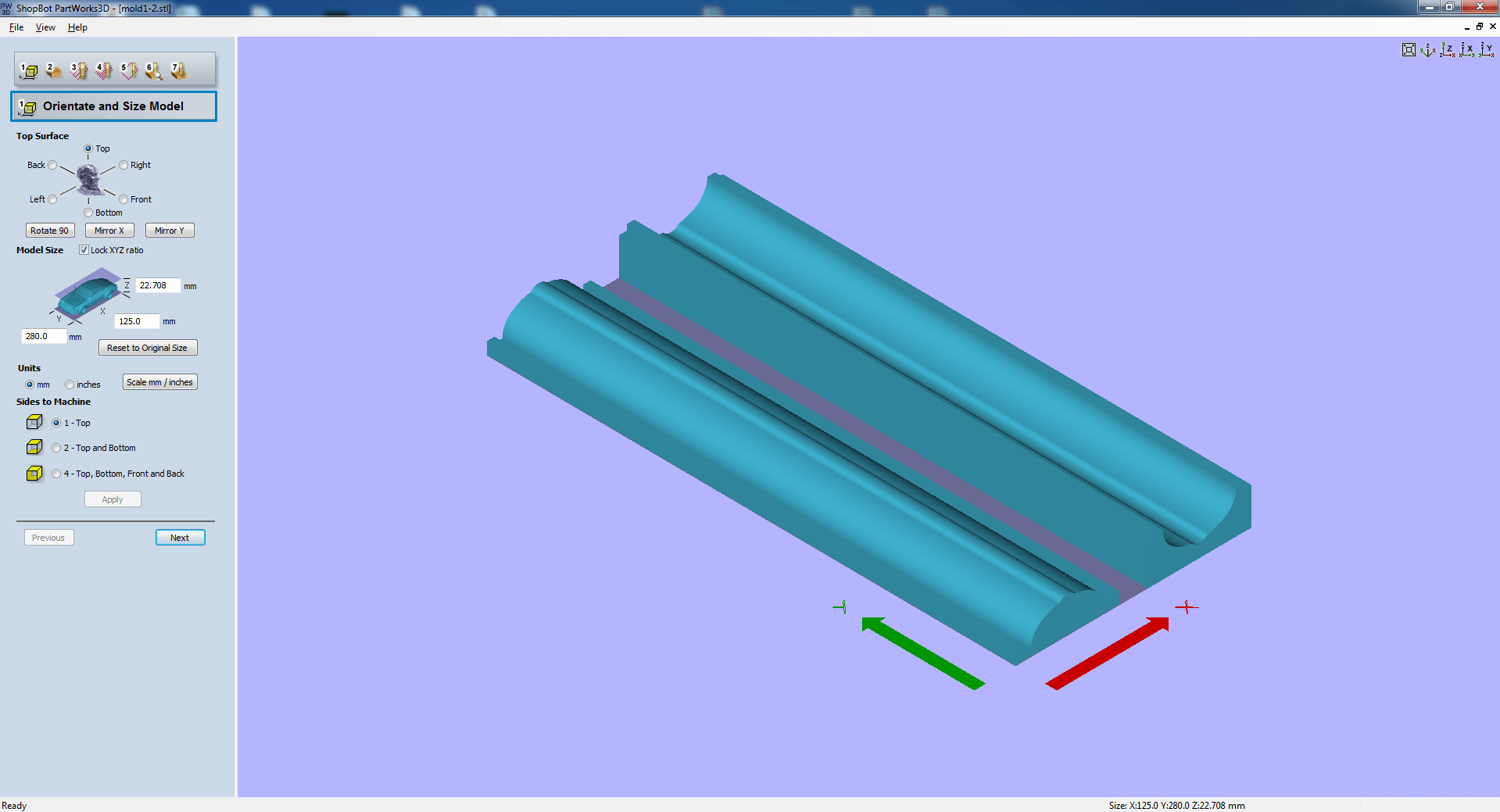

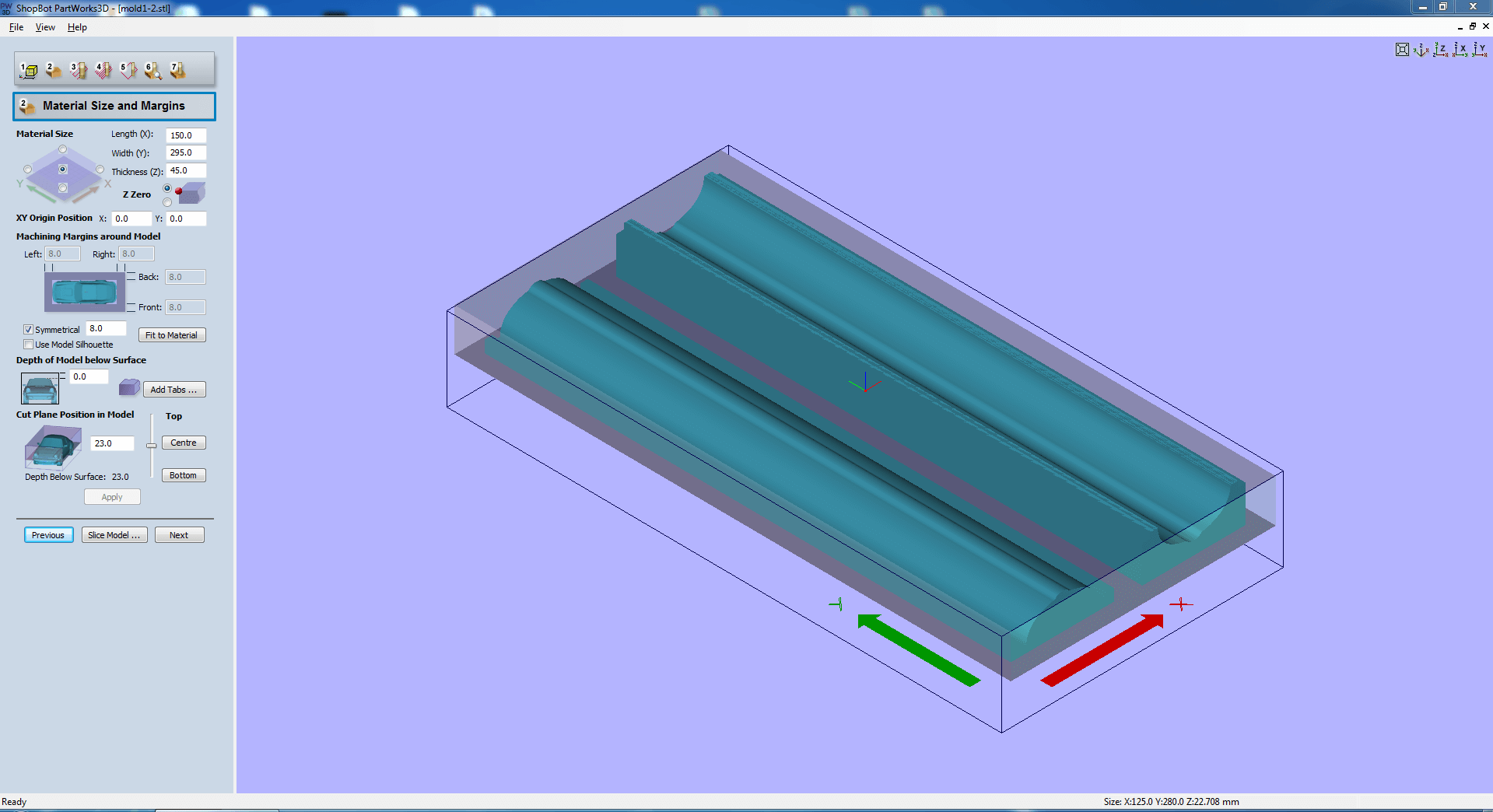

