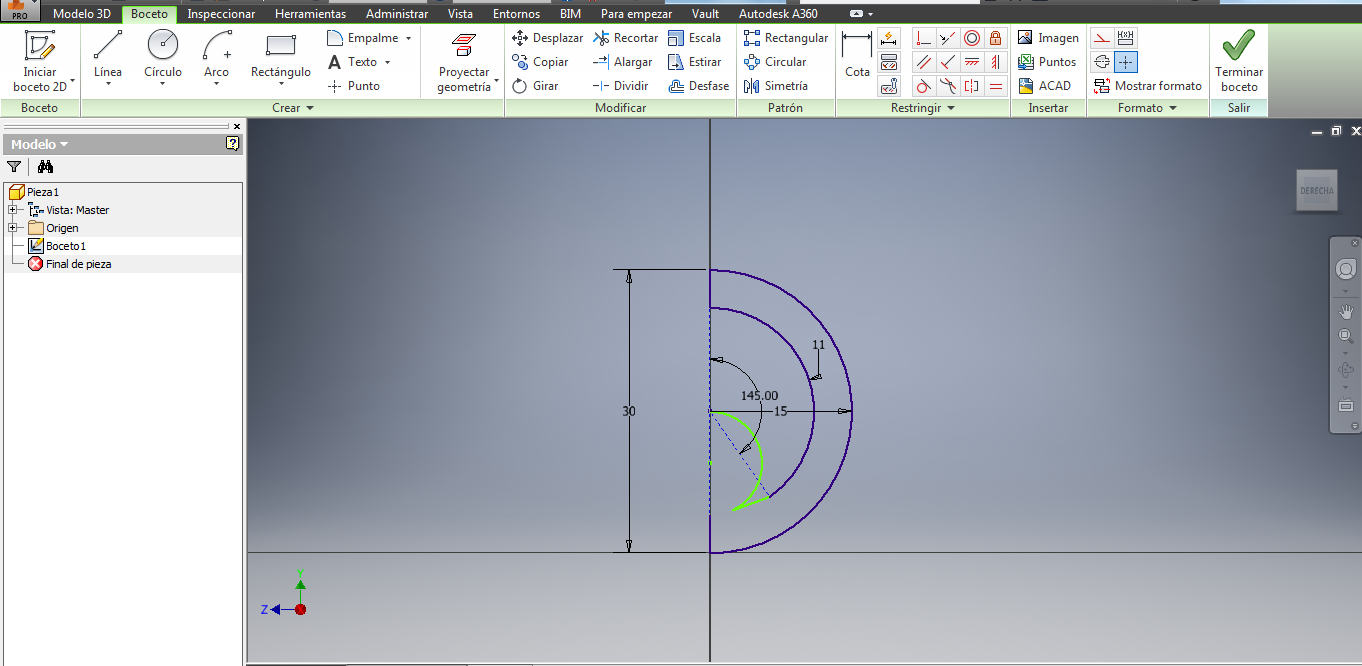

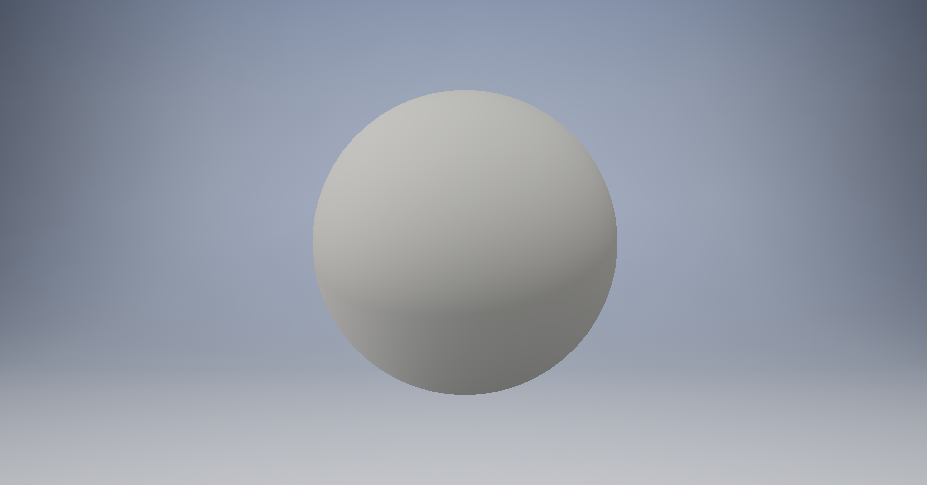

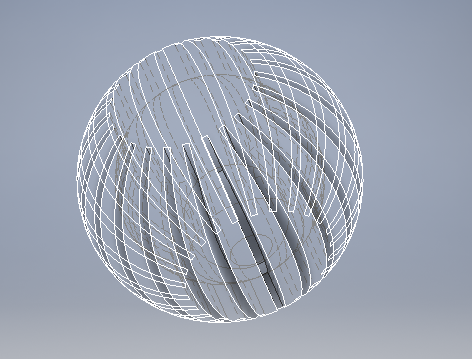

The first part of this assignment is to design an object that can not be made substractively. So, since I am becoming a little bit stressed, I'll design a little toy for me. So I came