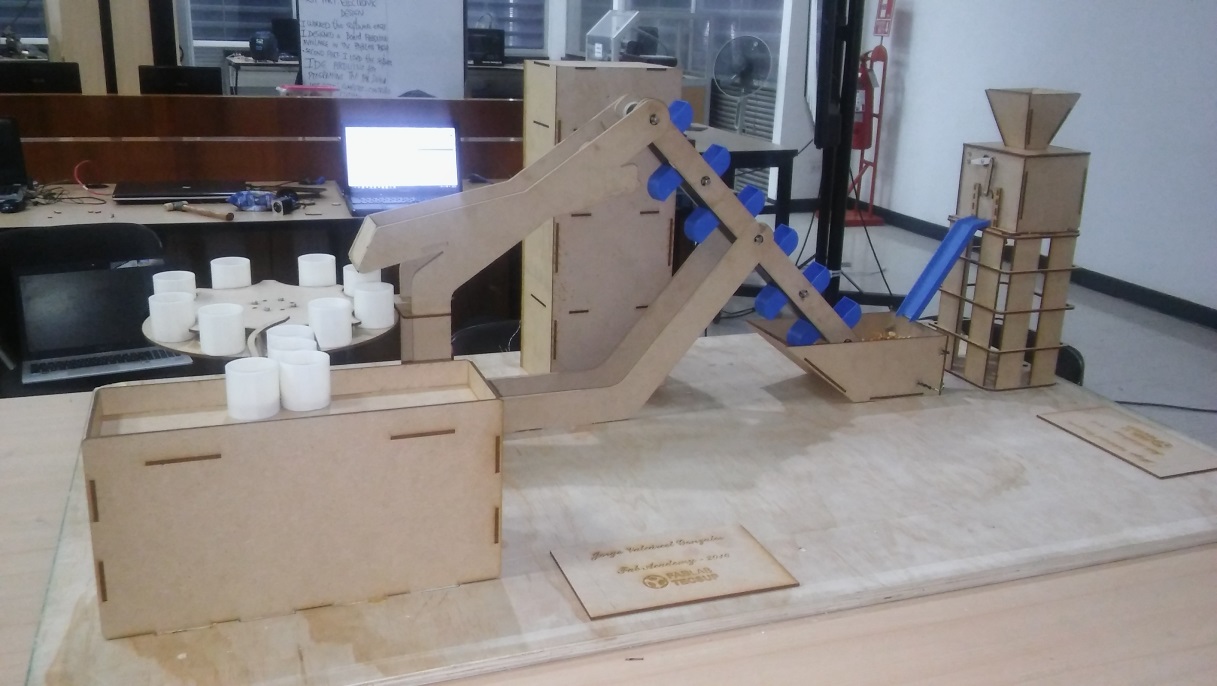

My project is to simulate an industrial process that consists of 4 very distinct stages.

First stage: Storage. At this stage the load (material) is received and stored in a tightly closed environment.

Second stage: lift. Collect the material of the tray No. 1 and raises it to another level through the buckets qiue is attached to the conveyor belt.

Stage Three: Filling. The high material falls down the ramp effect of the force of gravity so that is deposited in small containers.

Stage Four: Gathering. Thanks to the rotation of the transport plate and as they arrive they will more material accommodating area collection through a guide located strategically.

The project will be used as a demonstration and training module for young hopefuls to study in TECSUP and also for students of racing Production and Industrial Management, Industrial Mechatronics and Industrial Electronics.

As industrially process if it exists and in many companies in the world, there are also various models of prototypes that make or process anything, however, this model has not yet been prototyping. It has included various electronic devices which makes it particular. Some companies that have implemented modules like this are Festo and Schneider Electric

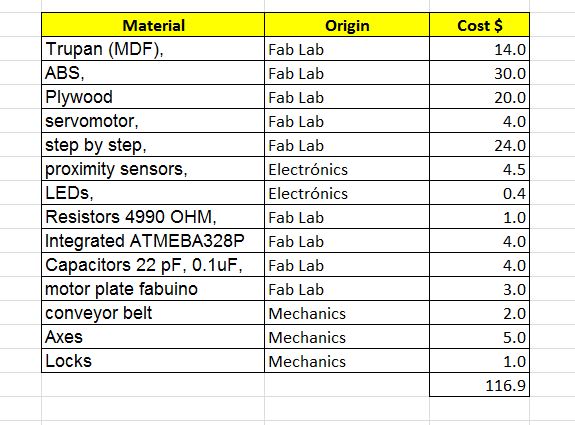

Structure

• Laser cut

• Cutting Shopbot

components

• 3D printing

• Axis machining

electronics

• Microcontroller ATME 328P

• Fabuino

• Sensors

laser cutter, 3D printer, Corte Shopbot, Design using inventor

This system requires some minor modifications such as would be very interesting to be a closed system, ie the material that reaches the storage area for return by a conveyor belt to the storage area and thus the process is continuous , for it requires more time analyzing how to make the material can have this tour.

Difficulties which it would have if the material recipiento to the conveyor for feedback poured?

What would be the most appropriate design for this system?

We could probra with higher density material?

For my project I have designed three weeks of work.

Week 1: Design of parts and first cuts and impressions

Week 2: Assembly parts and adjustments

Week 3: Final testing and fine-tuning.

I believe that my project should be evaluated by the application of the Fab Lab tools and the utility will give the young students.