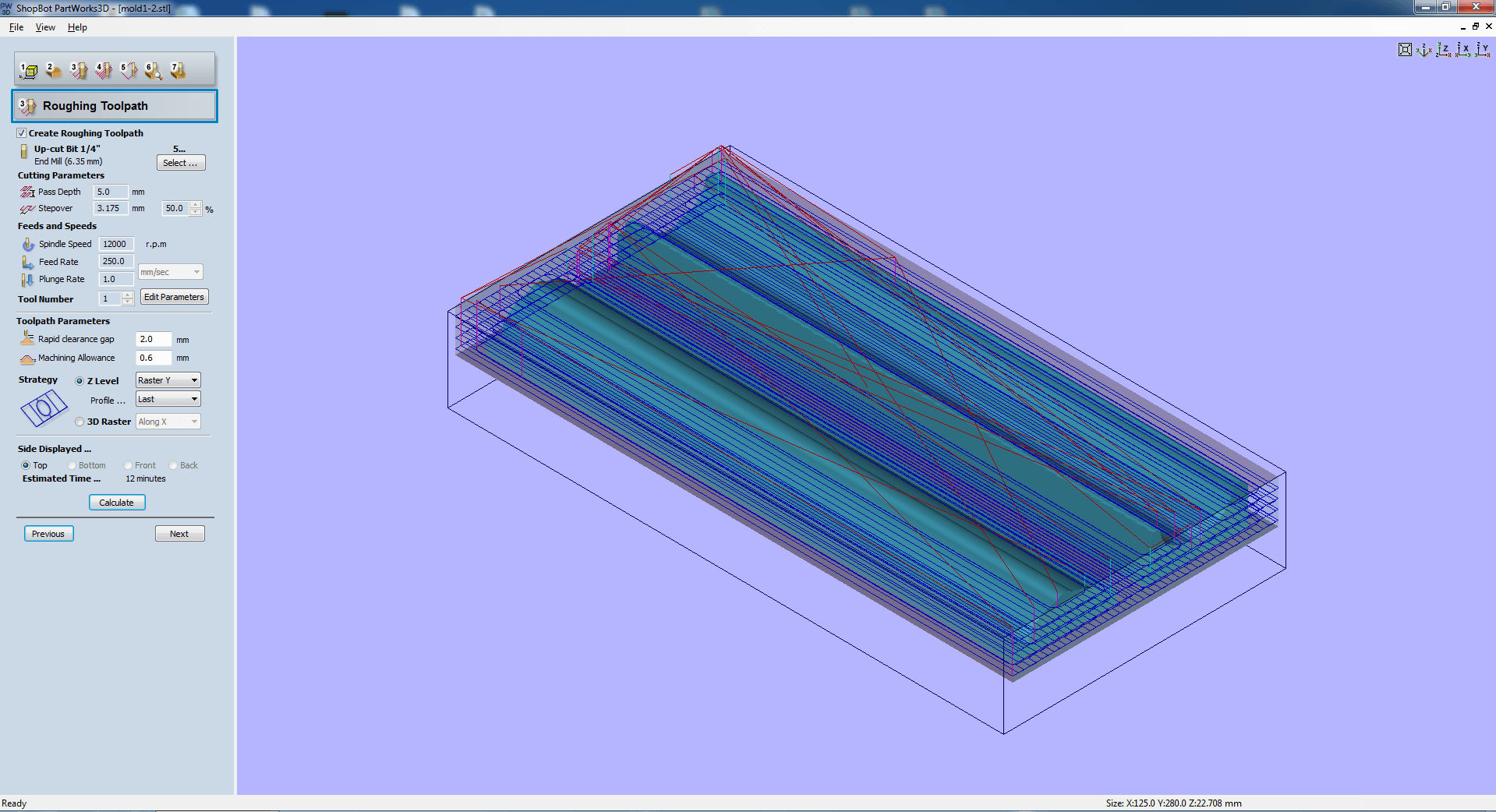

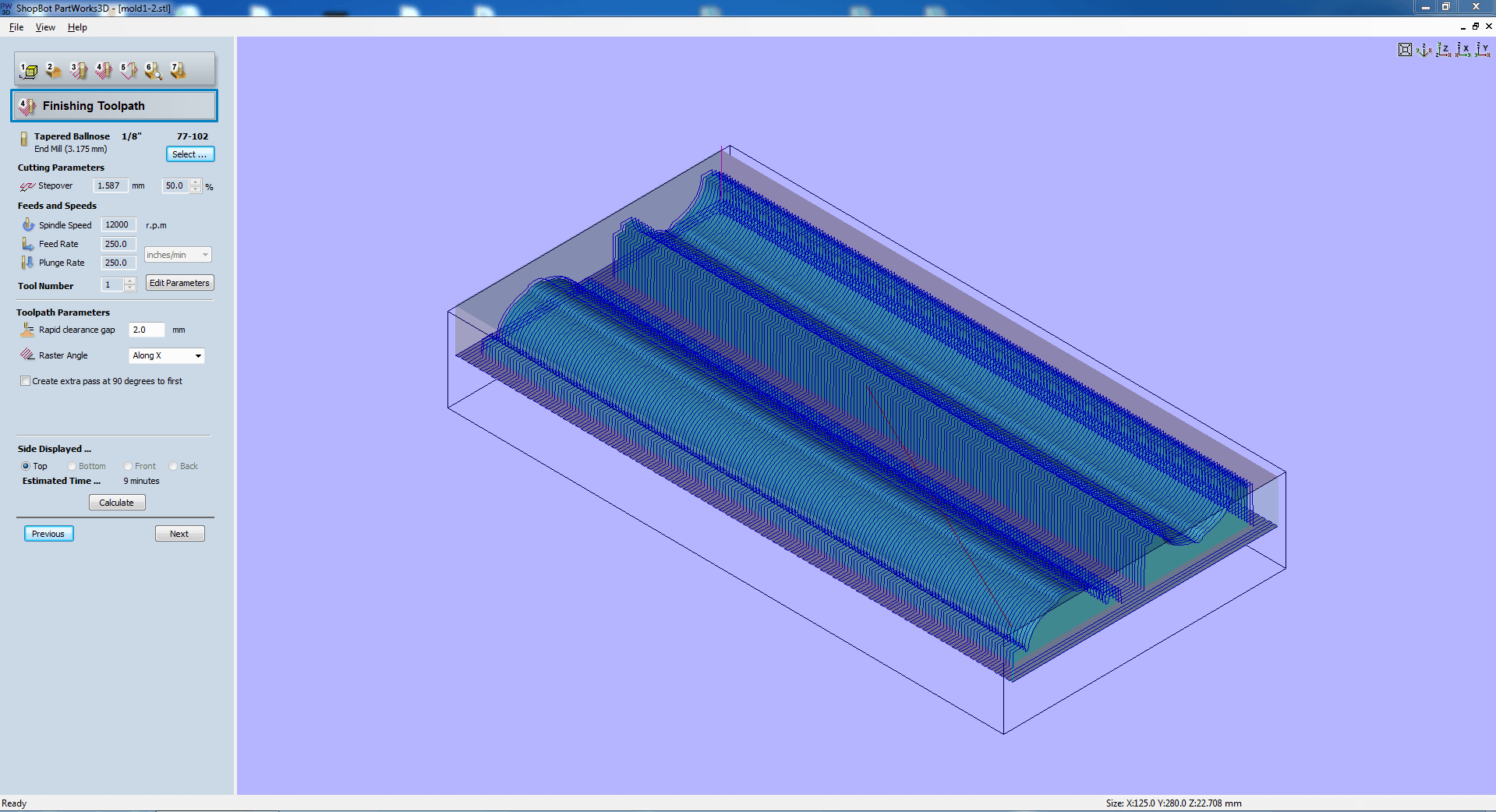