up with the idea of making a bell. The next images are the process of design using inventor. First I designed the central ball and the external cover. Then I revolved it.

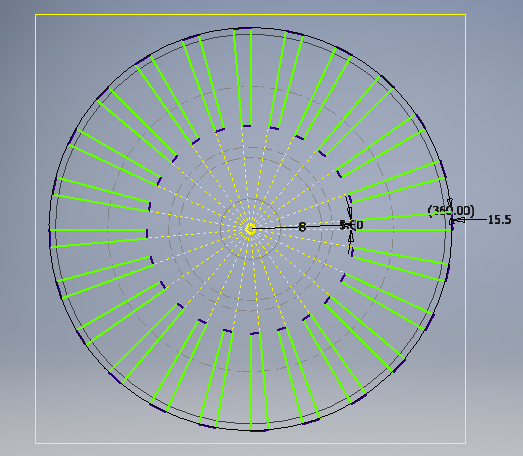

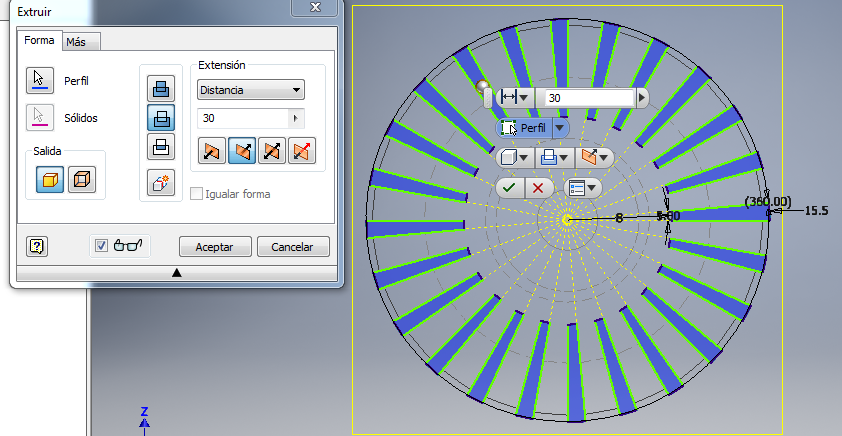

After that I extruded as a cut the shown pattern.

