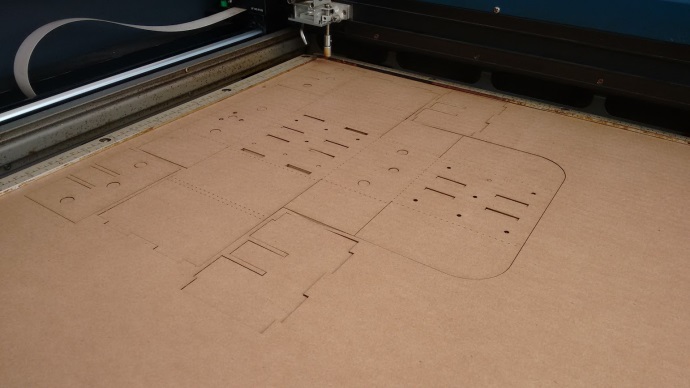

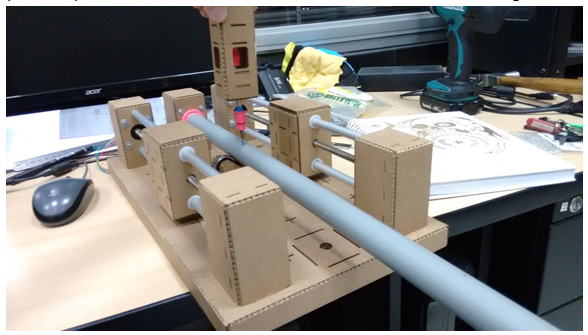

For this group activity we decided to make a cutting machine CNC pipe. The proposed challenge was that the machine should be made of cardboard and which definitely achieved our goal.

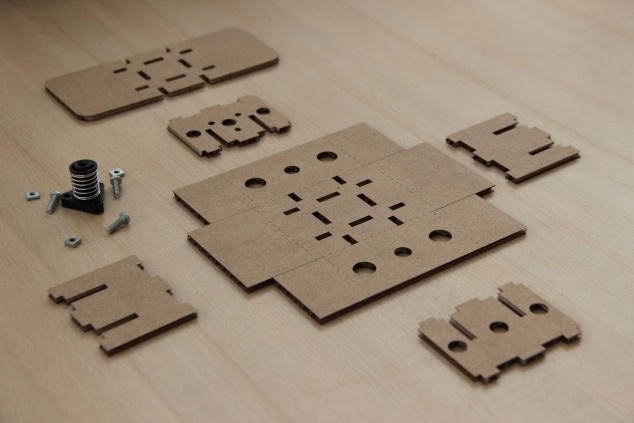

We began to observe Guides team how to use the cardboard to start the assembly of the machine, which from my perception was not so complicated but always with the idea of optimizing all possible material

Fab Lab in Tecsup we are 4 people who took the Academy, two industrial designers, a chemical engineer and industrial engineer with technical studies of mechanics. The challenge of designing an automated machine with simple materials such as cardboard undoubtedly represented the task that took more effort as a team. We came to work independently because here we should integrate and do work very coordinated

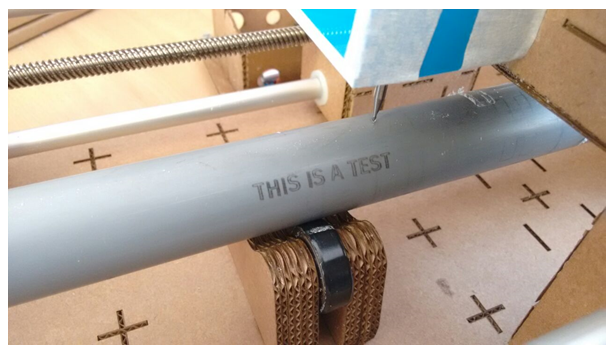

For this group activity we decided to make a cutting machine CNC pipe. The proposed challenge was that the machine should be made of cardboard and which definitely achieved our goal.

By working together we distribute activities. My contribution was the mechanical design of the fittings and solve problems that they can generate activity, so one of the first problems began to be noticeable is the motor shaft because the initial design of the coupling was made and manufactured in the 3D printer as it is shown in Figure

In working together we distribute activities. I undertook to solve the mechanical problems as they arise in the activity, for which one of the first problems began to be noticeable is the engine shaft coupling cutting.

You definitely have to be aware and know the difference that rotation elements and power transmission ABS plastic is not appropriate, we corroborate this idea when testing rotation as the movement was very unstable by vibration of the cutter which cuts material.

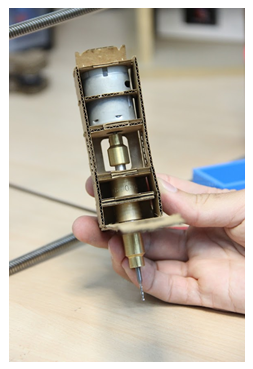

Because of these failures is presented opted for the manufacture of rotating element (shaft coupling) bronze material. Was necessary to use a manual lathe with which we here at facilities Tecsup No. 1

For the machining of this piece took into account different aspects such as the type of material, speeds, cutting tools used, and especially the security aspect since being a machine tool high speed danger is present in all times.

Once the piece was made on the lathe make holes for studs to grip the axles and ensure good transfer of rotation. To make this work I used a hand drill with a drill of 3.8 mm to ensure the through hole. The next step to making the wires enter hole for stud. I used for this purpose males 3 passes thus achieving the purpose as shown in Figure.

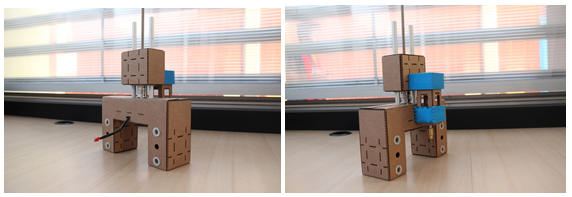

At the end of making the couplings that ensure a good transmission of turning the machine head is shown as is;

Another problem presented was to hold the tube to be cut because the length was a bit long and we had to ensure good stability in the cutting process. We try to put thrust bearing on the way but note that it was not so appropriate this practice because we had to ensure that there is the minimum number of items on the road

He was placed two supports to ensure good stability of the pipe, thus the testing we realized it worked well so we gave for completed this stage of the construction of the machine.