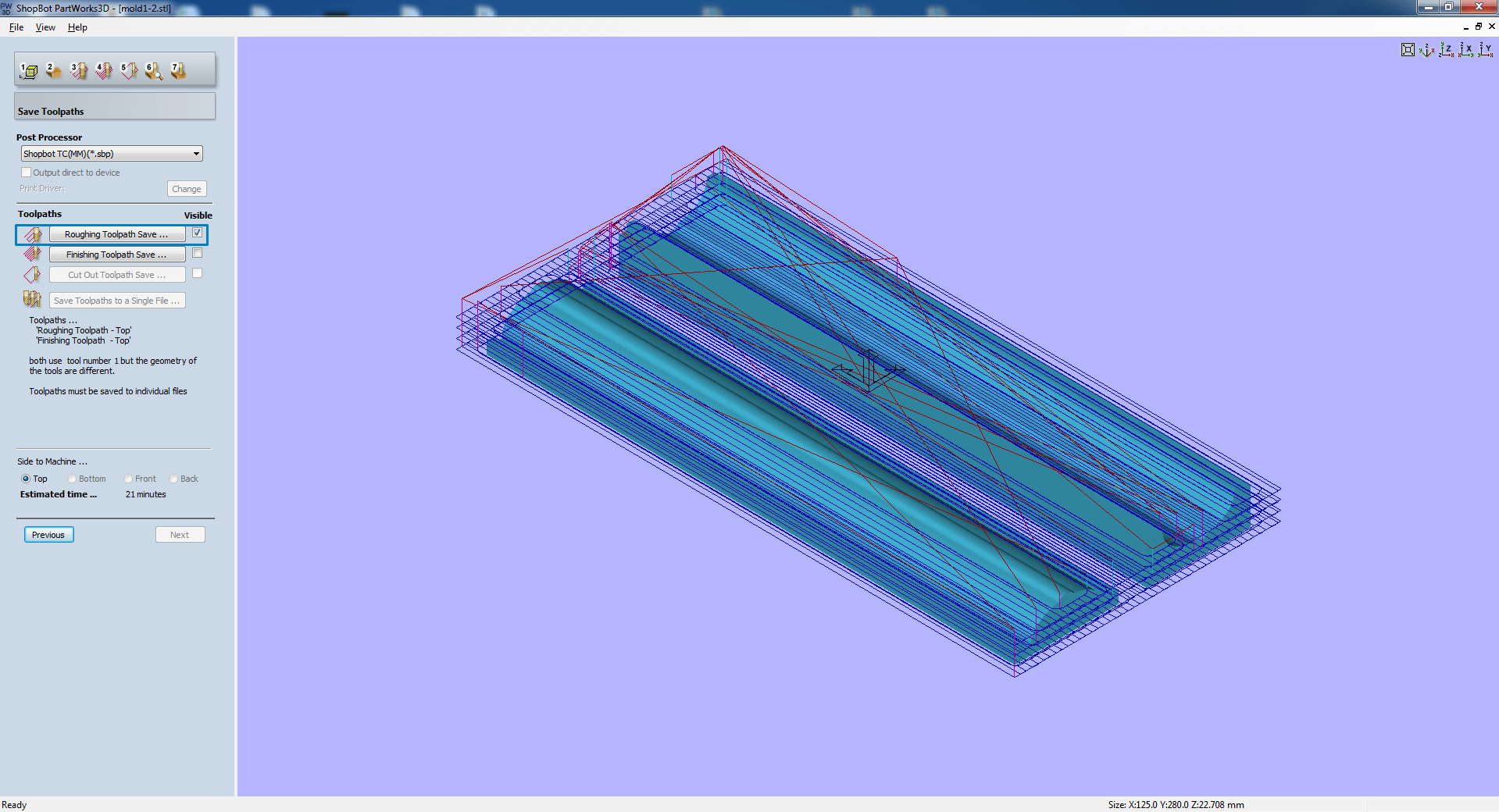