So finally i get this shape to print

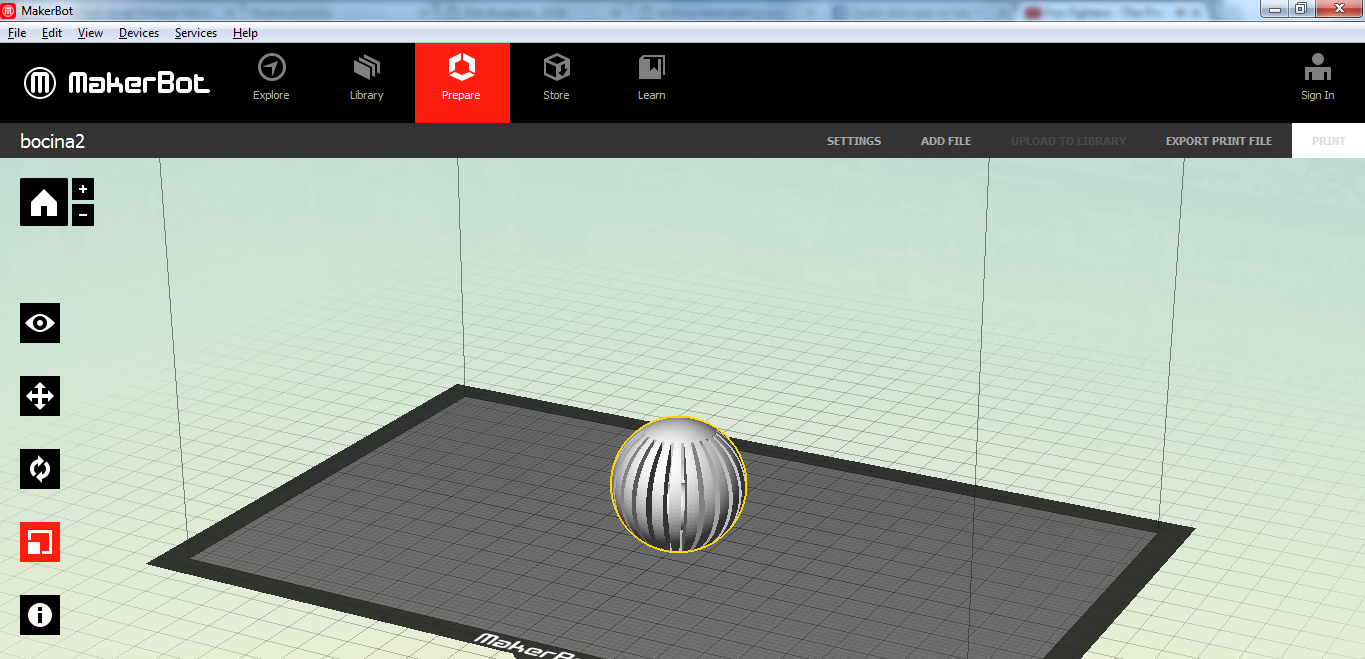

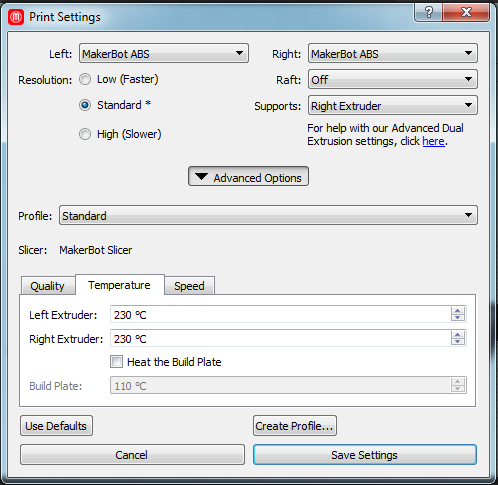

And this is the final result. I also show the parameters and the printing process