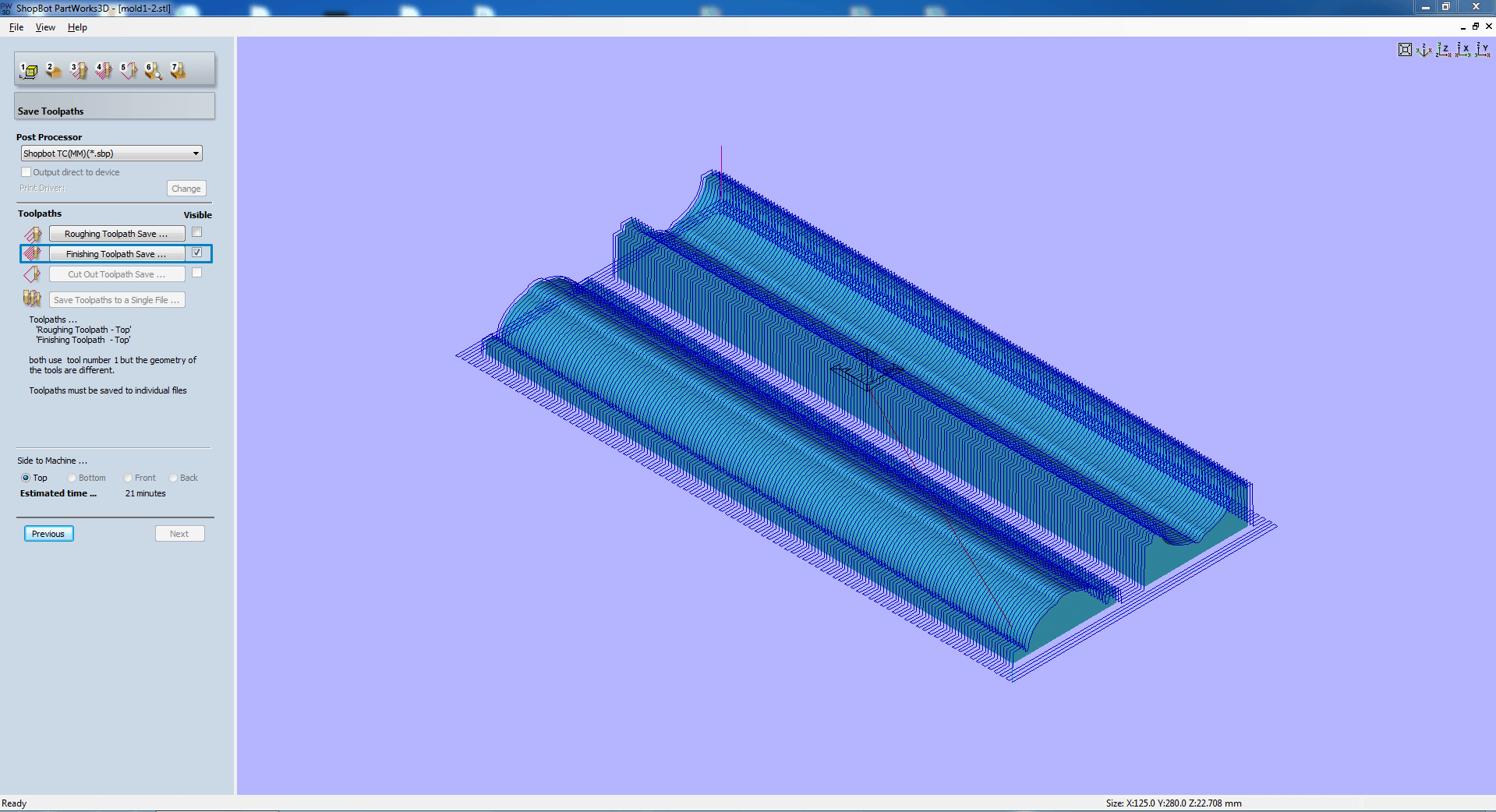

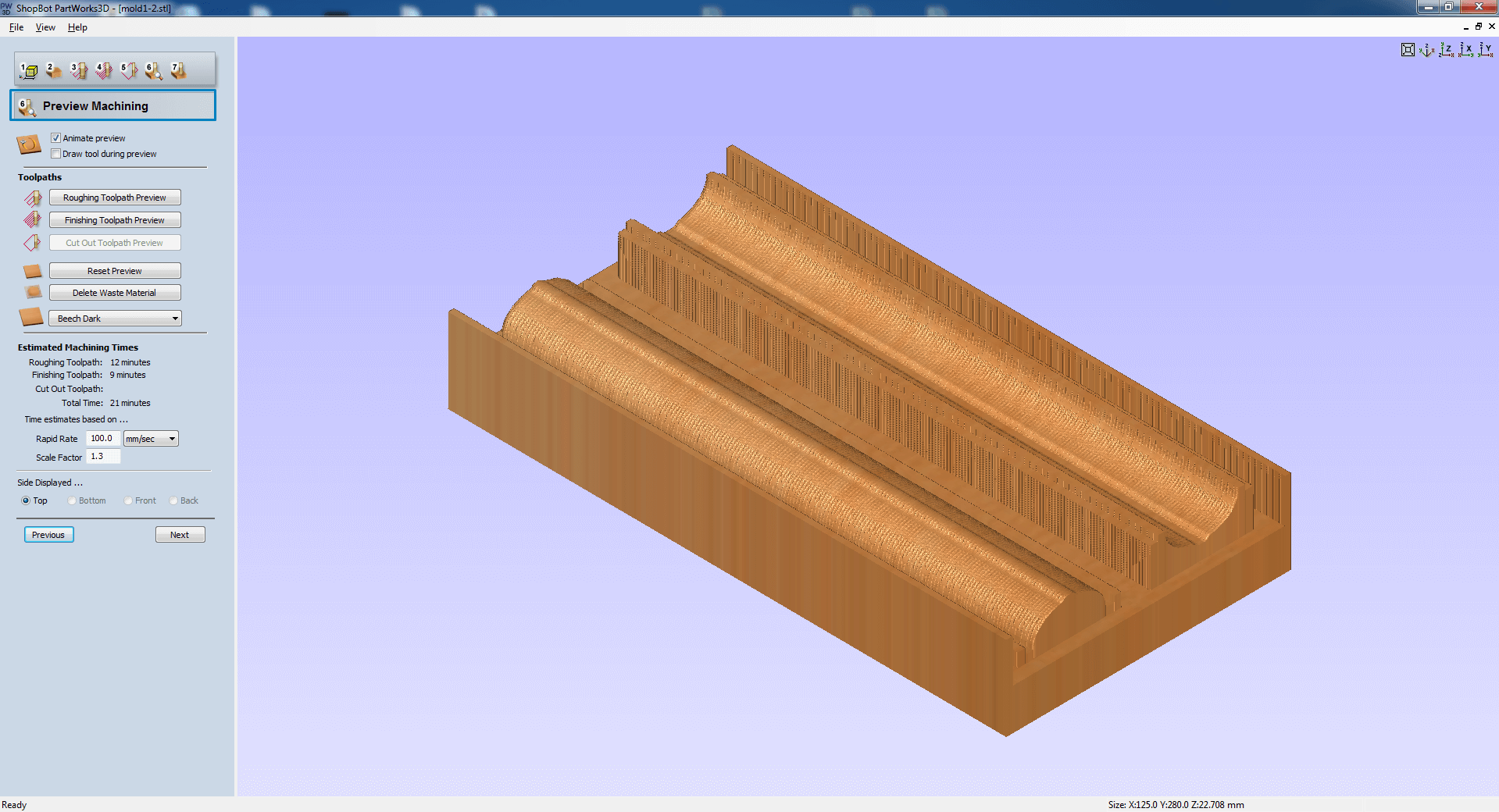