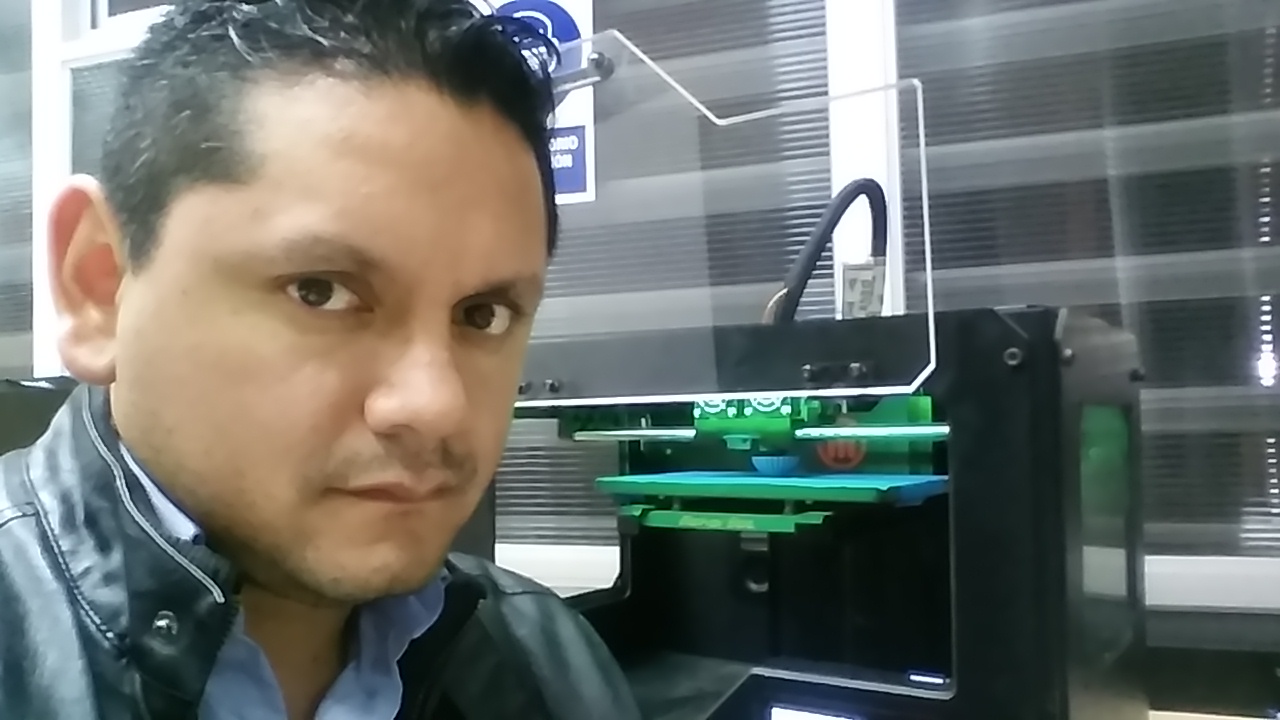

The other part of the task this week is to scan a 3D object and print. The material used is the type ABS plastic The task No. 5 was a challenge because I learned how you can get a solid from the design using 3D printers, for it initially had to download the program 123D Catch my cell phone and start taking pictures around a solid.

Once the program is installed proceeded to take pictures around the solid this time I chose a water bottle.

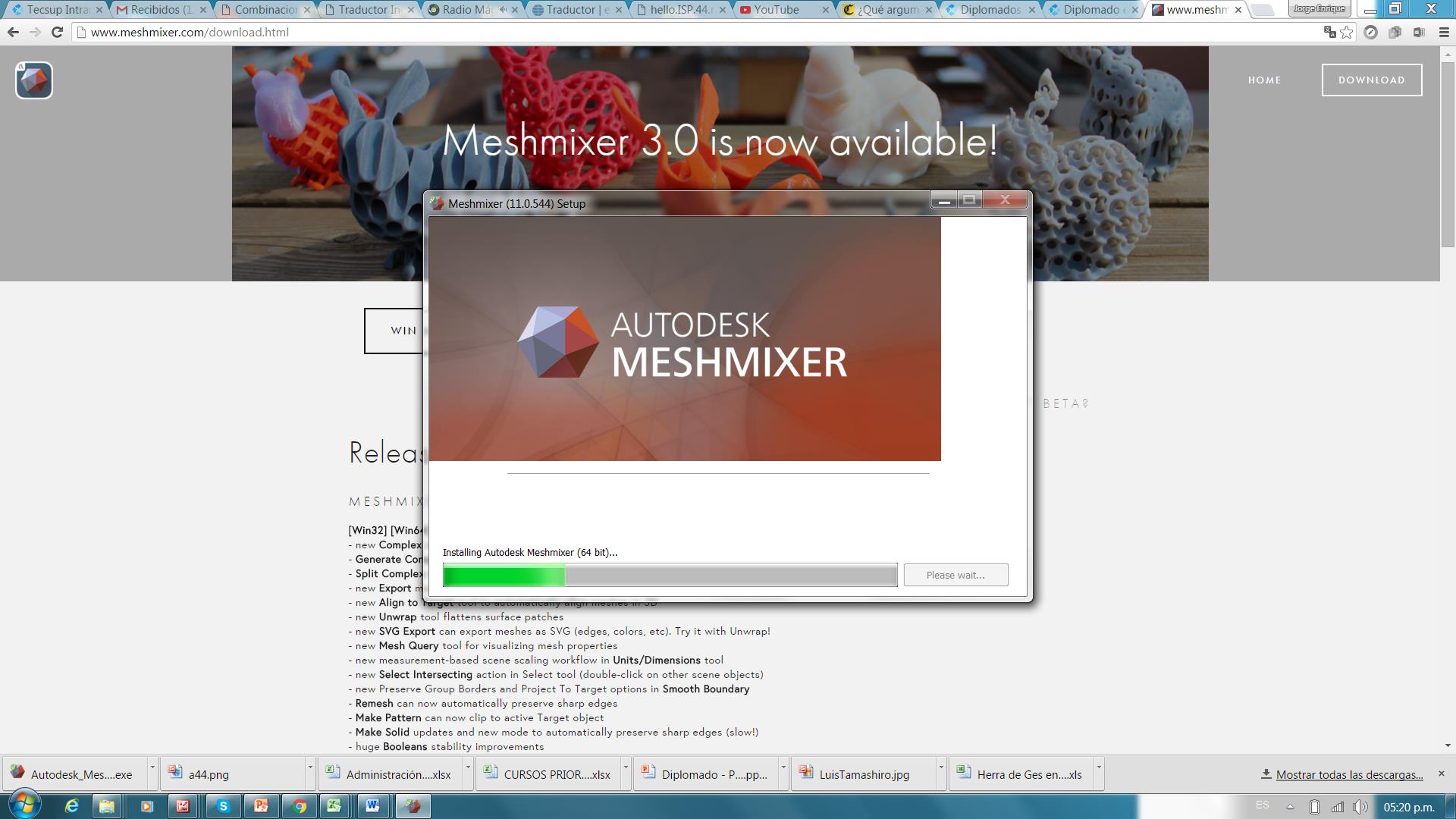

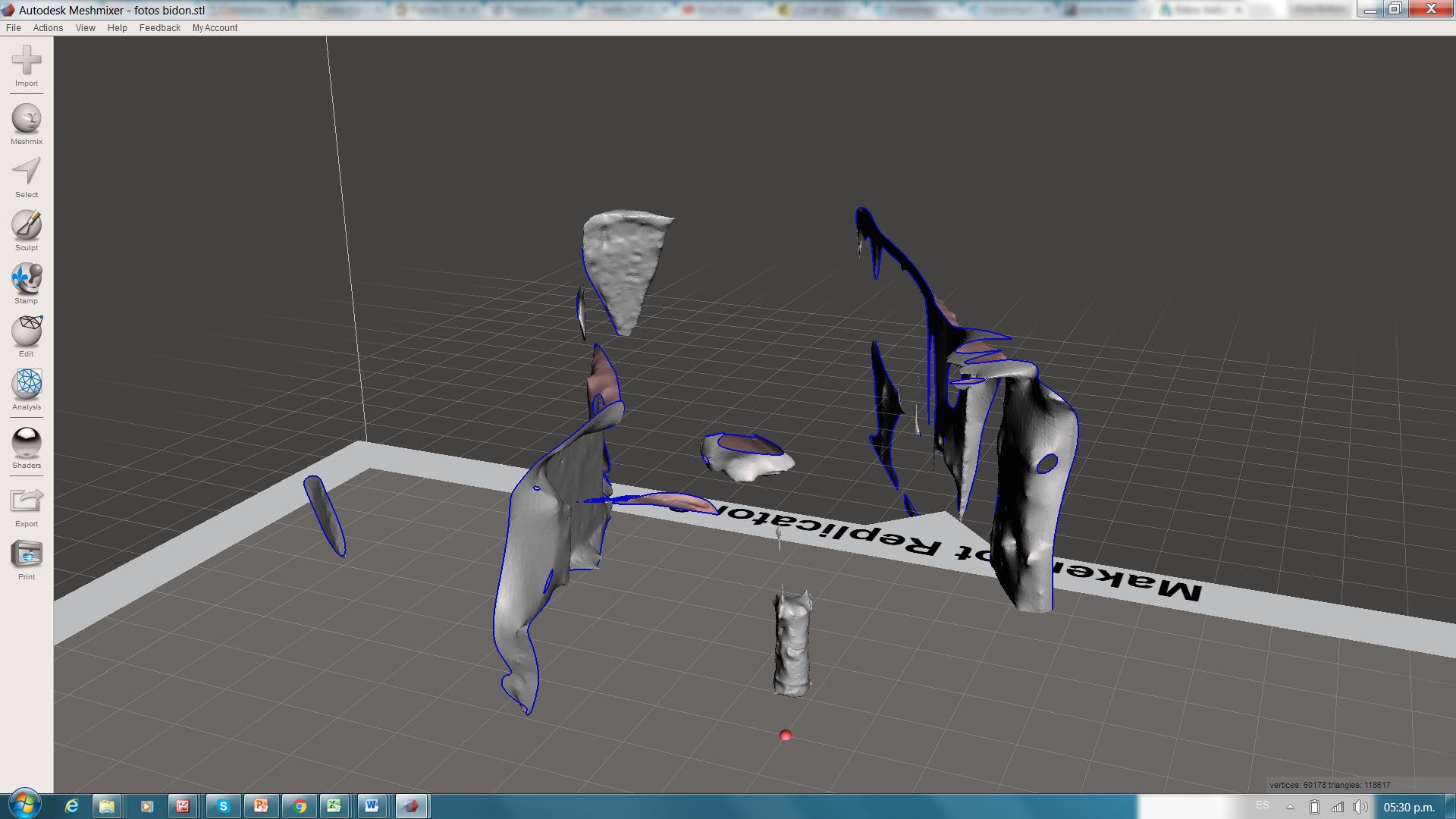

For work with the Meshmixer Scanner program is used. Initially, the scanning could not be obtained in a uniform way so I had to repeat several times the same operation.