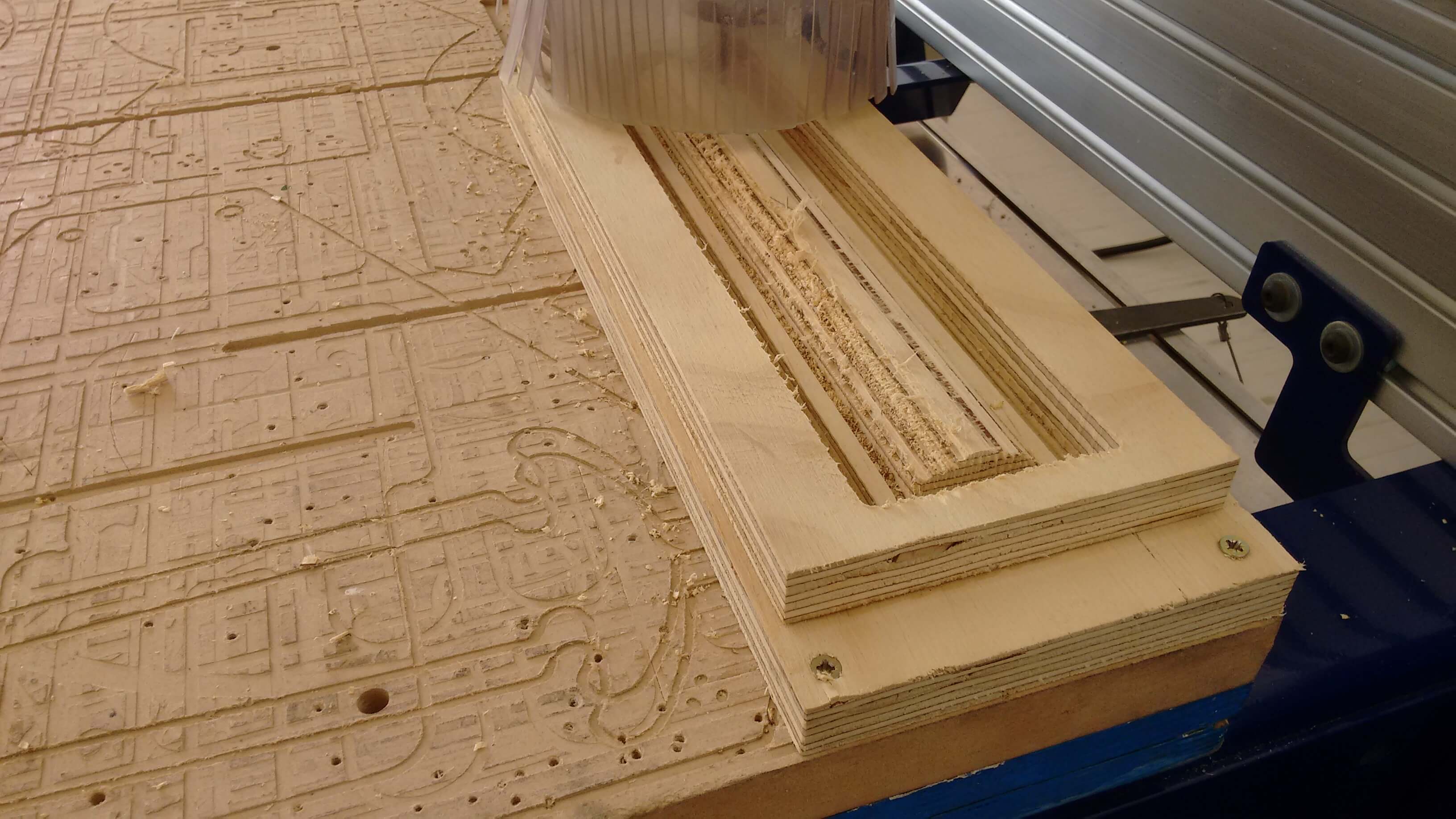

And mechanized in the shopbot with PartWorks 3D.In the images you can see the steps to use PartWorks 3D.