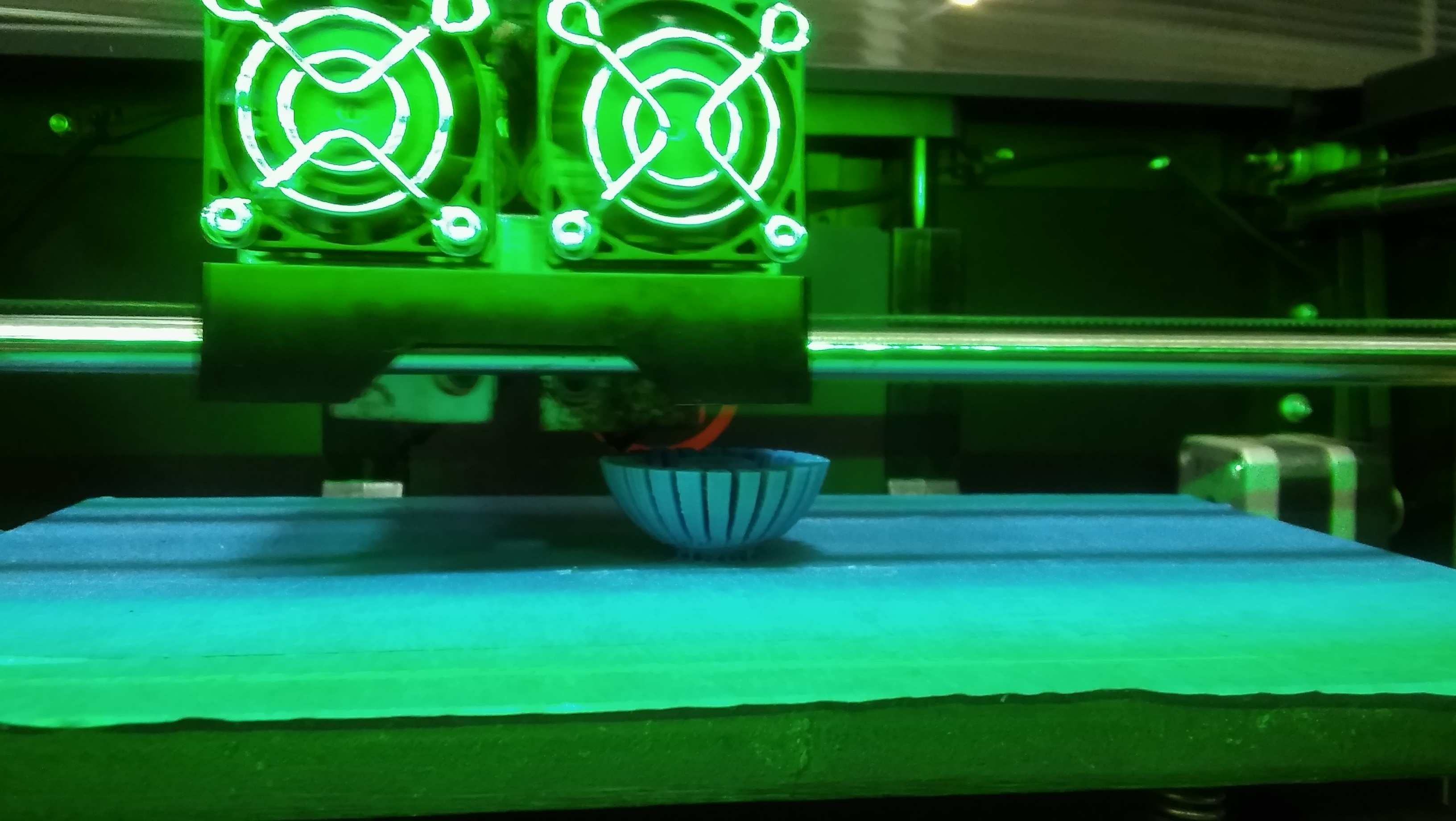

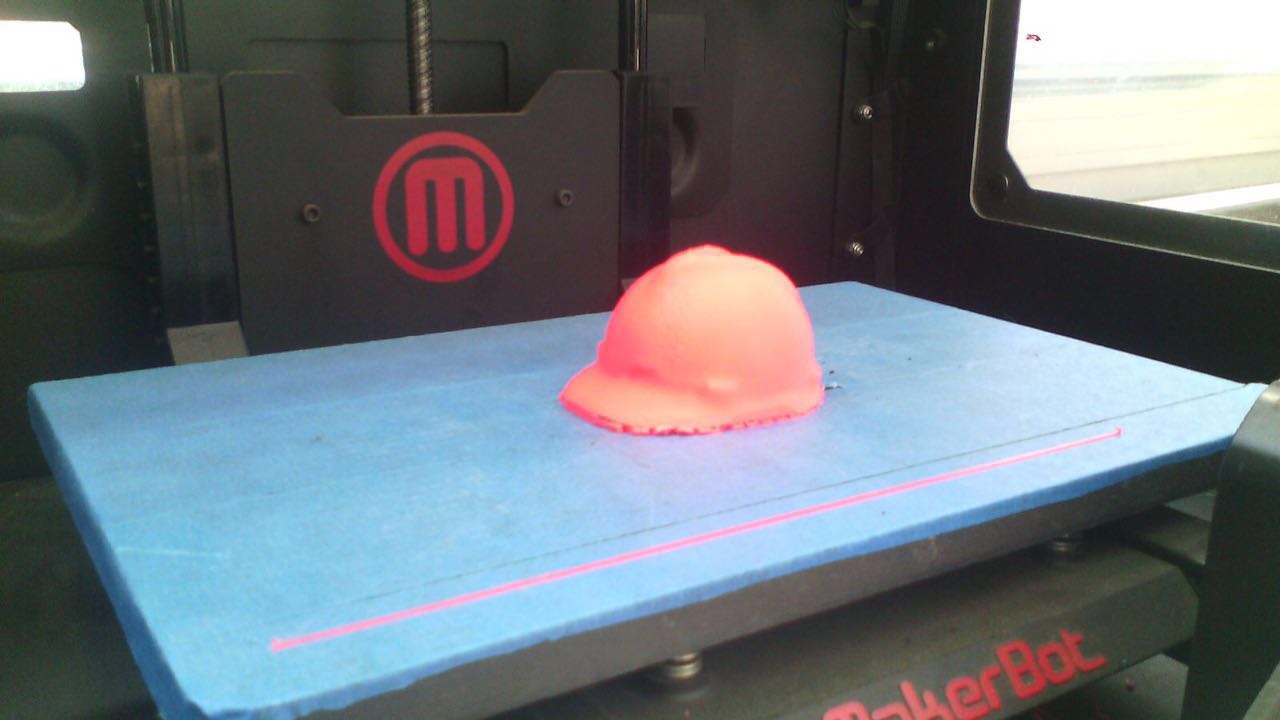

I used the 3D printer Makerbot Replicator 2X I decided to change the subject with a more compact and wore a helmet.

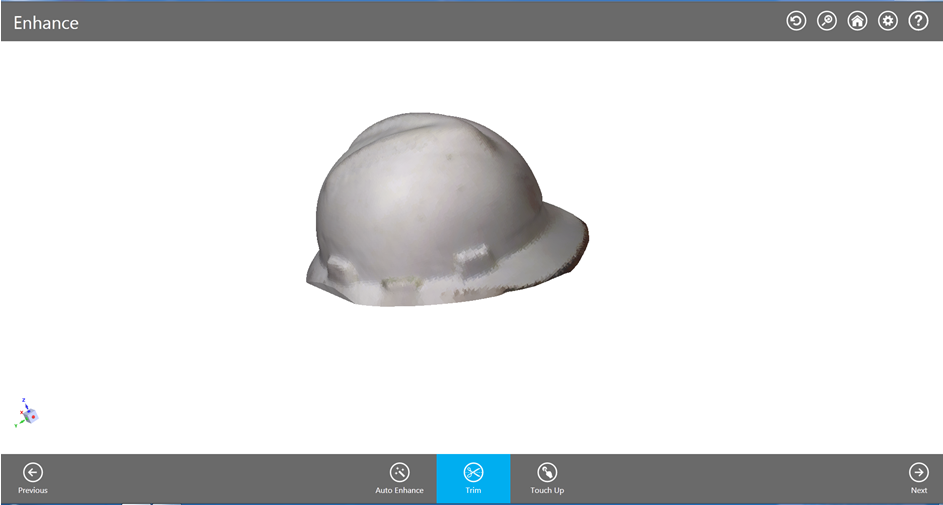

Here I show the helmet scan. I had the problem that the scanner got more than I needed, and also scanned the base. So I procesed the scan on the same software, it was solidified, trimmed and cropped, and finally exported in .stl format.

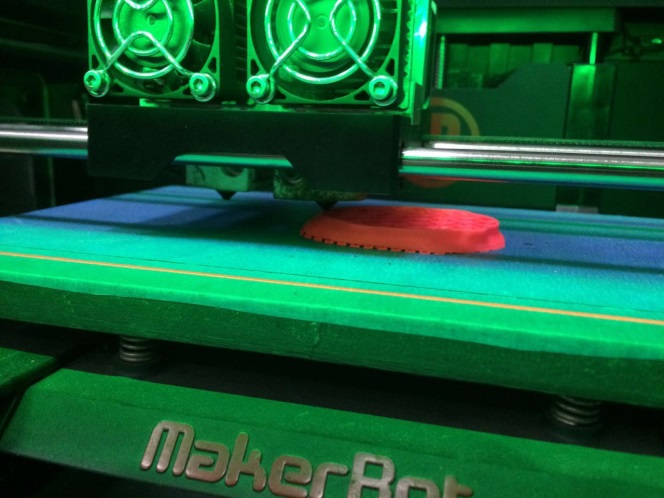

I can show you here in these images as 3D printing started. I had to print it since the helmet has some protuberances that couldn't be milled in 3 axis CNC's.

In this task I learned to use the different ways you can scan and print 3D objects, which was fun because I experienced several times the same procedure.