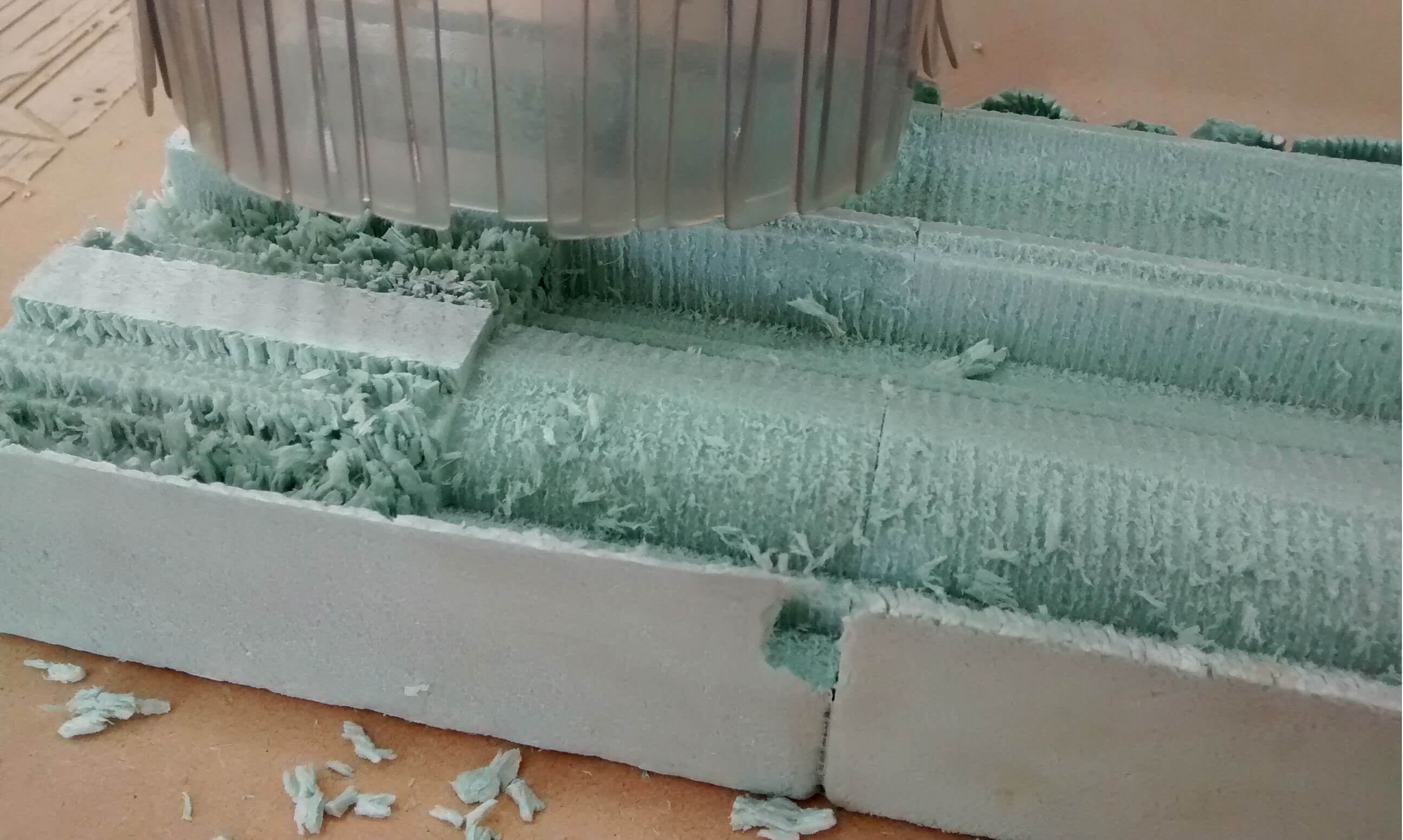

I also mechanize in triplay because when i make my first composites in the foam the pieces were glued together be separated at the time of demolding.

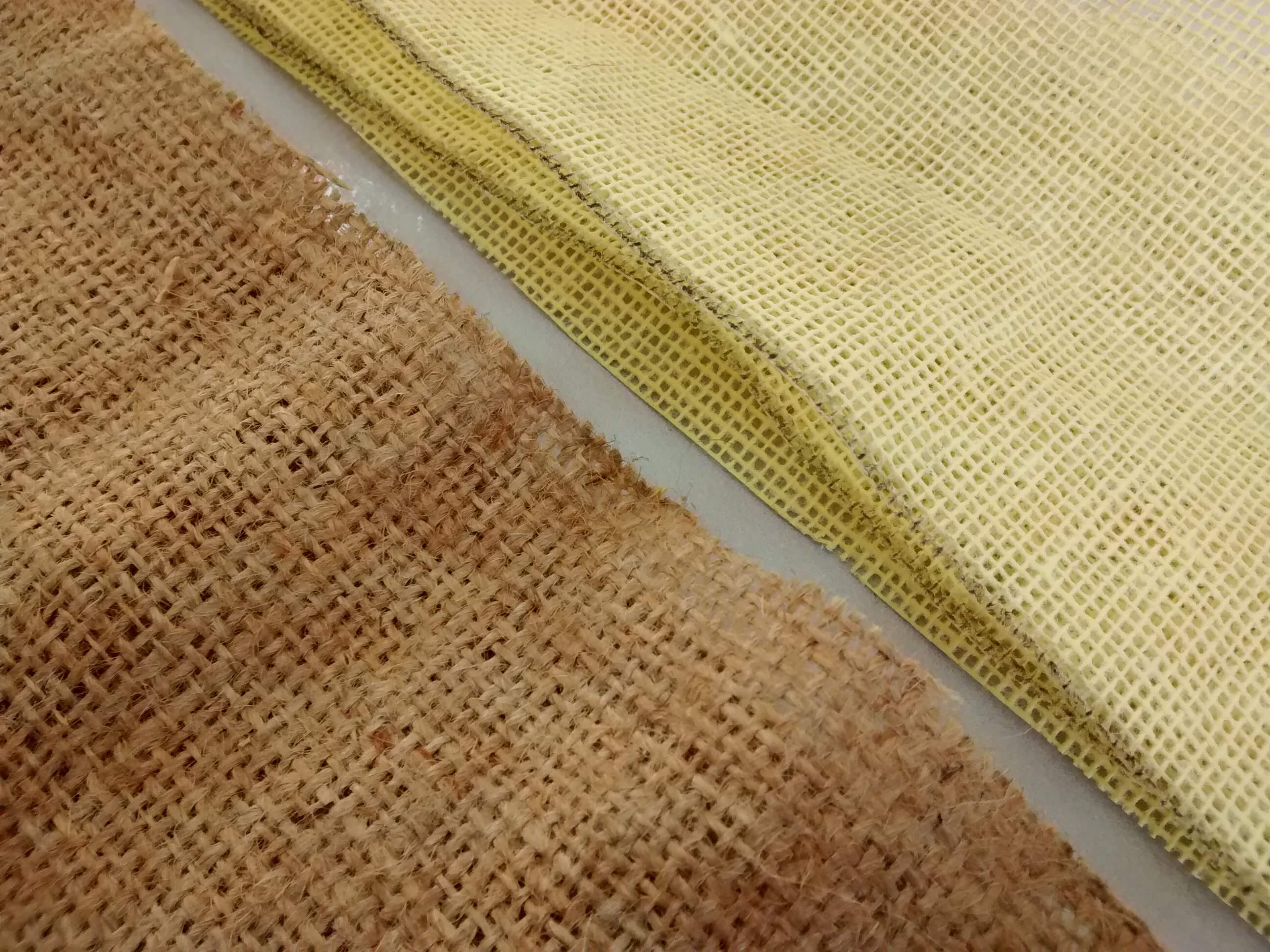

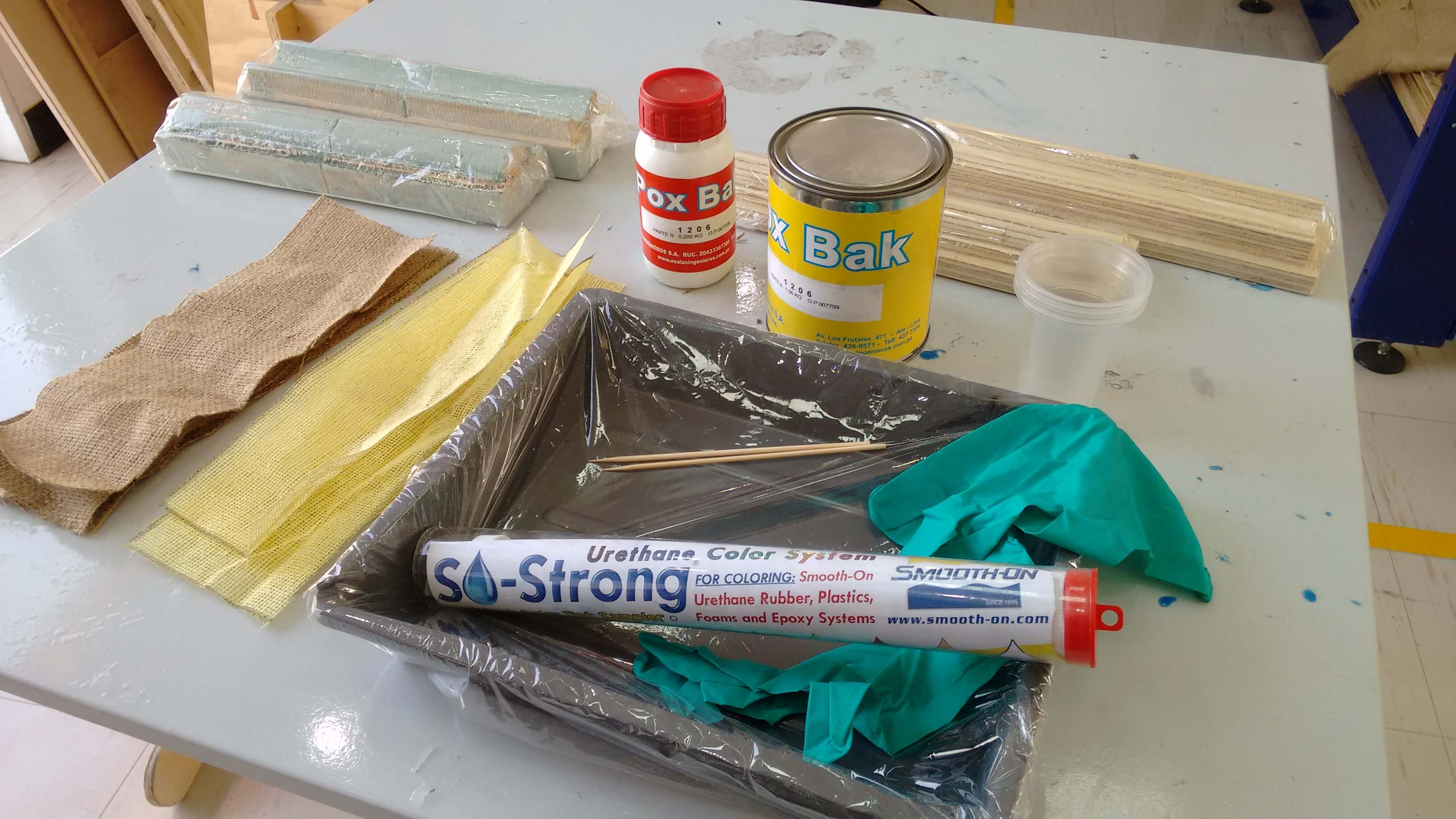

I tested three differents materials for make my composites; cotton fabric, natural jute and synthetic jute.

The first try, i used car wax as release agent, but in the foam it don't work well, for this reason in the second try i change the car wax to film plast.

I used de resine Pox Bac 1206 and also tint it with the urethane color system of Smooth-on. Decide use white color because it help me to diffuse the LED strip light.

| Composites | Advantage | Disadvantage |

|---|---|---|

| COTTON FABRIC | Best suited to the mold | Haven't enough rigidity |

| NATURAL JUTE | Good plastic finish | Dificult to tint |

| SYNTHETIC JUTE (triplay model) | Good plastic finish | With triplay model don't permit more than 2 layers |